Abstract

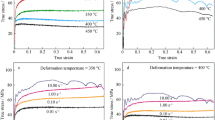

Hot compression behaviors of Pb-Mg-Al-B-0.4Y alloy under strain rate of 0.001-1 s−1 and temperature of 493-613 K were performed by employing hot compressing tests. According to the experimental stress–strain curves, as the strain increases, the flow stress increases firstly, then reaches the peak stress, and finally decreases to a steady state. Constitutive equations in traditional Arrhenius model and improved Arrhenius model in multi-linear regression were used to predict the flow stress of Pb-Mg-Al-B-0.4Y alloy. The values of MARE and RMSE in the traditional Arrhenius model are 11.780 and 21.169%, respectively, which are larger than 7.227 and 7.447% of the improved Arrhenius model, indicating that the predicted accuracy of the improved Arrhenius model is more accurate. The hot processing maps under the experimental conditions were established. Based on processing maps and microstructure observation, the optimum processing parameters are 0.001 s−1 ≤ \(\dot{\varepsilon }\) ≤ 0.01 s−1 and 587 K ≤ T ≤ 613 K.

Similar content being viewed by others

References

W.R. Osório, D.M. Rosa, and A. Garcia, The Roles of Cellular and Dendritic Microstructural Morphologies on the Corrosion Resistance of Pb-Sb Alloys for Lead Acid Battery Grids, J. Power Sources, 2008, 175, p 595–603

J. Zeng, W. Chen, W. Yan, Y. Yang, and A. McLean, Effect of Permanent Magnet Stirring on Solidification of Sn-Pb Alloy, Mater. Des., 2016, 108, p 364–373

Y. Pan, Theoretical Discovery of High Capacity Hydrogen Storage Metal Tetrahydrides, Int. J. Hydrog. Energy, 2019, 44, p 18153–18158

Y. Pan, Y. Li, and Q. Zheng, Influence of Ir Concentration on the Structure, Elastic Modulus and Elastic Anisotropy of Nb-Ir Based Compounds from First-Principles Calculations, J. Alloys Compd., 2019, 789, p 860

Y. Pan, First-Principles Investigation of the New Phases and Electrochemical Properties of MoSi2 as the Electrode Materials of Lithium Ion Battery, J. Alloys Compd., 2019, 779, p 813–820

A. Iddaoudi, C. Servant, N. Selhaoui, S. Kardellass, K. Mahdouk, and L. Bouirden, Thermodynamic Modeling of the RE-Pb (RE = Sc, Dy, Gd) Systems, J. Alloys Compd., 2014, 589, p 192–199

Y.Y. Liu, G.B. Jia, and B. Yang, Molecular Dynamics Simulation on Diffusion Properties of Pb-Mg Alloy, Sci. China Ser. E Technol. Sci., 2010, 53, p 2328–2332

Z.C. Sun, H.L. Wu, J. Cao, and Z.K. Yin, Modeling of Continuous Dynamic Recrystallization of Al-Zn-Cu-Mg Alloy During Hot Deformation Based on the Internal-State-Variable (ISV) Method, Int. J. Plast., 2018, 106, p 73–87

L. Wen, K. Yu, H. Xiong, Y. Dai, S. Yang, X. Qiao, F. Teng, and S. Fan, Composition Optimization and Electrochemical Properties of Mg-Al-Pb-(Zn) Alloys as Anodes for Seawater Activated Battery, Electrochim. Acta, 2016, 194, p 40–51

B.B. Pai, U.T.S. Pillai, P. Manikandan, and A. Srinivasan, Modification of AZ91 Mg Alloys for High Temperature Applications, Trans. Indian Inst. Met., 2012, 65, p 601–606

G.H. Park, J.T. Kim, H.J. Park, Y.S. Kim, H.J. Jeong, N. Lee, Y. Seo, J.Y. Suh, H.T. Son, W.M. Wang, J.M. Park, and K.B. Kim, Development of Lightweight Mg-Li-Al Alloys with High Specific Strength, J. Alloys Compd., 2016, 680, p 116–120

