Abstract

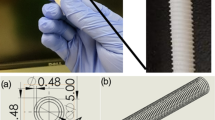

In order to analyze the effect of vascular wall structures on static and dynamic mechanical properties of vascular grafts, small calibre PHBHHx (Poly(3-hydroxybutyrate-co-3-hydroxhexanoate)) vascular grafts (inner diameter 6 mm) with various wall shapes and thicknesses were fabricated by changing electrospinning time and receiving molds. As spinning time increased, wall thickness of the vascular grafts increased and both circumferential tensile strength and suture retention strength improved significantly. When the wall thicknesses of straight grafts were about 120 μm, the great radial dynamic compliance was exhibited, however, the tensile strength and suture retention strength of the straight tubes can’t reach the requirements of normal blood vessel grafting. With the wall thicknesses increasing above 250 μm, although the circumferential tensile strength and suture retention strength gradually achieved the transplanting requirements, the dynamic compliance of the straight tubes declined too sharply to adapt the blood radial shock. For corrugated grafts, the effect of wall thickness on radial dynamic compliance was little, and the radial dynamic compliance was close to that of the commercial vascular grafts. The circumferential tensile strength and suture retention strength of the corrugated grafts were also improved to approach the commercial vessels’ performances with the wall thickness improving to about 425 μm. Elastic recovery rates of all the prepared vascular grafts were superior to that of the commercial sample. Along with the wall thickness exceeding 250 μm, the water permeabilities of both the straight and the corrugated grafts were less than 300 ml/(cm2·min).

Similar content being viewed by others

References

D. Mozaffarian, E. J. Benjamin, A. S. Go, D. K. Arnett, M. J. Blaha, M. Cushman, S. de Ferranti, J. P. Despres, H. J. Fullerton, V. J. Howard, M. D. Huffman, S. E. Judd, B. M. Kissela, D. T. Lackland, J. H. Lictman, L. D. Lisabeth, S. Liu, R. H. Mackey, D. B. Matchar, D. K. McGuire, E. R. Mohler, C. S. Moy, P. Muntner, M. E. Mussolino, K. Nasir, R. W. Neumar, G. Nichol, L. Palaniappan, D. K. Pandey, M. J. Reeves, C. J. Rodriquez, P. D. Sorlie, J. Stein, A. Towfighi, T. N. Turan, S. S. Virani, J. Z. Willey, D. Woo, R. W. Yeh, and M. B. Turner, Circulation, 131, 434 (2015).

X. Yang, L. Wang, G. Guan, M. W. King, Y. Li, L. Peng, Y. Guan, and X. Hu, J. Biomater. Appl., 28, 676 (2014).

J. H. Campbell, J. L. Efendy, and G. R. Campbell, Circ. Res., 85, 1173 (1999).

J. C. Lin and S. L. Cooper, Biomaterials, 16, 1017 (1995).

S. Sarkar, G. Burriesci, A. Wojcik, N. Aresti, Hamilton, G, and A. M. Seifalian, J. Biomech., 42, 722 (2009).

H. Sonoda, K. Takamizawa, Y. Nakayama, H. Yasui, and T. Matsuda, J. Biomed. Mater. Res., 55, 266 (2001).

X. Li, J. Tang, L. Bao, L. Chen, and F. F. Hong, Carbohydr. Polym., 178, 394 (2017).

C. Norotte, F. S. Marga, L. E. Niklason, and G. Forgacs, Biomaterials, 30, 5910 (2009).

A. E. Mercado-Pagan, Y. Kang, M. W. Findlay, and Y. Yang, Mater. Sci. Eng. C-Mater. Biol. Appl., 49, 541 (2015).

L. Zhang, J. Zhou, Q. Lu, Y. Wei, and S. Hu, Biotechnol. Bioeng., 99, 1007 (2008).

R. Khosravi, C. A. Best, R. A. Allen, and C. E. Stowell, Ann. Biomed. Eng., 44, 2402 (2016).

N. Bhardwaj and S. C. Kundu, Biotechnol. Adv., 28, 325 (2010).

H. Inoguchi, I. K. Kwon, E. Inoue, K. Takamizawa, Y. Maehara, and T. Matsuda, Biomaterials, 27, 1470 (2006).

M. R. Williamson, R. Black, and C. Kielty, Biomaterials, 27, 3608 (2006).

A. M. Díez-Pascual and A. L. Díez-Vicente, J. Mat. Chem. B, 4, 600 (2016).

D. J. Green, M. T. E. Hopman, J. Padilla, M. H. Laughlin, and D. H. J. Thijssen, Physiol. Rev., 97, 495 (2017).

J. Lee, Y. H. Jeong, and D. W. Cho, Macromol. Mater. Eng., 299, 1050 (2014).

X. Fang, C. Y. Shen, and G. Dai, Fiber. Polym., 18, 303 (2017).

P. D. Ballyk, C. Walsh, J. Butany, and M. Ojha, J. Biomech., 31, 229 (1998).

S. F. C. Stewart and D. J. Lyman, Ann. Biomed. Eng., 32, 991 (2004).

W. Trubel, H. Schima, and A. E. Moritz, Eur. J. Vasc. Surg., 10, 415 (1995).

R. L. Binns, D. N. Ku, M. T. Stewart, J. P. Ansley, and K. A. Coyle, J. Vasc. Surg., 10, 326 (1989).

I. Surovtsova, J. Biomech., 38, 2078 (2005).

L. Soletti, Y. Hong, J. Guan, J. J. Stankus, M. S. El-Kurdi, W. R. Wagner, and D. A. Vorp, Acta Biomater., 6, 110 (2010).

Acknowledgments

This work was supported by the Science & Technology Project for Major Disease Prevention and Control under Grant (No. 2017ZX01001); and Fundamental Research Funds for the Central Universities under Grant (No. 2232018G-01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, J., Huang, Z., Guo, H. et al. Effect of Wall Structures on Mechanical Properties of Small Caliber PHBHHx Vascular Grafts. Fibers Polym 20, 2261–2267 (2019). https://doi.org/10.1007/s12221-019-9342-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-9342-9