Abstract

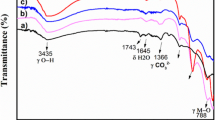

In this study, mesoporous alumina was synthesized using aluminium isopropoxide as Al precursor and cationic surfactant cetyl trimethylammonium bromide (CTAB) as structure directing agent and it was tested in the dehydration reaction of fructose into 5-HMF. The experiments were carried out in a microwave reactor at 200 °C for 5 min. The various ratio of CTAB/Al2O3 and calcination temperature between 400 and 700 °C were selected as synthesis parameters. The synthesized samples were analyzed by BET and XRD. The highest surface area was obtained as 602.22 m2/g with the weight ratio of CTAB to Al2O3 of 1.00 at the calcination temperature of 400 °C. When calcination temperature increased from 400 to 700 °C, surface area decreased into 286.14 m2/g. N2 adsorption/desorption isotherms of samples showed characteristic mesoporous type IV according to IUPAC classification. According to XRD patterns, all catalysts were in the amorphous structure. The maximum 5-HMF yield of 51% was achieved with the alumina catalyst calcined at 400 °C and CTAB/Al2O3 ratio of 1.0. Although the surface area decreased by rising the calcination temperature from 400 to 550 °C, the fructose conversion reached the highest value (97.54%).

Similar content being viewed by others

References

De Bhowmick G, Sarmah AK, Sen R (2018) Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Biores Technol 247:1144–1154

Cao Z, Fan Z, Chen Y, Li M, Shen T, Zhu C, Ying H (2019) Efficient preparation of 5-hydroxymethylfurfural from cellulose in a biphasic system over hafnyl phosphates. Appl Catal B 244:170–177

Svenningsen GS, Kumar R, Wyman CE, Christopher P (2018) Unifying mechanistic analysis of factors controlling selectivity in fructose dehydration to 5-hydroxymethylfurfural by homogeneous acid catalysts in aprotic solvents. ACS Catal 8:5591–5600

Yemiş O, Mazza G (2019) Catalytic performance of various solid catalysts and metal halides for microwave-assisted hydrothermal conversion of xylose, xylan, and straw to furfural. Waste Biomass Valor 10:1343–1345

Ahlkvist J, Wärnå J, Salmi T, Mikkola JP (2016) Heterogeneously catalyzed conversion of nordic pulp to levulinic and formic acids. Reac Kinet Mech Cat 119:415

Qi X, Watanabe M, Aida TM, Smith RL (2009) Sulfated zirconia as a solid acid catalyst for the dehydration of fructose to 5-hydroxymethylfurfural. Catal Commun 10:1771–1775

Kılıç E, Yılmaz S (2015) Fructose Dehydration to 5-Hydroxymethylfurfural over Sulfated TiO2–SiO2, Ti-SBA-15, ZrO2, SiO2, and Activated Carbon Catalysts. Ind Eng Chem Res 54:5220–5225

de Carvalho EGL, Rodrigues FA, Monteiro RS, Ribas RM, da Silva MJ (2018) Experimental design and economic analysis of 5-hydroxymethylfurfural synthesis from fructose in acetone-water system using niobium phosphate as catalyst. Biomass Conv Bioref 8:635–646

Shahangi F, Chermahini AN, Saraji M (2018) Dehydration of fructose and glucose to 5-hydroxymethylfurfural over Al-KCC-1 silica. J Energy Chem 27:769–780

Wang H, Kong Q, Wang Y, Deng T, Chen C, Hou X, Zhu Y (2014) Graphene Oxide catalyzed dehydration of fructose into 5-hydroxymethylfurfural with isopropanol as cosolvent. ChemCatChem 6:728–732

Yang Z, Qi W, Huang R, Fang J, Su R, He Z (2016) Functionalized silica nanoparticles for conversion of fructose to 5-hydroxymethylfurfural. Chem Eng J 296:209–216

