Abstract

Basalt fiber reinforced polymer (BFRP) rebars reinforced coral aggregate concrete is a new type of concrete used in ocean engineering. In order to investigate the bond performance between BFRP rebars and coral concrete, 30 pull-out tests were carried out in 10 groups with different diameters of BFRP rebars, bonding lengths and strength of the coral concrete. The results show that good bonding between BFRP rebars and coral concrete were achieved. The main failure modes can be categorized as BFRP rebars pull out destruction, splitting failure of coral concrete and BFRP rebars fracture. The bond slip (\(\tau{\text{-}}s\)) curves of the BFRP rebars and coral concrete were obtained during the tests. It was found to be similar to the common concrete using fiber reinforced polymer (FRP) bars. The bond-slip relation can be roughly divided into micro-slip phase, slip phase, decline phase, and the residual stress stage. The bond between BFRP rebars and coral concrete increases with the increase of the bond length and diameter of BFRP rebars, but the average bond stress will decrease. Moreover, increasing the strength of coral concrete is effective to improve the bond performance of BFRP rebars. In this paper, the continuous bond slip model (Gao et al. in J Zhengzhou Univ 23:1–5, 2002) was used to represent the \(\tau{\text{-}}s\) constitutive relationship of BFRP rebars and coral concrete. The analysis show that the proposed model has a high degree of accuracy in representing \(\tau{\text{-}}s\) curve of BFRP rebars and coral concrete.

Similar content being viewed by others

1 Introduction

Under the trend of economic globalization and the vigorous development of marine construction around the world, marine projects such as cross-sea bridges, port terminals and island construction have ushered in a new wave of construction. The ocean contains a wealth of post-mortem products of coral polyps—coral debris, the main component of which is calcium carbonate. Without damaging the natural environment, the use of coral reefs and other island reef deposits as aggregates instead of ordinary gravel as well as seawater instead of freshwater in produce coral concrete, which can greatly reduce the production and transportation costs of reef construction, reduction in duration, and have a high economic value and important strategic significance(Zhang 2014; Wang 2012; Lyu et al. 2019). However, the corrosion caused by coral debris and the large amount of salt contained in seawater transferred to the surface of the reinforced steel through capillary holes are the main obstacles that have long plagued the application of coral concrete engineering under the humid and hot marine environment (Song et al. 2008; Angst et al. 2009). Fiber-reinforced composite (FRP) bars, which are characterized by high strength, light weight and high corrosion resistance, can replace steel bars(Francesco et al. 2004) and solve the problem of steel corrosion caused by high salinity of coral concrete and maintain good performance in marine environment.

In recent years, researchers have conducted extensive research on the factors affecting the bonding between FRP bars and concrete as well as correspondent bond-slip models. In 2004, (Pilakoutas and Zenon 2004) showed that when the strength of concrete is less than 15 MPa, the bond between FRP and concrete is determined by the strength of concrete,when the strength of concrete is greater than 30 MPa, the bond strength of FRP is determined by the strength of FRP rebars. In 2005, (Roman et al. 2005) conducted a bond test on FRP bars of different bond lengths and found that the bond strength decreased with the increase of anchor length. In 2007, Xue et al. (2007) tested the bond properties of Glass Fiber Reinforced Polymer (GFRP) bars and concrete with sticky sand, the results show that the bond strength decreases with the increase of the rib diameter and bond length. In 2013, (Sharaky et al. 2013) studied the influence of different factors on the bond performance of FRP reinforced concrete, the results show that fiber rib diameter and surface treatment of are the key factors affecting the performance and failure mode of the specimens. At present, there are five main kinds of bond-slip models. The BPE model (Eligehausen et al. 1983) was proposed by Elligehausen based on the bond-slip curve of deformed steel bars, which is also applicable to the bonding test of FRP bars and concrete. Malvar proposed a Malvar model (Malvar 1995) based on the bond test between GFRP and concrete. Cosenza removed the platform segment that did not exist in the BPE model, proposes a modified BPE model (Cosenza et al. 1996) which applies to some FRP bars. Cosenza and Tighiouart have successively proposed a new model of the bond slip curve to represent the ascending part of the curve, which is called CMR model (Cosenza et al. 1997; Tighiouart et al. 1998). Gao et al. (2002) proposed a continuous curve model for the fact that the ascending and descending segments were discontinuous in the existing model, who considered that the rising and falling segments of the bond-slip curve are a continuous curve.

