Abstract

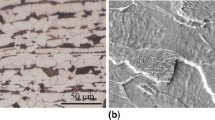

Ultrasonic impact treatment (UIT) combined with high-energy electropulsing (EP) was applied to D36 low-carbon steel with three different electrical regimes. Submicron crystalline was obtained on the superficial region after the treatment due to continuous dynamic recrystallization. The cementite experienced strain-induced decomposition and precipitation. The microstructure is significantly determined by the current density and temperature. A strengthened layer with a maximum hardness of 285 HV was obtained in EP-UIT, in comparison with the hardness of 227 HV resulted from UIT solely. Alongside with high hardness, the strengthened layer extended to a remarkable depth of nearly 2 mm due to acoustic softening, electroplasticity and thermal softening engaged simultaneously. A 3-μm oxide layer in average consisting of magnetite and hematite formed on the treated surface. Joule heat and athermal effect of EP are the factors inducing these phenomena.

Similar content being viewed by others

References

S. Juang and Y. Tarng, Process parameter selection for optimizing the weld pool geometry in the tungsten inert gas welding of stainless steel, J. Mater. Process. Technol., 2002, 122(1), p 33–37

O. Hatamleh, J. Lyons, and R. Forman, Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-T7351 aluminum alloy joints, Int. J. Fatigue, 2007, 29(3), p 421–434

T. Wang, J. Yu, and B. Dong, Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 1Cr18Ni9Ti stainless steel, Surf. Coat. Technol., 2006, 200(16–17), p 4777–4781

K. Darling, M. Tschopp, A. Roberts, J. Ligda, and L. Kecskes, Enhancing grain refinement in polycrystalline materials using surface mechanical attrition treatment at cryogenic temperatures, Scripta Mater., 2013, 69(6), p 461–464

A. Abdullah, M. Malaki, and A. Eskandari, Strength enhancement of the welded structures by ultrasonic peening, Mater. Des., 2012, 38(38), p 7–18

N. Krylov and A. Polischuk, The use of ultrasonic equipment for metal structure stabilization, Basic Physics of Industrial Ultrasonic Applications, 1970, 1, p 70

M. Liao, W. Chen, and N. Bellinger, Effects of ultrasonic impact treatment on fatigue behavior of naturally exfoliated aluminum alloys, Int. J. Fatigue, 2008, 30(4), p 717–726

B. Mordyuk, G. Prokopenko, K. Grinkevych, N. Piskun, and T. Popova, Effects of ultrasonic impact treatment combined with the electric discharge surface alloying by molybdenum on the surface related properties of low-carbon steel G21Mn5, Surf. Coat. Technol., 2017, 309, p 969–979

M. Malaki and H. Ding, A review of ultrasonic peening treatment, Mater. Des., 2015, 87, p 1072–1086

T. Deguchi, M. Mouri, J. Hara, D. Kano, T. Shimoda, F. Inamura, T. Fukuoka, and K. Koshio, Fatigue strength improvement for ship structures by ultrasonic peening, J. Mar. Sci. Tech, 2012, 17(3), p 360–369

G. Jinu, P. Sathiya, G. Ravichandran, and A. Rathinam, Investigation of the fatigue behaviour of butt-welded joints treated by ultrasonic peening process and compared with fatigue life assessment standards, Int. J. Adv. Manu. Tech, 2009, 40(1–2), p 74–83

S. Roy, J.W. Fisher, and B.T. Yen, Fatigue resistance of welded details enhanced by ultrasonic impact treatment (UIT), Int. J. Fatigue, 2003, 25(9), p 1239–1247

Y. Liu, D. Wang, C. Deng, L. Xia, L. Huo, L. Wang, and B. Gong, Influence of re-ultrasonic impact treatment on fatigue behaviors of S690QL welded joints, Int. J. Fatigue, 2014, 66, p 155–160

H. Shimanuki and T. Okawa, Effect of stress ratio on the enhancement of fatigue strength in high performance steel welded joints by ultrasonic impact treatment, Int. J. Steel. Struct, 2013, 13(1), p 155–161

R.T. Yekta, K. Ghahremani, and S. Walbridge, Effect of quality control parameter variations on the fatigue performance of ultrasonic impact treated welds, Int. J. Fatigue, 2013, 55, p 245–256

B. Langenecker, Effects of ultrasound on deformation characteristics of metals, IEEE transactions on sonics and ultrasonics, 1966, 13(1), p 1–8

