Abstract

Effects of the crystallographic structures of metal-phthalocyanines (metal: Co, Ni, Cu, Zn) between α and β phases on electrochemical oxygen reduction catalytic activities were investigated in acidic condition. As the distances of centered-metal in the structures of α and β phases are 3.8 Å and 4.8 Å, respectively, they were closed to the size of an oxygen molecule (3.6 Å). The phases of metal-phthalocyanines were conducted by an interface deposition method. The obtained catalyst powders were characterized by means of X-ray diffraction and X-ray photoelectron spectra analyses. Electrochemical oxygen reduction performances were mainly measured by using a gas diffusion type carbon electrode loaded with a metal-phthalocyanine. It was confirmed that the catalytic activities of cobalt- and copper-centered phthalocyanines were enhanced by the conversion from β to α phases. The effects of the distance between the metals in the crystallographic structures of metal-phthalocyanines should be explained by the adsorbed oxygen states that depend on the distance between the metals. The α phase has the distance which allows to form the bridge configuration of oxygen molecule which requires two adsorption sites and that eventually produces H2O by the direct 4-electron pathway. Analysis with the rotating disk electrode system showed that the α-phased metal-phthalocyanines enhance the 4-electron reduction pathway.

.

Similar content being viewed by others

Introduction

The development of catalysts for oxygen reduction reaction (ORR) has been conducted for applications relating to next-generation clean energy systems such as fuel cells and metal-air batteries [1,2,3,4,5,6,7,8,9,10,11]. In most cases, the ORR required a highly active electrocatalyst due to the slow electron transfer and transformation steps. The catalysts for proton conductive polymer electrolyte fuel cells (PEFC) also require a tolerance in an acidic condition; therefore, noble metal-based catalysts [12, 13] are widely used. However, high cost of the noble metal catalysts has been preventing expansion of commercial markets for PEMFCs. So far, many researchers have made great efforts for the development of the non-noble metal catalysts and have tried various materials [4, 9, 14,15,16]. Phthalocyanine compounds are well known to show high selective catalytic activities’ various areas including ORR which is similar to active sites in the enzyme; therefore, they are candidates for being a catalyst with high performance and low cost. Especially, 3d transition metal-phthalocyanines (MPcs) are attractive as their chemical and thermal stabilities [17,18,19,20,21,22].

It is also well known that the kind of central metal in MPc has a large influence on the catalytic property of MPc [23]. High catalytic activity for ORR requires that the energy level of HOMO of MPc should be sufficient and transformable to the π* orbital of O2 [24, 25]. Another factor is that the types of configuration for O2 adsorbed on MPc can affect catalytic properties [25,26,27]. Three configuration types with different arrangements of O2 as shown in Fig. 1 are as follows [27]:

-

1.

Side-on configuration: an O2 molecule is parallel to an MPc plane with a bonding of two oxygen atoms in an O2 molecule to a central metal.

-

2.

End-on configuration: an O2 molecule is vertical to an MPc plane having the central metal bonded with one oxygen atom from the O2 molecule.

-

3.

Bridge configuration: each oxygen atom of an O2 molecule vertically binds to the two central metals of two MPc molecules.

Possible configurations for O2 adsorption on an electrode surface [4]