The current research focuses on the bond performance of FRP bars reinforced concrete(Hunebum et al. 2014; Vilanova et al. 2015; Zhou et al. 2015); Antonietta et al. (2007) assessed the Bond Performances of FRP Rebar-Reinforced Concrete Gooranorimi et al. (2017) developed a Model for the Bond-Slip of a GFRP Bar in Concrete. There is still insufficient understanding of the bond performance of this type of concrete (Wang et al. 2018a, b, c; Yang et al. 2018; Zhao et al. 2011; Wang and Fan 2015). Studies have shown that basalt fiber reinforced polymer (BFRP) bars are the best anti-seawater corrosion FRP products (Dong et al. 2016; Altalmas and El Refai 2015), however, whether it can replace the conventional steel bar to solve the its durability problem depends on its bond strength to coral concrete. In view of this, the pull test of the basalt fibre reinforced composite (BFRP) bars reinforced coral concrete was conducted in this paper. The effects of BFRP bar diameter, bond length, coral concrete strength and coral aggregate properties on the bonding performance of BFRP bar and coral concrete and the mechanism of interface bonding damage between BFRP bar and coral concrete were analyzed. The research results will contribute to the development of FRP reinforced coral concrete structure in design theories and construction technology.

2 Pull out Test

2.1 Test Procedure

In this paper, as shown in Fig. 1, six tyeps of BFRP bars with different diameters and rib surface containing 70% fiber were used for testing. In order to reduce the error caused by the measurement, the average value must be measured several times when calculating rib spacing and rib depth. Due to the weak shear resistance of the fiber material, the tension test of the BFRP bar needs to be filled with a steel pipe sleeve and anchored to both ends of the BFRP bar, and the strain under the load of the BFRP bar is tested with a strain gauge in the middle of the BFRP bar in the same time, the elongation of the fascia was measured by an extensometer.

2.2 Test Material

The mechanical performance index is shown in Table 1. Coral debris were obtained from the dredged harbor and waterway of Weizhou Island, Beihai, Guangxi, China. As shown in Fig. 2, the shape, gradation and mechanical properties of coral aggregate are different from those of common aggregates. The strip shape particles accounts of 28.7% of the total aggregates. The mechanical property of BFRP bars, gradation and mechanical properties of aggregate are shown in Tables 2 and 3. The density of fine aggregate is 2675 kg/m3 and the gradation is 2.53. The P.O 42.5 grade ordinary Portland cement produced by Xingan Cement Co.; Ltd. is mixed to artificial 3.5% salt consistency of seawater.

2.3 Test Specimens

In accordance to the Chinese Standard for Testing Methods of Concrete Structures (GB/T 50152-2012) (Chinese Standard 2012), the specimens of 150 mm × 150 mm × 150 mm of coral concrete cubic with FRP bars were casted for pull out tests. In this paper, 10 groups of 30 coral concrete specimens with BFRP bars were designed to study the effects of BFRP bars diameter, bond length and strength of coral concrete on bond behavior. Specimens are denoted in term of Bd-l-c, in which D denotes the diameter of BFRP bars, l denotes the bond length, C denotes the strength grade of coral concrete. For example, B6-5d-C30 denotes the diameter of BFRP bars, d = 6 mm, bond length is l/d = 5, and strength grade of coral concrete is C30. In order to avoid the stress concentration caused by local compression of coral concrete at the loading end of specimens, the BFRP bars and coral concrete were separated by a certain length of plastic sleeve at loading end. The sleeve is also used to adjust the bond length, as shown in Fig. 3. In accordance to Chinese Technical Specification for Lightweight Aggregate Concrete (JGJ 51-2002) (Chinese Standard 2002), the coral concrete with strength grades of C15, C20 and C30 was prepared. The mix proportion is shown in Table 4. At the same time, six standard cubes and three standard prisms were casted in the same batch to determine the cube compressive strength and tensile strength of coral concrete. After demolition, the samples were cured under the same conditions for 28 days. The average test results were obtained as shown in Table 5, and the failure modes were shown in Fig. 4.