N. Wang, R. Wang, C. Peng, B. Peng, Y. Feng, and C. Hu, Discharge Behaviour of Mg-Al-Pb and Mg-Al-Pb-In Alloys as Anodes for Mg-Air Battery, Electrochim. Acta, 2014, 149, p 193–205

M. Socjusz-Pedosek and L. Lityńska, Effect of Yttrium on Structure and Mechanical Properties of Mg Alloys, Mater. Chem. Phys., 2003, 80, p 472–475

C.C. Jain and C.H. Koo, Creep and Corrosion Properties of the Extruded Magnesium Alloy Containing Rare Earth, Mater. Trans., 2007, 48, p 265–272

M. Mabuehi and Y. Chino, Tensile Properties at Room Temperature to 823 K of Mg-4Y-3RE Alloy, Mater. Trans., 2002, 43(8), p 2063–2068

A. Rusinek, J.A. Rodríguez-Martínez, and A. Arias, A Thermo-Viscoplastic Constitutive Model for FCC Metals with Application to OFHC Copper, Int. J. Mech. Sci., 2010, 52, p 120–135

H. Shin and J.B. Kim, A Phenomenological Constitutive Equation to Describe Various Flow Stress Behaviors of Materials in Wide Strain Rate and Temperature Regimes, J. Eng. Mater. Technol., 2010, 132, p 021009

T. Al-Samman and G. Gottstein, Deformation Microstructures of Mg-3Al-1Zn Magnesium Alloy Compressed Over Wide Regions of Temperature and Strain Rate, Mater. Sci. Eng. A, 2008, 490, p 411–420

H.G. Jeong, Y.G. Jeong, and W.J. Kim, Micro-Forming of Zr 65 Al 10 Ni 10 Cu 15 Metallic Glasses Under Superplastic Condition, J. Alloys Compd., 2009, 483, p 279–282

J.A. del Valle and O.A. Ruano, Influence of Texture on Dynamic Recrystallization and Deformation Mechanisms in Rolled or ECAPed AZ31 Magnesium Alloy, Mater. Sci. Eng. A, 2008, 487, p 473–480

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, and H. Beladi, Dynamic Recrystallization in AZ31 Magnesium Alloy, Mater. Sci. Eng. A, 2007, 456, p 52–57

J.G. Niu, X. Zhang, Z.M. Zhang, and B.C. Li, Influence on the Microstructure and Properties of AZ61 Magnesium Alloy at Warm Deformation, J. Mater. Process. Technol., 2007, 187–188, p 780–782

X. Zhou, M. Wang, Y. Fu, Z. Wang, Y. Li, S. Yang, H. Zhao, and H. Li, Effect of Borides on Hot Deformation Behavior and Microstructure Evolution of Powder Metallurgy High Borated Stainless Steel, Mater. Charact., 2017, 124, p 182–191

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322, p 43–63

D. Sang, R. Fu, and Y. Li, Combined Deformation Behavior and Microstructure Evolution of 7050 Aluminum Alloy During Hot Shear-Compression Deformation, Mater. Charact., 2016, 122, p 154–161

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138

Y. Duan, P. Li, L. Ma, and R. Li, Dynamic Recrystallization and Processing Map of Pb-30Mg-9Al-1B Alloy During Hot Compression, Metall. Mater. Trans. A, 2017, 48, p 3419–3431

Y.H. Duan, Hot Deformation and Processing Map of Pb-Mg-10Al-1B Alloy, J. Mater. Eng. Perform., 2013, 22, p 3049–3054

Y.H. Duan, L.S. Ma, R.Y. Li, and P. Li, Developed Constitutive Models, Processing Maps and Microstructural Evolution of Pb-Mg-10Al-0.5 B alloy, Mater. Charact., 2017, 129, p 353–366

C. Zener and J.H. Hollomon, Effect of Strain-Rate Upon the Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22–27

W.I. Zuzin, M.Y. Browman, and A.E.F. Melikov, Flow Resistance of Steel at Hot Forming, Metallurgy, Moscow, 1964

