Abstract

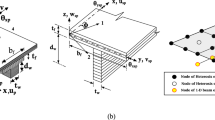

In this paper, a novel numerical simulation framework using meso-scale finite element model is developed to predict the mechanical properties and damage mechanisms for one-layer biaxial braided composite tubes with gradient braided structures in axial direction, which involves braided reinforcements with an evolution of braiding angle. To bridge the relationships between the braiding procedure and geometric model, this paper develops an automatic algorithm that generates the geometric model with requiring braiding parameters as input parameters. The braided fabric model is generated by circularly arraying the yarn model, which is established by sweeping varying cross-sections along the centerline with the control of guidelines. The geometric model of matrix pockets is obtained by extracting the fabric model from the whole geometric model of composite tube. After that, a braiding yarn mesh in hexahedron format and co-node matrix mesh in tetrahedron format are generated from the assembled braided fabric and matrix pockets. The framework established in this paper is validated by comparison with the experimental results of the composite tubes with braiding angles from 36.6° to 49.6° subjected to quasi-static axial compression.

Similar content being viewed by others

References

Kyosev, Y.: Braiding Technology for Textiles: Principles, Design and Processes. Elsevier, London (2014)

Chiu, C.H., Tsai, K.-H., Huang, W.J.: Effects of braiding parameters on energy absorption capability of Triaxially braided composite tubes. J. Compos. Mater. 32(21), 1964–1983 (1998). https://doi.org/10.1177/002199839803202105

Karbhari, V.M., Haller, J.E.: Rate and architecture effects on progressive crush of braided tubes. Compos. Struct. 43(2), 93–108 (1998). https://doi.org/10.1016/s0263-8223(98)00083-x

Ping, Z., Gui, L., Fan, Z.: Experimental investigation on the energy absorption characteristic of braided composite circular tubes subjected to quasi-static axial compression. Acta Materiae Compositae Sinica. 24, 146–150 (2007)

Karbhari, V.M., Falzon, P.J., Herzberg, I.: Energy absorption characteristics of hybrid braided composite tubes. J. Compos. Mater. 31(12), 1164–1186 (1997). https://doi.org/10.1177/002199839703101201

Zhang, P., Gui, L.-J., Fan, Z.-J., Yu, Q., Li, Z.-K.: Finite element modeling of the quasi-static axial crushing of braided composite tubes. Comput. Mater. Sci. 73, 146–153 (2013). https://doi.org/10.1016/j.commatsci.2013.01.026

Xiao, X., Botkin, M.E., Johnson, N.L.: Axial crush simulation of braided carbon tubes using MAT58 in LS-DYNA. Thin-Walled Struct. 47(6–7), 740–749 (2009). https://doi.org/10.1016/j.tws.2008.12.004

Miravete, A., Bielsa, J.M., Chiminelli, A., Cuartero, J., Serrano, S., Tolosana, N., de Villoria, R.G.: 3D mesomechanical analysis of three-axial braided composite materials. Compos. Sci. Technol. 66(15), 2954–2964 (2006). https://doi.org/10.1016/j.compscitech.2006.02.015

Wu, Z., Ding, H., Ying, Z., Yuan, Y., Hu, X.: Influence of braided fabric on the fracture modes of a composite tube under quasi-static compression. J. Reinf. Plast. Compos. 36(10), 766–779 (2017). https://doi.org/10.1177/0731684417690927

Zhou, H., Zhang, W., Liu, T., Gu, B., Sun, B.: Finite element analyses on transverse impact behaviors of 3-D circular braided composite tubes with different braiding angles. Compos. A: Appl. Sci. Manuf. 79, 52–62 (2015). https://doi.org/10.1016/j.compositesa.2015.09.012

Wu, L., Zhang, F., Sun, B., Gu, B.: Finite element analyses on three-point low-cyclic bending fatigue of 3-D braided composite materials at microstructure level. Int. J. Mech. Sci. 84, 41–53 (2014). https://doi.org/10.1016/j.ijmecsci.2014.03.036

