Abstract

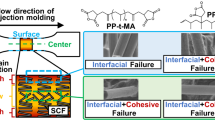

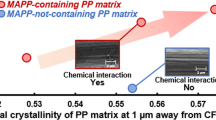

The interfacial adhesion property of telechelic polypropylenes (PPs) imparted by the controlled thermal degradation of commercial PPs and the subsequent end group transformation was investigated to determine the potential of telechelic PP as a candidate for PP matrix resin-coupling agents for CF-reinforced PP composites. In particular, we studied the interfacial shear strength (IFSS) between telechelic PPs with terminal double bonds or terminal hydroxyl groups and CFs for the first time. The hydroxyl-terminated PP showed higher IFSS than that of commercial PPs. The hydroxyl groups of hydroxyl-terminated PP interacted with CF surfaces via hydrogen bonding, which led to higher interfacial adhesion. Furthermore, hydroxyl-terminated PP homopolymer (hPP-OH_27k) was mixed with conventional isotactic polypropylene (iPP), and used as a coupling agent. The IFSS of the iPP/hPP-OH_27k blend was comparable to that of iPP/maleic anhydride-grafted polypropylene (MAPP), which is typically used as a coupling agent of the PP matrix. The iPP/hPP-OH_27k blend showed higher crystallinity and higher tensile strength than the iPP/MAPP blend based on the DSC measurements and tensile tests. These results indicated that hPP-OH_27k functions as a novel coupling agent of the PP matrix.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Pickering SJ. Recycling technologies for thermoset composite materials-current status. Compos Part A: Appl Sci Manuf. 2006;37:1206–15.

Pimenta S, Pinho ST. Recycling carbon fibre reinforced polymers for structural application: technology review and market outlook. Waste Manag. 2011;31:378–92.

Yamaguchi A, Hashimoto Y, Kakichi Y, Urushisaki M, Sakaguchi T. Recyclable, adhesive, acetal-linkage-containing epoxy resins: measuring the adhesive properties with carbon fibers. Kobunshi Ronbunshu. 2016;73:244–51.

Harima I, Yamada H, Kajioka N, Takagaki Y, Nakai A, Ohtani A, Hamada H. Interfacial shear strength and mechanical properties of carbon fiber reinforced polypropylene. Stud Sci Technol. 2016;5:163–8.

Han SH, Oh HJ, Kim SS. Evaluation of fiber surface treatment on the interfacial behavior of carbon fiber-reinforced polypropylene composites. Compos: Part B. 2014;60:98–105.

Brandl W, Marginean G, Chirila V, Warschewski W. Production and characterisation of vapour grown carbon fiber/polypropylene composites. Carbon. 2004;42:5–9.

Karsli NG, Aytac A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des. 2011;32:4069–73.

Wong KH, Mohammed DS, Pickering SJ, Brooks R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos Sci Technol. 2012;72:835–44.

Sawaguchi T, Ikemura T, Seno M. Preparation of α,ω-diisopropenyloligopropylene by thermal degradation of isotactic polypropylene. Macromolecules. 1995;28:7973–8.

Hagiwara T, Saitoh H, Tobe A, Sasaki D, Yano S, Sawaguchi T. Functionalization and application of telechelic oligopropylenes: preparation of α,ω-dihydroxy- and diaminooligopropylenes. Macromolecules. 2005;38:10373–8.

Sasaki D, Suzuki Y, Hagiwara T, Yano S, Sawaguchi T. Chemical recycling of waste polypropylenes by controlled thermal degradation. J Jpn Inst Energy. 2008;87:208–14.

Dudić D, Djoković V, Kostoski D. The high temperature secondary crystallisation of aged isotactic polypropylene. Polym Test. 2004;23:621–7.

Nakanishi Y, Ikuta N. Interphase of FRP and its chemical control. J Soc Mat Sci, Jpn. 1996;45:1307–15.

Nakatani M, Nakao F. Effect of fiber/matrix interphase on the properties of CFRP. Sen’i Gakkaishi. 1988;44:61–66.

Taketa I, Kalinka G, Gorbatikh L, Lomov S, Verpoest I. Influence of cooling rate on the properties of carbon fiber unidirectional composites with polypropylene, polyamide 6, and polyphenylene sulfide matrices. J Jpn Soc Compos Mater. 2018;44:123–8.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Yamaguchi, A., Hashimoto, T., Uematsu, H. et al. Investigation of interfacial adhesion of telechelic polypropylenes for carbon fiber-reinforced plastics. Polym J 52, 413–419 (2020). https://doi.org/10.1038/s41428-019-0295-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0295-z

This article is cited by

-

Effects of different types of functionalized polypropylenes on the tensile strength of short carbon fiber-reinforced polypropylene composites

Polymer Journal (2024)

-

Effects of different types of maleic anhydride-modified polypropylene on the interfacial shear strengths of carbon fiber-reinforced polypropylene composites

Polymer Journal (2023)

-

Growth of polypropylene crystals in the vicinity of carbon fibers and improvement of their interfacial shear strength

Polymer Journal (2022)