E. Ghassemieh and A. Siddiq, Thermomechanical analyses of ultrasonic welding process using thermal and acoustic softening effects, Mech. Mater., 2008, 40(12), p 982–1000

A. Siddiq and S.T. El, Ultrasonic-assisted manufacturing processes: variational model and numerical simulations, Ultrasonics, 2012, 52(4), p 521–529

B. Mordyuk, G. Prokopenko, P.Y. Volosevich, L. Matokhnyuk, A. Byalonovich, and T. Popova, Improved fatigue behavior of low-carbon steel 20GL by applying ultrasonic impact treatment combined with the electric discharge surface alloying, Mater. Sci. Eng., A, 2016, 659, p 119–129

Y. Liu, D. Wang, C. Deng, L. Huo, L. Wang, and S. Cao, Feasibility study on preparation of coatings on Ti–6Al–4 V by combined ultrasonic impact treatment and electrospark deposition, Mater. Des., 2014, 63, p 488–492

H. Conrad, Electroplasticity in metals and ceramics, Mater. Sci. Eng., A, 2000, 287(2), p 276–287

K. Klimov, G. Shnyrev, and I. Novikov, On electroplasticity of metals, Dokl. Akad. Nauk SSSR, 1974, 219(2), p 323–324

M.I. Molotskii, Theoretical basis for electro-and magnetoplasticity, Mater. Sci. Eng., A, 2000, 287(2), p 248–258

H. Conrad and A.F. Sprecher, The electroplastic effect in metals, Elsevier Science, Amsterdam, 1989

G. Tang, J. Zhang, Y. Yan, H. Zhou, and W. Fang, The engineering application of the electroplastic effect in the cold-drawing of stainless steel wire, J. Mater. Process. Technol., 2003, 137(1–3), p 96–99

Z. Xu, G. Tang, S. Tian, F. Ding, and H. Tian, Research of electroplastic rolling of AZ31 Mg alloy strip, J. Mater. Process. Technol., 2007, 182(1), p 128–133

W. Zhang, M. Sui, Y. Zhou, and D. Li, Evolution of microstructures in materials induced by electropulsing, Micron, 2003, 34(3), p 189–198

H. Wang, G. Song, and G. Tang, Enhanced surface properties of austenitic stainless steel by electropulsing-assisted ultrasonic surface rolling process, Surf. Coat. Technol., 2015, 282, p 149–154

H. Wang, G. Song, and G. Tang, Effect of electropulsing on surface mechanical properties and microstructure of AISI, 304 stainless steel during ultrasonic surface rolling process, Mater. Sci. Eng., A, 2016, 662, p 456–467

Y. Jiang, G. Tang, C. Shek, and Y. Zhu, Effect of electropulsing treatment on microstructure and tensile fracture behavior of aged Mg–9Al–1Zn alloy strip, Appl. Phys. A, 2009, 97(3), p 607–615

J. Chen, H. Zhang, P. Zhang, Z. Yu, Y. Zhang, C. Yu, and H. Lu, The Zn accumulation behavior, phase evolution and void formation in Sn-xZn/Cu systems by considering trace Zn: a combined experimental and theoretical study, Journal of Materials Research and Technology, 2019, 8(5), p 4141–4150

A. Rahnama and R. Qin, The effect of electropulsing on the interlamellar spacing and mechanical properties of a hot-rolled 014% carbon steel, Mater. Sci. Eng., A, 2015, 627, p 145–152

L. Tao, X. Li, G. Tang, and G. Song, Effect of ultrasonic impact treatment assisted with high energy electropulsing on microstructure of D36 carbon steel, J. Mater. Res., 2016, 31(24), p 3956–3967

E.S. Statnikov, O.V. Korolkov, and V.N. Vityazev, Physics and mechanism of ultrasonic impact, Ultrasonics, 2006, 44(4), p e533–e538

B.N. Mordyuk and G.I. Prokopenko, Ultrasonic impact peening for the surface properties’ management, J. Sound & Vibra, 2007, 308(3), p 855–866

X.J. Cao, Y.S. Pyoun, and R. Murakami, Fatigue properties of a S45C steel subjected to ultrasonic nanocrystal surface modification, Appl. Surf. Sci., 2010, 256(21), p 6297–6303

P. Belkin, A. Yerokhin, and S. Kusmanov, Plasma electrolytic saturation of steels with nitrogen and carbon, Surf. Coat. Technol., 2016, 307, p 1194–1218

