Abstract

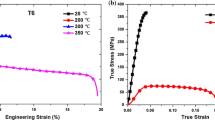

The dynamic compression behavior and microstructure evolution at 400 °C of an extruded Mg–8Gd–4Y–Nd–Zr alloy with different tempers were investigated. The peak-aged samples exhibit the highest compressive strength, followed by as-extruded samples and over-aged samples. The highest dynamic compressive strength of 582 MPa was achieved by peak-aged sample compressed at 1224 s−1. The high strength was attributed to the formation of abundant thermally stable βʹ precipitates and some dynamic precipitates. The dynamic compressive strength of peak-aged sample and over-aged sample is not sensitive to strain rates, while that of the as-extruded sample is sensitive to strain rates. The dynamic compressive strength of the as-extruded alloy can reach 535 MPa when compressed at 2024 s−1. The high strength was mainly ascribed to the formation of numerous dynamic precipitates and the work hardening effect caused by dislocations. The cracks are composed of crack that is 45° to loading direction on the cylindrical surface and crack on the compressed surface. Microstructure observation indicates that the crack was easily propagated along the interface between the adiabatic shear band and matrix, grain boundaries. The equilibrium phase β in over-aged sample was unable to hinder the crack propagation.

Graphic Abstract

Similar content being viewed by others

References

K. Wen, K. Liu, Z.H. Wang, S.B. Li, W.B. Du, Mater. Sci. Eng. A 674, 33 (2016)

H.M. Xie, B. Jiang, J.J. He, X.S. Xia, F.S. Pan, Tribol. Int. 93, 63 (2016)

Y. Zou, L.H. Zhang, Y. Li, H.T. Wang, J.B. Liu, P.K. Liaw, H.B. Bei, Z.W. Zhang, J. Alloys Compd. 735, 2625 (2018)

J.K. Zheng, R.C. Luo, X.Q. Zeng, B. Chen, Mater. Des. 137, 316 (2018)

J. Sun, L. Jin, J. Dong, F.H. Wang, S. Dong, W.J. Ding, A.A. Luo, Int. J. Plast. (2019). https://doi.org/10.1016/j.ijplas.2019.07.014

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, G. Myilsamy, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00346-8

C. Xu, M.Y. Zheng, S.W. Xu, K. Wu, E.D. Wang, S. Kamado, G.J. Wang, X.Y. Lv, Mater. Sci. Eng. A 547, 93 (2012)

W.W. Jian, G.M. Cheng, W.Z. Xu, H. Yuan, M.H. Tsai, Q.D. Wang, C.C. Koch, Y.T. Zhu, S.N. Mathaudhu, Mater. Res. Lett. 1, 61 (2013)

Z.J. Yu, Y.D. Huang, X. Qiu, G.F. Wang, F.Z. Meng, N. Hort, J. Meng, Mater. Sci. Eng. A 622, 121 (2015)

C. Xu, G.H. Fan, T. Nakata, X. Liang, Y.Q. Chi, X.G. Qiao, G.J. Cao, T.T. Zhang, M. Huang, K.S. Miao, M.Y. Zheng, S. Kamado, H.L. Xie, Metall. Mater. Trans. A 49, 1931 (2018)

X.W. Heng, Y. Zhang, W. Rong, Y.J. Wu, L.M. Peng, Mater. Des. 169, 107666 (2019)

S.J. Liu, K. Wang, J.F. Wang, S. Huang, S.Q. Gao, X. Peng, H. Hu, F.S. Pan, Mater. Sci. Eng. A 758, 96 (2019)

W. Rong, Y. Zhang, Y.J. Wu, Y.L. Chen, M. Sun, J. Chen, L.M. Peng, Mater. Sci. Eng. A 740–741, 262 (2019)

W.S. Lee, W.C. Sue, C.F. Lin, C.J. Wu, J. Mater. Process. Technol. 100, 116 (2000)

W.L. Zhang, X.F. Chen, B.C. Zhuo, P.J. Li, L.J. He, Mater. Sci. Eng. A 730, 336 (2018)

P.L. Mao, J.C. Yu, Z. Liu, Y. Dong, J. Magn. Alloys 1, 64 (2013)

J.C. Yu, Z. Liu, Y. Dong, Z. Wang, J. Magn. Alloys 3, 134 (2015)

C.P. Tang, X.Z. Wang, W.H. Liu, D. Feng, K. Wu, C. Zhang, G.D. Miao, W.Y. Liang, J. Li, X. Liu, Q. Li, Mater. Sci. Eng. A 759, 172 (2019)

S.M. Zhu, J.F. Nie, M.A. Gibson, M.A. Easton, Scr. Mater. 77, 21 (2014)

X. Gao, S.M. He, X.Q. Zeng, L.M. Peng, W.J. Ding, J.F. Nie, Mater. Sci. Eng. A 431, 322 (2006)

X.M. Zhang, C.P. Tang, Y.L. Deng, L. Yang, W.J. Liu, J. Alloys Compd. 509, 6170 (2011)

C.P. Tang, W.H. Liu, Y.Q. Chen, X. Liu, Y.L. Deng, Mater. Sci. Eng. A 659, 63 (2016)

Acknowledgements

The authors would like to appreciate the financial supports from National Natural Science Foundation of China (Grant Nos. 51605159 and 51601062), and Hunan Provincial Natural Science Foundation of China (Grant No. 2016JJ5042).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, C., Wu, K., Liu, W. et al. Dynamic Compression Behavior of a Mg–Gd-Based Alloy at Elevated Temperature. Met. Mater. Int. 27, 1438–1447 (2021). https://doi.org/10.1007/s12540-019-00558-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00558-y