Abstract

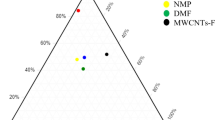

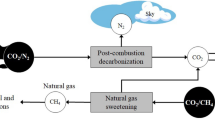

In recent years, carbon capture technology has received much attention to limit the adverse effect caused by rising carbon dioxide (CO2) concentration in the atmosphere. Membrane technology has risen as an attractive option for carbon capture as it is less energy–intensive and more environmentally friendly compared with adsorption, absorption, and cryogenic separation. Polymeric membranes dominate the gas separation industries as they are cheaper and easier to fabricate compared with inorganic membranes but are bound to the permeance-selectivity trade-off limitation. Recently, researchers have been modifying polymeric membrane by polymer blending and mixed matrix membranes (MMMs) to overcome the limitation. Polymer blending yields a polymer blend that combines the benefits of two or more polymeric material. Polyethylene glycol (PEG) and polyethersulfone (PES) are common polymeric materials used in the gas separation industry for membrane fabrication. PEG and PES were reviewed in this paper as potential polymer blends that efficiently separate CO2 due to their chemical characteristics. Another technique to overcome the trade-off limitation is fabricating MMMs that incorporate both polymeric membrane material and inorganic filler. However, MMM fabrication presents challenges such as polymer-filler incompatibility, void formation, and filler agglomeration due to unsuitable filler. Functionalized multi-walled carbon nanotubes (MWCNTs-F) were reviewed as fillers that are able to overcome the dispersion and polymer-compatibility issues and increase the gas separation performance of membranes. Hence, MMM that is fabricated from PEG, PES, and MWCNTs-F that combines both polymer blending and MMM techniques is believed to be a breakthrough for CO2/N2 separation.

Similar content being viewed by others

Abbreviations

- 6FDA-Durene:

-

4,4′-(Hexafluoroisopropylidene)-diphthalic anhydride-2,3,5,6-tetramethyl-1,3-phenyldiamine

- CA:

-

Cellulose acetate

- CAB:

-

Cellulose acetate butyrate

- CH4 :

-

Methane

- CMS:

-

Carbon molecular sieves

- CNTs:

-

Carbon nanotubes

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- dC i/dx :

-

Concentration gradient of component i over length of x

- D ij :

-

Diffusion coefficient

- d p :

-

Pore size

- d s :

-

Molecular size of transported species

- GO:

-

Graphene oxide

- H2 :

-

Hydrogen

- H2O:

-

Water

- J i :

-

Flux of component i

- MEA:

-

Monoethanolamine

- MMM:

-

Mixed matrix membrane

- MMMs:

-

Mixed matrix membranes

- M-PVDF:

-

Modified poly(vinylidene fluoride)

- MWCNTs:

-

Multi-walled carbon nanotubes

- N2 :

-

Nitrogen

- NIPS:

-

Non-solvent induced phase separation

- NOx :

-

Nitrogen oxides

- O2 :

-

Oxygen

- P84:

-

Polyimide P84

- PEBA:

-

Polyether-block-amide

- PEG:

-

Polyethylene glycol

- PEI:

-

Polyetherimide

- PES:

-

Polyethersulfone

- PI:

-

Polyimide

- PSA:

-

Pressure swing adsorption

- PSF:

-

Polysulfone

- PTFPMS:

-

Polytrifluoropropylmethylsiloxane

- PU:

-

Polyurethane

- PVA:

-

Polyvinyl alcohol

- PVAc:

-

Polyvinyl acetate

- PVDF:

-

Poly(vinylidene fluoride)

- SO2 :

-

Sulfur dioxide

- SWCNTs:

-

Single-walled carbon nanotubes

- T g :

-

Glass transition temperature

- TIPS:

-

Thermal induced phase separation

- TSA:

-

Temperature swing adsorption

- VIPS:

-

Vapor induced phase separation

- ZIF-8:

-

Zeolitic imidazolate framework-8

- Zn/Ni-ZIF-8:

-

Nickel-substituted seolitic imidazolate framework-8

- λ :

-

Mean free path

References

United Nations DoEaSA, Population Division (2019) World Population Prospects 2019: Highlights (ST/ESA/SER.A/423)

US EIA (2019) International Energy Outlook 2019 with projections to 2050

Kannan N, Vakeesan D (2016) Solar energy for future world: a review. Renew Sust Energ Rev 62:1092–1105. https://doi.org/10.1016/j.rser.2016.05.022

US EIA (2018) Electricity and the environment – basics. https://www.eia.gov/energyexplained/print.php?page=electricity_environment. Accessed 18 Mar 2019

