Electrocatalysis ( IF 2.7 ) Pub Date : 2019-09-13 , DOI: 10.1007/s12678-019-00556-z S. Ghobrial , K. M. Cole , D. W. Kirk , S. J. Thorpe

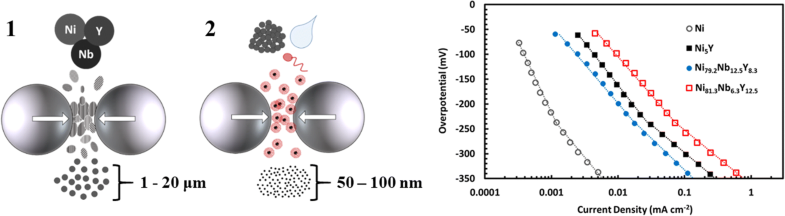

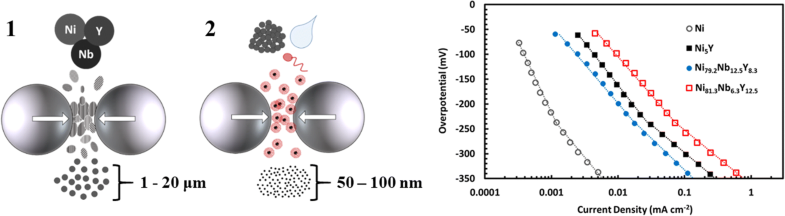

Amorphous Ni79.2Nb12.5Y8.3 and Ni81.3Nb6.3Y12.5 nanoparticles were synthesized using cryogenic mechanical alloying followed by surfactant-assisted high energy ball milling (SA-HEBM). These alloys were tested towards the hydrogen evolution reaction (HER) along with pure crystalline Ni and Ni5Y nanoparticles also produced through SA-HEBM. This two-stage ball milling process provided a novel processing route for the production of nanostructured/amorphous materials with a wide range of possible compositions not achievable through rapid solidification, electrodeposition, or chemical reduction techniques. The investigation of different surfactant and solvent concentrations resulted in improved nanoparticle yields whereby average particle sizes between 41 and 89 nm were obtained for crystalline and amorphous materials. Electrochemical testing showed that Ni81.3Nb6.3Y12.5 exhibited the lowest Tafel values and the fastest HER kinetics on both an electrochemically active surface area and on a mass loading basis. This investigation demonstrates their potential for use in anion exchange membrane water electrolysis.

Graphical Abstract

中文翻译:

表面活性剂辅助球磨制氢反应的非晶态Ni-Nb-Y纳米粒子的表征

使用低温机械合金化,然后进行表面活性剂辅助高能球磨(SA-HEBM),合成了非晶态Ni 79.2 Nb 12.5 Y 8.3和Ni 81.3 Nb 6.3 Y 12.5纳米粒子。这些合金与纯结晶Ni和Ni 5一起进行了放氢反应(HER)的测试。Y纳米颗粒也是通过SA-HEBM生产的。这种两阶段的球磨工艺为纳米结构/非晶材料的生产提供了一条新颖的工艺路线,该材料具有通过快速凝固,电沉积或化学还原技术无法实现的多种可能的成分。对不同表面活性剂和溶剂浓度的研究导致纳米颗粒收率提高,从而结晶和无定形材料的平均粒径在41至89 nm之间。电化学测试表明Ni 81.3 Nb 6.3 Y 12.5在电化学活性表面积和质量负载上均显示出最低的Tafel值和最快的HER动力学。这项研究证明了其在阴离子交换膜水电解中的潜力。

图形概要

京公网安备 11010802027423号

京公网安备 11010802027423号