2.4 Pull out Tests Set up

The test is set up as shown in Fig. 5. The absolute slip value of the free end of the BFRP bar is measured by placing electronic dial gauge 1 at the center point of the free end of the BFRP bar; electronic dial gauge 2 measures the downward displacement of free-end coral concrete caused by the deformation of the plate as close as possible to the free end of the BFRP bar. The difference between them is the relative slip value of the free end of the BFRP bars. In order to avoid impact damage of the BFRP bar specimen, loading rate was intentionally kept uniform as VF = 0.03 d2 (VF is the loading rate, KN/min; d is the nominal diameter of the BFRP bar, mm), the loads and the corresponding reading of the two electronic dial gauges are recorded during the pull test, and the test phenomenon were observed. When the BFRP bars were broken, the coral concrete split or the free end slip exceeded 40 mm, the test was terminated.

The shear stress on the bond interface between BFRP bars and coral concrete is defined as the bond stress (Gao et al. 2000). The bond stress changes along the length of BFRP bars. This paper calculates the average bond stress by using formula (1).

where: \(\tau_{i}\) is the average bond stress, \(F_{i}\) is the pull-out force, \(d\) is the diameter of BFRP reinforcement, \(l_{a}\) is the bond length of BFRP reinforcement.

3 Test Results Analysis

3.1 Failure Mode and Bond-Slip (\(\tau{\text{-}}s\)) Relation

The main failure modes observed are pull-out failure of BFRP bar, splitting failure of coral concrete and fracture of BFRP bar. For the specimens with smaller diameter of BFRP bars and relative short bonding length, because the bonding force between BFRP bars and coral concrete is less than the ultimate tensile force of the bars, the failure mode of the pull out of the bars were dominant. As shown in Fig. 6a, there were powder coral concrete debris around the holes noticed during the tests, and the surface of the pulled-out BFRP bars was slightly worn with thin layer of concrete (Table 6).

When the diameter of BFRP bars is larger and the thickness of cover is smaller, the coral concrete splitting failure occurs. During the pull-out process, cracks first appear at the loading end of the concrete block. With the increase of load, cracks developed from inside to outside around the surface of BFRP bars, accompanied by small splitting sound. Then coral concrete is split into several blocks and separated from BFRP bars, as shown in Fig. 6b.

Due to internal damage to the BFRP bar or the stress concentration caused by the BFRP bar being too close to the circular hole of the steel plate during the loading process, as a result, the BFRP bar is broken. And the bond between the BFRP bar and the coral concrete does not produce relative slip when it is damaged, and the load at the time of destruction does not reach the limit tensile stress of the BFRP bar, as shown in Fig. 6c.

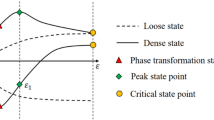

The bond-slip curve of BFRP bars-coral concrete is similar to ordinary concrete, the bond curve can also be divided into four stages: micro-slip stage, slip stage, descending stage and residual stage.

-

1.

Micro-slip stage: at the initial stage of loading, the relationship is close to linear change. The bond between BFRP bars and coral concrete is primarily rely on chemical glue. The slip is small, the bond stress increases rapidly, and the initial slope is large.

-

2.

Slip stage: With the increase of pull-out force, the bond-slip relationship curve gradually deviates from the straight line. The bond stress is primarily relied on the friction force, mechanical occlusion force and gradually reduced chemical bond force of BFRP bars and coral concrete. The curve is in the non-linear rising stage. Thereafter, the slip increases faster when the average bond stress reaches the ultimate bond stress, and the curve tends to be linear.

-

3.

Decline stage: After the average bond stress reaches the peak value, the bond stress does not disappear completely, but decreases gradually with the increase of slip. In this stage, the mechanical occlusion force decreases, and the friction force weakens gradually due to the wear of BFRP ribs, which leads to the rapid increase of slip.

-

4.

Residual stress stage: after the average bond stress drops to the lowest point, it starts to rise again, and the curve enters the residual stress stage. At this stage, the bond stress still consists of friction force and part of mechanical occlusion force. In this stage, the BFRP bars slip significantly, and the average bond stress decreases in the repeated fluctuation, and the fluctuation curve is approximately a sinusoidal function curve with decreasing amplitude.