It has been reported that the type of the adsorbed oxygen configuration determines the ORR pathway [26,27,28,29]. (1) The side-on configuration is formed with σ type bond that is associated with the dz2 orbital and π type bonds, which are, associated with the dxz and dxz orbitals. This configuration then ruptures the O-O bond after protonation, finally producing H2O by ORR via 4-electron pathway. These π type bonds have a strong π electron back donation; therefore, the central metals are oxidized, resulting with the oxidized central metals being easily separated from the phthalocyanine. Then, MPcs without metal lose catalytic activity. (2) The end-on configuration has σ type bond interacts between the metal dz2 and oxygen π orbitals, producing H2O2 by 2-electron reduction without a rupture of the O-O bond. (3) In the bridge configuration, an O2 molecule binds the two central metals with similar bond types as an end-on configuration, but this O-O bond can be broken. Therefore, when the O-O bond ruptures, it produces H2O with protonation. The ORR with bridge configuration should show a higher ORR current compared to an end-on configuration. The formation of the bridge configuration of oxygen needs a distance smaller than 4 Å for two adsorption sites [3]; however, it is difficult for MPc molecules to align at well- defined orientations and separations [27]. We focused on the effects of crystallographic structures of MPc molecules on the electrocatalytic activities of MPc. In the two major crystallographic structures for MPcs, α phase (α-MPc) and β phase (β-MPc), the planes of MPc molecules were orderly arranged in parallel at a distance of 3.4 Å as shown in Fig. 2 [30, 31]. The distances for central metals are 3.8 Å in α-MPc and 4.8 Å in β-MPc due to parallel shifts of the molecular plane. α-MPc having the distance close to 4 Å may be optimal for forming a bridge configuration. On the other hand, O2 molecules might form end-on configuration in β-MPc, which will result in producing H2O2. It seems that α-MPc shows a higher catalytic activity than β-MPc. So far, there have been few studies regarding the development of α-MPc electro-catalysts because of the difficulty in the preparation of α-MPc powders. In contrast, β-MPc powders are easily obtained from a wet-chemical synthesis; therefore, most of the commercial powders are β-MPc having high thermal stability due to the strong Van der Waals force in β-MPc [1]. On the other hand, α-MPc is mainly prepared by a vapor deposition method [32], which is suitable for preparation of MPc thin-films applicable for solar cells and semi-conductor devices. Other Yamanouchi et al. reported the electrophoretic deposition method for the preparation of α-MPc [33]; however, there are few reports about the preparation of α-MPc powders. In fact, the formation of α-MPc from monomolecular MPc takes precedence over β-MPc because of a large π-π interaction by a large overlapping area of the macrocyclic ligand. In other words, α-MPc is more stable than β-MPc without dense molecular packing. We have tried to obtain various α-MPc powders by the wet chemical method, and developed a new wet method for preparation of α-MPc powders using chemical deposition reaction on a hydrophilic-hydrophobic interface [34]. In this paper, we report on the preparation of the various α type MPcs (M = Mn, Fe, Co, Ni, Cu, Zn) by an interface deposition method and second, their ORR properties in an acid medium were reported with the influence of the crystallographic structures.

Schematic representations of the arrangement of the MPc molecules in α and β phases [30]

Experimental Section

Chemicals

All chemical reagents were used without further purification. Phthalocyanine manganese (MnPc) was purchased from Acros Organics. Phthalocyanine iron (FePc), phthalocyanine cobalt (CoPc), and phthalocyanine copper (CuPc) were purchased from Tokyo Chemical Industry. Phthalocyanine nickel (NiPc) and Triton X-100 were purchased from Kishida Chemical. Phthalocyanine zinc (ZnPc) and potassium hydroxide (KOH) were purchased from Kanto Chemical. Dichloromethane and trifluoro acetic acid were purchased from FUJIFILM Wako Pure Chemical. Ketjen black (ECP600JD) and DENKA black (AB-7) were provided by Lion Co. Ltd. and DENKA Co. Ltd. respectively. Teflon dispersion (PTFE, D-210C) was provided by Daikin Co. Ltd.

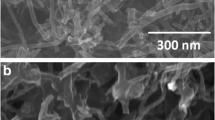

Catalyst Crystal Conversion from β-MPc to α-MPc Type Powders

Each MPc (M = Mn, Fe, Co, Ni, Cu, Zn) (1 mM) organic solution was prepared by dissolving of MPc powder in CH2Cl2 containing CF3COOH (1 M) with ultrasonic treatment. The MPc solution 200 mL was put in a 300 mL KOH (1 M) aqueous solution, which was then filtered, dried, and resulted in a powder. Finally, this powder was dried at 120 °C after washing with purified water [34]. For characterization of the obtained powders, X-ray diffraction (XRD) patterns were determined on a JDX-3500K (JEOL) diffractometer by Cu Kα1 radiation (λ = 1.5406 Å). X-ray photoelectron spectroscopy (XPS) analysis was performed using Kratos AXIS Nova spectrometer (Shimadzu).