US EPA (2018) Inventory of U.S. Greenhouse gas emissions and sinks 1990–2016

IPCC (2014) Climate change 2014: synthesis report. Contribution of working Groups I, II and III to the fifth assessment report of the intergovernmental panel on climate change. IPCC, Geneva

Pires JCM, Martins FG, Alvim-Ferraz MCM, Simões M (2011) Recent developments on carbon capture and storage: an overview. Chem Eng Res Des 89(9):1446–1460. https://doi.org/10.1016/j.cherd.2011.01.028

Leung DYC, Caramanna G, Maroto-Valer MM (2014) An overview of current status of carbon dioxide capture and storage technologies. Renew Sust Energ Rev 39:426–443. https://doi.org/10.1016/j.rser.2014.07.093

Gibbins J, Chalmers H (2008) Carbon capture and storage. Energy Policy 36(12):4317–4322. https://doi.org/10.1016/j.enpol.2008.09.058

Sugu L, Jawad ZA (2019) Formation of low acetyl content cellulose acetate membrane for CO2 /N2 separation. J Phys Sci 30(1):111–125. https://doi.org/10.21315/jps2019.30.1.9

Ahmad AL, Salaudeen YO, Jawad ZA (2019) Polymeric membrane for flue gas separation and other minor components in carbon dioxide capture. In: Jawad ZA (ed) Membrane technology for CO2 sequestration and separation. CRC Press, Boca Raton

Jansen D, Gazzani M, Manzolini G, Dijk EV, Carbo M (2015) Pre-combustion CO2 capture. Int J Greenh Gas Con 40:167–187. https://doi.org/10.1016/j.ijggc.2015.05.028

Scholes CA, Smith KH, Kentish SE, Stevens GW (2010) CO2 capture from pre-combustion processes – strategies for membrane gas separation. Int J Greenh Gas Con 4(5):739–755. https://doi.org/10.1016/j.ijggc.2010.04.001

Stanger R, Wall T, Spörl R, Paneru M, Grathwohl S, Weidmann M, Scheffknecht G, McDonald D, Myöhänen K, Ritvanen J, Rahiala S, Hyppänen T, Mletzko J, Kather A, Santos S (2015) Oxyfuel combustion for CO2 capture in power plants. Int J Greenh Gas Con 40:55–125. https://doi.org/10.1016/j.ijggc.2015.06.010

Jain N, Srivastava A, Singh TN (2016) Carbon capture, transport and geologic storage: a brief introduction. Geologic Carbon Sequestration. Springer, Cham. https://doi.org/10.1007/978-3-319-27019-7_1

Xue B, Yu Y, Chen J, Luo X, Wang M (2016) A comparative study of MEA and DEA for post-combustion CO2 capture with different process configurations. Int J Coal Sci Technol 4(1):15–24. https://doi.org/10.1007/s40789-016-0149-7

Mason JA, McDonald TM, Bae T-H, Bachman JE, Sumida K, Dutton JJ, Kaye SS, Long JR (2015) Application of a high-throughput analyzer in evaluating solid adsorbents for post-combustion carbon capture via multicomponent adsorption of CO2, N2, and H2O. J Am Chem Soc 137(14):4787–4803. https://doi.org/10.1021/jacs.5b00838

Adewole J, Ahmad A (2017) Polymeric membrane materials selection for high-pressure CO2 removal from natural gas. J Polym Res 24(5):1–13. https://doi.org/10.1007/s10965-017-1231-6

Wang M, Lawal A, Stephenson P, Sidders J, Ramshaw C (2011) Post-combustion CO2 capture with chemical absorption: a state-of-the-art review. Chem Eng Res Des 89(9):1609–1624. https://doi.org/10.1016/j.cherd.2010.11.005

Sanders DF, Smith ZP, Guo R, Robeson LM, McGrath JE, Paul DR, Freeman BD (2013) Energy-efficient polymeric gas separation membranes for a sustainable future: a review. Polymer 54(18):4729–4761. https://doi.org/10.1016/j.polymer.2013.05.075

Yuan P, Qiu Z, Liu J (2017) Recent enlightening strategies for CO2 capture: a review. Paper presented at the IOP Conf. Ser. Earth Environ. Sci

Knapik E, Kosowski P, Stopa J (2018) Cryogenic liquefaction and separation of CO2 using nitrogen removal unit cold energy. Chem Eng Res Des 131:66–79. https://doi.org/10.1016/j.cherd.2017.12.027

Wilcox J (2012) Carbon capture. Springer, New York. https://doi.org/10.1007/978-1-4614-2215-0

Belaissaoui B, Moullec YL, Willson D, Favre E (2012) Hybrid membrane cryogenic process for post-combustion CO2 capture. J Membrane Sci 415–416:424–434. https://doi.org/10.1016/j.memsci.2012.05.029

