Abstract

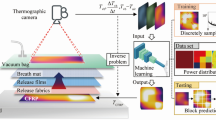

Compared with processing methods using conductive heating, microwave processing technology has many advantages such as its extremely short processing time and low energy consumption. However, the uneven temperature on the composite surface resulted from the uneven electromagnetic field distribution have become a big problem. Because the traditional model-based approach was difficult to establish the relationship between the composite temperature behaviors and microwave control strategies, existing methods mainly alleviated this problem by generating a relative movement between the microwave field and the object being heated, which cannot essentially achieve a uniform temperature distribution due to the uncertainty of the random compensation principle. In this paper, a data-driven method was proposed to solve this problem using an optimized convolutional neural network with extensive historical data. On this basis, the monitored uneven temperature distribution on the composite surface was accurately compensated in real time. Experimental results indicated that a reduction of ~53% in temperature difference was achieved compared with existing methods.

Similar content being viewed by others

Abbreviations

- MCS :

-

microwave control strategy

- HP :

-

heating pattern

- X :

-

heating rate/temperature

- X ′ :

-

relative heating rate/temperature

- Ave :

-

average value of the component

- Max :

-

maximum value of the component

- δ :

-

standardization coefficient

- E :

-

loss

- p :

-

batch size

- δ ij :

-

component of the label MCS

- \( {\hat{\delta}}_{ij} \) :

-

component of the MCS predicted by the CNN model

- w new :

-

weight after update

- w old :

-

weight before update

- Δw(q):

-

update value

- η :

-

learning rate

- α :

-

tuning factor

- Average error rate:

-

prediction error rate of the CNN model on the test set

- Accuracy :

-

prediction accuracy of the CNN model on the test set

- N :

-

sample size of the test set

- l :

-

number of magnetrons

- ΔTmax :

-

preset temperature threshold

- r1, r2 :

-

acceleration coefficient

- NC1, NC2, NC3 :

-

number of filters in the 3 convolutional layers

- Nh1, Nh2 :

-

number of filters in the 2 hidden layers

- \( {\mathbf{P}}_i^k \) :

-

position of the i-th particle on the k-th step

- \( {\mathbf{V}}_i^k \) :

-

velocity of the i-th particle on the k-th step.

- \( {\mathbf{P}}_{i, Best}^k \) :

-

best position recorded by the i-th particle on the k-th step

- \( {\mathbf{P}}_{Best}^k \) :

-

best position of the particle swarm on the k-th step

References

Menéndez, J.A., Arenillas, A., Fidalgo, B., Fernández, Y., Zubizarreta, L., Calvo, E.G., Bermúdez, J.M.: Microwave heating processes involving carbon materials. Fuel Process. Technol. 91(1), 1–8 (2010)

Green, J.E., Nuhiji, B., Zivtins, K., Bower, M.P., Grainger, R.V., Day, R.J., Scaife, R.J.: Internal model control of a domestic microwave for carbon composite curing. IEEE T. Microw. Theory. 65(11), 4335–4346 (2017)

Beaumont, P.W.R., Soutis, C., Johnson, A.: Fitness considerations for contemporary composite materials: (Who’s afraid of the composite micro-crack?). Appl. Compos. Mater. 24(6), 1265–1285 (2017)

Lachaud, F., Espinosa, C., Michel, L., Rahme, P., Piquet, R.: Modelling strategies for predicting the residual strength of impacted composite aircraft fuselages. Appl. Compos. Mater. 22(6), 599–621 (2015)

Nuhiji, B., Swait, T., Bower, M., Green, J.E., Day, R.J., Scaife, R.J.: Tooling materials compatible with carbon fibre composites in a microwave environment. Compos. Part B-Eng. 163, 769–778 (2019)

Li, Y., Cheng, L., Zhou, J.: Curing multidirectional carbon fiber reinforced polymer composites with indirect microwave heating. Int. J. Adv. Manuf. Tech. 97(1–4), 1137–1147 (2018)

