Abstract

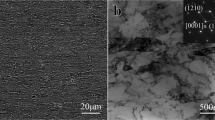

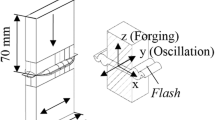

The microstructure of localized deformation layers is inevitably altered in the machining process. In this study, the microstructural evolution of localized deformation layers due to tool wear in the turning of titanium alloy (Ti–6Al–4V) was examined via analysis of the grain boundaries, crystallographic texture, and phase transformation. The machined surface exhibited strong plastic activities within the flowing region in the case of a worn tool, and additional mechanical loads caused deeper deformation because of more ranges of the softened materials. The plastic activities in the localized deformation layer were enhanced by the additional thermomechanical loads because of tool wear, causing grain distortions, elongation, and deformed grain boundaries. High-density grain boundaries were clustered in the localized deformation layer with the increase in the tool wear, and the tool wear promoted the generation of local misorientation and a corresponding gradient. With the increase in the tool wear, the percentages of small grains increased, and various degrees of refinement occurred. The texture enhancement regions indicated that the preferential deformation texture was modified by the retained shearing, where the basal texture {10–10}〈0001〉 changed to shear C fibre textures. The phase transformation was analysed from the viewpoints of the variation in the relative peak intensities and the phase volume fractions. The microstructural evolution underwent a gradual transition process, which was determined by the thermomechanical conditions associated with the tool wear. The results have great significance for optimizing the tool wear values to improve the surface integrity and provide a novel avenue for material design.

Similar content being viewed by others

References

Wu SQ, Lu YJ, Gan YL, Huang TT, Zhao CQ, Lin JJ, Guo S, Lin JX (2016) Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J Alloys Compd 672:643–652

Liang X, Liu Z, Wang B (2018) State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: a review. Measurement 132:150–181

Meng B, Fu MW, Shi SQ (2016) Deformation behavior and microstructure evolution in thermal-aided mesoforming of titanium dental abutment. Mater Des 89:1283–1293

M’Saoubi R, Outeiro JC, Chandrasekaran H, Dillon OW Jr, Jawahir IS (2008) A review of surface integrity in machining and its impact on functional performance and life of machined products. Int J Sustain Manuf 1:203–236

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tool Manuf 51(3):250–280

Yang D, Liu Z (2015) Surface plastic deformation and surface topography prediction in peripheral milling with variable pitch end mill. Int J Mach Tool Manuf 91:43–53

Jeelani S, Ramakrishnan K (1983) Subsurface plastic deformation in machining 6Al–2Sn–4Zr–2Mo titanium alloy. Wear 85(1):121–130

Moussaoui K, Mousseigne M, Senatore J, Chieragatti R, Monies F (2013) Influence of milling on surface integrity of Ti6Al4V-study of the metallurgical characteristics: microstructure and microhardness. Int J Adv Manuf Technol 67(5–8):1477–1489

Wang QQ, Liu ZQ (2016) Plastic deformation induced nano-scale twins in Ti–6Al–4V machined surface with high speed machining. Mater Sci Eng A 675:271–279

Velásquez JDP, Tidu A, Bolle B, Chevrier P, Fundenberger JJ (2010) Sub-surface and surface analysis of high speed machined Ti–6Al–4V alloy. Mater Sci Eng A 527(10–11):2572–2578

Basu S, Wang Z, Liu R, Saldana C (2016) Enhanced subsurface grain refinement during transient shear-based surface generation. Acta Mater 116:114–123

Basu S, Shankar MR (2015) Crystallographic textures resulting from severe shear deformation in machining. Metall Mater Trans A 46(2):801–812

Rotella G, Dillon OW, Umbrello D, Settineri L, Jawahir IS (2014) The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int J Adv Manuf Technol 71(1–4):47–55

Li A, Pang J, Zhao J (2017) FEM-simulation of machining induced surface plastic deformation and microstructural texture evolution of Ti–6Al–4V alloy. Int J Mech Sci 123:214–223

Wang Q, Liu Z, Yang D, Mohsan AUH (2017) Metallurgical-based prediction of stress-temperature induced rapid heating and cooling phase transformations for high speed machining Ti–6Al–4V alloy. Mater Des 119:208–218

Wang Q, Liu Z, Wang B, Mohsan AUH (2017) Stress-induced orientation relationship variation for phase transformation of α-Ti to β-Ti during high speed machining Ti–6Al–4V. Mater Sci Eng A 690:32–36

