Abstract

Bioelectrochemical systems (BES) have been intensively studied as a new technology for wastewater treatment. However, the treatment efficiency of BES anodes is limited and the anode effluent usually cannot be directly discharged or reused. To enhance the treatment, BES cathodes may be used for additional treatment of selected contaminants. This has been investigated in a number of approaches, which can be grouped into cathode-stimulated treatment and cathode-supported treatment. The former involves electron transfer directly to reduce contaminants like nitrate or dye compounds, while the latter can accomplish contaminant removal by aerobic oxidation, algal growth, production of strong oxidants for advanced oxidation, and/or membrane treatment. This paper aims to provide a concise view and discussion on the cathode-promoted wastewater treatment in BES, analyze challenges pertaining to the cathode treatment, and offer suggestions on the future development of BES for maximized treatment performance.

Similar content being viewed by others

Introduction

Bioelectrochemical systems (BESs) are dynamic systems that utilize the interaction between microbes and solid electron acceptors/donors (e.g., an electrode) to accomplish the removal of contaminants in wastewater with simultaneous electricity generation.1 In a typical BES such as a microbial fuel cell (MFC), microorganisms oxidize organics in the anode and transfer electrons to an anode electrode, which then transports electrons to a cathode electrode for reducing a terminal electron acceptor like oxygen.2 This electron flow generates an electrical current or power when a load is added to the circuit. Researchers have used the electron flow to achieve hydrogen production (via hydrogen evolution reaction) in microbial electrolysis cells (MECs),3 drive desalination in microbial desalination cells (MDCs),4 or synthesize value-added compounds in microbial electrosynthesis cells (MES).5,6 In recent years, BESs have been advanced particularly in system scaling up, and several large-scale systems have been investigated for treating various wastewaters.2,7 In addition, there is a great interest in employing BESs for recovery of valuable resources from wastewater, including nutrient, energy, and water (NEW).8

Along the BES development, wastewater treatment is considered a basic function and also of great importance to possible implementation of this technology. Organic removal is a primary goal for wastewater treatment, and in BESs the removal efficiency is highly variable depending on several factors such as the composition and strength of wastewater, hydraulic retention time, reactor configurations, temperature, etc. Most removal occurs in the BES anode for producing electrons.9 In general, BESs can achieve good removal of organic matter from low-strength wastewater or simple organic substrates, while the removal efficiency would become much lower when dealing with high-strength wastewater or complex organic compounds.10 Nutrients such as nitrogen and phosphorus, however, can hardly be removed in the anode of a BES, because their removal (if via biological pathways) would need to involve aerobic conditions. Therefore, the effluent from the BES anode is a partially treated stream, which still contains residue compounds such as organics and nutrients. This has been demonstrated in several previous studies of MFCs treating actual domestic wastewater, in which the removal of both organic and ammonium compounds were significantly enhanced with cathodic treatment.11,12 In many cases, such as a stream cannot be either directly discharged or reused for non-potable purposes.

To enhance the treatment of wastewater in BESs while avoiding the addition of more reactors, we can consider to take advantage of the cathode of a BES for further treatment. A cathode can provide more physical space to host biological processes for extended treatment, and cathodic reduction reaction can be used to accomplish the removal of several types of contaminants that cannot be removed in the anode. Integration of membrane in the cathode will be able to reject a wide range of contaminants including pathogens and deliver a high-quality effluent. Although cathodes have been investigated for wastewater treatment, there have not been any strong attentions or focuses in the past BES studies. This paper aims to provide a concise perspective on cathode-promoted wastewater treatment in BESs, discuss and analyze several major cathodes stimulated or supported treatments, and encourage more efforts to explore this approach for improving BES effluent quality.

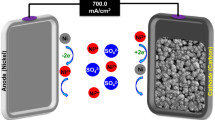

Cathode-stimulated treatment

Cathode-stimulated treatment is realized by accepting electrons from a cathode electrode; thus, it is a reduction reaction process. In theory, any compounds that can be reduced will be able to act as electron acceptors to a BES cathode; however, in reality such a reduction is only feasible in the presence of an appropriate catalyst, either abiotic or biological, which can reduce the activation energy and thus facilitate electron transfer from a cathode electrode to a terminal electron acceptor. In addition to commonly used electron acceptors such as oxygen (for electricity generation) and protons (for hydrogen production), there have been various compounds that can be removed by cathodic reduction reactions, including recalcitrant compounds, metals, nitrogen compounds, and carbon dioxide (Fig. 1). Because carbon dioxide is not a contaminant (despite a greenhouse gas and recently intensive research of microbial electrosynthesis13), we will not discuss its reduction in BESs here.