3.2 Parameters Affecting the Bond Performance of BFRP Reinforced Coral Concrete

3.2.1 Effect of the BFRP Diameter to the Bond Behavior

The diameter and surface finish of BFRP bars have significant effects on their bond performance in coral concrete. With the increase of the diameter of BFRP bars, the bond force increases, but the average bond stress decreases, as shown in Fig. 7. The larger the diameter, the larger the bond area between BFRP bars and coral concrete, the larger the bond force that can be provided to resist the maximum pull-out force. The experimental results show that the bond strength between BFRP bars and coral concrete is correlated with their relative bond area (4/d) (Guo 2006), as shown in Fig. 8. In addition, it can be seen from Fig. 9 that the initial stiffness of specimens with different diameters of BFRP bars does not differ much in the early stage of the test. During the slip developing, the larger the diameter of BFRP bars, the greater the slip. There are two reasons: Firstly, the force distribution will become less uniform with the increase of diameter; secondly, with the increase of diameter, the relative values of rib spacing and rib depth and diameter (r/d, h/d) of BFRP bar used in the experiment decrease, causing the roughness of the surface of BFRP bar to decrease this further reduce the chemical adhesive force and mechanical interlocking force.

3.2.2 Effect of the Bond Length to the Bond Behavior

Figure 10 shows the 10 \(\tau{\text{-}}s\) curves of specimens with different bond length but same diameter of BFRP bars and grade of coral concrete. The bond lengths of BFRP bars in coral concrete are 5 d, 10 d and 12 d, respectively. As shown in Fig. 10, the maximum bond strength increases, and the bond strength decreases with the increase of BFRP bond length. Similarly, with the increase of bond length, the bond area increases, and then the maximum bond force increases. When the bond length is small, the high stress zone of BFPR is relatively long, the stress distribution is more uniform, and the ultimate bond stress is higher. When the bond length is large, the stress distribution is uneven and the high stress zone is relatively short, so the ultimate bond stress is lower (Guo 2006). It is also notice that, the wave length in the pullout curve is slightly equal to the rib spacing of the BFRP bar.

3.2.3 Effect of the Coral Concrete Strength to the Bond Behavior

For conventional reinforcement, the average bond strength of reinforced concrete is proportional to the square root of concrete strength. Though it is not applicable to FRP bars, the increase of the strength of coral concrete is still improve its bond performance, especially for coral concrete with lower strength grade. The chemical bonding force produced by cement cementitious on the surface of BFRP bars and the mechanical bonding force between BFRP bars and coral concrete will gradually increase with the increase of concrete strength. At the same time, it can effectively reduce the deformation and tensile splitting stress of concrete in the interface area, and then improve the bonding strength. As shown in the curves of C15, C20 and C30 pull-out specimens in Fig. 11. During the test, it was observed in most of the specimens that coral concrete cracked and the surface of BFRP bars were slight worn, accompanied by the weakening or shear failure of the ribs on the surface of the bars.

When the failure of specimens occurs mainly in the form of shear failure of BFRP bars, the remaining section of the bond slip curve of some specimens does not show the significant decline but shows an increase trend. The main reason is that when BFRP bars are pulled out from coral concrete, the surface resin and fibres are peeled off by concrete, which fills the interface gap and the internal pore of coral concrete to a certain extent. The accumulation of the debris further squeezes the rebar and produces certain extrusion force on BFRP bars, which leads to a certain increase in the bonding force between BFRP bars and coral concrete. The failure of low strength coral concrete specimens is mainly characterized by the crack of coral concrete at the bonding interface. The BFRP bars are worn off by the coral concrete become smoother at the surface, therefore the curve shows a downward trend.

3.2.4 Effect of the Coral Aggregate to the Bond Behavior

The bond strength between BFRP bars and coral concrete is lower than that between BFRP bars and ordinary concrete (Wu 2009) due to the influence of material properties such as low strength, high porosity, high compressibility and fragility of coral aggregate (Yu 2006), as shown in Fig. 12. Coral aggregate is more sensitive to the extrusion stress transmitted by BFRP bars than ordinary concrete aggregate. Under the same stress level, coral concrete will produce greater deformation, and its restraint effect on BFRP bars is weaker. In addition, the mechanical interlocking force between the ribs of BFRP bars and surrounding concrete is the main source of bond stress, With the increase of load, the concrete between the BFRP bar ribs will be sheared at the beginning stage when load is small, and the interlocking force decrease gradually when the load increases until it cannot produce sufficient mechanical interlocking force ribs, the bond strength decreases.

