Abstract

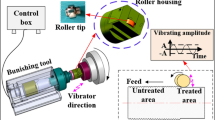

Ultrasonic energy can promote the dislocation motion in ultrasonic-assisted machining. The phase redistribution of Ti-6Al-4V alloy will occur in ultrasonic-assisted machining with appropriate ultrasonic powers. The variations of the volume fractions of β-Ti and α-Ti influence the microhardness on the processed surface. In the present paper, various rotary ultrasonic roller burnishing experiments were conducted to investigate the ultrasonic-induced phase redistribution of Ti-6Al-4V at different ultrasonic powers. The volume fractions of β-Ti and α-Ti were measured by X-ray diffraction. SEM images of the processed surfaces were used to analyze the microstructure evolution and grain refinement of Ti-6Al-4V at various ultrasonic powers. Then, the distributions of local misorientation, texture and grain boundary were observed by EBSD. The results indicated that the microhardness approached the maximum value on the processed surface while the volume fraction of β-Ti reached its maximum value. Finally, the modified phenomenological model was applied to elucidate the relationship among the microhardness, the phase volume fractions and the grain refinement. The fitting degree for microhardness between the modified phenomenological model prediction and experimental measurement was 92.2 pct.

Similar content being viewed by others

References

F. Blaha and B. Langenecker: Sci. Nat. Heidelberg., 1955, vol. 42, pp. 556–55.

B. Langenecker: IEEE Trans. Sonics Ultrasonics., 1966, vol. 13, pp. 1–8.

B. Langenecker and C.W. Fountain: Phil. Mag., 1965, vol. 11, pp. 512-519.

A. Abdulla, M. Sotoodezadeh, R. Abedini and V. Fartashvand: Int. J. Precis. Eng. Manuf., 2013, vol. 14, pp. 191–98.

C. Yang, X. Shan and T. Xie: Int. J. Adv. Manuf. Technol., 2016, vol. 83, pp. 645–55.

Y. Wang, H. Gong, F.Z. Fang and H. Ni: Int. J. Adv. Manuf. Technol., 2016, vol. 83, pp. 461–74.

Z. Yao, G.Y. Kim, L. Faidley, Q. Zou, D. Mei and Z. Chen: Mater. Manuf. Process., 2013, vol. 28, pp. 584–588.

Y. Liu, L.J. Wang and D.P. Wang: J. Mater. Process. Technol., 2011, vol. 211, pp. 2106–13.

A.T. Bozdana, N.N.Z. Gindy and H. Li: Int. J. Mach. Tools Manuf., 2005, vol. 45, pp. 713–18.

J. Huuki and S.V. Laakso: P. I. Mech. Eng. B-J. Eng., 2013, vol. 227, pp. 45–53.

J. Huuki, M. Hornborg and J. Juntunen: J. Eng., 2014, vol. 2014, pp. 5–7.

M. Salmi, J. Huuki and I.F. Ituarte: Prog. Addit. Manuf., 2017, vol. 2, pp. 31-41.

Z.H. Yao, G.Y. Kim, Z.H. Wang, L.A. Faidley, Q.Z. Zou, D.Q. Mei and Z.C. Chen: Int. J. of Plasticity., 2012, vol.39, pp. 75-87.

T. Wen, L. Wei, X. Chen and C.L. Pei: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 70–76.

T. Liu, J. Lin, Y. J. Guan, Z. D. Xie, L. H. Zhu and J.Q. Zhai: Ultrasonics., 2018, vol. 89, pp. 26–33.

A. Maurotto, R. Muhammad, A. Roy and V.V. Sillberschmidt: Ultrasonics., 2013, vol. 53, pp. 1242–50.

Y.C. Wang and T.G. Langdon: Mat. Sci. Eng. A., 2013, vol. 559, pp. 861–67.

J. Fu, H. Ding, Y. Huang, W. Zhang and T.G. Langdon: J. Mater. Res. Technol., 2015, vol. 4, pp. 2–7.

H.W. Zhou, H.Q. Liu, D.Q. Yi, Y. Xiao, X.L. Zhao, J. Wang and Q. Gao: J. Iron. Steel. Res. Int., 2017, vol. 24, pp. 811–22.

J.W. Elmer, T.A. Palmer, S.S. Babu and E.D. Specht: Mat. Sci. Eng. A., 2005, vol. 391, pp. 104–13.

