Recently, Professor Xiaosong Hu of VPSL at Chongqing University and his collaborators (from Ontario Institute of Technology, Canada, University of Maryland, USA) published a review article “Battery Lifetime Prognostics” on the international top journal Joule (under Cell press). This article systematically elucidates the latest research progress of three types of battery life prediction technologies, including model-based, data-driven and fusion algorithm based; and comprehensively summarized the key technical problems and challenges of the existing battery life prediction technology. Future trends and research directions of battery life prediction technology have also been discussed.

Article Overview

Research Purpose

In recent years, in order to cope with the depletion of traditional fossil fuels and environmental degradation, lithium-ion batteries have been widely used in new energy vehicles and energy storage in power grids. However, the performance degradation of lithium-ion batteries during use is a key technical difficulty, which limits the remaining useful life (RUL) of the battery. Lithium-ion battery is a complex electrochemical system, which will produce side reactions such as SEI film growth, lithium plating, and electrolyte oxidation during the working process. The side reaction of the battery will cause the performance of the battery to decay. Macroscopically, the capacity is reduced and the internal resistance is increased, thereby reducing the service life of the battery. Accurately predicting the remaining service life of lithium-ion batteries under different usage conditions can not only ensure the safe and reliable operation of the system, but also maximize the use of the remaining value of the battery. Therefore, the remaining life prediction is very important for battery management and secondary utilization. This article will provide strong support for the remaining life prediction technology of lithium-ion batteries.

Aging Mechanism of Li-ion Batteries

A lithium-ion battery is a dynamic and time-varying electrochemical system with nonlinear behavior and complicated internal mechanisms. As the number of charge and discharge cycles increases, the performance and life of the lithium-ion battery gradually deteriorate. There are many different causes for battery degradation, including both physical mechanisms (e.g., thermal stress and mechanical stress) and chemical mechanisms (e.g., side reactions). Figure 1 illustrates the most common battery degradation mechanisms. Different degradation mechanisms contribute to battery degradation, and they can be divided into two main degradation modes: (1) loss of lithium inventory, which is caused by consumption of lithium ions through side reactions. (2) Loss of active material, which results in a loss of storage capacity. More specifically, the loss of active material is mainly caused by graphite exfoliation, binder decomposition, loss of electrical contact owing to corrosion of current collectors, and electrode particle cracking. Loss of lithium inventory is mainly caused by solid electrolyte interphase (SEI) film formation and decomposition, electrolyte decomposition, and lithium plating. It is worth mentioning that these degradation mechanisms are highly related to materials. For example, the working voltage of graphite anode is lower than the electrochemical window of commonly used electrolytes, which leads to the formation of SEI film. However, there would be no SEI film formation in the lithium titanium oxide (LTO) anode because LTO’s potential is located in the electrochemical window of the electrolyte. Another example is that the volume change of the lithium iron phosphate (LFP) cathode is smaller than that of the lithium manganese oxide (LMO) cathode, and therefore, its structural deformation is also smaller.

Fig. 1 Main Degradation Mechanisms in Lithium-Ion Batteries(Adapted from Birkl, C.R., Roberts, M.R., McTurk, E., Bruce, P.G., and Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources, 2017, 341:373–386.)

Classification of RUL Prognostic Methodologies

In recent years, battery RUL prediction technology has made great progress. Literature often divides RUL prediction technology into three categories: model-based, data-driven and fusion-based. However, the existing literature is not uniform in the classification criteria and fails to include the latest results of RUL prediction. To this end, based on the latest research progress of battery RUL prediction, this paper has unified classification of RUL algorithm. (1) Model-based prediction method: A battery physical model or an empirical model is established by mathematical methods to describe the aging behavior of the battery. The model of this method is usually composed of a series of algebra and differential equations. The characteristic of the model-based method is that the established RUL prediction model is only for a specific system (for example, the prediction models of the battery system and the bearing system are different). (2) Data-driven prediction method: Based on statistical theory and machine learning theory, historical data is used directly to build a prediction model without relying on a specific physical model. The data-driven model is easier to apply to different occasions (for example, the prediction model structure of the battery and the bearing system is the same, and only the model parameters need to be adjusted). (3) Based on the fusion algorithm: combine the model with the data-driven method and give play to their respective advantages.

Model-Based Approaches

The model-based approach aims to establish a mathematical model to describe battery aging behavior. One of the methods is to establish a complex mechanism model or empirical regression model that couples battery side reactions (such as SEI film growth) and extrapolates model parameters to achieve RUL prediction. However, battery aging behavior is non-linear. For long-term prediction (prediction steps greater than 50), the mechanism model of coupled side reactions can maintain high accuracy, and the prediction error of the empirical model with fixed parameters will increase. A commonly used method to improve long-term prediction accuracy is to use the model in combination with a filtering algorithm, and use the filtering algorithm and available data to continuously update model parameters. As shown in Figure 2, first select the appropriate model according to the characteristics of the battery data, and then convert the model into a state-space equation and initialize the filtering algorithm and model parameters. Then based on the historical data before the prediction starting point, the filtering algorithm is used to continuously update the model parameters until the prediction starting point. Finally, the model extrapolation is used at the starting point of the prediction to perform RUL prediction of the battery.

