Abstract

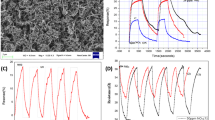

Surface heat transfer measurement is an important aspect in many research problems. Thin film heat flux sensor (TFHFS) is mostly considered in such situations for heat flux measurement due to its quick response and high accuracy. In the present studies, multi-walled carbon nanotubes (MWCNTs) are mixed with platinum while making the TFHFSs. Such addition is noticed to increase the sensitivity and decrease the temperature coefficient of resistance (TCR) of the thin film sensors. Improved sensitivity by 151% and 119% for Macor and Quartz sensors has led to increase in strength of the temperature response of the sensors during dynamic calibration experiments. Though heat flux recovery is seen to have encouraging agreement for all the sensors, sensitivity enhancement is noticed to be more prominent and advantageous for Macor based sensors. Present studies recommend adequately finished substrate for better adhesion. Further, use of MWCNTs is advisable especially for low heat flux measurement and also for Macor substrate since either situation demands the higher sensitivity to increase the output response.

Similar content being viewed by others

Abbreviations

- k:

-

thermal conductivity (W/mK)

- c:

-

specific heat (J/kgK)

- ρ:

-

density (kg/m3)

- \( \sqrt{\uprho \mathrm{ck}} \) :

-

thermal effusivity (J/m2 s0.5 K)

- g:

-

grams

- T:

-

temperature (K or °C)

- R:

-

electrical resistance (Ω)

- S:

-

sensitivity (ohm/K)

- r:

-

coefficient of correlation

- α:

-

temperature coefficient of resistance (K−1)

- q:

-

heat flux (W/m2)

- t:

-

test time (s)

- τ:

-

scaled time (s)

- x:

-

depth of substrate (m)

- 0:

-

room temperature

- s:

-

substrate

- h:

-

heating

- c:

-

cooling

References

Jones TV, Oldfield MLG, Ainsworth RW, Arts T (1993) Transient cascade testing, NATO advanced Group for Aerospace Research and Development AG328 (Chapter 5)

Vidal RJ (1956) Model instrumentation techniques for heat transfer and force measurements in a hypersonic shock tunnel. Cornell Aeronautical Laboratory, Report No WADC TN 56-315

Kulkarni V, Hegde GM, Jagadeesh G, Arunan E, Reddy KPJ (2008) Aerodynamic drag reduction by heat addition into the shock layer for a large angle blunt cone in hypersonic flow. Phys Fluids 20(8):081703

Buttsworth DR, Jones TV (1998) A fast-response total temperature probe for unsteady compressible flows. J Eng Gas Turbines Power 120(4):694–702

Nagai H, Oumi S, Asai K, Nakaita K (2006) Effect of temperature sensitive paint layer on global heat transfer measurement in hypersonic flow. J Visual Soc Jpn 26(1):201–204

Mosharov V, Orlov A, Radchenko V (2003) Temperature Sensitive Paint (TSP) for Heat Transfer Measurement in Short Duration Wind Tunnels. Proceedings of 20th international congress on instrumentation in aerospace simulation facilities (ICIASF 03), August 25–29, pp 351–356

Miller CG III (1981) Comparison of thin-film resistance heat-transfer gauges with thin skin transient calorimeter gages in conventional hypersonic wind tunnels. NASA Technical Memorandum, 83197

Sanderson SR, Sturtevant B (2002) Transient heat flux measurement using a surface junction thermocouple. Rev Sci Instrum 73(7):2781–2787

Mohammed H, Salleh H, Yusoff MZ (2008) Design and fabrication of coaxial surface junction thermocouples for transient heat transfer measurements. Int Commun Heat Mass Transfer 35(7):853–859

Desikan SLN, Suresh K, Srinivasan K, Raveendran PG (2016) Fast response co-axial thermocouple for short duration impulse facilities. Appl Therm Eng 96:48–56

Ainsworth RW, Schultz DL, Davies MRD, Forth CJP, Hildith MA, Oldfield MLG, Sheard AG (1988) Developments in instrumentation and processing for transient heat transfer measurement in full stage model turbine. ASME 88-GT-11

Iliopoulou V, Denos R, Billiard N, Arts T (2004) Time-averaged and time-resolved heat flux measurements on a turbine stator blade using two-layered thin-film gauges. In ASME Turbo expo 2004: power for land, sea, and air (pp. 553–561)

Kinnear K, Lu F (1997) Design, calibration and testing of transient thin film heat transfer gauges. In 20th AIAA advanced measurement and ground testing technology conference (p. 2504)

Epstein AH, Guenette GR, Norton RJG, Yuzhang C (1985) High frequency response heat flux gauge for metal blading. In in AGARD heat transfer and cooling in gas turbines 16 p (SEE N86-29823 21-07)

Sahoo N, Saravanan S, Jagadeesh G, Reddy KPJ (2006) Simultaneous measurement of aerodynamic and heat transfer data for large angle blunt cones in hypersonic shock tunnel. Sadhana 31(5):557–581

Flaherty W, Austin JM (2011) Comparative surface heat transfer measurements in hypervelocity flow. J Thermophys Heat Transf 25(1):180–183

Kumar R, Sahoo N, Kulkarni V, Singh A (2011) Laser based calibration technique of thin film gauges for short duration transient measurements. J Therm Sci Eng Appl 3(4):044504

Kumar R, Sahoo N, Kulkarni V (2010) Design, fabrication and calibration of heat transfer gauges for transient measurement. Proceedings of ASME international mechanical engineering congress and exhibition, Vancouver, British Columbia, Canada, Nov. 13–18, Paper No. IMECE2010–40253

