Abstract

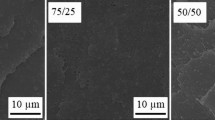

In this study, the effect of different contents of poly(lactide-co-trimethylene carbonate) (PLT) as a compatibilizer on the blends of PLGA and PTMC has been investigated. The PLGA/PTMC/PLT ternary composites were prepared by using the solution co-precipitation method. The PLT component played a very important role in determining internal structure, and thermal, mechanical, and hydrophilic properties of whole composites. Our results showed that the PLT addition made the glass transition temperature of PLGA and PTMC close to that of each other and improved their compatibility. When the amount of PLT addition was 3 wt%, the two-phase interface of the composite fracture surface almost disappeared, which further demonstrated that PLT could improve the interfacial compatibility of PLGA and PTMC. The tensile strength and tensile modulus and the elongation of the PLGA/PTMC/PLT composites were 54.01 ± 2.1 MPa, 1.11 ± 0.05 GPa, 49.29 ± 3.6% respectively after the 3 wt% random copolymers was added. The results of XRD and POM showed that the crystalline morphology of the composites was spherocrystal, where the second crystalline phase was not found. Interestingly, PLT reduced the hydrophilicity of PLGA/PTMC/PLT composites. In conclusion, PLGA/PTMC/PLT composites are expected to have a fascinating role in the field of bone defect repair.

Graphical abstract

Similar content being viewed by others

References

Pappalardo D, Mathisen T, Finne-Wistrand A (2019) Biocompatibility of resorbable polymers: a historical perspective and framework for the future. Biomacromolecules 20:1465–1477

Castillo-Dali G, Velazquez-Cayon R, Angeles Serrera-Figallo M, Rodriguez-Gonzalez-Elipe A, Gutierrez-Perez J-L, Torres-Lagares D (2015) Importance of poly(lactic-co-glycolic acid) in scaffolds for guided bone regeneration: a focused review. J Oral Implantol 41:E152–E157

Salonius E, Muhonen V, Lehto K, Jarvinen E, Pyhalto T et al (2019) Gas-foamed poly(lactide-co-glycolide) and poly(lactide-co-glycolide) with bioactive glass fibres demonstrate insufficient bone repair in lapine osteochondral defects. J Tissue Eng Regen Med 13:406–415

Jeong SI, Kim SY, Cho SK, Chong MS (2007) Tissue-engineered vascular grafts composed of marine collagen and PLGA fibers using pulsatile perfusion bioreactors. Biomaterials 28:1115–1122

Liu Q, Jiang L, Shi R, Zhang L (2012) Synthesis, preparation, in vitro degradation, and application of novel degradable bioelastomers—a review. Prog Polym Sci 37:715–765

Yousefi AM, James PF, Akbarzadeh R, Subramanian A et al (2016) Prospect of stem cells in bone tissue engineering: a review. Stem Cells Int. https://doi.org/10.1155/2016/6180487

Martina M, Hutmacher DW (2007) Biodegradable polymers applied in tissue engineering research: a review. Polym Int 56:145–157

Fukushima K (2016) Poly(trimethylene carbonate)-based polymers engineered for biodegradable functional biomaterials. Biomater Sci 4:9–24

Vilay V, Mariatti M, Ahmad Z, Pasomsouk K, Todo M (2009) Characterization of the mechanical and thermal properties and morphological behavior of biodegradable poly(L-lactide)/poly(ε-caprolactone) and poly(L-lactide)/poly(butylene succinate-co-L-lactate) polymeric blends. J Appl Polym Sci 114:1784–1792

Zhu Y, Wang Z, Li L et al (2017) In vitro degradation behavior of a hydroxyapatite/poly(lactide-co-glycolide) composite reinforced by micro/nano-hybrid poly(glycolide) fibers for bone repair. J Mater Chem B 5:8695–8706

Chou SF, Woodrow KA (2017) Relationships between mechanical properties and drug release from electrospun fibers of PCL and PLGA blends. J Mech Behav Biomed Mater 65:724–733

Han Y, Jin X, Yang J et al (2012) Totally bioresorbable composites prepared from poly(l-lactide)-co-(trimethylene carbonate) copolymers and poly(l-lactide)-co-(glycolide) fibers as cardiovascular stent material. Polym Eng Sci 52:741–750

Zhang F, Song Q, Huang X, Li F, Wang K, Tang Y, Hou C, Shen H (2016) A novel high mechanical property PLGA composite matrix loaded with nanodiamond-phospholipid compound for bone tissue engineering. ACS Appl Mater Interfaces 8:1087–1097

Fernandes KR, Magri AMP, Kido HW et al (2017) Biosilicate/PLGA osteogenic effects modulated by laser therapy: in vitro and in vivo studies. J Photochem Photobiol B Biol 173:258–265

Li X, Zhang S, Zhang X et al (2017) Biocompatibility and physicochemical characteristics of poly(epsilon-caprolactone)/poly(lactide-co-glycolide)/nano-hydroxyapatite composite scaffolds for bone tissue engineering. Mater Des 114:149–160

Guo J, Ning C, Liu X (2018) Bioactive calcium phosphate silicate ceramic surface-modified PLGA for tendon-to-bone healing. Colloids Surf B Biointerfaces 164:388–395

Liang X, Duan P, Gao J et al (2018) Bilayered PLGA/PLGA-HAp composite scaffold for osteochondral tissue engineering and tissue regeneration. Acs Biomater Sci Eng 4:3506–3521