4 Bond-Slip Model

Establishing an accurate bond-slip relationship model between BFRP bars and concrete can well describe the bond-slip mechanism between FRP bars and concrete, which is an important theoretical basis for analysing the structural performance of FRP bars concrete members. At present, the bond-slip model mainly includes BPE model (Eligehausen et al. 1983), improved BPE model (Cosenza et al. 1996), Malvar model (Malvar 1995), CMR model (Cosenza et al. 1997; Tighiouart et al. 1998), and continuous curve model (Gao et al. 2002). The results show that the BPE model (Eligehausen et al. 1983) does not follow the real bond slip curve of the FRP reinforced concrete after the rising phase of the curve, and the error is large. The improved BPE model (Cosenza et al. 1996) has a good agreement in the ascending phase of the bond slip curve, rather than descending phase. The formula of the Malvar model (Malvar 1995) is too complicated, as many parameters are used, and the initial slope of the curve in microslip phase is small, but in fact, the bond slip curve in the micro-slip phase is close to infinity under the initial stage of loading. The CMR model (Cosenza 1997; Tighiouart et al. 1998) is only suitable for describing the ascending phase.

Since it is usually only necessary to consider the stage of structure in use, ignores the mechanical interlocking effect in the residual stress stage is a reasonable simplification of the model. Therefore, the continuous curve model (Gao et al. 2002) only has ascending and descending parts of the curve. It is optimized by combining the advantages of BPE model, improved BPE model, Malvar model and CMR model. It is in good agreement with the real bond behaviour of FRP bars reinforced ordinary concrete. The curve is continuous and smooth, so it is easy to use.

The ascending and descending phases of the continuous curve model (Gao et al. 2002) can be described as follows:

Ascending phase 0 < \(s\) < \(s_{u}\).

Descending phase \(s_{u}\) < s < \(s_{r}\)

where: \(\tau\) is the theoretical value of the bond stress, MPa; \(\tau_{u}\) is the peak ultimate bond stress, MPa; \(s_{u}\) is the free end slip value of the BFRP rib corresponding to the peak ultimate bond strength, mm; \(s\) is the measured free end slip value, mm; \(\tau_{r}\) is the bond strength of the peak and valley points of the descending section, MPa; \(s_{r}\) is the slip value of the free end of the peak and valley points of the descending section, mm.

As shown in Fig. 13, the bond slip curve fitted by the above continuous curve model (Gao et al. 2002) agrees well at zero point, peak point, convergence point and falling phase, however, the rising phase of the fitted curve is significantly different from the actual value in the micro-slip and slip phase, and then the continuous curve model improved by Gao (2009) for the ascending segment is used, as follows:

Ascending segments 0 < \(s\) < \(s_{u}\).

In this paper, the continuous curve model and improved model (Gao 2009) are used to develop the bond-slip model of BFRP and coral concrete, as shown in Fig. 13.

It can be seen from the graph that the rising part of the curve is non-linear, the peak value is continuous and smooth, and the descending part also fit well with the test result. It can be concluded that the bond-slip curve from the continuous curve model and subsequent improved model match well with the test result, indicating it can better describe the bond-slip of BFRP bars reinforced coral concrete. The model can be further used for the design of BFRP bars reinforced coral concrete.

5 Conclusion

-

1.

BFRP bars reinforced coral concrete can maintain good bonding performance and provide a certain reference for the design and engineering application of FRP-Coral Concrete. Its bond-slip behaviour is similar to those of FRP reinforced common concrete. There are three main failure modes: pull-out failure of BFRP bars, splitting failure of coral concrete and fracture of BFRP bars. The bond-slip curves can be roughly divided into micro-slip stage, slip stage and decline stage and residual stress stage.

-

2.

The diameter and surface condition of BFRP bars have a significant influence on the bond strength between BFRP bars and coral concrete. The bond strength between BFRP bars and coral concrete increases with the increase of the bond length and diameter of BFRP bars, but the average bond stress decreases. Increasing the surface roughness of BFRP bars can significantly improve the bond strength with coral concrete.