Fig. 2 Flowchart of the Model-Based Algorithm

Model-based RUL prediction methods specifically include three categories. The first type is a mechanism model based on the internal electrochemical reaction mechanism of the battery. For example, a pseudo-two-dimensional (P2D) model based on porous media theory and solid-liquid phase continuity assumptions, or a molecular scale model established by dynamic Monte Carlo method (KMC) considering anisotropy between phase interfaces. The mechanism model can describe the main factor that causes the capacity attenuation of the SEI membrane growth. The model has high prediction accuracy, but the calculation complexity is very large. The second category is the equivalent circuit model (ECM) that describes battery characteristics based on circuit components. The model is based on the mapping relationship between battery internal resistance growth and capacity decay. The ECM model is used to identify internal resistance changes and establish empirical equations to predict battery RUL by extrapolation. Generally, ECM models use filtering algorithms to update model parameters to improve prediction accuracy. The third type is a purely empirical model established by analyzing a large amount of battery historical attenuation data. The empirical model uses different regression model forms (such as linear and exponential) to describe the battery decay behavior and extrapolate to predict the future decay trend. The empirical model ignores the internal mechanism of the battery, and only predicts RUL by establishing a mapping relationship between historical data and battery health factors (capacity and internal resistance). As the battery ages and the working environment changes, the above mapping relationship keeps changing with time. Therefore, most empirical models are often combined with filtering algorithms to continuously update model parameters using historical data before the starting point of prediction to improve prediction accuracy.

Data-Driven Approaches

The data-driven method directly uses historical data to predict the future aging trend of the battery, and does not require an understanding of the aging mechanism and expansion laws. This method does not establish a specific physical model, but builds a statistical model or a machine learning model based on the data. Because the data-driven method avoids the complex mathematical modeling process and expert knowledge, the method is more flexible and easy to use, and has attracted researchers' attention on a global scale. The battery-driven RUL prediction methods can be further divided into three categories: machine learning, statistical methods, and signal processing methods.

As shown in Fig. 3, the algorithm structure of the battery RUL prediction data driving algorithm can be divided into four categories.

a. Iterative prediction (Fig. 3a). The structure of iterative prediction uses the capacity of multiple historical moments to predict the battery capacity at the next moment, and predicts future capacity changes through loop iteration.

b. Non-iterative prediction (Fig. 3b). Non-iterative prediction establishes a mapping relationship between the number of battery cycles and the battery capacity, so that the corresponding capacity value of the battery in the future can be calculated by substituting the number of cycles.

c. Short-term forecast (Fig. 3c). The short-term forecast is based on the use of historical capacity data, and adds online measurement data (such as temperature, current, and voltage) at the current time. Short-term prediction can achieve good prediction accuracy in a short time scale by incorporating rich measurement data, but cannot achieve long-term prediction of battery capacity.

d. Direct prediction (Fig. 3d). The predicted output of the above three algorithm structures is the capacity change trajectory of the battery in the future, and the battery RUL is calculated by calculating the time that the capacity decayed to the retirement threshold (such as 20% capacity decay). The direct prediction directly obtains the battery RUL by establishing the direct mapping relationship between the historical data and the battery RUL (such as the Wiener process establishing the battery RUL probability density distribution function).

Fig. 3 Algorithm Structures of the Data-Driven Approaches

Hybrid Approaches

The nonlinear mapping based on the data-driven method is strong and easy to implement, but insufficient or biased training data will result in reduced prediction accuracy or complete error. The model-based approach relies on expert knowledge to build physical models, and has poor applicability. However, the model-based method requires fewer data and has better robustness and stability. In recent years, the fusion method combining model and data drive has absorbed the advantages of different methods and has better accuracy, which has become a hot spot of research.