Jiang L, Ma B, Li Y, Ding H, Su S, Xiong C (2019) Effect of bamboo fiber on the degradation behavior and in vitro cytocompatibility of the nano-hydroxyapatite/poly(lactide-co-glycolide) (n-HA/PLGA) composite. Cellulose 26:1099–1110

Wu LB, Ding JD (2014) In vitro degradation of three-dimensional porous poly(D,L-lactide-co-glycolide) scaffolds for tissue engineering. Biomaterials 25:5821–5830

Luo YR, Zhang L, Chen C et al (2018) The delayed degradation mechanism and mechanical properties of beta-TCP filler in poly(lactide-co-glycolide)/beta-tricalcium phosphate composite suture anchors during short-time degradation in vivo. J Mater Res 33:4278–4286

van Leeuwen AC, Huddleston Slater JJR, Gielkens PFM, de Jong JR, Grijpma DW, Bos RR (2012) Guided bone regeneration in rat mandibular defects using resorbable poly(trimethylene carbonate) barrier membranes. Acta Biomater 8:1422–1429

Zhang Z, Zou S, Vancso GJ, Grijpma DW, Feijen J (2005) Enzymatic surface erosion of poly(trimethylene carbonate) films studied by atomic force microscopy. Biomacromolecules 6:3404–3409

Guillaume O, Geven MA, Sprecher CM et al (2017) Surface-enrichment with hydroxyapatite nanoparticles in stereolithography-fabricated composite polymer scaffolds promotes bone repair. Acta Biomater 54:386–398

Zhang X, Geven MA, Wang X et al (2018) A drug eluting poly(trimethylene carbonate)/poly(lactic acid)-reinforced nanocomposite for the functional delivery of osteogenic molecules. Int J Nanomedicine 13:5701–5718

Hiroharu A, Yoshikazu T et al (2014) Surface control of hydrophilicity and degradability with block copolymers composed of lactide and cyclic carbonate bearing methoxyethoxyl groups. Polymer 55:3591–3598

Nalinthip C, Hiroharu A (2018) Preparation of thermosensitive biodegradable hydrogel using poly(5-[2-{2-(2-methoxyethoxy)ethyoxy}-ethoxyme thyl]-5-methyl-1,3-dioxa-2-one) derivatives. Materialia 5:100178

Bai H, Huang C, Xiu H, Gao Y, Zhang Q, Fu Q (2013) Toughening of poly(L-lactide) with poly(epsilon-caprolactone): combined effects of matrix crystallization and impact modifier particle size. Polymer 54:5257–5266

Moon HK, Choi YS, Lee JK, Ha CS, Lee WK, Gardella JA Jr (2009) Miscibility and hydrolytic behavior of poly(trimethylene carbonate) and poly(L-lactide) and their blends in monolayers at the air/water interface. Langmuir 25:4478–4483

Xie XL, Bai W, Wu H et al (2015) Increasing the compatibility of poly(l-lactide)/poly(para-dioxanone) blends through the addition of poly(para-dioxanone-co-l-lactide). J Appl Polym Sci. https://doi.org/10.1002/app.41323

Todo M, Park SD, Takayama T, Arakawa K (2007) Fracture micromechanisms of bioabsorbable PLLA/PCL polymer blends. Eng Fract Mech 74:1872–1883

Lin W, Qu JP (2019) Enhancing impact toughness of renewable poly(lactic acid)/thermoplastic polyurethane blends via constructing cocontinuous-like phase morphology assisted by ethylene-methyl acrylate-glycidyl methacrylate copolymer. Ind Eng Chem Res 58:10894–10907

Rathi SR, Coughlin EB, Hsu SL et al (2012) Effect of midblock on the morphology and properties of blends of ABA triblock copolymers of PDLA-mid-block-PDLA with PLLA. Polymer 53:3008–3016

Oyama HT (2009) Super-tough poly(lactic acid) materials: reactive blending with ethylene copolymer. Polymer 50:747–751

Phetwarotai W, Phusunti N, Aht-Ong D (2019) Preparation and characteristics of poly(butylene adipate-co-terephthalate)/polylactide blend films via synergistic efficiency of plasticization and compatibilization. Chin J Polym Sci 37:68–78

Kang H, Qiao B, Wang R et al (2013) Employing a novel bioelastomer to toughen polylactide. Polymer 54:2450–2458

Zhang K, Mohanty AK, Misra M (2012) Fully biodegradable and biorenewable ternary blends from polylactide, poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) with balanced properties. ACS Appl Mater Interfaces 4:3091–3101

Huang S, Sun H, Sun J et al (2014) Biodegradable tough blends of poly(L-lactide) and poly(castor oil)-poly(L-lactide) copolymer. Mater Lett 133:87–90

Jia Z, Zhang K, Tan J et al (2009) Crystallization behavior and mechanical properties of crosslinked plasticized poly(L-lactic acid). J Appl Polym Sci 111:1530–1539

Na YH, He Y, Shuai X, Kikkawa Y, Doi Y, Inoue Y (2002) Compatibilization effect of poly(epsilon-caprolactone)-b-poly(ethylene glycol) block copolymers and phase morphology analysis in immiscible poly(lactide)/poly(epsilon-caprolactone) blends. Biomacromolecules 3:1179–1186

Funding

This research was financially supported by the Science and Technology supporting program of Sichuan province, China (No.

2014SZ0128).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qi, J., Feng, S., Zhang, Y. et al. Investigations on the compatibilization between poly(lactic-co-glycolic acid)/poly(trimethylene carbonate) blends and poly(lactide-co-trimethylene carbonate). Colloid Polym Sci 298, 169–178 (2020). https://doi.org/10.1007/s00396-019-04595-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-019-04595-2