S.L. Semiation, S.L. Knisley, P.N. Fagin, D.R. Barker and F. Zhang: Metall. Mater. Trans. A., 2003, vol. 34, pp. 2377–386.

P. Nandwana, Y. Lee, C. Ranger, D.R. Anthony, R.D. Ryan and S.B. Sudarsanam: Metall. and Mat. Trans. A, 2019, vol. 50, pp. 3429–39.

X. Tan, Y. Kok, Y.J. Tan, M. Descoins, D. Mangelinck, S.B. Tor, K.F. Leong and C.K. Chua: Acta. Mater., 2015, vol. 97, pp. 1–16.

A.A. Antonysamy, J. Meyer and P.B. Prangnell: Mater. Charact., 2013, vol. 84, pp. 153–68.

J. Donoghue, A.A. Antonysamy, F. Martina, P.A. Colegrove, S.W. Williams and P.B. Prangnell: Mater. Charact., 2016, vol. 114, pp. 103–14.

E. Chikarakara, S. Naher and D. Brabazon: Surf. Coat. Tech., 2012, vol. 206, pp. 3223–29.

F. Martina, P.A. Colegrove, S.W. Williams and J. Meyer: Metall. and Mat. Trans. A, 2015, vol. 46, pp. 6103–18.

J. Hu, T. Shimizu and M. Yang: Ultrason. Sonochem., 2018, vol. 48, pp. 240–48.

J. Zhao and Z.Q. Liu: Mater. Des., 2016, vol. 107, pp. 238–49.

V. Fartashvand, A. Abdullah and S.A.S. Vanini: Ultrason. Sonochem., 2016, vol. 38, pp. 744–49.

J. Luo, M. Li, W. Yu and H. Li: Mat. Sci. Eng. A., 2009, vol. 504, pp. 90–98.

X.G. Fan, H. Yang, Z.C. Sun and D.W. Zhang: Mat. Sci. Eng. A., 2010, vol. 527, pp. 5391–99.

S. Mironov, M. Murzinova, S. Zherebtsov, G.A. Salishchev and S.L. Semiatin: Acta. Mater., 2009, vol. 57, pp 2470–81.

C. Leyens and M. Peters: Titanium and Titanium Alloys: Fundamentals and Applications, First ed., Wiley, Weinheim, 2003, pp. 3–6.

J.J. Lin, Y.H. Lv, Y.X. Liu, B.S. Xu, Z. Sun, Z.G. Li and Y.X. Wu: Mater. Des., 2016, vol. 102, pp. 30–40.

H. Zhou, H. Cui, Q.H. Qin, H. Wang and Y. Shen: Mat. Sci. Eng. A., 2017, vol. 682, pp. 376–88.

B. Nagarajan, D. Kumar, Z. Fan and S. Castagne: Mat. Sci. Eng. A., 2018, vol. 728, pp. 196–207.

S. Roy and S. Suwas: J. Alloy. Compd., 2013, vol. 548, pp. 110–25.

Y. Liu and M. Li: Mat. Sci. Eng. A., 2016, vol. 669, pp. 7–13.

G. Rotella, O.W.J. Dillon, D. Umbrello, L. Settineri and I.S. Jawahir: Int. J. Adv. Manuf. Technol., 2014, vol. 71, pp. 47–55.

P.C. Collins, C.V. Haden, I. Ghamarian, B.J. Hayes, T. Ales, G. Penso, V. Dixit and G. Harlow: Jom., 2014, vol. 66, pp 1299–1309.

F. Khodabakhshi, M. Haghshenas, H. Eskandari and B. Koohbor: Mat. Sci. Eng. A., 2015, vol. 636, pp 331–39.

Acknowledgments

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (51425503 and 91860207). This work was also supported by Grants from Taishan Scholar Foundation and the National Key Research and Development Program of China (2018YFB2002201).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 12, 2019.

Rights and permissions

About this article

Cite this article

Zhao, J., Liu, Z., Chen, L. et al. Ultrasonic-Induced Phase Redistribution and Acoustic Hardening for Rotary Ultrasonic Roller Burnished Ti-6Al-4V. Metall Mater Trans A 51, 1320–1333 (2020). https://doi.org/10.1007/s11661-019-05594-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05594-2