The fusion algorithm aims to solve three types of problems by combining the model with data driving. The first category is to use data drive to improve the accuracy of the filtering algorithm, as shown in Figure 4a. In traditional filtering algorithms, the initial value of any parameter selected will reduce the convergence speed of the algorithm or cause divergence. In addition, the particle filter (PF) algorithm will reduce the accuracy of the algorithm due to the defects of particle degradation and sample depletion. The first type of fusion algorithm uses data-driven (such as D-S evidence theory) to initialize the filtering algorithm, or through data-driven (such as support vector regression SVR) to calculate the weight of the resampled particles to improve the RUL prediction accuracy. The second category is the use of data-driven filtering algorithms to construct future "virtual observations." When the RUL prediction time scale is longer, the parameters of the empirical prediction model need to be continuously updated by the filtering algorithm to track the non-linear aging behavior of the battery. However, due to the lack of observation data in the future, the filtering algorithm cannot play a role, resulting in a large prediction error. As shown in Fig. 4b, the second type of fusion algorithm uses data-driven (such as correlation vector machine RVM, autoregressive model AR) to construct observation equations, so as to continuously update model parameters and improve RUL prediction accuracy based on the filtering algorithm. The third category is to use data-driven algorithms to preprocess the original battery data. The capacity recovery effect in the original battery attenuation data will cause the attenuation curve to fluctuate. At the same time, the noise and measurement errors introduced in the measurement will also affect the data quality. Using the original battery data for model parameter identification or data-driven algorithm training will greatly reduce the RUL prediction accuracy. The third method uses data-driven (such as empirical mode decomposition EMD) to separate abnormal data, or data-driven (such as wavelet denoising WD) to reduce data noise. By improving data quality, the model can be trained more efficiently and the prediction accuracy of RUL can be improved.