Kumar R, Sahoo N, Kulkarni V (2012) Conduction based calibration of handmade platinum thin film heat transfer gauges for transient measurements. Int J Heat Mass Transf 55(9–10):2707–2713

Sahoo N, Kumar R (2016) Performance assessment of thermal sensors during short-duration convective surface heating measurements. Heat Mass Transf 52(9):2005–2013

Cook WJ, Felderman EJ (1966) Reduction of data from thin-film heat-transfer gages-a concise numerical technique. AIAA J 4(3):561–562

Sahoo N, Peetala RK (2011) Transient surface heating rates from a nickel film sensor using inverse analysis. Int J Heat Mass Transf 54(5–6):1297–1302

Sahoo N, Peetala RK (2010) Transient temperature data analysis for a supersonic flight test. ASME J Heat Transf 132(8):084503

Kawale B, Peetala R, Sahoo N, Kulkarni V (2010) Numerical methods to determine convective heating rates on aerodynamic surfaces. Int J Hyperson 1:1

Peetala RK, Sahoo N, Kulkarni V (2013) Prediction of short-duration transient surface heat flux using various analytical techniques. Heat Transf Asian Res 42(6):530–543

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58

Ventura DN, Li S, Baker CA, Breshike CJ, Spann AL, Strouse GF, Kroto HW, Acquah SF (2012) A flexible cross-linked multi-walled carbon nanotube paper for sensing hydrogen. Carbon 50(7):2672–2674

Cantalini C, Valentini L, Armentano I, Kenny JM, Lozzi L, Santucci S (2004) Carbon nanotubes as new materials for gas sensing applications. J Eur Ceram Soc 24(6):1405–1408

Cao J, Wang Q, Dai H (2003) Electromechanical properties of metallic, quasimetallic, and semiconducting carbon nanotubes under stretching. Phys Rev Lett 90(15):157601

Zhao Q, Frogley MD, Wagner HD (2002) Direction-sensitive strain-mapping with carbon nanotube sensors. Compos Sci Technol 62(1):147–150

Ghosh S, Sood AK, Kumar N (2003) Carbon nanotube flow sensors. Science 299:1042–1044

Wang J, Musameh M (2003) Carbon nanotube/teflon composite electrochemical sensors and biosensors. Anal Chem 75(9):2075–2079

Chen HW, Wu RJ, Chan KH, Sun YL, Su PG (2005) The application of CNT/Nafion composite material to low humidity sensing measurement. Sensors Actuators B Chem 104(1):80–84

Sarma S, Lee J (2018) Developing efficient thin film temperature sensors utilizing layered carbon nanotube films. Sensors 18(10):3182

Matzeu G, Pucci A, Savi S, Romanelli M, Di Francesco F (2012) A temperature sensor based on a MWCNT/SEBS nanocomposite. Sensors Actuators A Phys 178:94–99

Sarma S, Fekas I, Filintoglou K, Arvanitidis J, Christofilos D, Hatzikraniotis E, Lidor O, Mastai Y, Unal A, Patsalas P (2019) Layer by layer deposition of alternate carbon nanotubes and Ni films for efficient multilayer thin film temperature gauges. J Phys D Appl Phys 52(9):095104

Cagatay E, Falco A, Abdellah A, Lugli P (2014, June) Carbon nanotube based temperature sensors fabricated by large-scale spray deposition. In 2014 10th conference on Ph. D. Research in microelectronics and electronics (PRIME) (pp. 1–4). IEEE

Di Bartolomeo A, Sarno M, Giubileo F, Altavilla C, Iemmo L, Piano S, Bobba F, Longobardi M, Scarfato A, Sannino D, Cucolo AM (2009) Multiwalled carbon nanotube films as small-sized temperature sensors. J Appl Phys 105(6):064518

Monea B, Ionete E, Spiridon S, Leca A, Stanciu A, Petre E, Vaseashta A (2017) Single wall carbon nanotubes based cryogenic temperature sensor platforms. Sensors 17(9):2071

Chu K, Guo H, Jia C, Yin F, Zhang X, Liang X, Chen H Thermal properties of carbon nanotube–copper composites for thermal management applications. Nanoscale Res Lett 2010, 5(5):868

Sarma S, Sahoo N, Unal A (2016) Thin-film gauges using carbon nanotubes as composite layers. J Eng Mater Technol 138(4):041014

Collins M, Chana K, Povey T (2015) New technique for the fabrication of miniature thin film heat flux gauges. Meas Sci Technol 26(2):025303

Cui LJ, Wang YB, Xiu WJ, Wang WY, Xu LH, Xu XB, Meng Y, Li LY, Gao J, Chen LT, Geng HZ (2013) Effect of functionalization of multi-walled carbon nanotube on the curing behavior and mechanical property of multi-walled carbon nanotube/epoxy composites. Mater Des 49:279–284

Mangum BW (1984) Stability of small industrial platinum resistance thermometers. J Res Nat Bur Stand 89(4):305

Žužek V, Batagelj V, Bojkovski J (2010) Determination of PRT hysteresis in the temperature range from− 50 °C to 300 °C. Int J Thermophys 31(8–9):1771–1778

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. Clarendon Press, Oxford

Acknowledgements

Authors are very much grateful to the “Department of Science and Technology- Science and Engineering Research Board (DST-SERB), Project Number- ECR/2017/000260” for providing financial support towards the fabrication of thin film sensors and experimental facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jadhav, A., Peetala, R. & Kulkarni, V. Multi-walled carbon nano-tubes for performance enhancement of thin film heat flux sensors. Heat Mass Transfer 56, 1537–1549 (2020). https://doi.org/10.1007/s00231-019-02765-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02765-0