当前位置:

X-MOL 学术

›

Bioresour. Bioprocess.

›

论文详情

Our official English website, www.x-mol.net, welcomes your

feedback! (Note: you will need to create a separate account there.)

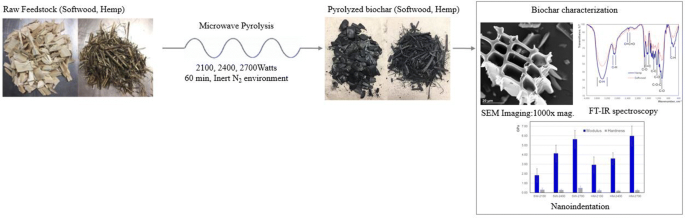

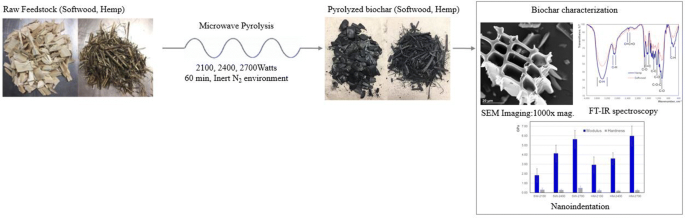

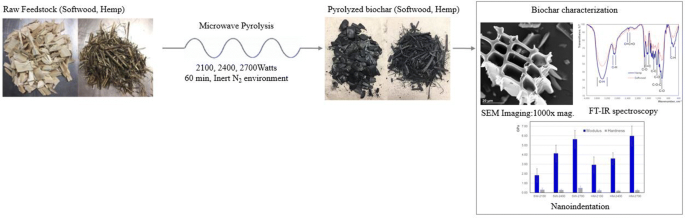

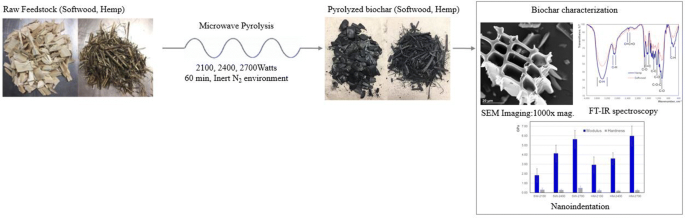

Effect of feedstock and microwave pyrolysis temperature on physio-chemical and nano-scale mechanical properties of biochar

Bioresources and Bioprocessing ( IF 4.3 ) Pub Date : 2019-09-13 , DOI: 10.1186/s40643-019-0268-2 Chase A. Wallace , Muhammad T. Afzal , Gobinda C. Saha

Bioresources and Bioprocessing ( IF 4.3 ) Pub Date : 2019-09-13 , DOI: 10.1186/s40643-019-0268-2 Chase A. Wallace , Muhammad T. Afzal , Gobinda C. Saha

Biochars were produced from softwood chips (spruce–fir mix) and hemp stalk biomasses in an in-house-developed microwave pyrolysis reactor. A kilogram batch raw biomass mixed with 10 wt% microwave absorber was pyrolyzed at 60-min residence time. Microwave power levels were set at 2100, 2400, and 2700 W with optimum heating rates ranging 25–50 °C/min. The proximate analysis indicated a progressive gain in biochar carbon content with power level increase. Both biochars showed a H:C ratio of < 1.2 with a graphite-like structure, which is an important observation for their potential use as a filler in bio-composites structural strength increase. Fourier Transfer Infrared (FT-IR) spectra showed a major loss of functional groups as the power level increased. Brunauer–Emmett–Teller (BET) surface area and porosity distribution contained higher volume of smaller pores in the hemp biochar. The char hardness and Young’s modulus, obtained via nanoindentation technique and load–depth curve analysis, indicated that hemp biochar possessed a higher Young’s modulus and lower hardness than softwood chip biochar.

中文翻译:

原料和微波热解温度对生物炭物理化学和纳米力学性能的影响

在内部开发的微波热解反应器中,由软木片(云杉-杉木混合物)和大麻茎生物量产生生物炭。将与10 wt%微波吸收剂混合的千克批次粗生物质在60分钟的停留时间热解。微波功率级别设置为2100、2400和2700 W,最佳加热速率范围为25–50°C / min。最近的分析表明,随着功率水平的提高,生物炭碳含量逐渐增加。两种生物炭的H:C比率均小于1.2,且具有石墨状结构,这对于它们可作为生物复合材料结构强度提高中的填料的潜在用途非常重要。傅立叶转移红外(FT-IR)光谱显示,随着功率水平的提高,官能团的损失也很大。Brunauer-Emmett-Teller(BET)的表面积和孔隙率分布在大麻生物炭中包含较大体积的较小孔。通过纳米压痕技术和载荷-深度曲线分析获得的木炭硬度和杨氏模量表明,与软木片生物炭相比,大麻生物炭具有较高的杨氏模量和较低的硬度。

更新日期:2019-09-13

中文翻译:

原料和微波热解温度对生物炭物理化学和纳米力学性能的影响

在内部开发的微波热解反应器中,由软木片(云杉-杉木混合物)和大麻茎生物量产生生物炭。将与10 wt%微波吸收剂混合的千克批次粗生物质在60分钟的停留时间热解。微波功率级别设置为2100、2400和2700 W,最佳加热速率范围为25–50°C / min。最近的分析表明,随着功率水平的提高,生物炭碳含量逐渐增加。两种生物炭的H:C比率均小于1.2,且具有石墨状结构,这对于它们可作为生物复合材料结构强度提高中的填料的潜在用途非常重要。傅立叶转移红外(FT-IR)光谱显示,随着功率水平的提高,官能团的损失也很大。Brunauer-Emmett-Teller(BET)的表面积和孔隙率分布在大麻生物炭中包含较大体积的较小孔。通过纳米压痕技术和载荷-深度曲线分析获得的木炭硬度和杨氏模量表明,与软木片生物炭相比,大麻生物炭具有较高的杨氏模量和较低的硬度。

京公网安备 11010802027423号

京公网安备 11010802027423号