Electrochemical Measurements

Gas Diffusion Type Carbon Electrode

Polarization for ORR measurements were carried out by using a potentiostat (HAL 3001 Hokuto Denko) and a function generator (HB-305 Hokuto Denko) with a three-electrode system in 1 M H2SO4 electrolyte at 70 °C. The electrochemical half-cell consists of a gas diffusion type carbon electrode (GDE) [35] fixed in a plastic holder (exposed area 1.76 cm2) as the working electrode, a reversible hydrogen reference electrode (RHE), and a platinum plate counter electrode, respectively. The reference electrode was placed externally to the cell and close to the working electrode through a Luggin capillary. The GDEs have a hydrophilic reaction layer and a hydrophobic gas diffusion layer with a nickel mesh current collector [12]. The nickel mesh is placed at an outer side of the gas diffusion layer as illustrated in Fig. 3. Pure oxygen gas (80 cc/min) was introduced from the gas diffusion layer side. The GDE is produced as follows: the reaction layer powder was prepared by mixing the MPc catalyst (32 wt%), Ketjen black (36 wt%), and PTFE (32 wt%) in a purified water with 1 wt% butanol, and dried at 120 °C for 12 h after filtration. The powder for the gas diffusion layer was prepared by mixing hydrophobic Denka black (60 wt%) and PTFE (40 wt%) in a purified water containing Triton as a surfactant which is equal to the weight of the Denka black. The reaction layer powder (60 mg), the gas diffusion layer carbon powder (120 mg), and a nickel mesh current collector were formed integrally by a hot-press method at 380 °C under 60 MPa, 10 s. The electrode was 22 mm in diameter and 0.4 mm in thickness. For testing the ORR activity, polarization curves were measured by a staircase voltammetry (SV) with a potential step of 25 mV and a holding time of 3 min at each potential. Tafel slopes were measured from the polarization curves at the lower current density range. In all I-V measurements, IR was not corrected, because the resistance of the GDE was as low as ca. 0.015 Ω.

Rotating Disk Electrode

The rotating disk electrode (RDE) experiments were performed using disk electrode apparatus (RDE-3A, BAS Inc.) which is controlled by potentiostat (Model 2323, ALS Co., Ltd). A saturated calomel reference electrode (SCE), a platinum wire counter electrode, and a glassy carbon-working electrode with MPc attached set in a thermostatic glass cell was filled with oxygen saturated 0.5 M H2SO4 electrolyte solution at 25 °C. The glassy carbon disk electrode having a diameter of 4 mm was polished with alumina powder. Preparation of catalyst inks with 1 mg of MPc was dispersed by ultrasonication with a mixture of 250 μL ethanol, distilled water of 250 μL, and 5 μL Nafion solution. The ink 20 μL was put on the disk electrode and dried at room temperature. The catalyst loading was 0.32 mg/cm2 and any carbon binder was not added. The potential of the disk electrode was scanned at a scan rate of 5 mV/s at various rotation speeds ranging from 400 to 2500 rpm.

Results and Discussion

XRD Analysis of Various MPcs

To confirm the crystal phase of MPcs, we investigated the powder X-ray diffraction (XRD) patterns of the commercial and prepared powders. Figure 4 shows XRD patterns of various commercial powders before and after wet-treatment. The XRD patterns for commercial CoPc, NiPc, CuPc, and ZnPc are identified with β phase by referring to the powder diffraction files (PDFs): 00-014-0948 (β-CoPc), 00-011-0744 (β-NiPc), 00-039-1881 (β-CuPc), 00-039-1882 (β-ZnPc), and commercial MnPc and FePc are identified with α phase, based on the PDF 00-022-1771 for α-FePc. On the other hand, the patterns for the wet-treated powders of CoPc, NiPc, CuPc, and ZnPc are also attributed to α phase with high crystallinity, which is based on the PDF 00-055-1995 for α-CoPc and PDF 00-022-1686 for α-CuPc. The prepared powder of MnPc and FePc is attributed to α phase with slight deterioration in crystallinity. The centered metals in MPcs were arranged at regular intervals along the b axis; therefore, the distance between metals is equal to the length of b in a unit cell. The distances are 3.8 Å and 4.8 Å in α-MPc and β-MPc, respectively [31].