Safdarnejad SM, Hedengren JD, Baxter LL (2015) Plant-level dynamic optimization of cryogenic carbon capture with conventional and renewable power sources. Appl Energy 149:354–366. https://doi.org/10.1016/j.apenergy.2015.03.100

Yu C-H, Huang C-H, Tan C-S (2012) A review of CO2 capture by absorption and adsorption. Aerosol Air Qual Res 12(5):745–769. https://doi.org/10.4209/aaqr.2012.05.0132

Olajire AA (2010) CO2 capture and separation technologies for end-of-pipe applications – a review. Energy 35(6):2610–2628. https://doi.org/10.1016/j.energy.2010.02.030

Lin Y, Pan T, Wong D, Jang SS, Chi Y, Yeh C (2011) Plantwide control of CO2 capture by absorption and stripping using monoethanolamine solution. Ind Eng Chem Res 50(3):1338–1345. https://doi.org/10.1021/ie100771x

Lv Y, Yan G, Xu C, Xu M, Sun L (2012) Review on membrane technologies for carbon dioxide capture from power plant flue gas. Adv Mater Res 602–604:1140–1144. https://doi.org/10.4028/www.scientific.net/AMR.602-604.1140

Roussanaly S, Anantharaman R, Lindqvist K, Zhai H, Rubin E (2016) Membrane properties required for post-combustion CO2 capture at coal-fired power plants. J Membrane Sci 511:250–264. https://doi.org/10.1016/j.memsci.2016.03.035

Nafisi V, Hägg M-B (2014) Development of dual layer of ZIF-8/PEBAX-2533 mixed matrix membrane for CO2 capture. J Membrane Sci 459:244–255. https://doi.org/10.1016/j.memsci.2014.02.002

Luo J, He X, Si Z (2017) Polysulfone membranes containing ethylene glycol monomers: synthesis, characterization, and CO2/CH4 separation. J Polym Res 24(1):1–14. https://doi.org/10.1007/s10965-016-1163-6

Rosli A, Low SC (2019) Molecularly engineered switchable photo-responsive membrane in gas separation for environmental protection. Environ Eng Res 0:0–0. https://doi.org/10.4491/eer.2019.090

Lee RJ, Jawad ZA, Ahmad AL, Chua HB, Ngang HP, Zein SHS (2019) Rheological evaluation of the fabrication parameters of cellulose acetate butyrate membrane on the CO2/N2 separation performance. In: Jawad ZA (ed) Membrane technology for CO2 sequestration and separation. CRC Press, Boca Raton

Khalilpour R, Mumford K, Zhai H, Abbas A, Stevens G, Rubin ES (2015) Membrane-based carbon capture from flue gas: a review. J Clean Prod 103:286–300. https://doi.org/10.1016/j.jclepro.2014.10.050

Ismail AF, Khulbe KC, Matsuura T (2015) Gas separation membranes: polymeric and inorganic. Springer International Publishing, Cham. https://doi.org/10.1007/978-3-319-01095-3

Norahim N, Yaisanga P, Faungnawakij K, Charinpanitkul T, Klaysom C (2018) Recent membrane developments for CO2 separation and capture. Chem Eng Technol 41(2):211–223. https://doi.org/10.1002/ceat.201700406

Manimaran D, Jawad ZA, Chew TL (2019) Effect of solvent evaporation time and casting thickness on the separation performance of cellulose acetate butyrate blend membrane. JAMST 23(2):11–28. https://doi.org/10.11113/amst.v23n2.151

Vinoba M, Bhagiyalakshmi M, Alqaheem Y, Alomair AA, Pérez A, Rana MS (2017) Recent progress of fillers in mixed matrix membranes for CO2 separation: a review. Sep Purif Technol 188:431–450. https://doi.org/10.1016/j.seppur.2017.07.051

Ladewig B, Al-Shaeli MNZ (2017) Fundamentals of membrane bioreactors. Springer transactions in civil and environmental engineering Springer, Singapore. https://doi.org/10.1007/978-981-10-2014-8_2

Mannan HA, Mukhtar H, Murugesan T, Nasir R, Mohshim DF, Mushtaq A (2013) Recent applications of polymer blends in gas separation membranes. Chem Eng Technol 36(11):1838–1846. https://doi.org/10.1002/ceat.201300342

Akbarian I, Fakhar A, Ameri E, Sadeghi M (2018) Gas-separation behavior of poly(ether sulfone)–poly(ethylene glycol) blend membranes. J Appl Polym Sci 135(44):46845. https://doi.org/10.1002/app.46845