M. Naeem, J. Iqbal, M. Abrar, K.H. Khan, J. Díaz-Guillén, C. Lopez-Badillo, M. Shafiq, M. Zaka-ul-Islam, and M. Zakaullah, The effect of argon admixing on nitriding of plain carbon steel in N2 and N2-H2 plasma, Surf. Coat. Technol., 2018, 350, p 48–56

J. Yang, Z. Yu, Y. Li, H. Zhang, and N. Zhou, Laser welding/brazing of 5182 aluminium alloy to ZEK100 magnesium alloy using a nickel interlayer, Sci. Technol. Weld. Joining, 2018, 23(7), p 543–550

F.R.N. Nabarro, Theory of crystal dislocations, Clarendon Press, Oxford, 1967

A.V. Kozlov, B.N. Mordyuk, and A.V. Chernyashevsky, On the additivity of acoustoplastic and electroplastic effects, Mater. Sci. Eng., A, 1995, 190(1–2), p 75–79

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions, Prog. Mater Sci., 2014, 60, p 130–207

S. Gourdet and F. Montheillet, An experimental study of the recrystallization mechanism during hot deformation of aluminium, Mater. Sci. Eng., A, 2000, 283(1–2), p 274–288

K. Tsuzaki, X. Huang, and T. Maki, Mechanism of dynamic continuous recrystallization during superplastic deformation in a microduplex stainless steel, Acta Mater., 1996, 44(11), p 4491–4499

T. Sakai, Plastic deformation: Role of recovery and recrystallization, Encyclopedia of materials: science and technology, 2001, 7, p 7079

N. Tao, Z. Wang, W. Tong, M. Sui, J. Lu, and K. Lu, An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment, Acta Mater., 2002, 50(18), p 4603–4616

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk nanostructured materials from severe plastic deformation, Prog. Mater Sci., 2000, 45(2), p 103–189

H. Zhang, Z. Hei, G. Liu, J. Lu, and K. Lu, Formation of nanostructured surface layer on AISI, 304 stainless steel by means of surface mechanical attrition treatment, Acta Mater., 2003, 51(7), p 1871–1881

S. Tjong and H. Chen, Nanocrystalline materials and coatings, Materials Science and Engineering: R: Reports, 2004, 45(1), p 1–88

L. Storojeva, D. Ponge, R. Kaspar, and D. Raabe, Development of microstructure and texture of medium carbon steel during heavy warm deformation, Acta Mater., 2004, 52(8), p 2209–2220

R. Song, D. Ponge, D. Raabe, and R. Kaspar, Microstructure and crystallographic texture of an ultrafine grained C-Mn steel and their evolution during warm deformation and annealing, Acta Mater., 2005, 53(3), p 845–858

J. Languillaume, G. Kapelski, and B. Baudelet, Cementite dissolution in heavily cold drawn pearlitic steel wires, Acta Mater., 1997, 45(3), p 1201–1212

X. Sauvage, J. Copreaux, F. Danoix, and D. Blavette, Atomic-scale observation and modelling of cementite dissolution in heavily deformed pearlitic steels, Philos. Mag. A, 2000, 80(4), p 781–796

V.G. Gavriljuk, Comment on “Effect of interlamellar spacing on cementite dissolution during wire drawing of pearlitic steel wires”, Scripta Mater., 2001, 45(12), p 1469–1472

Y. Li, P. Choi, C. Borchers, S. Westerkamp, S. Goto, D. Raabe, and R. Kirchheim, Atomic-scale mechanisms of deformation-induced cementite decomposition in pearlite, Acta Mater., 2011, 59(10), p 3965–3977

P. Liaw, R. Viswanathan, K. Murty, E. Simonen, D. Frear, Microstructures and Mechanical Properties of Aging Materials, 1993.

H. Conrad, Effects of electric current on solid state phase transformations in metals, Mater. Sci. Eng., A, 2000, 287(2), p 227–237

Acknowledgment

This work has been funded and assisted by CIMC (China International Marine Containers (Group) Co., Ltd.). This work is also funded by projects from Shenzhen Government (Grant No. HYCYGJ20140512010015).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, T., Li, X., Tang, G. et al. Microstructure Evolution and Recrystallization of D36 Steel during Ultrasonic Impact Assisted with Electropulsing and Heat. J. of Materi Eng and Perform 29, 541–553 (2020). https://doi.org/10.1007/s11665-019-04522-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04522-0