ORR Properties of α-MPc

For comparison of the ORR properties between α-MPc and β-MPc (M = Co, Ni, Cu, Zn), polarization curves were measured with GDEs loaded with various MPcs (MPc-GDE) in 1.0 M H2SO4 (Fig. 5). The ORR current value for α-CoPc-GDE was double than that for the β-CoPc-GDE at the wide potential range. The ORR current value for α-CuPc-GDE was also a higher than for β-CuPc-GDE. Tafel curves shown in Fig. 6 were obtained from above the polarization curves. Tafel slopes were determined from the slopes at low over-potential in Tafel curves, and are summarized in Table 1. Tafel slope (49 mV/dec.) for α-CoPc is smaller than the one for β-CoPc (ca. 62 mV/dec.). This tendency was also observed in case of CuPc. The results suggest that the conversion to α phase from β phase is effective in improving the catalytic performance on CoPc and CuPc. In the case of NiPc and ZnPc, the small cathode current values were observed, and the difference of the values between α and β phases is quite small. From the results for NiPc and ZnPc, the improvement of catalytic activity for ORR was not observed by the conversion of the crystallographic structure from β phase to α phase. There were not observed clear difference in ORR of α- and β-MPcs (M = Ni, Zn). They come from higher adsorption energy of H2O for both α- and β-MPcs.

XPS Spectra of Oxygen on MPc

The adsorbed oxygen on the MPcs has been investigated by XPS analysis. The O 1 s spectra of oxygen on β-MPc surface are shown in Fig. 7. MPc molecules do not have any oxygen atoms; therefore, the spectra are attributed to adsorbed oxygen. The peaks are divided, observed at β-CoPc and β-CuPc and 532 eV and 534 eV, which are ascribed to M-O and O-O− respectively. It indicates that the end-on configuration, which has an M-O-O− bond, is forming. On the other hand, only one peak was observed for β-NiPc and β-ZnPc at the 532 eV, and this can be attributed to M-O. It had been reported that the H2O adsorption is more energetically favorable than O2 adsorption on NiPc and ZnPc [26]. It seems that the O 1 s spectra do not come from adsorbed O2 molecules. High activity catalysts for ORR should be favorable to adsorb O2 than H2O; therefore, the low ORR currents of GDE-NiPc and ZnPc are explained. The O1s spectra on α-CoPc and α-CuPc are shown in Fig. 7; each spectra has a large peak, and this indicates that adsorbed oxygens have one kind of binding state, which differs on β-CoPc and β-CuPc, and may result in the formation of a bridge configuration, which has an M-O-O-M bonding.

ORR Mechanism

To investigate the reaction kinetics of CoPc and CuPc catalysts during ORR, polarization curves were measured with RDE electrode system (Fig. 8). Electrode potentials were converted to the reversible hydrogen electrode scale. The polarization curves for CoPc show mass transport limiting ORR currents and the currents increase with the increase of rotation speeds. In the case of α-CoPc, the further increase of current was observed in the potential over the limiting current range. The polarization curves for both α-CuPc and β-CuPc gave small current values, which did not have any limiting current range; however, ORR currents for α-CuPc were higher than that of β-CuPc. Zagal et al. discussed the ORR activity of CoPc and CuPc based on the frontier molecular orbitals of MPc and molecular oxygen [26, 36]. These frontier orbitals of CoPc and CuPc are a single occupied molecular orbital (SOMO). The SOMO of CoPc has a large contribution from the centered cobalt, and can react with the SOMO of the O2 in an inner sphere. In contrast, in the SOMO of CuPc, the metal center does not possess the symmetry for interacting with the O2 molecule. Therefore, the interaction of O2 with the centered copper is very weak and CuPc shows the low catalytic activity for ORR.

The transferred electron numbers per oxygen molecule is determined by the Koutecky-Levich equation with the limiting current values at − 0.40 V vs. SCE (Fig. 9).

Here, Id is the measured current density, Ik is the kinetic current density, n is the electron exchange number per an oxygen molecule, F is the Faraday constant (96485 C/mol), A is the area of the disk electrode (0.1257 cm2), D0 is the O2 diffusion coefficient (1.9 × 10−5 cm2/s) in 0.5 M-H2SO4, v is the kinematic viscosity (1.0 × 10−2 cm2/s), C0 is the concentration of saturated oxygen (1.26 × 10−3 mol·/L), and ω is the rotation rate in the radian [37]. From the slopes of the Koutecky-Levich plots, n for α-CoPc and β-CoPc are calculated to 2.70 and 2.04, respectively. From these results, it seems that the ORR on α-CoPc are proceeded by a coexisting pathway involving both the 2-electron and 4-electron transfer; on the other hand, the ORR on β-CoPc only has a 2-electron pathway.