Low BT, Zhao L, Merkel TC, Weber M, Stolten D (2013) A parametric study of the impact of membrane materials and process operating conditions on carbon capture from humidified flue gas. J Membrane Sci 431:139–155. https://doi.org/10.1016/j.memsci.2012.12.014

Liu J, Hou X, Park HB, Lin H (2016) High-performance polymers for membrane CO2/N2 separation. Chemistry 22(45):15980–15990. https://doi.org/10.1002/chem.201603002

Yuenyao C, Chittrakarn T, Tirawanichakul Y, Sirijarukul S (2016) Surface modification of asymmetric polysulfone/polyethylene glycol membranes by DC Ar-glow discharge plasma. Int JPolym Sci 2016(2016). https://doi.org/10.1155/2016/4759150

Zuo D-y, Xu Y-y, Xu W-l, Zou H-t (2008) The influence of PEG molecular weight on morphologies and properties of PVDf asymmetric membranes. Chinese J Polym Sci 26(04):405–414. https://doi.org/10.1142/S0256767908003072

Boutilier MSH, Hadjiconstantinou NG, Karnik R (2017) Knudsen effusion through polymer-coated three-layer porous graphene membranes. Nanotechnology 28(18):184003. https://doi.org/10.1088/1361-6528/aa680f

Naderi A, Yong WF, Xiao Y, Chung T-S, Weber M, Maletzko C (2018) Effects of chemical structure on gas transport properties of polyethersulfone polymers. Polymer 135:76–84. https://doi.org/10.1016/j.polymer.2017.12.014

Mansourpanah Y, Ostadchinigar A (2017) Preparation of chemically attached polyamide thin film membrane using different diamines: separation and computational investigation. J Polym Res 24(2):1–16. https://doi.org/10.1007/s10965-017-1186-7

Hadi SHAA, Mannan HA, Mukhtar H, Shaharun MS, Murugesan T (2016) Morphological analysis of polyethersulfone/polyvinyl acetate blend membrane synthesized at various polymer concentrations. Paper presented at the IOP Conf. Ser. Earth Environ. Sci

Yong WF, Chung T-S, Weber M, Maletzko C (2018) New polyethersulfone (PESU) hollow fiber membranes for CO2 capture. J Membrane Sci 552:305–314. https://doi.org/10.1016/j.memsci.2018.02.008

Lalia BS, Kochkodan V, Hashaikeh R, Hilal N (2013) A review on membrane fabrication: structure, properties and performance relationship. Desalination 326:77–95. https://doi.org/10.1016/j.desal.2013.06.016

Amirilargani M, Sadrzadeh M, Mohammadi T (2010) Synthesis and characterization of polyethersulfone membranes. J Polym Res 17(3):363–377. https://doi.org/10.1007/s10965-009-9323-6

Eykens L, De Sitter K, Dotremont C, Pinoy L, Van Der Bruggen B (2017) Membrane synthesis for membrane distillation: a review. Sep Purif Technol 182:36–51. https://doi.org/10.1016/j.seppur.2017.03.035

Adatia K, Raja M, Vadgama P (2017) An electrochemical study of microporous track-etched membrane permeability and the effect of surface protein layers. Colloids Surf B 158:84–92. https://doi.org/10.1016/j.colsurfb.2017.06.032

Miyazaki T, Takenaka M (2017) Precise small-angle X-ray scattering evaluation of the pore structures in track-etched membranes: comparison with other convenient evaluation methods. Nucl Instr Meth Phys Res B 394:121–125. https://doi.org/10.1016/j.nimb.2017.01.002

Makkonen-Craig S, Yashina K, Paronen M (2014) Track-etched ultrafiltration polymer membranes produced by light ion irradiation, vol 11. Arcada Working Papers.

Idris A, Man Z, Maulud AS, Khan MS (2017) Effects of phase separation behavior on morphology and performance of polycarbonate membranes. Membranes 7(2). https://doi.org/10.3390/membranes7020021

Tsai HA, Kuo CY, Lin JH, Wang DM, Deratani A, Pochat-Bohatier C, Lee KR, Lai JY (2006) Morphology control of polysulfone hollow fiber membranes via water vapor induced phase separation. J Membrane Sci 278(1–2):390–400. https://doi.org/10.1016/j.memsci.2005.11.029

Kuo C-Y, Su S-L, Tsai H-A, Su Y-S, Wang D-M, Lai J-Y (2008) Formation and evolution of a bicontinuous structure of PMMA membrane during wet immersion process. J Membrane Sci 315(1–2):187–194. https://doi.org/10.1016/j.memsci.2008.02.034