Ding H, Shin YC (2013) Multi-physics modeling and simulations of surface microstructure alteration in hard turning. J Mater Process Technol 213(6):877–886

Pan Z, Liang SY, Garmestani H, Shih DS (2016) Prediction of machining-induced phase transformation and grain growth of Ti–6Al–4V alloy. Int J Adv Manuf Technol 87(1–4):859–866

Wang Q, Liu Z, Wang B, Song Q, Wan Y (2016) Evolutions of grain size and micro-hardness during chip formation and machined surface generation for Ti–6Al–4V in high-speed machining. Int J Adv Manuf Technol 82(9–12):1725–1736

Arisoy YM, Özel T (2015) Prediction of machining induced microstructure in Ti–6Al–4V alloy using 3-D FE-based simulations: effects of tool micro-geometry, coating and cutting conditions. J Mater Process Technol 220:1–26

Pretorius CJ, Soo SL, Aspinwall DK, Harden PM, M’Saoubi R, Mantle AL (2015) Tool wear behaviour and workpiece surface integrity when turning Ti–6Al–2Sn–4Zr–6Mo with polycrystalline diamond tooling. CIRP Ann Manuf Technol 64(1):109–112

Ginting A, Nouari M (2009) Surface integrity of dry machined titanium alloys. Int J Mach Tool Manuf 49(3–4):325–332

Liang X, Liu Z, Wang B, Hou X (2018) Modeling of plastic deformation induced by thermo-mechanical stresses considering tool flank wear in high-speed machining Ti–6Al–4V. Int J Mech Sci 140:1–12

Liang X, Liu Z (2018) Tool wear behaviors and corresponding machined surface topography during high-speed machining of Ti–6Al–4V with fine grain tools. Tribol Int 121:321–332

Zhang P, Liu Z (2017) Plastic deformation and critical condition for orthogonal machining two-layered materials with laser cladded Cr-Ni-based stainless steel onto AISI 1045. J Clean Prod 149:1033–1044

Sui SC, Feng PF (2016) The influences of tool wear on Ti6Al4V cutting temperature and burn defect. Int J Adv Manuf Technol 85(9–12):2831–2838

Wielewski E, Arthington MR, Siviour CR, Petrinic N (2015) Characterising the effects of strain rate, crystallographic texture and direction of loading on the mechanical behaviour of Ti–6Al–4V. J Dyn Behav Mater 1(4):462–471

Beausir B, Tóth LS, Neale KW (2007) Ideal orientations and persistence characteristics of hexagonal close packed crystals in simple shear. Acta Mater 55(8):2695–2705

Sagapuram D, Efe M, Moscoso W, Chandrasekar S, Trumble KP (2013) Controlling texture in magnesium alloy sheet by shear-based deformation processing. Acta Mater 61:6843–6856

Wang YN, Huang JC (2003) Texture analysis in hexagonal materials. Mater Chem Phys 81:11–26

Chapuis A, Liu Q (2015) Simulations of texture evolution for HCP metals: influence of the main slip systems. Comput Mater Sci 97:121–126

Wang Q, Liu Z (2017) Investigation the effect of strain history on crystallographic texture evolution based on the perspective of macro deformation for high speed machining Ti–6Al–4V. Mater Charact 131:331–338

Liang X, Liu Z (2017) Experimental investigations on effects of tool flank wear on surface integrity during orthogonal dry cutting of Ti–6Al–4V. Int J Adv Manuf Technol 93(5–8):1617–1626

Sieniawski J, Filip R, Ziaja W (1997) The effect of microstructure on the mechanical properties of two-phase titanium alloys. Mater Des 18(4–6):361–363

Sarkar R, Karamched PS, Ghosal P, Prasad KS, Nandy TK, Ray KK (2014) Crystallographic orientation relationships of boride and carbide particles with α and β phases in a β-Ti alloy. J Alloys Compd 612:435–442

Acknowledgements

The authors would like to acknowledge financial support from the National Natural Science Foundation of China (91860207, 51425503, and 51705293). This work was also supported by grants from Taishan Scholar Foundation, the National Key Research and Development Program of China (2018YFB2002201), and Shandong Provincial Natural Science Foundation of China (ZR2019MEE073).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical standards

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, X., Liu, Z., Wang, Q. et al. Tool wear-induced microstructure evolution in localized deformation layer of machined Ti–6Al–4V. J Mater Sci 55, 3636–3651 (2020). https://doi.org/10.1007/s10853-019-04214-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04214-z