The ORR mechanisms on α-CoPc and β-CoPc were investigated in regard to the distance of cobalt in CoPc, which determines the adsorbed oxygen configuration. According to previous reports, Wang et al. performed DFT calculations of the adsorption energy, the electronic structure, and the O-O bond length in an oxygen molecule on β-CoPc with distance between cobalts about 5 Å to explain the preferentially formation of the adsorbed oxygen configuration bind to one adsorbed site [29]. The calculation results show that the end-on configuration is energy favorable on a cobalt-centered CoPc and is constructed with namely σ type bond formed with the dz2 and dx2-y2 and π type bond formed with dxz. In the end-on configuration, one oxygen atom lies right above the centered cobalt, and the other oxygen atom tilts away from the cobalt. After the addition of proton to both oxygen atoms, the O-O bond length is similar in regard to H2O2, and the H2O2 may remove from the CoPc. Thus, the total ORR procedure is 2-electron pathway for ORR.

N. Karim et al. extend on these results of DFT calculations by investigating the ORR when it is forming a bridge configuration with two CoPc molecules [28]. If there are two CoPc molecules within the distance allowing an oxygen molecule adsorption to two-centered cobalt in CoPcs as α-CoPc, O2 can form a bridge configuration. The O2 has a longer O-O bond than those that have H2O2 molecules; the O-O bond should break apart and producing H2O. From the above, the ORR mechanisms on α-CoPc and β-CoPc are proposed below with kinetics parameters presented by Karim et al. [28]

(ORR on β-CoPc with oxygen molecule adsorption by an end-on configuration)

(ORR on α-CoPcs with an oxygen molecule adsorption by trans-bridge configuration)

Here, the adsorption energy (Eads) is calculated as

A negative adsorption energy indicated that the adsorption states are stable. These values of the O-O bond length and the adsorption energies support that the 2-electron pathway and a 4-electron pathway simultaneously occurred on the α-CoPc.

Therefore, for the ORR mechanism, it appeared that first oxygen molecule was adsorbed and formed an end-on configuration, following a protonation and the bonding to another cobalt, because their adsorption energies are similar. When an adsorption rate of oxygen molecules increases to the second centered cobalt, the ORR proceeds shifts to a 4-electron pathway.

Conclusion

In this paper, we reported the effect of the crystal structure conversion of MPc (M = Co, Ni, Cu, Zn) on the catalytic performance for oxygen reduction. The crystallographic conversions to α phase from β phase were conducted by a facile liquid phase method with deposition at hydrophilic-hydrophobic interface. From the results of X-ray diffraction analysis, it was confirmed that the powder with α phase of cobalt, nickel, copper, and zinc centered MPcs were obtained. MPc- carrying gas diffusion type carbon electrodes were used for the electrochemical measurement in an acid electrolyte to evaluate the catalytic performance.

The current values and Tafel slope from polarization curves reveal that cobalt and copper centered MPc with α phase showed higher catalytic activity than β phase. There were not observed clear difference in ORR of α- and β-MPcs (M = Ni, Zn). They come from higher adsorption energy of H2O for both α- and β-MPcs. According to X-ray photoelectron spectra of O 1 s on α and β phases, it appears that the different configurations of adsorbed oxygen molecules follow difference pathways for oxygen reduction. In α phase, an oxygen molecule can bind to two metals, which are centered MPc due to the short distance of metals, then a 4-electron reduction reaction can proceed.

These results indicated that a crystal structure conversion reduces the distance of metals centered MPc and can lead to the improvement of catalytic activities.

References

T. Enokida, R. Hirohashi, Cobalt phthalocyanine crystal synthesized at low temperature. Chem. Mater. 3(5), 918–921 (1991)

H. Zhang, S. Hwang, M. Wang, Z. Feng, S. Karakalos, L. Luo, Z. Qiao, X. Xie, C. Wang, D. Su, Y. Shao, G. Wu, Single atomic iron catalysts for oxygen reduction in acidic media: particle size control and thermal activation. J. Am. Chem. Soc. 139, 14143 (2017)

E. Yeager, Electrocatalysts for O2 reduction. Electrochim. Acta 29(11), 1527–1537 (1984)

J.-H. Kim, A. Ishihara, S. Mitsushima, N. Kamiya, K.-I. Ota, Catalytic activity of titanium oxide for oxygen reduction reaction as a non-platinum catalyst for PEFC. Electrochim. Acta 52(7), 2492–2497 (2007)