Figoli A, Marino T, Simone S, Di Nicol E, Li XM, He T, Tornaghi S, Drioli E (2014) Towards non-toxic solvents for membrane preparation: a review. Green Chem 16(9):4034–4059. https://doi.org/10.1039/c4gc00613e

Bakeri G, Ismail A, Rahimnejad M, Matsuura T (2014) Analysis of polyetherimide/N-methyl-2-pyrrolidone/nonsolvent phase separation behavior. J Polym Res 21(4):1–7. https://doi.org/10.1007/s10965-014-0386-7

Kuo C-Y, Lin H-N, Tsai H-A, Wang D-M, Lai J-Y (2008) Fabrication of a high hydrophobic PVDF membrane via nonsolvent induced phase separation. Desalination 233(1):40–47. https://doi.org/10.1016/j.desal.2007.09.025

Chang HH, Beltsios KG, Yu HF, Wu YH, Cheng LP (2015) Novel phase inversion process for symmetric membrane formation through thermal quenching of polymer solution in same solvent. J Appl Polym Sci 132(29):42282. https://doi.org/10.1002/app.42282

Morgado PI, Aguiar-Ricardo A, Correia IJ (2015) Asymmetric membranes as ideal wound dressings: an overview on production methods, structure, properties and performance relationship. J Membrane Sci 490:139–151. https://doi.org/10.1016/j.memsci.2015.04.064

Tsai H-A, Kuo C-Y, Su S-L, Wang D-M, Lai J-Y (2009) The morphological evolution of solvent-containing PMMA membranes in various solvent removal processes. J Membrane Sci 345(1):288–297. https://doi.org/10.1016/j.memsci.2009.09.011

Xiao T, Wang P, Yang X, Cai X, Lu J (2015) Fabrication and characterization of novel asymmetric polyvinylidene fluoride (PVDF) membranes by the nonsolvent thermally induced phase separation (NTIPS) method for membrane distillation applications. J Membrane Sci 489:160–174. https://doi.org/10.1016/j.memsci.2015.03.081

Tan P, Ooi B, Ahmad A, Low S (2017) Size control and stability study of zeolitic imidazolate framework-8 to prepare mixed matrix membrane. J Phys Sci 28(Suppl. 1):215–226. https://doi.org/10.21315/jps2017.28.s1.14

Cha WC, Jawad ZA (2019) The influence of cellulose acetate butyrate membrane structure on CO2 /N2 separation: effect of casting thickness and solvent exchange time. Chem Eng Commun 0. https://doi.org/10.1080/00986445.2019.1605359

Mannan HA, Mukhtar H, Shima Shaharun M, Roslee Othman M, Murugesan T (2016) Polysulfone/poly(ether sulfone) blended membranes for CO2 separation. J Appl Polym Sci 133(5). https://doi.org/10.1002/app.42946

Robeson LM (2008) The upper bound revisited. J Membrane Sci 320(1):390–400. https://doi.org/10.1016/j.memsci.2008.04.030

Galizia M, Chi WS, Smith ZP, Merkel TC, Baker RW, Freeman BD (2017) 50th anniversary perspective: polymers and mixed matrix membranes for gas and vapor separation: a review and prospective opportunities. Macromolecules 50(20):7809–7843. https://doi.org/10.1021/acs.macromol.7b01718

Patel A, Acharya N (2019) CO2 plasticization effect and selectivity for Pt-Pd alloy coated polycarbonate membrane. J Polym Res 26(5):1–7. https://doi.org/10.1007/s10965-019-1775-8

Soleimany A, Hosseini SS, Gallucci F (2017) Recent progress in developments of membrane materials and modification techniques for high performance helium separation and recovery : a review. Chem Eng Process 122:296–318. https://doi.org/10.1016/j.cep.2017.06.001

Tan PC, Ooi BS, Ahmad AL, Low SC (2018) Monomer atomic configuration as key feature in governing the gas transport behaviors of polyimide membrane. J Appl Polym Sci 135(14). https://doi.org/10.1002/app.46073

Liu SL, Shao L, Chua ML, Lau CH, Wang H, Quan S (2013) Recent progress in the design of advanced PEO-containing membranes for CO2 removal. Prog Polym Sci 38(7):1089–1120. https://doi.org/10.1016/j.progpolymsci.2013.02.002

Zhang Y, Sunarso J, Liu S, Wang R (2013) Current status and development of membranes for CO2/CH4 separation: a review. Int J Greenh Gas Con 12:84–107. https://doi.org/10.1016/j.ijggc.2012.10.009

Tan PC, Jawad ZA, Ooi BS, Ahmad AL, Low SC (2016) Correlation between polymer packing and gas transport properties for CO2 /N2 separation in glassy fluorinated polyimide membrane. JESTEC 11(7):935–946