Zhang, L., Li, Y., Zhou, J.: Anisotropic dielectric properties of carbon fiber reinforced polymer composites during microwave curing. Appl. Compos. Mater. 25(6), 1339–1356 (2018)

Zhou, J., Li, Y., Li, N., Liu, S., Cheng, L., Sui, S., Gao, J.: A multi-pattern compensation method to ensure even temperature in composite materials during microwave curing process. Compos. Part A-Appl. S. 107, 10–20 (2018)

Chinedum, O.M., Danning, L., Meng-Fang, L., Paul, D.L., Kali, B.K., Vijay, T.K., Hamed, Y.N.: Accelerated microwave curing of fibre-reinforced thermoset polymer composites for structural applications: a review of scientific challenges. Compos. Part A-Appl. S. 115, 88–103 (2018)

Kwak, M., Robinson, P., Bismarck, A., Wise, R.: Microwave curing of carbon–epoxy composites: penetration depth and material characterization. Compos. Part A-Appl. S. 75, 18–27 (2015)

Mishra, R.R., Sharma, A.K.: Microwave-material interaction phenomena: heating mechanisms, challenges and opportunities in material processing. Compos. Part A-Appl. S. 81, 78–97 (2016)

Feher, L.E., Thumm, M.K.: Microwave innovation for industrial composite fabrication-the HEPHAISTOS technology. IEEE T. Plasma. Sci. 32(1), 73–79 (2004)

Sturm, G.S.J., Stefanidis, G.D., Verweij, M.D., Van Gerven, T.D.T., Stankiewicz, A.I.: Design principles of microwave applicators for small-scale process equipment. Chem. Eng. Process. 49(9), 912–922 (2010)

Chen, X., Zhan, L., Huang, M., Chang, T., Li, S., Peng, W.: A novel method for curing carbon fiber reinforced plastics by high-pressure microwave. Fiber. Polym. 17(12), 2143–2152 (2016)

Veronesi, P., Leonelli, C., Grisoni, F.: Numerical simulation of an industrial microwave assisted filter dryer: criticality assessment and optimization. J. Microwave Power EE. 41, 4–12 (2007)

Chandrasekaran, S., Ramanathan, S., Basak, T.: Microwave material processing—a review. AICHE J. 58(2), 330–363 (2012)

Plaza-González, P., Monzó-Cabrera, J., Catalá-Civera, J.M., Sánchez-hernández, D.: Effect of mode-stirrer configurations on dielectric heating performance in multimode microwave applicators. IEEE T. Microw. Theory. 53(5), 1699–1706 (2005)

Ku, H.S.L., Yusaf, T.: Processing of composites using variable and fixed frequency microwave facilities. Prog. Electromagn. Res. 5, 185–205 (2008)

Cuccurullo, G., Giordano, L., Albanese, D., Cinquanta, L., Di Matteo, M.: Infrared thermography assisted control for apples microwave drying. J. Food Eng. 112(4), 319–325 (2012)

Nair, V., Hinton, G.E.: Rectified linear units improve restricted Boltzmann machines [C]//Proceedings of the 27th international conference on machine learning (ICML-10), pp. 807–814 (2010)

Weimer, D., Scholz-Reiter, B., Shpitalni, M.: Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann-Manuf. Techn. 65(1), 417–420 (2016)

Wang, P., Gao, R.X., Yan, R.: A deep learning-based approach to material removal rate prediction in polishing. CIRP Ann-Manuf. Techn. 66(1), 429–432 (2017)

Acknowledgements

This project was supported by National Natural Science Foundation of China (Grant no. 51875288 and no. 51575275), jointly supported by Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX17_0282). The authors sincerely appreciate the continuous support provided by our industrial collaborators.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, D., Li, Y., Zhou, J. et al. A Novel Method to Improve Temperature Uniformity in Polymer Composites Microwave Curing Process through Deep Learning with Historical Data. Appl Compos Mater 27, 1–17 (2020). https://doi.org/10.1007/s10443-019-09791-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09791-5