M. Watanabe, M. Tomikawa, S. Motoo, Experimental analysis of the reaction layer structure in a gas diffusion electrode. J. Electroanal. Chem. 195(1), 81–93 (1985)

M. Watanabe, H. Sei, P. Stonehart, The influence of platinum crystallite size on the electroreduction of oxygen. J. Electroanal. Chem. 261(2), 375–387 (1989)

K. Elumeeva, J. Masa, J. Sierau, F. Tietz, M. Muhler, W. Schuhmann, Perovskite-based bifunctional electrocatalysts for oxygen evolution and oxygen reduction in alkaline electrolytes. Electrochim. Acta 208, 25–32 (2016)

H. Yano, M. Kataoka, H. Yamashita, H. Uchida, M. Watanabe, Oxygen reduction activity of carbon-supported Pt−M (M = V, Ni, Cr, Co, and Fe) alloys prepared by nanocapsule method. Langmuir 23(11), 6438–6445 (2007)

H.R. Byon, J. Suntivich, Y. Shao-Horn, Graphene-based non-noble-metal catalysts for oxygen reduction reaction in acid. Chem. Mater. 23(15), 3421–3428 (2011)

K. Fujii, Y. Sato, S. Takase, Y. Shimizu, Effects of oxygen vacancies and reaction conditions on oxygen reduction reaction on pyrochlore-type lead-ruthenium oxide. J. Electrochem. Soc. 162(1), F129–F135 (2015)

M.J. Trahan, Q. Jia, S. Mukerjee, E.J. Plichta, M.A. Hendrickson, K.M. Abraham, Cobalt Phthalocyanine catalyzed lithium-air batteries. J. Electrochem. Soc. 160(9), A1577–A1586 (2013)

T. Toda, H. Igarashi, M. Watanabe, Enhancement of the electrocatalytic O2 reduction on Pt–Fe alloys. J. Electroanal. Chem. 460(1-2), 258–262 (1999)

S. Sui, X. Wang, X. Zhou, Y. Su, S. Riffat, C.-J. Liu, A comprehensive review of Pt electrocatalysts for the oxygen reduction reaction: nanostructure, activity, mechanism and carbon support in PEM fuel cells. J. Mater. Chem. A 5(5), 1808–1825 (2017)

N. Alonso Vante, H. Tributsch, Erratum: Energy conversion catalysis using semiconducting transition metal cluster compounds. Nature 324(6096), 491 (1986)

U.I. Kramm, J. Herranz, N. Larouche, T.M. Arruda, M. Lefèvre, F. Jaouen, P. Bogdanoff, S. Fiechter, I. Abs-Wurmbach, S. Mukerjee, J.-P. Dodelet, Structure of the catalytic sites in Fe/N/C-catalysts for O2-reduction in PEM fuel cells. Phys. Chem. Chem. Phys. 14(33), 11673 (2012)

K. Lee, A. Ishihara, S. Mitsushima, N. Kamiya, K.-I. Ota, Stability and electrocatalytic activity for oxygen reduction in WC + Ta catalyst. Electrochim. Acta 49(21), 3479–3485 (2004)

R. Jasinski, Cobalt phthalocyanine as a fuel cell cathode. J. Electrochem. Soc. 112(5), 526 (1965)

A. Kozawa, V.E. Zilionis, R.J. Brodd, Oxygen and hydrogen peroxide reduction at a ferric phthalocyanine-catalyzed graphite electrode. J. Electrochem. Soc. 117(12), 1470 (1970)

J.A.R. van Veen, C. Visser, Oxygen reduction on monomeric transition metal phthalocyanines in acid electrolyte. Electrochim. Acta 24(9), 921–928 (1979)

A. Elzing, A. van der Putten, W. Visscher, E. Barendrecht, The cathodic reduction of oxygen at cobalt phthalocyanine. J. Electroanal. Chem. 200(1-2), 313–322 (1986)

S. Baranton, C. Coutanceau, C. Roux, F. Hahn, J.-M. Léger, Oxygen reduction reaction in acid medium at iron phthalocyanine dispersed on high surface area carbon substrate: tolerance to methanol, stability and kinetics. J. Electroanal. Chem. 577(2), 223–234 (2005)