Fig. 4 Hybrid Approaches for Battery RUL Prediction

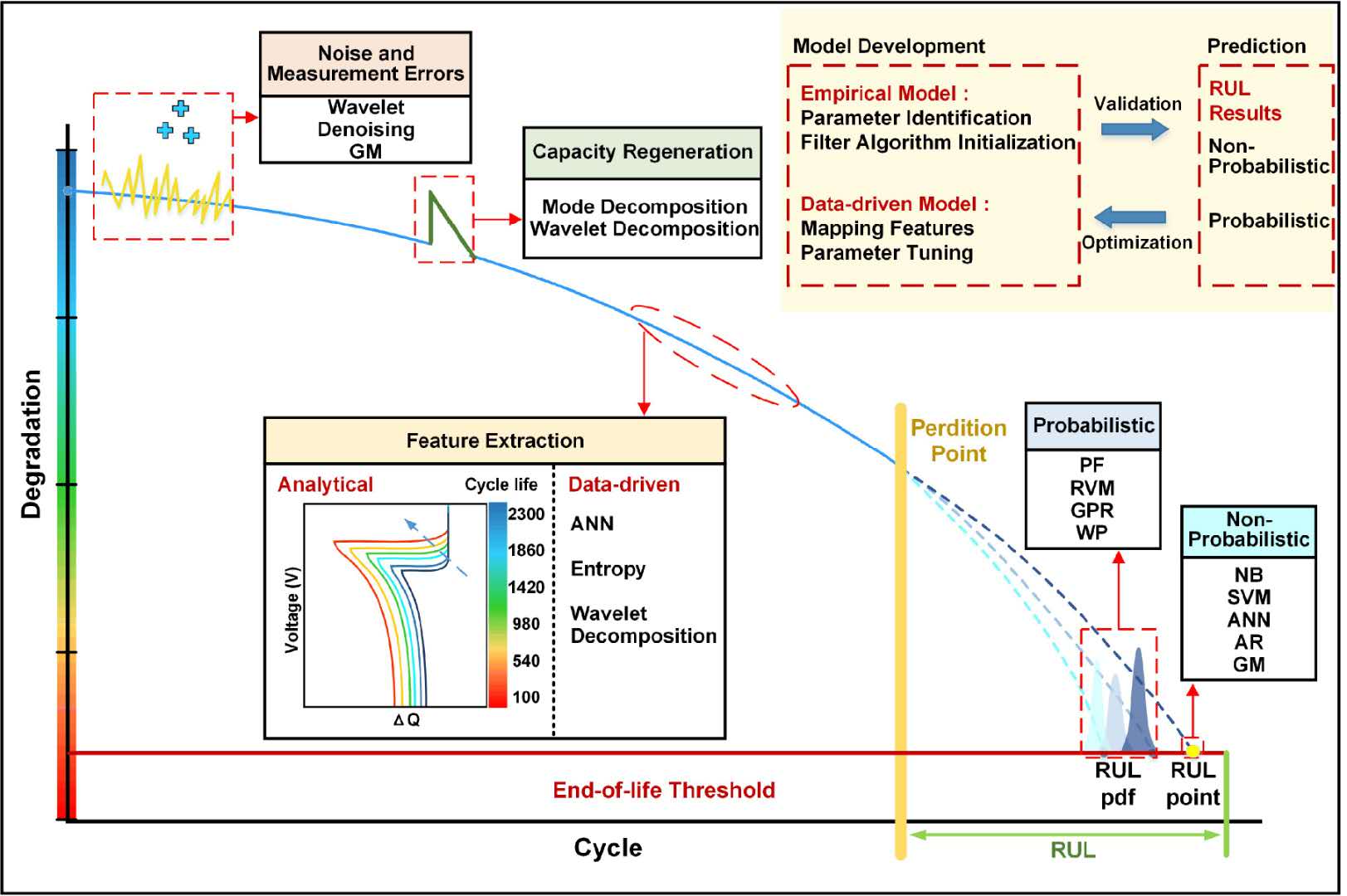

RUL Prediction Algorithm for Engineering Application

Based on the development level of the existing battery RUL prediction technology, this article provides the following suggestions for the selection of RUL algorithm in practical engineering applications. When computing resources are abundant (such as the maintenance stage of electric vehicles), the prediction technology based on the mechanism model can detect the internal health status of the battery in detail and accurately predict the battery RUL. When the battery is in use, the empirical model and the data-driven model algorithm with low computational complexity can better realize the online application in the battery management system. Figure 5 further provides a reference for the selection of empirical models and data-driven models. Before using the original measurement data to fit the empirical model parameters or training the data to drive the model, you can use wavelet denoising and other methods to preprocess the original data to eliminate noise. At the same time, in order to eliminate the data anomaly caused by the capacity recovery effect in the original data, methods such as modal decomposition can be used. When using pre-processed data for feature extraction, you can choose analytical methods (such as incremental capacity analysis) or data-driven methods (such as extracting data sample entropy) to improve the correlation between health features and battery decay behavior. In order to provide prediction results with confidence intervals, prediction methods based on probability frameworks (such as particle filtering and Gaussian process regression) should be used. Finally, it is worth noting that when the battery operating conditions change compared to the training conditions, the empirical model and the data-driven model need to be retrained to ensure prediction accuracy.

Fig. 5 Selection of Empirical and Data-Driven RUL Prognostic Methods at Different Stages

The Key Challenges and Trends of RUL Prediction Technology

At present, battery RUL prediction technology has made great progress. However, existing studies are mostly based on battery life prediction under single operating conditions (such as constant temperature and constant current). In order to achieve engineering applications, four key technical issues need to be broken through.

(1) Battery data set closer to the actual working conditions: the existing literature mostly uses battery aging data under constant temperature and CC / CV working conditions for algorithm establishment and verification. However, in most battery energy storage applications, batteries will experience dynamically changing operating conditions. In addition, with the widespread application of battery energy storage systems, battery life prediction technology under extreme operating conditions such as fast charging has become increasingly important.

(2) The battery life prediction technology incorporating the mechanism: The mechanism model with low calculation complexity can accurately predict the remaining life of the battery under different working conditions. However, the complex nonlinear electrochemical behavior inside the battery makes the establishment of the above model extremely difficult. Therefore, it is one of the main challenges to integrate the mechanism into the prediction algorithm and reduce the computational complexity to the level that can be applied online.

(3) Early prediction algorithm: An algorithm for early life prediction based on a small amount of data is very important to prevent battery failure. However, the training data volume of most prediction algorithms accounts for 40% -70% of the total data. In addition, some aging behavior of the battery is not obvious in the early stage, such as the voltage curve changes and the capacity remains unchanged. Therefore, developing small-sample training algorithms and extracting more effective battery health feature factors is the key and challenge to achieve early prediction.

(4) RUL technology for engineering applications: There are four major challenges in the engineering application of battery RUL prediction. One is to develop RUL prediction technology for large-scale battery packs for large battery energy storage applications. There are inconsistencies and temperature gradients in battery packs composed of different series and parallel methods, and the complexity of the prediction model will be greatly increased. The second is to develop battery life prediction technology based on cloud computing technology. Through the introduction of cloud computing to increase the speed of calculation, the application of more complex prediction algorithms (such as mechanism models) can be realized. The third is to develop a battery data sharing ecosystem based on blockchain technology. By sharing battery usage data among all users, the RUL prediction algorithm is more efficiently trained, and the prediction accuracy of the prediction algorithm in different regions and working conditions is improved. The fourth is to develop RUL prediction technology that takes into account the use of battery cascades. As the battery ages, its attenuation mechanism will change, and there will be an aging turning point for a sudden drop in capacity. In addition, the battery's historical operating conditions have a great impact on its secondary life. Therefore, it is necessary to develop RUL prediction technology for the full life cycle of the battery in order to realize the full utilization of the remaining value of the battery.

Publication Information

Source

Xiaosong Hu*, Le Xu, Xianke Lin, and Michael Pecht. Battery lifetime prognostics. Joule, 4: 1-37, 2020.

Full-text link: www.cell.com/joule/fulltext/S2542-4351(19)30585-9

Extra Introduction

Joule

Joule is an authoritative journal under Cell Press. It mainly consists of the latest research findings and scientific research progress in the energy field, involving batteries, catalysis, solar energy, and bioenergy, heat transfer and other related fields.