Yoshioka T, Kojima K, Shindo R, Nagai K (2017) Gas-separation properties of amine-crosslinked polyimide membranes modified by amine vapor. J Appl Polym Sci 134(10). https://doi.org/10.1002/app.44569

Mosleh S, Mozdianfard M, Hemmati M, Khanbabaei G (2016) Synthesis and characterization of rubbery/glassy blend membranes for CO2/CH4 gas separation. J Polym Res 23(6):1–14. https://doi.org/10.1007/s10965-016-1005-6

Lillepärg J, Georgopanos P, Shishatskiy S (2014) Stability of blended polymeric materials for CO2 separation. J Membrane Sci 467:269–278. https://doi.org/10.1016/j.memsci.2014.05.039

Nie F, He G, Zhao W, Ju J, Liu Y, Dai Y (2014) Improving CO2 separation performance of the polyethylene glycol (PEG)/polytrifluoropropylsiloxane (PTFPMS) blend composite membrane. J Polym Res 21(1):1–9. https://doi.org/10.1007/s10965-013-0319-x

Mustafa J, Farhan M, Hussain M (2016) CO2 Separation from flue gases using different types of membranes. J Membrane Sci Technol 6(2). https://doi.org/10.4172/2155-9589.1000153

Mukhtar H, Mannan HA, Minh D, Nasir R, Moshshim DF, Murugesan T (2016) Polymer blend membranes for CO2 separation from natural gas. Paper presented at the IOP Conf. Ser.: Earth Environ. Sci

Farnam M, Mukhtar H, Shariff AM (2016) An investigation of blended polymeric membranes and their gas separation performance. RSC Adv 6(104):102671–102679. https://doi.org/10.1039/c6ra21574b

Shirvani H, Sadeghi M, Taheri Afarani H, Bagheri R (2018) Polyurethane/poly(vinyl alcohol) blend membranes for gas separation. Fiber Polym 19(5):1119–1127. https://doi.org/10.1007/s12221-018-1023-6

Prasad K, Nikzad M, Sbarski I (2018) Permeability control in polymeric systems: a review. J Polym Res 25(11):1–20. https://doi.org/10.1007/s10965-018-1636-x

Nasir R, Mukhtar H, Man Z, Mohshim DF (2013) Material advancements in fabrication of mixed-matrix membranes. Chem Eng Technol 36(5):717–727. https://doi.org/10.1002/ceat.201200734

Ismail AF, Rahim NH, Mustafa A, Matsuura T, Ng BC, Abdullah S, Hashemifard SA (2011) Gas separation performance of polyethersulfone/multi-walled carbon nanotubes mixed matrix membranes. Sep Purif Technol 80(1):20–31. https://doi.org/10.1016/j.seppur.2011.03.031

Ahmad AL, Jawad ZA, Low SC, Zein SHS (2014) A cellulose acetate/multi-walled carbon nanotube mixed matrix membrane for CO2/N2 separation. J Membrane Sci 451:55–66. https://doi.org/10.1016/j.memsci.2013.09.043

Lee RJ, Jawad ZA, Ahmad AL, Chua HB (2018) Incorporation of functionalized multi-walled carbon nanotubes (MWCNTs) into cellulose acetate butyrate (CAB) polymeric matrix to improve the CO2/N2 separation. Process Saf Environ 117:159–167. https://doi.org/10.1016/j.psep.2018.04.021

Feijani EA, Tavassoli A, Mahdavi H, Molavi H (2018) Effective gas separation through graphene oxide containing mixed matrix membranes. J Appl Polym Sci 135(21). https://doi.org/10.1002/app.46271

Guo A, Ban Y, Yang K, Yang W (2018) Metal-organic framework-based mixed matrix membranes: synergetic effect of adsorption and diffusion for CO2/CH4 separation. J Membrane Sci 562:76–84. https://doi.org/10.1016/j.memsci.2018.05.032

Zhang X, Zhang T, Wang Y, Li J, Liu C, Li N, Liao J (2018) Mixed-matrix membranes based on Zn/Ni-ZIF-8-PEBA for high performance CO2 separation. J Membrane Sci 560:38–46. https://doi.org/10.1016/j.memsci.2018.05.004

Goh PS, Ismail AF, Sanip SM, Ng BC, Aziz M (2011) Recent advances of inorganic fillers in mixed matrix membrane for gas separation. Sep Purif Technol 81(3):243–264. https://doi.org/10.1016/j.seppur.2011.07.042

Jenkins S (2017). Zeolites. Chemical Engineering 124(7):28

Jusoh N, Yeong YF, Chew TL, Lau KK, Mohd Shariff A (2016) Current development and challenges of mixed matrix membranes for CO2 /CH4 separation. Sep Purif Rev 45(4):321–344. https://doi.org/10.1080/15422119.2016.1146149