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, and K.V. Kasiviswanathan, Constitutive Equations to Predict High Temperature Flow Stress in a Ti-Modified Austenitic Stainless Steel, Mater. Sci. Eng. A, 2009, 500, p 114–121

W. Li, H. Li, Z.X. Wang, and Z.Q. Zheng, Constitutive Equations for High Temperature Flow Stress Prediction of Al–14Cu–7Ce Alloy, Mater. Sci. Eng. A, 2011, 528, p 4098–4103

D. Samantaray, C. Phaniraj, S. Mandal, and A.K. Bhaduri, Strain Dependent Rate Equation to Predict Elevated Temperature Flow Behavior of Modified 9Cr-1Mo (P91) Steel, Mater. Sci. Eng. A, 2011, 528, p 1071–1077

J. Zhao, H. Ding, W. Zhao, M. Huang, D. Wei, and Z. Jiang, Modelling of the Hot Deformation Behaviour of a Titanium Alloy Using Constitutive Equations and Artificial Neural Network, Comput. Mater. Sci., 2014, 92, p 47–56

P.M. Phaniraj and K.A. Lahiri, The Applicability of Neural Network Model to Predict Flow Stress for Carbon Steels, J. Mater. Proc. Tech., 2003, 141, p 219–227

Y.C. Lin and G. Liu, Effects of Strain on the Workability of a High Strength Low Alloy Steel in Hot Compression, Mater. Sci. Eng. A, 2009, 523, p 139–144

T.D. Kil, J.M. Lee, and Y.H. Moon, Quantitative Formability Estimation of Ring Rolling Process by Using Deformation Processing Map, J. Mater. Process. Technol., 2015, 220, p 224–230

Y.V.R.K. Prasad, Recent Advances in the Science of Mechanical Processing, Ind. J. Technol., 1990, 28, p 435–451

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Mater. Trans. A, 1984, 15, p 1883–1892

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43, p 243–252

Y.V.R.K. Prasad, D.H. Sastry, and S.C. Deevi, Processing Maps for Hot Working of a P/M Iron Aluminide Alloy, Intermetallics, 2000, 8, p 1067–1074

H.Z. Li, H.J. Wang, Z. Li, C.M. Liu, and H.T. Liu, Flow Behavior and Processing Map of as-cast Mg-10Gd-4.8 Y-2Zn-0.6 Zr Alloy, Mater. Sci. Eng. A, 2010, 528, p 154–160

Z.W. Cai, Z.W. Chen, F.X. Ma, F.J. Guo, and J. Qing, Dynamic Recrystallization Behavior and Hot Workability of AZ41M Magnesium Alloy During Hot Deformation, J. Alloys Compd., 2016, 670, p 55–63

S. Ramanathan, R. Karthikeyan, and G. Ganasen, Development of Processing Maps for 2124Al/SiCp Composites, Mater. Sci. Eng., A, 2006, 441, p 321–325

R. Raj, Development of a Processing Map for use in Warm-Forming and Hot-Forming Processes, Metal. Trans. A, 1981, 12, p 1089–1097

H. Wu, S.P. Wen, H. Huang, B.L. Li, X.L. Wu, K.Y. Gao, W. Wang, and Z.N. Nie, Effects of Homogenization on Precipitation of Al3(Er, Zr) Particles and Recrystallization Behavior in a New Type Al-Zn-Mg-Er-Zr Alloy, Mater. Sci. Eng., A, 2017, 698, p 313–322

Acknowledgments

This work was supported by the Yunnan Ten Thousand Talents Plan Young & Elite Talents Project under Grant No. YNWR-QNBJ-2018-044, the Reserve Talents Project of Yunnan Province under Grant No. 2015HB019, and the National Natural Science Foundation of China under Grant No. 51761023.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, W., Bao, L., Liu, D. et al. Constitutive Equations, Processing Maps, and Microstructures of Pb-Mg-Al-B-0.4Y Alloy under Hot Compression. J. of Materi Eng and Perform 29, 607–619 (2020). https://doi.org/10.1007/s11665-019-04544-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04544-8