Chiu, C.H., Tsai, K.-H., Huang, W.J.: Crush-failure modes of 2D triaxially braided hybrid composite tubes. Compos. Sci. Technol. 59(11), 1713–1723 (1999). https://doi.org/10.1016/s0266-3538(99)00036-6

Priem, C., Othman, R., Rozycki, P., Guillon, D.: Experimental investigation of the crash energy absorption of 2.5D-braided thermoplastic composite tubes. Compos. Struct. 116, 814–826 (2014). https://doi.org/10.1016/j.compstruct.2014.05.037

McGregor, C., Zobeiry, N., Vaziri, R., Poursartip, A., Xiao, X.: Calibration and validation of a continuum damage mechanics model in aid of axial crush simulation of braided composite tubes. Compos. A: Appl. Sci. Manuf. 95, 208–219 (2017). https://doi.org/10.1016/j.compositesa.2017.01.012

Beard, S.J., Chang, F.K.: Energy absorption of braided composite tubes. Int J Crashworthiness. 7(2), 191–206 (2002). https://doi.org/10.1533/cras.2002.0214

Mahdi, E., Hamouda, A.M.S., Sebaey, T.A.: The effect of fiber orientation on the energy absorption capability of axially crushed composite tubes. Materials & Design (1980–2015). 56, 923–928 (2014). https://doi.org/10.1016/j.matdes.2013.12.009

Cater, C., Xiao, X., Goldberg, R.K., Kohlman, L.W.: Experimental and numerical analysis of triaxially braided composites utilizing a modified subcell modeling approach. In: Nasa Tm-2015-218814, pp. 1–47 (2015)

Xu, K., Qian, X.: A new analytical model on predicting the elastic properties of 3D full five-directional braided composites based on a multiunit cell model. Compos. Part B. 83, 242–252 (2015). https://doi.org/10.1016/j.compositesb.2015.08.052

Phoenix, S.L.: Mechanical response of a tubular braided cable with an elastic Core. Text. Res. J. 48(2), 81–91 (2016). https://doi.org/10.1177/004051757804800204

Siromani, D., Henderson, G., Mikita, D., Mirarchi, K., Park, R., Smolko, J., Awerbuch, J., Tan, T.-M.: An experimental study on the effect of failure trigger mechanisms on the energy absorption capability of CFRP tubes under axial compression. Compos. A: Appl. Sci. Manuf. 64, 25–35 (2014). https://doi.org/10.1016/j.compositesa.2014.04.019

Eshkoor, R.A., Oshkovr, S.A., Sulong, A.B., Zulkifli, R., Ariffin, A.K., Azhari, C.H.: Effect of trigger configuration on the crashworthiness characteristics of natural silk epoxy composite tubes. Compos. Part B. 55, 5–10 (2013). https://doi.org/10.1016/j.compositesb.2013.05.022

Yan, L., Chouw, N., Jayaraman, K.: Effect of triggering and polyurethane foam-filler on axial crushing of natural flax/epoxy composite tubes. Materials & Design (1980–2015). 56, 528–541 (2014). https://doi.org/10.1016/j.matdes.2013.11.068

Sivagurunathan, R., Way, S.L.T., Sivagurunathan, L., Yaakob, M.Y.: Effects of triggering mechanisms on the crashworthiness characteristics of square woven jute/epoxy composite tubes. J. Reinf. Plast. Compos. 37(12), 824–840 (2018). https://doi.org/10.1177/0731684418763218

Cheng, J.: Material modeling of strain rate dependent polymer and 2D triaxially braided composites. Ph.D. dissertation Akron. University of Akron, Ohio (2006)

Littell, J.D., Binienda, W.K., Goldberg, R.K., Roberts, G.D.: A Modeling Technique and Representation of Failure in the Analysis of Triaxial Braided Carbon Fiber Composites. NASA/TM (2008)

