当前位置:

X-MOL 学术

›

Bioresour. Bioprocess.

›

论文详情

Our official English website, www.x-mol.net, welcomes your feedback! (Note: you will need to create a separate account there.)

Thermo-Catalytic Reforming of spent coffee grounds

Bioresources and Bioprocessing ( IF 4.6 ) Pub Date : 2019-11-21 , DOI: 10.1186/s40643-019-0281-5 Mohamed Elmously , Nils Jäger , Andreas Apfelbacher , Robert Daschner , Andreas Hornung

Bioresources and Bioprocessing ( IF 4.6 ) Pub Date : 2019-11-21 , DOI: 10.1186/s40643-019-0281-5 Mohamed Elmously , Nils Jäger , Andreas Apfelbacher , Robert Daschner , Andreas Hornung

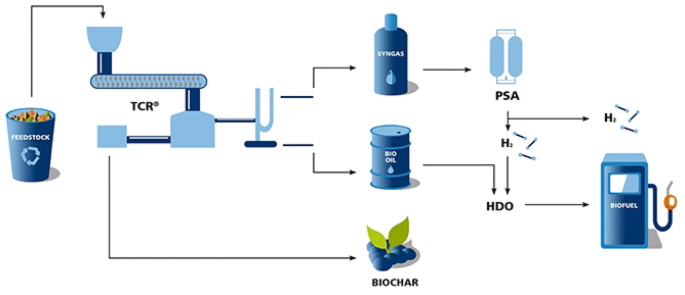

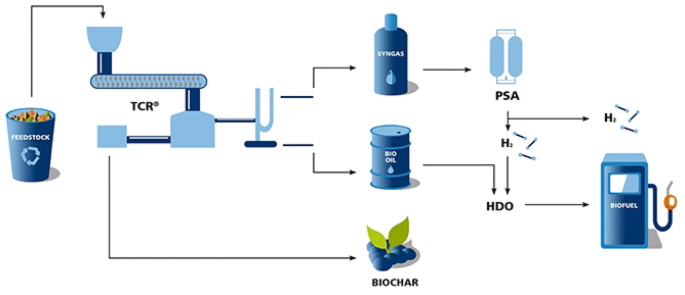

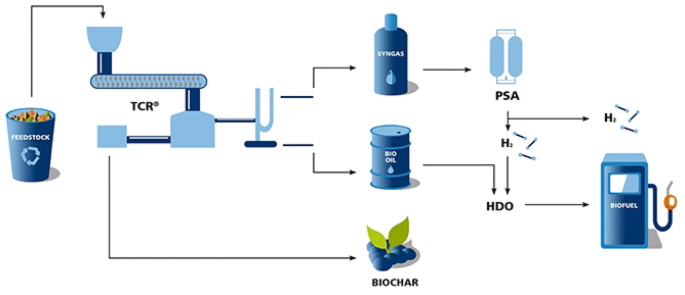

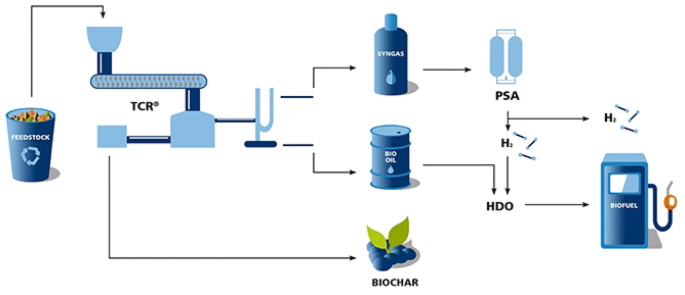

Conversion of spent coffee grounds through the Thermo-Catalytic Reforming system (TCR®) is evaluated in this study. While, the TCR® is a technology that has been developed by Fraunhofer UMSICHT, which combines an intermediate pyrolysis and a catalytic reforming. The temperature of the catalytic reformer is varied between 500 and 700 °C to achieve an optimum yield quantities and qualities of the products. The hydrogen concentration is maximized at a reforming temperature of 700 °C, and a gas yield up to 52 wt% is achieved. The thermal stable bio-oil produced at 700 °C has the highest calorific value of 36.8 MJ/kg with significantly low oxygen and water content, low viscosity and low TAN (total acid number). Furthermore, the maximum bio-oil and char yields are obtained at the lowest reforming temperature of 500 °C. Overall spent coffee grounds show a great potential as feedstock in the Thermo-Catalytic Reforming for energy and bio-chemicals production.

中文翻译:

废咖啡渣的热催化重整

通过热催化重整系统(TCR的咖啡残渣转化®)在这项研究进行评估。同时,该TCR ®是由Fraunhofer UMSICHT开发的一项技术,结合了中间热解和催化重整。催化重整器的温度在500至700°C之间变化,以实现最佳的产量和产品质量。在700℃的重整温度下,氢浓度最大,并且气体产率高达52wt%。在700°C时产生的热稳定生物油的最高发热量为36.8 MJ / kg,氧和水含量极低,粘度低,TAN(总酸值)低。此外,在最低的500°C重整温度下可获得最大的生物油和焦炭收率。总体而言,用过的咖啡渣显示出在热催化重整中用作能源和生化产品生产的巨大潜力。

更新日期:2019-11-21

中文翻译:

废咖啡渣的热催化重整

通过热催化重整系统(TCR的咖啡残渣转化®)在这项研究进行评估。同时,该TCR ®是由Fraunhofer UMSICHT开发的一项技术,结合了中间热解和催化重整。催化重整器的温度在500至700°C之间变化,以实现最佳的产量和产品质量。在700℃的重整温度下,氢浓度最大,并且气体产率高达52wt%。在700°C时产生的热稳定生物油的最高发热量为36.8 MJ / kg,氧和水含量极低,粘度低,TAN(总酸值)低。此外,在最低的500°C重整温度下可获得最大的生物油和焦炭收率。总体而言,用过的咖啡渣显示出在热催化重整中用作能源和生化产品生产的巨大潜力。

京公网安备 11010802027423号

京公网安备 11010802027423号