Li Y, Liu H, Song C, Gu X, Li H, Zhu W, Yin S, Han C (2013) The dehydration of fructose to 5-hydroxymethylfurfural efficiently catalyzed by acidic ion-exchange resin in ionic liquid. Biores Technol 133:347–353

Jin P, Zhang Y, Chen Y, Pan J, Dai X, Liu M, Yan Y, Li C (2017) Facile synthesis of hierarchical porous catalysts for enhanced conversion of fructose to 5-hydroxymethylfurfural. J Taiwan Inst Chem Eng 75:59–69

Raveendra G, Srinivas M, Pasha N, Rao AVP, Prasad PSS, Lingaiah N (2015) Heteropoly tungstate supported on tantalum oxide: a highly active acid catalyst for the selective conversion of fructose to 5-hydroxy methyl furfural. Reac Kinet Mech Cat 115:663–678

Liu Z, Sun Z, Qin D, Yang G (2019) Sulfonic acid-functionalized hierarchical SAPO-34 for fructose dehydration to 5-hydroxymethylfurfural. Reac Kinet Mech Cat. https://doi.org/10.1007/s11144-019-01603-y

Morales-Leal FJ, de la Rosa JR, Lucio-Ortiz CJ, De Haro-Del Rio DA, Maldonado CS, Wi S, Casabianca LB, Garcia CD (2019) Dehydration of fructose over thiol– and sulfonic– modified alumina in a continuous reactor for 5–HMF production: study of catalyst stability by NMR. Appl Catal B 244:250–261

Song C, Liu H, Li Y, Ge S, Wang H, Zhu W, Chang Y, Han C, Li H (2014) Production of 5-hydroxymethylfurfural from fructose in ionic liquid efficiently catalyzed by Cr(III)-Al2O3 Catalyst. Chin J Chem 32:434–442

Kurumada M, Koike C, Kaito C (2005) Laboratory production of δ and θ alumina grains and their characteristic infrared spectra. Mon Not R Astron Soc 359:643–647

Al’myasheva OV, Korytkova EN, Maslov AV, Gusarov VV (2005) Preparation of nanocrystalline alumina under hydrothermal conditions. Inorg Mater 41:460–467

Grant SM, Vinu A, Pikus S, Jaroniec M (2011) Adsorption and structural properties of ordered mesoporous alumina synthesized in the presence of F127 block copolymer. Colloids Surf A 385:121–125

Čejka J (2003) Organized mesoporous alumina: synthesis, structure and potential in catalysis. Appl Catal A 254:327–338

Yun YS, Park DS, Yi J (2014) Effect of nickel on catalytic behaviour of bimetallic Cu–Ni catalyst supported on mesoporous alumina for the hydrogenolysis of glycerol to 1,2-propanediol. Catal Sci Technol 4:3191–3202

Niesz K, Yang P, Somorjai AG (2005) Sol-gel synthesis of ordered mesoporous alumina. Chem Commun 15:1986–1987

Martín MI, Gómez LS, Milosevic O, Rabanal ME (2010) Nanostructured alumina particles synthesized by the Spray Pyrolysis method: microstructural and morphological analyses. Ceram Int 36:767–772

Lafficher R, Digne M, Salvatori F, Boualleg M, Colson D, Puel F (2017) Development of new alumina precipitation routes for catalysis applications. J Cryst Growth 468:526–530

Martins L, Alves Rosa MA, Pulcinelli SH, Santilli CV (2010) Preparation of hierarchically structured porous aluminas by a dual soft template method. Microporous Mesoporous Mater 132:268–275

Wu Z, Li Q, Feng D, Webley PA, Zhao D (2010) Ordered mesoporous crystalline γ-Al2O3 with variable architecture and porosity from a single hard template. J Am Chem Soc 132:12042–12050

Xu N, Liu Z, Bian S, Dong Y, Li W (2016) Template-free synthesis of mesoporous γ-alumina with tunable structural properties. Ceram Int 42:4072–4079