Sadeghi M, Ahmad M (2018) The gas separation performance of polyurethane–zeolite mixed matrix membranes. Adv Polym Tech 37(2):339–348. https://doi.org/10.1002/adv.21672

Dong G, Li H, Chen V (2013) Challenges and opportunities for mixed-matrix membranes for gas separation. J Mater Chem A 1(15):4610–4630. https://doi.org/10.1039/c3ta00927k

Nasir R, Mukhtar H, Shima Shaharun M, Man Z (2015) Effect of carbon molecular sieve (CMS) concentration on mixed matrix membranes (MMMs) performance for carbon dioxide removal. Appl Mech Mater 754–755(Advanced Materials Engineering and Technology III):869–873. https://doi.org/10.4028/www.scientific.net/AMM.754-755.869

Ferreira FV, Cividanes LDS, Brito FS, BRCD M, Franceschi W, EAN S, Thim GP (2016) Functionalization of carbon nanotube an applications. In: Ferreira FV, LDS C, Brito FS et al (eds) Functionalizing graphene and carbon nanotubes: a review. Springer International Publishing, Cham, pp 31–61. https://doi.org/10.1007/978-3-319-35110-0

Meyyappan M, Barrera E, Corral EL, Han J, Li J, Li J, Loutfy RO, McGuire K, Moravsky AP, Nguyen CV, Rao AM, Sarrazin P, Shofner ML, Srivastava D, Wexler EM, Yamada T (2005) Carbon nanotubes: science and applications. CRC Press, Boca Raton

Zhao D, Ren J, Wang Y, Qiu Y, Li H, Hua K, Li X, Ji J, Deng M (2017) High CO2 separation performance of Pebax®/CNTs/GTA mixed matrix membranes. J Membrane Sci 521:104–113. https://doi.org/10.1016/j.memsci.2016.08.061

Nejad MN, Asghari M, Afsari M (2016) Investigation of carbon nanotubes in mixed matrix membranes for gas separation: a review. ChemBioEng Reviews 3(6):276–298. https://doi.org/10.1002/cben.201600012

Sun H, Wang T, Xu Y, Gao W, Li P, Niu QJ (2017) Fabrication of polyimide and functionalized multi-walled carbon nanotubes mixed matrix membranes by in-situ polymerization for CO2 separation. Sep Purif Technol 177:327–336. https://doi.org/10.1016/j.seppur.2017.01.015

Zhao N, Liu T, Liu Z, Su Y, Yu H, Ma J, Yang Y, Jiang Z (2017) Synthesis and properties of sulfonated biphenyl poly(ether sulfone) and its mixed-matrix membranes containing carbon nanotubes for gas separation. J Appl Polym Sci 134(29). https://doi.org/10.1002/app.44995

Rezakazemi M, Ebadi Amooghin A, Montazer-Rahmati MM, Ismail AF, Matsuura T (2014) State-of-the-art membrane based CO2 separation using mixed matrix membranes (MMMs): an overview on current status and future directions. Prog Polym Sci 39(5):817–861. https://doi.org/10.1016/j.progpolymsci.2014.01.003

Shimekit B, Mohd Shariff A, Mukhtar H, Bustam MA, Elkhalifah AEI, Ullah S, Riaz N (2014) Interfacial defects on mixed matrix membranes and mitigation techniques for gas separation: a review. Appl Mech Mater 625(3):653–656. https://doi.org/10.4028/www.scientific.net/AMM.625.653

Rosli A, Ahmad AL, Low SC (2019) Anti-wetting polyvinylidene fluoride membrane incorporated with hydrophobic polyethylene-functionalized-silica to improve CO2 removal in membrane gas absorption. Sep Purif Technol 221:275–285. https://doi.org/10.1016/j.seppur.2019.03.094

Tan PC, Ooi BS, Ahmad AL, Low SC (2019) Formation of a defect-free polyimide/zeolitic imidazolate framework-8 composite membrane for gas separation: in-depth analysis of organic–inorganic compatibility. J Chem Technol Biotechnol 94(9):2792–2804. https://doi.org/10.1002/jctb.5908

Lin R, Ge L, Diao H, Rudolph V, Zhu Z (2016) Ionic liquids as the MOFs/polymer interfacial binder for efficient membrane separation. ACS Appl Mater Interfaces 8(46):32041–32049. https://doi.org/10.1021/acsami.6b11074

Chen XY, Vinh-Thang H, Ramirez AA, Rodrigue D, Kaliaguine S (2015) Membrane gas separation technologies for biogas upgrading. RSC Adv 5(31):24399–24448. https://doi.org/10.1039/c5ra00666j

