Abstract

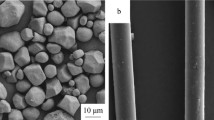

Interfacial properties play a key role in determining the solubility of solids in liquids for both low- and high-temperature processes. In this study, the interfacial interactions between inclusions comprising TiO2 or TiN and the mold flux were investigated. The results of sessile drop tests show that the wettability of the mold flux on the TiO2 substrate was better than that on the TiN substrate when the temperature was below 1503 K. However, the contact angle on the TiN substrate decreased more than that on the TiO2 substrate when the temperature was above 1503 K due to the enhancement of the interfacial reaction. The thermodynamic calculations suggest that the reactions of TiN with O2 and SiO2 resulted in a bubbling phenomenon during the TiN sessile drop test. The scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) results show that the final products of the interfacial interaction between the mold flux and the TiO2 substrate comprised perovskites, whereas those for the TiN substrate comprised perovskites and SiTi.

Similar content being viewed by others

References

[1] B. Ozturk, R. Matway and R. J. Fruehan: Metall. Mater. Trans. B, 1995, vol.26, pp.563-567.

[2] Q. Wang, Y. J. Lu, S. P. He, K. C. Mills and Z. S. Li: Ironmak. Steelmak., 2011, vol.38, pp.297-301.

[3] J. O. Jo, W. Y. Kim, D. S. Kim and J. J. Pak: Met. Mater. Int.,2008, vol.14, pp.531-537.

[4] X. Yin, Y. Sun, Y. Yang, X. Bai, M. Barati and A. Mclean: Metall. Mater. Trans. B, 2016, vol.47, pp.3274-3284.

[5] D. Kruger and A. Garbers-Craig: Metall. Mater. Trans. B, 2017, vol.48, pp.1514-1532.

[6] J. H. Park and Y. Kang: Steel. Res. Int., 2017, vol.88, pp.1700130.

[7] S. Xu, X. Q. Wu, E. H. Han, W. Ke and Y. Katada: Mater. Sci. Eng. A, 2008, vol.490, pp.16-25.

[8] M. B. Leban and R. Tisu: Eng. Fail. Anal., 2013, vol.33, pp.430-438.

[9] H. Park, J. Y. Park, G. H. Kim and I. Sohn: Steel Res. Int., 2012, vol.83, pp.150-156.

[10] Z. Wang, Q. Shu and K. Chou: Metall. Mater. Trans. B, 2013, vol.44, pp.606-613.

[11] J. B. Kim and I. Sohn: J. Non-Cryst. Solids, 2013, vol.379, pp.235-243.

[12] Z. Hao, W. Chen and C. Lippold: Metall. Mater. Trans. B, 2010, vol.41, pp.805-812.

[13] M. Sharma, H. A. Dabkowska and N. Dogan: Steel Res. Int., 2019, vol.90, pp.1800367.

[14] Z. Ren, X. Hu, X. Hou, X. Xue and K. Chou: Int. J. Min. Met. Mater., 2014, vol.21, pp.345-352.

[15] B. Ozturk: Metall. Mater. Trans. B, 1992, vol.23, pp.523-526.

[16] S. K. Michelic and C. Bernhard: Scanning, 2017, vol.2017, pp.1-14.

[17] W. Wang, E. Gao, L. Zhou, L. Zhang and H. Li: J. Iron Steel Res. Int., 2019, vol.26, pp.335-364.

[18] T. Mukongo, P. C. Pistorius and A. M. Garbers-Craig: Ironmaking& steelmaking, 2004, vol.31, pp.135-143.

[19] P. Rocabois, J. Lehmann, C. Gatellier and J. P. Teres: Ironmaking& steelmaking, 2003, vol. 30, pp.95-100.

[20] O. K. Tokovoi and D. V. Shaburov: Steel In Trans., 2013, vol.43, pp.678-680.

[21] Z. Chen, M. Li, X. Wang, S. He and Q. Wang: Metals, 2019, vol.9, pp.635-650.

[22] L. Zhou, J. Li, W. Wang and I. Sohn: Metall. Mater. Trans. B, 2017, vol.48, pp.1943–1950.

[23] W. Wang, J. Li, L. Zhou and J. Yang: Met. Mater. Int., 2016, vol.22, pp.700-706.

Acknowledgments

This work was supported by the national natural science foundation of China (51874363, U1760202), the Natural Science Foundation of Hunan Province (2019JJ40345), and Hunan Scientific Technology projects (2018RS3022, 2018WK2051).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 5, 2019.

Rights and permissions

About this article

Cite this article

Zhou, L., Pan, Z., Wang, W. et al. Interfacial Interactions Between Inclusions Comprising TiO2 or TiN and the Mold Flux During the Casting of Titanium-Stabilized Stainless Steel. Metall Mater Trans B 51, 85–94 (2020). https://doi.org/10.1007/s11663-019-01746-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01746-2