Although many recalcitrant compounds require an oxidation removal process, a few can be removed by reduction. For example, nitrobenzene, a widely used industrial compound, can be cathodically reduced to aniline that is less toxic and more biodegradable, and this approach could significantly reduce organic dosage compared to conventional anaerobic degradation.14 Many dye compounds have been studied for reduction-based removal and decolorization in BESs.15 Perchlorate, an emerging drinking contaminant, can act as a sole electron acceptor in the cathode of an MFC.16 Despite potential benefits of low energy consumption, there is a key issue in BES removal of those compounds: incomplete removal. As mentioned above, nitrobenzene is reduced to aniline. Sulfanilic acid was found to be a major product of dye reduction in the BES cathode.15 Thus, post treatment such as aerobic treatment may still be needed. In addition, some studies applied co-substrates to enhance decolorization of dye compounds by adding easily degraded organic compounds into the cathode.17,18 Such an approach is questionable, because those added organic compounds are electron donors and will compete with the cathode electrode for electron donation, thereby lowering the efficiency of the cathodic electron transfer.

Metals, especially heavy metals, are important contaminants produced from various industries; they are toxic, not biodegradable, and widely distributed, and their removal is usually involving immobilization and/or filtration.19 Many metal compounds will change their soluble state to an insoluble state after reduction reactions, and such a process can be conducted by a BES cathode.20 A classic example is chromium: hexavalent chromium (Cr(VI)) is carcinogenic and mutagenic, and also highly soluble in water; cathodic reaction of Cr(VI), catalyzed by microorganisms or abiotic catalysts, produces Cr(III) that is much less toxic and also less soluble, and thus can be removed via precipitation.21 In recent years, more efforts have been devoted to recovery of valuable metals such as gold and silver, a step beyond removal. More details about BES removal and recovery of metals can be found in several review papers.20,22 What has been missing in the vast literature on this subject is how to effectively and efficiently collect the recovered metals. Abiotic reduction of metals by accepting electrons from a cathode electrode is expected to deposit metals on the surface of the cathode electrode, in a way like electroplating. However, many BES studies employed microorganisms to catalyze metal reduction, resulting in intracellular metal deposition. By using a fluorescent probe, researchers found that less than half of total chromium accumulated within the bacterial cells, consisting of a composite of Cr(III) ions and other forms of chromium complex.23 Thus, there could be two ways to collect the recovered metals: (1) intracellular accumulation of metals may allow the collection by harvesting microbial cells (with further extraction); and (2) deposition on the cathode electrode may be extracted for metal collection. However, both methods could affect the operation of BESs (e.g., loss of microorganisms and periodic replacement of cathode electrodes). Furthermore, metal precipitated on the wall and separator of a BES reactor will require an appropriate removal method without significant influence on BES operation.

Unlike recalcitrant and metal compounds that are mostly presented in industrial wastewaters, nitrogen is a key inorganic contaminant in domestic wastewaters and can be in the forms of ammonia, nitrite, nitrate, etc. Cathodic reduction of nitrate was firstly demonstrated in a BES containing a pure culture Geobacter metallireducens that could reduce nitrate to nitrite with an electrode as the sole electron donor.24 This finding was extended to a mixed-culture BES achieving a removal rate of 0.080 kg NO3−-N m−3 and a conclusion that bioelectrochemical nitrate reduction did not involve hydrogen gas as an electron donor.25 Since then, there have been many more studies of nitrate reduction in BES, as summarized in several review papers.26,27,28 The characteristics of water/wastewater can impose a strong effect on BES nitrate reduction. In general, two types of streams have been investigated for nitrate removal in BES cathodes. First, domestic wastewater in which nitrogen is in the form of ammonia must go through a nitrification process that converts ammonia to nitrate. This requires either a separate nitrifying reactor or combined nitrification and bioelectrochemical denitrification in a cathode.29 Precise control of dissolved oxygen is a key to successful combination of nitrification and denitrification. Second, nitrate is a common contaminant in groundwater and in this scenario, bioelectrochemical denitrification can be directly applied. However, deployment of BESs for groundwater nitrate removal must consider the associated energy demand, depending on how/where the treatment system will be installed. It was estimated that a specific energy consumption of 0.341 and 1.602 kWh kg NO3−-N-1 could be obtained from in situ and ex situ MFC treatments, respectively, with pumping energy as the main contributor.30

Cathode-supported treatment

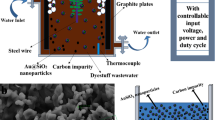

Cathode-supported treatment occurs in the cathode compartment but does not directly accept electrons from the cathode electrode. That is, such a treatment takes advantage of the physical space of a cathode compartment, and may have positive or negative effects on the cathode electrode/reactions. Several examples of such treatments, such as loop operation, algal bioreactor, advanced oxidation, and membrane integration, are summarized in Table 1.

