当前位置:

X-MOL 学术

›

Arch. Civ. Mech. Eng.

›

论文详情

Our official English website, www.x-mol.net, welcomes your

feedback! (Note: you will need to create a separate account there.)

Sheet metal forming using environmentally benign lubricant

Archives of Civil and Mechanical Engineering ( IF 4.4 ) Pub Date : 2020-04-30 , DOI: 10.1007/s43452-020-00053-x Wojciech Więckowski , Janina Adamus , Marcin Dyner

中文翻译:

使用环境友好的润滑剂进行钣金成型

Archives of Civil and Mechanical Engineering ( IF 4.4 ) Pub Date : 2020-04-30 , DOI: 10.1007/s43452-020-00053-x Wojciech Więckowski , Janina Adamus , Marcin Dyner

Abstract

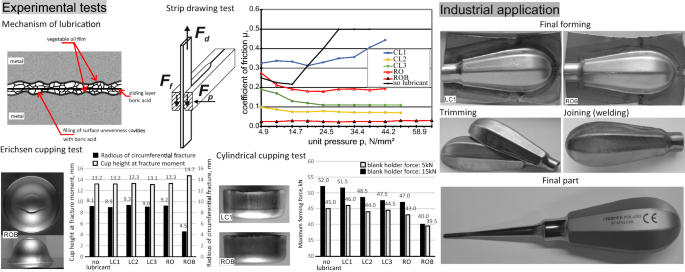

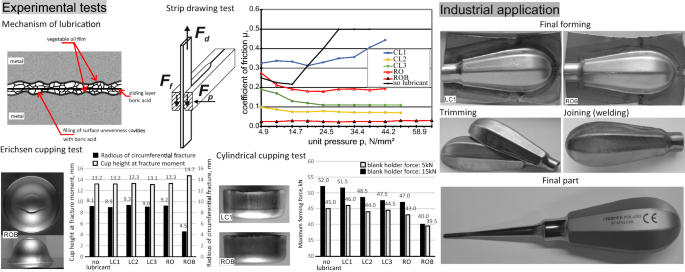

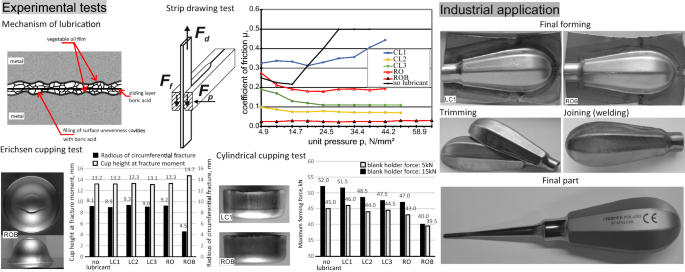

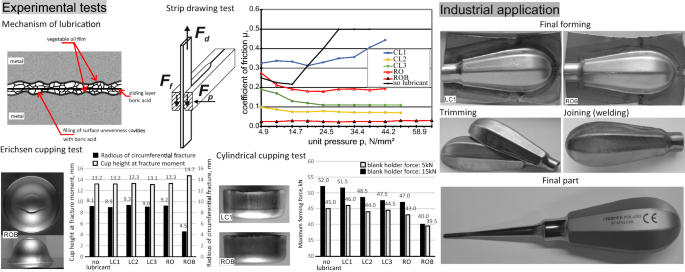

Sheet metal forming belongs to one of the most important technologies enabling the production durable but quite lightweight metal parts. The quality of the drawn parts depends on the deformed sheet metal, applied forming technology and process parameters, such as contact pressure, relative velocity, temperature or lubrication. The forming of steel (1.4021) parts using benign lubricant is analysed. The paper proposes replacing conventional mineral/synthetic lubricants with ones based on vegetable oils and boric acid. The effectiveness of the lubricants was assessed in laboratory strip drawing and cupping tests, and in production. An oil-based lubricant with an additive of boric acid is very effective in reducing frictional resistance and protecting the forming tools against galling.Graphic abstract

中文翻译:

使用环境友好的润滑剂进行钣金成型

摘要

钣金成型属于最重要的技术之一,可生产耐用但重量轻的金属零件。拉伸零件的质量取决于变形的钣金,应用的成型技术和工艺参数,例如接触压力,相对速度,温度或润滑。分析了使用良性润滑剂对钢(1.4021)零件的成型。本文提出用基于植物油和硼酸的矿物/合成润滑剂代替传统的矿物/合成润滑剂。在实验室试纸拉拔和拔罐测试以及生产中评估了润滑剂的有效性。含硼酸添加剂的油基润滑剂在降低摩擦阻力和防止成型工具磨损方面非常有效。图形摘要

京公网安备 11010802027423号

京公网安备 11010802027423号