-

3.

Influenced by the material characteristics of coral concrete, the bond strength between BFRP bars and coral concrete is lower than that between BFRP bars and ordinary concrete. Under the same stress level, greater slip and deformation will occur. Increasing the strength of coral concrete is beneficial to improve its bond performance of BFRP bars, and the improvement of coral concrete with lower strength level is more obvious.

-

4.

The bond-slip curve developed based on the continuous curve model matched well with the test results. The model is suitable for the bond-slip constitutive relationship between BFRP bars and coral concrete.

Availability of data and materials

The data used to support the findings of this study are available from the authors upon request.

References

Altalmas, A., El Refai, A., & Abed, F. (2015). Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Construction and Building Materials, 81, 162–171.

Angst, U., Elsener, B., Larsen, C. K., et al. (2009). Critical chloride content in reinforced concrete a review. Cement and Concrete Research, 39(12), 1122–1138.

Antonietta Aiello, M., Leone, M., & Pecce, M. (2007). Bond performances of FRP rebars-reinforced concrete. Journal of Materials in Civil Engineering., 19(3), 205–213.

Chinese Standard. (2002). Technical specification for lightweight aggregate concrete: JGJ 51-2002. Beijing: China Architecture & Building Press.

Chinese Standard. (2012). Standard for test method of concrete structures: GB/T 50152-2012. Construction and Building Materials, 18(2004), 491–503.

Cosenza, E., Manfredi, G., & Realfonzo, R. (1996). Bond characteristics and anchorage length of FRP rebars. In M. M. EL-Badry (Ed.), Advanced Composite Materials in Bridges and Structures and International Conference (pp. 909–916). Montreal: Canadian Society for Civil Engineering.

Cosenza, E., Manfredi, G., & Realfonzo, R. (1997). Behavior and modeling of bond of FRP rebars to concrete. Journal of Composites for Construction, 1(2), 40–51.

Dong, Z., Wu, G., Xu, B., et al. (2016). Bond durability of BFRP bars embedded in concrete under seawater conditions and the long-term bond strength prediction. Materials and Design, 92, 552–562.

Eligehausen, R., Popov, E. P. & Bertero, V. V. (1983). Local bond stress-slip relationships of deformed bars under generalized excogitations. Report no. 83/23, EERC (pp. 162–169) Berkely: University of California.

Gao, D., & Benmokrane, B. (2000). Bonding mechanism and calculating method for embedded length of fiber reinforced polymer rebars in concrete. Journal of Hydraulic Engineering., 11, 70–78.

Gao, D., Li, C. H. & Li, S., et al. (2009). Experimental research on bond-slip performance of GFRP rebar with concrete. In: Proceedings of the 6th national FRP academic exchange meeting. Chinese Society of Civil Engineering, National Committee of FRP and Engineering Applications: Chinese Society of Civil Engineering (pp. 107–112).

Gao, D., Xie, J., & Li, C. (2002). Basic problems of bonding properties of fiber polymer reinforced concrete. Journal of Zhengzhou University., 23(1), 1–5.

Gooranorimi, O., Suaris, W., & Nanni, A. (2017). A model for the bond-slip of a GFRP bar in concrete. Engineering Structures, 146, 34–42.

Guo, H. (2006) Experimental study and theoretical analysis on bond and anchorage properties of FRP bars concrete (Master’s thesis). Southeast University.

Ko, H., Matthys, S., Palmieri, A., & Sato, Y. (2014). Development of a simplified bond stress-slip model for bonded FRP-concrete interfaces. Construction and Building Materials, 68, 142–157.

Lyu, B., Wang, A., et al. (2019). Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate. Cement and Concrete Composites, 100(7), 25–34.

Malvar, L. J. (1995). Tensile and pond properties of GFRP reinforcing bars. ACI Materials Journal, 92(3), 54–59.

Micelli, F., & Nanni, A. (2004). Durability of FRP rods for concrete structures. Construction and Building materials., 18, 491–503.

Okelo, R., & Yuan, R. L. (2005). Bond strength of fiber reinforced polymer rebars in normal strength concrete. Journal of Composites for Construction, 9, 203–213.

