Abstract

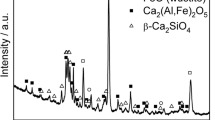

Reuse of steelmaking slags is important for the effective use of natural resources. Free magnesia (f-MgO) in steelmaking slag may cause serious problems because of a hydration reaction followed by expansion when it is reused for road construction. We present a promising method to identify f-MgO that causes volume expansion rapidly by investigating cathodoluminescence (CL) images and spectra of a steelmaking slag sample. f-MgO emitted red–orange luminescence from a peak at 755 nm. The mineral phases, 3CaO·SiO2 and 2CaO·SiO2, emitted red and yellow luminescence from peaks at 720 and 590 nm, respectively. No luminescence of FeO and 2CaO·Fe2O3 was detected. f-MgO changed its composition in the slag sample that was immersed in hot (70 °C) water for a week. f-MgO that was responsible for the volume expansion (combined content of FeO and MnO below 30 mass pct) retained a red–orange luminescence, whereas the other f-MgO lost luminescence. The CL intensity of the f-MgO that retained luminescence was more than 10 times larger than that of 3CaO·SiO2 and 2CaO·SiO2. Therefore, we can distinguish f-MgO that causes volume expansion by detecting the intense red–orange luminescence from the peak at 755 nm in the CL image within a few seconds.

Similar content being viewed by others

References

1. Y. Jiang, T.-C. Ling, C. Shi and S.-Y. Pan: Resour. Conserv. Recycl., 2018, vol. 136, pp. 187-197.

2. J. Li, S.Y. Pan, H. Kim, J.H. Linn and P.C. Chiang: J. Environ. Manage., 2015, vol. 162, pp. 158-70.

3. S.-Y. Pan, R. Adhikari, Y.-H. Chen, P. Li and P.-C. Chiang: J. Clean Prod., 2016, vol. 137, pp. 617-631.

4. İ. Yüksel: Environ. Dev. Sustain., 2016, vol. 19, pp. 369-384.

5. G. Wang, Y. Wang and Z. Gao: J. Hazard. Mater., 2010, vol. 184, pp. 555-560.

6. C. Kambole, P. Paige-Green, W.K. Kupolati, J.M. Ndambuki and A.O. Adeboje: Constr. Build. Mater., 2017, vol. 148, pp. 618-631.

7. S. Chatterji: Cem. Concr. Res., 1995, vol. 25, pp. 51-56.

8. L.F. Amaral, I.R. Oliveira, P. Bonadia, R. Salomão and V.C. Pandolfelli: Ceram. Int., 2011, vol. 37, pp. 1537-1542.

Juckes LM (2003) Trans Inst Min Metall C 112:177-197

Japanese Industrial Standards (2018) JI Standards. Japanese Industrial Standards, Tokyo

