当前位置:

X-MOL 学术

›

J. Sustain. Metall.

›

论文详情

Our official English website, www.x-mol.net, welcomes your

feedback! (Note: you will need to create a separate account there.)

Oxygen-Rich Side-Blown Bath Smelting of Copper Dross: A Process Study

Journal of Sustainable Metallurgy ( IF 2.5 ) Pub Date : 2020-05-19 , DOI: 10.1007/s40831-020-00278-3 Peng Chen , Hui Xiao , Jiang Chen , Lin Chen , Duchao Zhang , Weifeng Liu , Tianzu Yang

中文翻译:

富氧侧吹浴熔炼铜渣的工艺研究

Journal of Sustainable Metallurgy ( IF 2.5 ) Pub Date : 2020-05-19 , DOI: 10.1007/s40831-020-00278-3 Peng Chen , Hui Xiao , Jiang Chen , Lin Chen , Duchao Zhang , Weifeng Liu , Tianzu Yang

Abstract

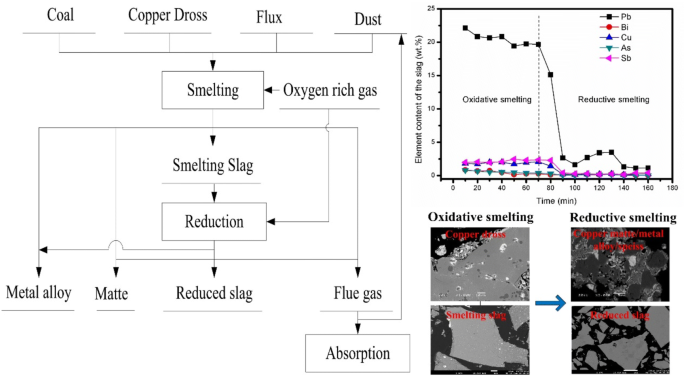

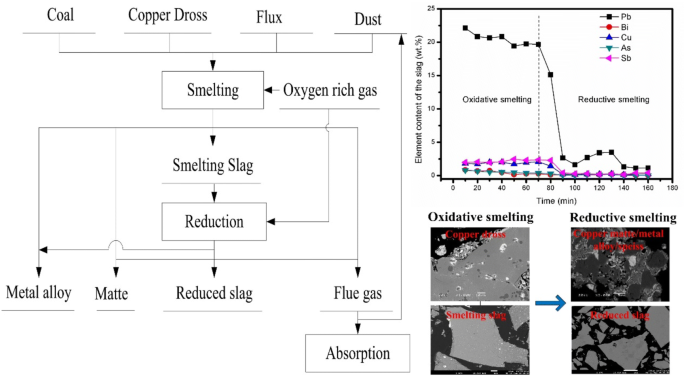

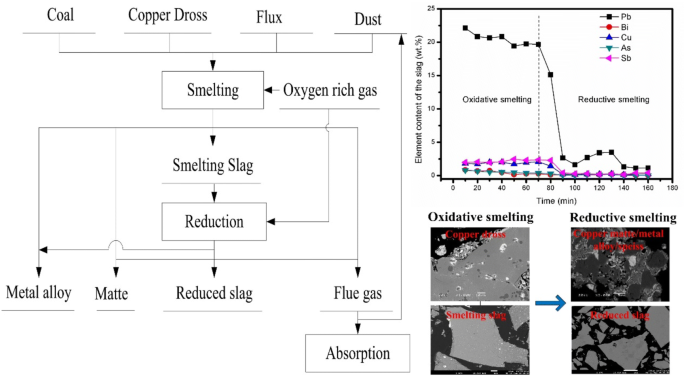

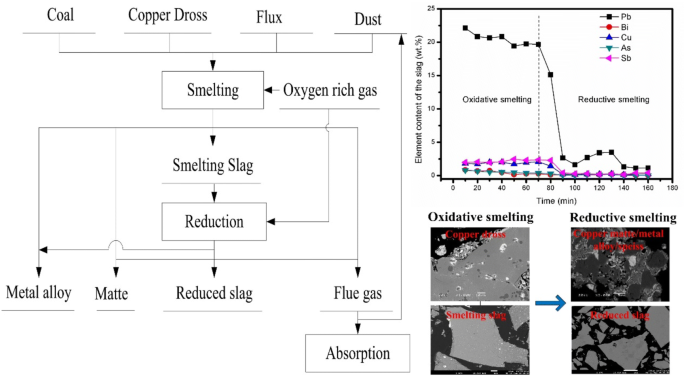

A complex copper dross containing Bi, Pb, Cu, As and Sb was processed in a 3.6 m2 industrial-scale oxygen-rich side-blown bath smelting furnace (OSBF). The products were collected and analyzed by chemical and mineralogical methods. Industrial statistical data showed that recoveries of Cu, Pb, Bi and Sb reached 87%, 96%, 97% and 60%, respectively. Slag composition indicated that the process can be divided into 2 steps, i.e., oxidative smelting and reductive smelting, due to the use of different oxygen-rich gas flow rate and enrichment. The effect of oxygen partial pressure (PO2) on the element partitioning was simulated by Factsage. The results indicated that increase of PO2 between 10–5 atm and 10–7 atm would significantly increase the partitioning of Cu, Pb, As and Sb to the slag; while element partitioning became almost independent of PO2 between 10–7.5 atm to 10–9.5 atm. Phase analysis for the slag indicated that the bath in the furnace was a “FeO”–CaO–SiO2–Al2O3–ZnO slag coexisting with solid spinels.Graphical Abstract

中文翻译:

富氧侧吹浴熔炼铜渣的工艺研究

摘要

在3.6 m 2工业规模的富氧侧吹浴熔炼炉(OSBF)中处理了包含Bi,Pb,Cu,As和Sb的复杂铜渣。收集产物并通过化学和矿物学方法进行分析。工业统计数据表明,Cu,Pb,Bi和Sb的回收率分别达到87%,96%,97%和60%。炉渣组成表明,由于使用了不同的富氧气体流量和富集工艺,该过程可分为两个步骤,即氧化冶炼和还原冶炼。通过Factsage模拟了氧分压(P O2)对元素分配的影响。结果表明,P O2在10 –5 atm和10 –7之间增加 atm将显着增加Cu,Pb,As和Sb在炉渣中的分配;而元素分配几乎独立于P O2在10 –7.5 atm至10 –9.5 atm之间。炉渣的相分析表明,熔炉中的熔池是与固态尖晶石共存的“ FeO” -CaO-SiO 2 -Al 2 O 3 -ZnO炉渣。图形概要

京公网安备 11010802027423号

京公网安备 11010802027423号