Abstract

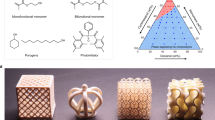

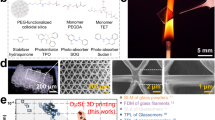

The digital fabrication of oxide glasses by three-dimensional (3D) printing represents a major paradigm shift in the way glasses are designed and manufactured, opening opportunities to explore functionalities inaccessible by current technologies. The few enticing examples of 3D printed glasses are limited in their chemical compositions and suffer from the low resolution achievable with particle-based or molten glass technologies. Here, we report a digital light-processing 3D printing platform that exploits the photopolymerization-induced phase separation of hybrid resins to create glass parts with complex shapes, high spatial resolutions and multi-oxide chemical compositions. Analogously to conventional porous glass fabrication methods, we exploit phase separation phenomena to fabricate complex glass parts displaying light-controlled multiscale porosity and dense multicomponent transparent glasses with arbitrary geometry using a desktop printer. Because most functional properties of glasses emerge from their transparency and multicomponent nature, this 3D printing platform may be useful for distinct technologies, sciences and arts.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding authors on reasonable request.

Code availability

The *.stl and encoded microstructure print files are available from the corresponding authors on reasonable request.

References

Pfaender, H. G. Schott Guide to Glass (Springer, 2012).

Pilkington, L. A. B. Review lecture: the float glass process. Proc. R. Soc. Lond. A 314, 1–25 (1969).

Hale, D. Strengthening of silicate glasses by ion exchange. Nature 217, 1115 (1968).

Klein, J. et al. Additive manufacturing of optically transparent glass. 3D Print. Addit. Manuf. 2, 92–105 (2015).

Nguyen, D. T. et al. 3D‐printed transparent glass. Adv. Mater. 29, 1701181 (2017).

Destino, J. F. et al. 3D printed optical quality silica and silica–titania glasses from sol–gel feedstocks. Adv. Mater. Technol. 3, 1700323 (2018).

Luo, J. et al. Additive manufacturing of transparent soda-lime glass using a filament-fed process. J. Manuf. Sci. Eng. 139, 061006 (2017).

Kotz, F. et al. Three-dimensional printing of transparent fused silica glass. Nature 544, 337–339 (2017).

Liu, C., Qian, B., Ni, R., Liu, X. & Qiu, J. 3D printing of multicolor luminescent glass. RSC Adv. 8, 31564–31567 (2018).

Bártolo, P. J. Stereolithography: Materials, Processes and Applications (Springer, 2011).

Wong, K. V. & Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 208760 (2012).

Wu, C., Luo, Y., Cuniberti, G., Xiao, Y. & Gelinsky, M. Three-dimensional printing of hierarchical and tough mesoporous bioactive glass scaffolds with a controllable pore architecture, excellent mechanical strength and mineralization ability. Acta Biomater. 7, 2644–2650 (2011).

Tesavibul, P. et al. Processing of 45S5 Bioglass® by lithography-based additive manufacturing. Mater. Lett. 74, 81–84 (2012).

Zocca, A. et al. SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer. J. Mater. Res. 28, 2243–2252 (2013).

Eckel, Z. C. et al. Additive manufacturing of polymer-derived ceramics. Science 351, 58–62 (2016).

Zanchetta, E. et al. Stereolithography of SiOC ceramic microcomponents. Adv. Mater. 28, 370–376 (2016).

Schmidt, J. & Colombo, P. Digital light processing of ceramic components from polysiloxanes. J. Eur. Ceram. Soc. 38, 57–66 (2018).

Brinckmann, S. A. et al. Stereolithography of SiOC polymer‐derived ceramics filled with SiC micronwhiskers. Adv. Eng. Mater. 20, 1800593 (2018).

Cooperstein, I., Shukrun, E., Press, O., Kamyshny, A. & Magdassi, S. Additive manufacturing of transparent silica glass from solutions. ACS Appl. Mater. Interfaces 10, 18879–18885 (2018).

Sanchez, C., Julián, B., Belleville, P. & Popall, M. Applications of hybrid organic–inorganic nanocomposites. J. Mater. Chem. 15, 3559–3592 (2005).

Nakanishi, K. & Soga, N. Phase separation in silica sol–gel system containing polyacrylic acid. I. Gel formation behavior and effect of solvent composition. J. Non-Cryst. Solids 139, 1–13 (1992).

Rabinovich, E. Preparation of glass by sintering. J. Mater. Sci. 20, 4259–4297 (1985).

Zhu, J., Chen, L. Q., Shen, J. & Tikare, V. Coarsening kinetics from a variable-mobility Cahn–Hilliard equation: application of a semi-implicit Fourier spectral method. Phys. Rev. E 60, 3564–3572 (1999).

Baret, G., Madar, R. & Bernard, C. Silica‐based oxide systems. I. Experimental and calculated phase equilibria in silicon, boron, phosphorus, germanium and arsenic oxide mixtures. J. Electrochem. Soc. 138, 2830–2835 (1991).

Klenin, V. J. & Shmakov, S. L. Features of phase separation in polymeric systems: cloud-point curves (discussion). Univers. J. Mater. Sci. 1, 39–45 (2013).

Dougherty, R. & Kunzelmann, K.-H. Computing local thickness of 3D structures with ImageJ. Microsc. Microanal. 13, 1678–1679 (2007).

Acknowledgements

This research was supported by the Swiss National Science Foundation through the National Centre of Competence in Research for Bio-Inspired Materials. Additional support by the Swiss Competence Center for Energy Research (SCCER—Capacity Area A3: Minimization of Energy Demand) and the Swiss National Science Foundation (consolidator grant no. BSCGIO_157696) is also acknowledged. The authors thank D. Naselli for helpful discussions and A. Lauria for support with the photoluminescence measurements.

Author information

Authors and Affiliations

Contributions

D.G.M., L.B., K.M. and A.R.S. conceived the idea together and designed the experiments. For the experimental work, D.G.M. focused more on the alkoxide chemistry, L.B. developed the sintering procedure and K.M. programmed the 3D printing microstructure. All the remaining experimental work was carried out by D.G.M., L.B. and K.M. D.G.M., L.B., K.M. and A.R.S. conducted the analysis and co-wrote the paper. All authors discussed the results and their implications, and revised the manuscript at all stages.

Corresponding authors

Ethics declarations

Competing interests

The authors have filed patent application EP18191209.8 related to this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Table 1, Supplementary Figs. 1–7 and Supplementary references.

Rights and permissions

About this article

Cite this article

Moore, D.G., Barbera, L., Masania, K. et al. Three-dimensional printing of multicomponent glasses using phase-separating resins. Nat. Mater. 19, 212–217 (2020). https://doi.org/10.1038/s41563-019-0525-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-019-0525-y

This article is cited by

-

Three-dimensional printing of silica glass with sub-micrometer resolution

Nature Communications (2023)

-

Templated freezing assembly precisely regulates molecular assembly for free-standing centimeter-scale microtextured nanofilms

Science China Chemistry (2023)

-

Additive manufacturing by digital light processing: a review

Progress in Additive Manufacturing (2023)

-

Direct sound printing

Nature Communications (2022)

-

λ/30 inorganic features achieved by multi-photon 3D lithography

Nature Communications (2022)