11. F.M. Lea: The Chemistry of Cement and Concrete. 3rd ed., Edward Arnold, Glasgow, 1970, pp. 111-112.

12. K. Hanada, M. Inose, S. Sato, K. Watanabe and K. Fujimoto: Tetsu-to-Hagané, 2016, vol. 102, pp. 24-28.

13. M. Kato, K. Tsukagoshi, M. Aimoto, S. Saito and M. Shibukawa: ISIJ Int., 2018, vol. 58, pp. 1834-1839.

14. K. Kanehashi and M. Aimoto: Tetsu-to-Hagané, 2013, vol. 99, pp. 543-551.

15. H. Tsuneda, S. Imashuku and K. Wagatsuma: Tetsu-to-Hagané, 2019, vol. 105, pp. 30-37.

16. S. Imashuku, K. Ono, R. Shishido, S. Suzuki and K. Wagatsuma: Mater. Charact., 2017, vol. 131, pp. 210-216.

17. S. Imashuku, K. Ono and K. Wagatsuma: X-Ray Spectrom., 2017, vol. 46, pp. 131-135.

18. S. Imashuku, K. Ono and K. Wagatsuma: Microsc. Microanal., 2017, vol. 23, pp. 1143-1149.

19. S. Imashuku and K. Wagatsuma: Metall. Mater. Trans. B, 2018, vol. 49, pp. 2868-2874.

S. Imashuku and K. Wagatsuma: Surf. Interface Anal., 2019, vol. 51, pp. 31-34.

S. Imashuku and K. Wagatsuma: X-Ray Spectrom., 2019, vol. 48, pp. 522-526.

S. Imashuku and K. Wagatsuma: Metall. Mater. Trans. B, 2019. https://doi.org/10.1007/s11663-019-01732-8.

23. S. Imashuku and K. Wagatsuma: Corros. Sci., 2019, vol. 154, pp. 226-230.

24. W.E. Lee, S. Zhang and M. Karakus: J. Mater. Sci., 2004, vol. 39, pp. 6675-6685.

Musante L, Martorello LF, Galliano PG, Cavalieri AL, Tomba Martinez AG (2012) Ceram Int 38:4035-4047

26. M. Karakus, M.D. Crites and M.E. Schlesinger: J. Microsc., 2000, vol. 200, pp. 50-58.

27. A. Niida, K. Okohira, A. Tanaka and T. Kai: Tetsu-to-Hagané, 1983, vol. 69, pp. 42-50.

28. M. Gautier, J. Poirier, F. Bodénan, G. Franceschini and E. Véron: Int. J. Miner. Process., 2013, vol. 123, pp. 94-101.

29. C. Liu, M. Guo, L. Pandelaers, B. Blanpain and S. Huang: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3237-3240.

30. S.-M. Liang and R. Schmid-Fetzer: J. Eur. Ceram. Soc., 2018, vol. 38, pp. 4768-4785.

31. T. Kato, G. Okada and T. Yanagida: J. Ceram. Soc. Jpn., 2016, vol. 124, pp. 559-563.

Gaft M, Reisfeld R, Panczer G (2005) Luminescence Spectroscopy of Minerals and Materials. Springer, Berlin

33. K. Ramseyer and J. Mullis: Geologic Application of Cathodoluminescence of Silicates. Springer, Berlin, 2000, pp. 177-191.

34. R. Dai, C. Tong, Y. Zhu, C. Xu, L. Yang and Y. Li: Opt. Mater., 2018, vol. 85, pp. 32-40.

35. Y. Sato, H. Kato, M. Kobayashi, T. Masaki, D.H. Yoon and M. Kakihana: Angew. Chem. Int. Ed. Engl., 2014, vol. 53, pp. 7756-9.

36. Z. Mao, Z. Lu, J. Chen, B.D. Fahlman and D. Wang: J. Mater. Chem. C, 2015, vol. 3, pp. 9454-9460.

37. P. Wu, G. Eriksson, A.D. Pelton and M. Blander: ISIJ Int., 1993, vol. 33, pp. 26-35.

38. P. Wu, G. Eriksson and A.D. Pelton: J. Am. Ceram. Soc., 1993, vol. 76, pp. 2065-2075.

39. A.S. Marfunin: Spectroscopy, Luminescence and Radiation Centers in Minerals. Springer-Verlag, Berlin, 1979.

40. D. Habermann, R.D. Neuser and D.K. Richter: Quantitative High Resolution Spectral Analysis of Mn 2+in Sementary Calcite. Springer, Berlin, 2000, pp. 331-358.

41. H. Suito, T. Yokomaku, Y. Hayashida and Y. Takahashi: Tetsu-to-Hagané, 1977, vol. 63, pp. 2316-2325.

Acknowledgments

This study was supported by JSPS KAKENHI (Grant Number 17H03435).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 26, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Imashuku, S., Tsuneda, H. & Wagatsuma, K. Rapid and Simple Identification of Free Magnesia in Steelmaking Slag Used for Road Construction Using Cathodoluminescence. Metall Mater Trans B 51, 27–34 (2020). https://doi.org/10.1007/s11663-019-01724-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01724-8