Goldberg, R.K., Blinzler, B.J., Binienda, W.K.: Modification of a macromechanical finite element–based model for impact analysis of Triaxially braided composites. J. Aerosp. Eng. 25(3), 383–394 (2012). https://doi.org/10.1061/(asce)as.1943-5525.0000135

Wang, C., Zhong, Y., Bernad Adaikalaraj, P.F., Ji, X., Roy, A., Silberschmidt, V.V., Chen, Z.: Strength prediction for bi-axial braided composites by a multi-scale modelling approach. J. Mater. Sci. 51(12), 6002–6018 (2016). https://doi.org/10.1007/s10853-016-9901-z

Shunjun, S., Waas, A.M., Shahwan, K.W., Faruque, O., Xinran, X.: Compression response of 2D braided textile composites: single cell and multiple cell micromechanics based strength predictions. J. Compos. Mater. 42(23), 2461–2482 (2008). https://doi.org/10.1177/0021998308096500

Zhao, C., Huang, Y., Chen, Z., Ha, S.K.: Progressive failure prediction of a landing gear structure of braided composites. Compos. Struct. 161, 407–418 (2017). https://doi.org/10.1016/j.compstruct.2016.11.076

Li, X., Binienda, W.K., Goldberg, R.K.: Finite-element model for failure study of two-dimensional Triaxially braided composite. J. Aerosp. Eng. 24(2), 170–180 (2011). https://doi.org/10.1061/(asce)as.1943-5525.0000029

Zhang, C., Li, N., Wang, W., Binienda, W.K., Fang, H.: Progressive damage simulation of triaxially braided composite using a 3D meso-scale finite element model. Compos. Struct. 125, 104–116 (2015). https://doi.org/10.1016/j.compstruct.2015.01.034

Binienda, W.K., Li, X.: Mesomechanical model for numerical study of two-dimensional Triaxially braided composite. J. Eng. Mech. 136(11), 1366–1379 (2010). https://doi.org/10.1061/(asce)em.1943-7889.0000181

Tan, P., Tong, L., Steven, G.P.: Modelling for predicting the mechanical properties of textile composites—a review. Compos. A: Appl. Sci. Manuf. 28(11), 903–922 (1997). https://doi.org/10.1016/s1359-835x(97)00069-9

KO, F.K.: Braiding. In: Engineered Materials Handbook, pp. 519–528. ASM International, Ohio (1987)

Wu, Z., Shu, Z., Kyosev, Y., Yuan, Y., Hu, X.: Numerical prediction methodology for tow orientation on irregular mandrels with constant cross-sections. J. Compos. Mater. 53(8), 1067–1078 (2018). https://doi.org/10.1177/0021998318795033

Abaqus Documentation. Providence (RI, USA): Dassault Systèmes Simulia Corp; 2014

Huang, H., Waas, A.M.: Compressive response of Z-pinned woven glass fiber textile composite laminates: modeling and computations. Compos. Sci. Technol. 69(14), 2338–2344 (2009). https://doi.org/10.1016/j.compscitech.2009.01.008

Pan, Z., Gu, B., Sun, B.: Thermo-mechanical behaviors of 3-D braided composite material subject to high strain rate compressions under different temperatures. Mech. Adv. Mater. Struct. 23(4), 385–401 (2015). https://doi.org/10.1080/15376494.2014.981619

Hooputra, H., Gese, H., Dell, H., Werner, H.: A comprehensive failure model for crashworthiness simulation of aluminium extrusions. Int J Crashworthiness. 9(5), 449–464 (2004). https://doi.org/10.1533/ijcr.2004.0289

Acknowledgements

The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was supported by the National Natural Science Foundation of China (Grant No. 51775514 and 51705466) and Zhejiang Provincial Natural Science Foundation of China under Grant No.LR18E050001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Z., Shi, L., Cheng, X. et al. Meso-Level Finite Element Modeling Method for Mechanical Response of Braided Composite Tube with Gradient Structure in Axial Direction. Appl Compos Mater 26, 1101–1119 (2019). https://doi.org/10.1007/s10443-019-09769-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-019-09769-3