Ding X, Li X, Zhao H, Wang R, Zhao R, Li H, Zhang Y (2018) Partial pore blockage and polymer chain rigidification phenomena in PEO/ZIF-8 mixed matrix membranes synthesized by in situ polymerization. Chinese J Chem Eng 26(3):501–508. https://doi.org/10.1016/j.cjche.2017.07.017

Shahid S, Nijmeijer K (2014) Performance and plasticization behavior of polymer-MOF membranes for gas separation at elevated pressures. J Membrane Sci 470:166–177. https://doi.org/10.1016/j.memsci.2014.07.034

Nordin NAHM, Ismail AF, Mustafa A, Murali RS, Matsuura T (2015) Utilizing low ZIF-8 loading for an asymmetric PSf/ZIF-8 mixed matrix membrane for CO 2 /CH 4 separation. RSC Adv 5(38):30206–30215. https://doi.org/10.1039/c5ra00567a

Fang M, Wu C, Yang Z, Wang T, Xia Y, Li J (2015) ZIF-8/PDMS mixed matrix membranes for propane/nitrogen mixture separation: experimental result and permeation model validation. J Membrane Sci 474:103–113. https://doi.org/10.1016/j.memsci.2014.09.040

Mittal G, Dhand V, Rhee KY, Park S-J, Lee WR (2015) A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J Ind Eng Chem 21:11–25. https://doi.org/10.1016/j.jiec.2014.03.022

Chen L, Xie H, Yu W (2011) Functionalization methods of carbon nanotubes and its applications. Carbon nanotubes application on electron devices. IntechOpen, Shanghai. https://doi.org/10.5772/18547

Park CH, Tocci E, Fontananova E, Bahattab MA, Aljlil SA, Drioli E (2016) Mixed matrix membranes containing functionalized multiwalled carbon nanotubes: mesoscale simulation and experimental approach for optimizing dispersion. J Membrane Sci 514:195–209. https://doi.org/10.1016/j.memsci.2016.04.011

Massoumi B, Ramezani M, Jaymand M, Ahmadinejad M (2015) Multi-walled carbon nanotubes-g-[poly(ethylene glycol)-b-poly(ε-caprolactone)]: synthesis, characterization, and properties. J Polym Res 22(11):1–10. https://doi.org/10.1007/s10965-015-0863-7

Golzar K, Modarress H, Amjad-Iranagh S (2017) Effect of pristine and functionalized single- and multi-walled carbon nanotubes on CO2 separation of mixed matrix membranes based on polymers of intrinsic microporosity (PIM-1): a molecular dynamics simulation study. J Mol Model 23(9):1–25. https://doi.org/10.1007/s00894-017-3436-3

Lee J (2009) A scattered data approximation tool to map carbon nanotube dispersion to the processing parameters in polymer nanocomposites. Rice University

Chen J, Dyer MJ, Yu MF (2001) Cyclodextrin-mediated soft cutting of single-walled carbon nanotubes. J Am Chem Soc 123(25):6201–6202. https://doi.org/10.1021/ja015766t

Wang S, Liang Z, Wang B, Zhang C, Rahman Z (2007) Precise cutting of single-walled carbon nanotubes. Nanotechnology 18(5):055301. https://doi.org/10.1088/0957-4484/18/5/055301

Shuba MV, Paddubskaya AG, Kuzhir PP, Maksimenko SA, Ksenevich VK, Niaura G, Seliuta D, Kasalynas I, Valusis G (2012) Soft cutting of single-wall carbon nanotubes by low temperature ultrasonication in a mixture of sulfuric and nitric acids. Nanotechnology 23(49):495714. https://doi.org/10.1088/0957-4484/23/49/495714

Pabby AK, Rizvi SSH, Requena AMS (2008) Handbook of membrane separations: chemical, pharmaceutical, food, and biotechnological applications2nd edn. CRC Press, Boca Raton

Nagy E (2012) Basic equations of the mass transport through a membrane layer1st edn. Elsevier, London

De Meis D (2017) Gas transport through porous membrane. ENEA. https://doi.org/10.13140/RG.2.2.25450.72641

Baker RW (2012) Membrane technology and applications3rd edn. Wiley-Blackwell, Oxford. https://doi.org/10.1002/9781118359686

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wong, K.K., Jawad, Z.A. A review and future prospect of polymer blend mixed matrix membrane for CO2 separation. J Polym Res 26, 289 (2019). https://doi.org/10.1007/s10965-019-1978-z

Published:

DOI: https://doi.org/10.1007/s10965-019-1978-z