Abstract

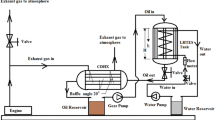

The wasted energy from a car exhaust can be considered as the heat supply for an absorption refrigeration cycle. In practice however, application of such cooling systems in automobiles has been facing a number of technical restrictions one of which is once the car engine runs idle or at low speed. To tackle this matter, the present experimental study has been carried out. A commercial diffusion absorption refrigerator with internal volume of 0.04 cubic meters (Electrolux 27A1) and the exhaust flow from a compact car engine (X100 KIA) are applied. Various engine speeds (1000–2500 rpm) have been tested. First, it was confirmed that the amount of heat transferred to the generator at low engine speeds was not adequate to obtain the low temperature required for the refrigerator compartment. A new generator was therefore designed and built. The experimental results show that by using the modified generator, the heat transfer to the generator improves by more than 19%. The evaporator and refrigerator compartment reached the desirable temperatures of −5.7 °C and 4.2 °C respectively at the engine speed of 2000 rpm. Further improvement of the results was observed at the engine speed of 1000 rpm where the temperatures at the evaporator and the refrigerator compartment were reduced by about 4 °C once the modified generator was applied.

Similar content being viewed by others

Abbreviations

- \( {\dot{Q}}_{exh} \) :

-

Heat transfer rate from energy source [W]

- \( {\dot{Q}}_{ref} \) :

-

Cooling capacity [W]

- \( {\dot{Q}}_{wall} \) :

-

Heat transfer through the walls [W]

- \( {\dot{Q}}_{ins} \) :

-

Heat loss through the insulated walls [W]

- \( \dot{m} \) :

-

Mass flow rate [kg s−1]

- \( \dot{V} \) :

-

Volumetric flow rate [m3 s−1]

- \( \overline{R} \) :

-

Universal gas constant [8314 J kmol−1 K−1]

- A :

-

Surface area [m2]

- COP :

-

Coefficient of Performance

- c :

-

Thermal capacity [J kg−1 K−1]

- e :

-

Specific enthalpy [J kg−1]

- h :

-

Heat transfer coefficient [W m−2 K−1]

- k f :

-

Fluid thermal conductivity [W m−1 K−1]

- L :

-

Characteristic length [m]

- M air :

-

Dry air molecular weight [kg kmol−1]

- m air :

-

Dry air mass [kg]

- m :

-

Mass [kg]

- P :

-

Absolute pressure [Pa]

- P s :

-

Water vapor saturation pressure [Pa]

- P v :

-

Water vapor partial pressure [Pa]

- P air :

-

Air partial pressure [Pa]

- Pr :

-

Prandtl number

- Ra L :

-

Rayleigh number

- T :

-

Temperature [K]

- T f :

-

Film temperature [K]

- U :

-

Internal energy [J]

- u :

-

Specific internal energy [J kg−1]

- u air :

-

Dry air specific internal energy [J kg−1]

- u v :

-

Water vapor specific internal energy [J kg−1]

- x :

-

Value of a property

- y :

-

Mass fraction

- ∆t :

-

Time interval [s]

- ∆T :

-

Temperature difference [K]

- ϕ :

-

Relative humidity [%]

- ω :

-

Specific humidity

- ρ :

-

Density [kg m−3]

- ν:

-

Volume inside the refrigerator [m3]

- air :

-

Air

- av :

-

Average

- amb :

-

Ambient

- exh :

-

Exhaust

- ex :

-

External

- ev. body :

-

Evaporator body and fins

- f :

-

Final

- i :

-

Initial

- in :

-

Internal

- ins :

-

Insulation

- inl :

-

Inlet

- outl :

-

Outlet

- sur :

-

Surface

- sh :

-

Sheet metal of the wall

- wall :

-

Wall

References

Aly SE (1992) Waste heat powered air conditioning in a diesel total energy system. Heat Mass Transf 27:273–279

Talom HL, Beyene A (2009) Heat recovery from automotive engine. Appl Therm Eng 29:439–444

Zhang LZ (2000) Design and testing of an automobile waste heat adsorption cooling system. Appl Therm Eng 20:103–114

Frosch RA (1981) Automotive absorption air conditioner utilizing solar and motor waste heat, US Patent 4,307,575

Lin G, Yuan X, Mei Z (1994) The feasibility study of the waste heat air-conditioning system for automobile. J Therm Sci 3(2):126–129

Deng D, Cheng JP (2017) Theoretical and experimental validation study on automotive air-conditioning based on heat pipe and LNG cold energy for LNG-fueled heavy vehicles. Heat Mass Transf 53(8):2551–2558