Aguado J, Escola JM, Castro MC, Paredes B (2005) Sol–gel synthesis of mesostructured γ-alumina templated by cationic surfactants. Microporous Mesoporous Mater 83:181–192

Yue MB, Jiao WQ, Wang YM, He MY (2010) CTAB-directed synthesis of mesoporous γ-alumina promoted by hydroxy polyacids. Microporous Mesoporous Mater 132:226–231

Sicard L, Llewellyn PL, Patarin J, Kolenda F (2001) Investigation of the mechanism of the surfactant removal from a mesoporous alumina prepared in the presence of sodium dodecylsulfate. Microporous Mesoporous Mater 44:195–201

Deng W, Bodart P, Pruski M, Shanks B (2002) Characterization of mesoporous alumina molecular sieves synthesized by nonionic templating. Microporous Mesoporous Mater 52:169–177

Wu Q, Zhang F, Yang J, Li Q, Tu B, Zhao D (2011) Synthesis of ordered mesoporous alumina with large pore sizes and hierarchical structure. Microporous Mesoporous Mater 143:406–412

Yuan Q, Yin AX, Luo C, Sun LD, Zhang YW, Duan WT, Liu HC, Yan CH (2008) Facile synthesis for ordered mesoporous γ-aluminas with high thermal stability. J Am Chem Soc 130:3465–3472

Ray JC, You KS, Ahn JW, Ahn WS (2007) Mesoporous alumina (I): comparison of synthesis schemes using anionic, cationic, and non-ionic surfactants. Microporous Mesoporous Mater 100:183–190

Berger D, Traistaru GA, Matei C (2012) Influence of different templates on the morphology of mesoporous aluminas. Cent Eur J Chem 10:1688–1695

Patel CK, Sarma PJ, De M (2015) Comparative parametric study on development of porous structure of aluminium oxide in presence of anionic and cationic surfactants. Ceram Int 41:3578–3588

Khalil KMS (2008) Formation of mesoporous alumina via hydrolysis of modified aluminum isopropoxide in presence of CTAB cationic surfactant. Appl Surf Sci 255:2874–2878

Liu Q, Wang A, Wang X, Zhang T (2007) Morphologically controlled synthesis of mesoporous alumina. Microporous Mesoporous Mater 100:35–44

Aguado J, Escola JM, Castro MC (2010) Influence of the thermal treatment upon the textural properties of sol–gel mesoporous γ-alumina synthesized with cationic surfactants. Microporous Mesoporous Mater 128:48–55

Zheng XL, Sun QP, Liu F, Zheng Y, Weng JB (2014) Effect of p-aminobenzoic acid on synthesizing ordered mesoporous alumina via the sol–gel method. J Porous Mater 21:819–825

Huang F, Zheng Y, Cai G, Zheng Y, Xiao Y, Wei K (2010) A new synthetic procedure for ordered mesoporous χ-alumina with a large surface area. Scripta Mater 63:339–342

Han D, Li X, Zhang L, Wang Y, Yan Z, Liu S (2012) Hierarchically ordered meso/macroporous γ-alumina for enhanced hydrodesulfurization performance. Microporous Mesoporous Mater 158:1–6

Wang J, Qu T, Liang M, Zhao Z (2015) Microwave assisted rapid conversion of fructose into 5-HMF over solid acid catalysts. RSC Adv. 5:106053–106060

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hoşgün, H.L., Türe, A.G., Hoşgün, E.Z. et al. Synthesis 5-hydroxymethylfurfural (5-HMF) from fructose over cetyl trimethylammonium bromide-directed mesoporous alumina catalyst: effect of cetyl trimethylammonium bromide amount and calcination temperature. Reac Kinet Mech Cat 129, 337–347 (2020). https://doi.org/10.1007/s11144-019-01699-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-019-01699-2