Pilakoutas, K., & Achillides, Z. (2004). Bond behavior of fiber reinforced polymer bars under direct pull out conditions. Journal of Composites for Construction, 8(2), 173–181.

Sharaky, I. A., Torres, L., Baena, M., & Mias, C. (2013). An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Composite Structures, 99, 350–365.

Song, H., Lee, C., & Ann, K. (2008). Factors influencing chloride transport in concrete structures exposed to marine environments. Cement & Concrete Composites, 30(2), 113–121.

Tighiouart, B., Benmokrane, B., & Gao, D. (1998). Investigation of bond in concrete member with fibre reinforced polymer (FRP) bars. Construction and Building Materials, 12(8), 453–462.

Vilanova, M., Baena, L. Torres, & Barris, C. (2015). Experimental study of bond-slip of GFRP bars in concrete under sustained loads. Composites: Part B, 74, 42–52.

Wang, L., & Fan, L. (2015). Strength characteristic and failure pattern analysis on coral debris concrete. China Concrete and Cement Products, 1, 1–4.

Wang, L., Li, W., Chen, S. H., et al. (2018a). Effects of sea water soaking on the bonding properties of FRP bars-coral concrete. Journal of Composite Materials, 35, 3458–3465.

Wang, L., Mao, Y., Li, W., et al. (2018b). Experimental research on bond performance between GFRP bars and the coral concrete. Journal of Building Materials, 21, 286–292.

Wang, L., Mao, Y., Lv, H., et al. (2018c). Bond properties between FRP bars and coral concrete under seawater conditions at 30, 60, and 80°. Construction and Building Materials, 162, 442–449.

Wang, L., Zhao, Y., & Lu, H. (2012). Prospect on the properties and application situation of coral aggregate concrete. Concrete, 2, 99–113.

Wu, F. (2009). The experimental research on bond behavior between BFRP rebars and the concrete (Master’s thesis). Liaoning: Dalian University of Technology.

Xue, W., Zheng, Q., et al. (2007). Sand deformation GFRP bond performance study. Civil Engineering Journal., 40(12), 59–68.

Yang, S. H., Yang, C. H., et al. (2018). Study on bond performance between FRP bars and seawater coral aggregate concrete. Construction and Building Materials, 173, 272–288.

Yu, H. (2006). Physical and mechanical properties of coral sand in the Nansha islands. Marine Science Bulletin-Beijing Then Tianjin-English Edition, 8(2), 31.

Zhang, H. (2014). Study on strategic value assessment of Nansha islands (Master’s thesis). Nanjing University.

Zhao, Y., Han, C., Zhang, S., et al. (2011). Experimental study on the compression age strength of seawater coral concrete. Concrete, 2, 43–45.

Zhou, Y., Fan, Z., Du, J., et al. (2015). Bond behavior of FRP-to-concrete interface under sulfate attack: An experimental study and modeling of bond degradation. Construction and Building Materials, 85, 9–21.

Acknowledgments

This paper is supported by the National Natural Science Foundation of China (51568013), the High-Level Innovation Team in Colleges and Universities and Excellence Scholar Program “Island and Coastal Environment Concrete Structure “in Guangxi (201738-2) and Innovation-driven Development Project “Development and Demonstration of High-Erosion Construction Materials in Complex Marine Environment” in Guangxi (AA18242007-5). The views expressed are the authors’ alone.

Funding

Funder: National Natural Science Foundation of China. Award Number 51868014.

Funder: Colleges and Universities and Excellence Scholar Program, Guangxi. Award Number: 201738-2.

Funder: Innovation-driven Development Project, Guangxi, Award Number AA18242007-5.

Author information

Authors and Affiliations

Contributions

LW designed the whole research methodology. LJY carried out the experiment test. LW and FF designed the structure of the manuscript. FF drafted the manuscript. LW, FF and KQ reviewed the manuscript. LW and FF revised the final manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Journal information: ISSN 1976-0485 / eISSN 2234-1315

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wang, L., Song, Z., Yi, J. et al. Experimental Studies on Bond Performance of BFRP Bars Reinforced Coral Aggregate Concrete. Int J Concr Struct Mater 13, 52 (2019). https://doi.org/10.1186/s40069-019-0367-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40069-019-0367-7