Chi RG, Park JC, Rhi SH (2017) Study on heat pipe assisted thermoelectric power generation system from exhaust gas. Heat Mass Transf 53(11):3295–3304

Lim LS, Abdullah MO (2010) Experimental study of an automobile exhaust heat-driven adsorption air-conditioning laboratory prototype by using palm activated carbon-methanol. Science and Technology for the Built Environment 16(2):221–231

Aktaş A, Doğu A (2008) Recovery of waste heat energy from gasoline engine exhaust. J Energy Inst 81(1):45–47

Vicatos G, Gryzagoridis J, Wang S (2008) A car air-conditioning system based on an absorption refrigeration cycle using energy from exhaust gas of an internal combustion engine. J Energy South Afr 19(4):6–11

Lu YZ, Wang S, Jianzhou S, Zhang M, Xu YX, Wu JY (2004) Performance of a diesel locomotive waste-heat-powered adsorption air conditioning system. Adsorption 10:57–68

Jianzhou S, Wang RZ, Lu YZ, Xu YX, Wu JY (2002) Experimental investigations on adsorption air-conditioner used in internal-combustion locomotive driver cabin. Appl Therm Eng 22:1153–1162

Seddiek IS, Mosleh M, Banawan AA (2012) Thermo-economic approach for absorption air condition onboard high-speed crafts. Int J Naval Archi Ocean Eng 4(4):460–476

Shu G, Liang Y, Wei H, Tian H, Zhao J, Liu L (2013) A review of waste heat recovery on two-stroke IC engine aboard ships. Renew Sustain Energy Rev 19:385–401

Koehler J, Tegethoff WJ, Westphalen D, Sonnekalb M (1997) Absorption refrigeration system for mobile applications utilizing exhaust gases. Heat Mass Transf 32:333–340

Horuz I (1998) An alternative road transport refrigeration. Turkish J Eng Environ Sci 22:211–222

Ramanathan A, Gunasekaran P (2008) Simulation of absorption refrigeration system for automobile application. Therm Sci 12(3):5–13

AlQdah KS (2011) Performance and evaluation of aqua ammonia auto air conditioner system using exhaust waste energy. Energy Proc. 6:467–476

Alam S (2006) A proposed model for utilizing exhaust heat to run automobile air-conditioner, the 2nd joint international conference on “sustainable energy and environment”, Bangkok, Thailand

Manzela AA, Hanriot SM, Cabezas-Gómez L, Sodré J (2010) Using engine exhaust gas as energy source for an absorption refrigeration system. Appl Energy 87:1141–1148

Manzela AA, Hanriot SM, Maia CB, Sodré JR (2011) An experimental comparison between LPG and engine energy source for an absorption refrigeration system. Int J Energy Res 35:1–9

Rego AT, Hanriot SM, Oliveira AF, Brito P, Rego TFU (2014) Automotive exhaust gas flow control for an ammonia-water absorption refrigeration system. Appl Therm Eng 64:101–107

Aly WIA, Abdo M, Bedair G, Hassaneen AE (2017) Thermal performance of a diffusion absorption refrigeration system driven by waste heat from diesel engine exhaust gases. Appl Therm Eng 114:621–630

Potgieter MC (2013) The evaluation of a solar-driven aqua-ammonia diffusion absorption heating and cooling cycle, Master's Thesis, North-West University Potchefstroom Campus

Incropera FP, DeWitt DP (1996) Fundamentals of heat and mass transfer, 4th edn. Wiley, New York

Book JD (1983) Thermophysical properties of fluids. Japan Society of Mechanical Engineers, Tokyo

Rahimi AR (2013) Improvement air manifold at X100 engine, Master's thesis, mechanical engineering department, K. N. Toosi university of technology

Coleman HW, Steel WG (2009) Experimentation, validation, and uncertainty analysis for engineers, 3rd edn. Wiley, New Jersey

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Exhaust waste heat of a car used to run a diffusion absorption refrigeration cycle.

• A new cycle generator designed and built to fit the low engine speed conditions.

• A minimum temperature of 4.2°C obtained at the refrigerator compartment.

• Cooling onset was preceded at low engine speeds by using the modified generator.

Rights and permissions

About this article

Cite this article

Farzadi, R., Bazargan, M. Experimental study of a diffusion absorption refrigeration cycle supplied by the exhaust waste heat of a sedan car at low engine speeds. Heat Mass Transfer 56, 1353–1363 (2020). https://doi.org/10.1007/s00231-019-02793-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02793-w