M. Kobayashi, H. Niwa, M. Saito, Y. Harada, M. Oshima, H. Ofuchi, K. Terakura, T. Ikeda, Y. Koshigoe, J.-I. Ozaki, S. Miyata, Indirect contribution of transition metal towards oxygen reduction reaction activity in iron phthalocyanine-based carbon catalysts for polymer electrolyte fuel cells. Electrochim. Acta 74, 254–259 (2012)

J. Zagal, M. Páez, A.A. Tanaka, J.R. dos Santos Jr., C.A. Linkous, Electrocatalytic activity of metal phthalocyanines for oxygen reduction. J. Electroanal. Chem. 339(1-2), 13–30 (1992)

R. Hoffmann, M. M.-L. Chen, and D. L. Thorn, Inorg. Chem. 16, 503 (1977)

M.-S. Liao, S. Scheiner, Electronic structure and bonding in metal phthalocyanines, Metal=Fe, Co, Ni, Cu, Zn, Mg. J. Chem. Phys. 114(22), 9780–9791 (2001)

J.H. Zagal, S. Griveau, J.F. Silva, T. Nyokong, F. Bedioui, Metallophthalocyanine-based molecular materials as catalysts for electrochemical reactions. Coord. Chem. Rev. 254(23-24), 2755–2791 (2010)

R. Chen, H. Li, D. Chu, G. Wang, Unraveling oxygen reduction reaction mechanisms on carbon-supported Fe-phthalocyanine and Co-phthalocyanine Catalysts in alkaline solutions. J. Phys. Chem. C 113, 20689 (2009)

N.A. Karim, S.K. Kamarudin, L.K. Shyuan, Z. Yaakob, W.R.W. Daud, A.A.H. Khadum, Novel cathode catalyst for DMFC: study of the density of states of oxygen adsorption using density functional theory. Int. J. Hydrog. Energy 39, 17295 (2014)

Z. Zhang, S. Yang, M. Dou, H. Liu, L. Gu, F. Wang, Systematic study of transition-metal (Fe, Co, Ni, Cu) phthalocyanines as electrocatalysts for oxygen reduction and their evaluation by DFT. RSC Adv. 6, 67049 (2016)

C. Ercolani, C. Neri, P. Porta, Synthesis and x-ray data of a stable in air crystalline modification of chromium(II) phthalocyanine (Cr-α-Pc). Inorg. Chim. Acta 1, 415–418 (1967)

P. Ballirano, R. Caminiti, C. Ercolani, A. Maras, M.A. Orrù, X-ray powder diffraction structure reinvestigation of the α and β forms of cobalt phthalocyanine and kinetics of the α → β phase transition. J. Am. Chem. Soc. 120, 12798 (1998)

N. Uyeda, M. Ashida, E. Suito, Orientation overgrowth of condensed polycyclic aromatic compounds vacuum‐evaporated onto cleaved face of mica. J. Appl. Phys. 36(4), 1453–1460 (1965)

H. Yamanouchi, K. Irie, T. Saji, Chem. Lett. 1, 10 (2000)

S. Takase, Y. Aoto, Y. Shimizu, Processing of α-phase metal–phthalocyanine powders by interface neutralization method. Chem. Lett. 45(9), 1066–1068 (2016)

W. Iwaya, S. Takase, Y. Shimizu, Wet-chemical preparation and oxygen reduction properties of nickel-based sulfide electrocatalysts for polymer electrolyte fuel cell. Electrochemistry 79(5), 364–366 (2011)

G. I. Ca, M. A. Gulppi, C. A. Caro, R. Rı, and H. Zagal, 46, 3227 (2001)

L. Zhang, H. Li, J. Zhang, Kinetics of oxygen reduction reaction on three different Pt surfaces of Pt/C catalyst analyzed by rotating ring-disk electrode in acidic solution. J. Power Sources 255, 242–250 (2014)

Funding

This work was partially supported by JSPS KAKENHI Grant Numbers JP26410207, JP17750183, and JST A-STEP Grant Number AS232Z00312B.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Takase, S., Aoto, Y., Ikeda, D. et al. Effects of Crystallographic Structures of Metal-Phthalocyanine on Electrocatalytic Properties of Oxygen Reduction in Acidic Condition. Electrocatalysis 10, 653–662 (2019). https://doi.org/10.1007/s12678-019-00553-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-019-00553-2