Loop operation was created to use the cathode compartment as a secondary treatment unit by flowing the anode effluent into the cathode. This helps address the issue of insufficient organic removal by the anode. It was reported that treating the anode effluent in the cathode could enhance the COD removal from 75 to 92%.31 A more significant benefit is the improved transfer of protons from the anode to the cathode that compensates the alkalization of a catholyte and results in smaller pH difference between the two electrodes, thereby eliminating the pH adjustment.32 One study observed that a loop operation has increased the maximum power generation by 180% in a batch mode and 380% in a continuous mode as compared to a negative control.31 However, introducing organic compounds in the anode effluent into the cathode also brings in electron donors, which will compete with the cathode electrode for terminal electron acceptors (e.g., oxygen). This competition can inhibit the cathodic reaction. Furthermore, fast growth of heterotrophic bacteria on organic matter will form biofilm on the surface of the cathode electrode and this biofouling would further decrease the cathode efficiency. Thus, using the cathode for improving organic removal may not be an ideal approach in BES. If organic concentration can be reduced to a very low level that does not significantly affect the cathodic reaction, then nitrogen compounds can be removed in the cathode via autotrophic nitrification (though still competing with the cathode electrode for oxygen) and bioelectrochemical denitrification as described previously.29 Therefore, a loop operation could be effective for organic removal in the anode and nitrogen removal in the cathode with benefits of decreasing catholyte pH.

Because aeration is a key energy consumer, alternative approaches for providing dissolved oxygen have been studied, and among them algal bioreactors are of strong interest. Cultivation of algae in the cathode will not only provide oxygen, but also consume nitrogen and phosphorus by algal growth, resulting in increased nutrient removal. In addition to electric energy production, such BESs also produce algal biomass that may be converted into bioenergy. A preliminary analysis revealed that algal biomass could contribute to 71–86% of total energy production in an MFC with an algal cathode, leading to a theoretically energy positive treatment system.33 More details about algal-cathode BESs can be found in several review papers.34,35,36 BESs with an algal cathode require special consideration in reactor design, because of the need for illumination that supports algal growth. Integrating BESs into open-pond or photobioreactor has been explored, and interaction between algae and bacteria in a cathode community warrants further investigation.37

BES cathodes may also play a role in removing bio-refractory organic compounds and emerging contaminants. Incomplete oxygen reduction via a two-electron pathway can generate hydrogen peroxide,38 which can then react with Fe2+ to produce hydroxyl radical, one of the strongest oxidants used in advanced oxidation processes. This has been investigated in a BES-Fenton system, for example to achieve complete degradation of Orange II, a dye commonly used in the textile, food and cosmetics industry.39 Production of hydrogen peroxide in the cathode requires precise control of reaction pathway to avoid four-electron reduction of oxygen to water. The use of gas diffusion layer in a composite cathode electrode made of carbon black and graphite has achieved a high H2O2 yield of 11.9 mg L−1 h−1 cm−2.40 After Fenton oxidation, the residue hydrogen peroxide can be removed by alternate switching between MFC and MEC operation.41 Like conventional Fenton treatment, a BES-Fenton system also faces the problems such as high chemical dosage and sludge production/disposal. The generated H2O2 can also be used for in situ treatment of contaminants, as demonstrated in a study that obtained the accelerated reduction of Cr (VI) with electrogenerated H2O2.42

Membrane is an excellent barrier to reject a wide range of contaminant and produce a high-quality effluent. Integration of various membranes into BESs, such as dynamic membrane, micro-ultrafiltration membrane, and forward osmosis membrane, has been actively studied.43 Installing membrane in the anode of a BES has experienced serious biofouling and lack of appropriate anti-fouling strategies without affecting the anode microbial process. Thus, having membrane in the cathode becomes a viable option. A study using membrane/biocathode assembly achieved the removal of 91% of bacterial cells and a water effluent with a turbidity of <0.1 NTU.44 Because the majority of organic matter has been removed by the anode, biofouling due to microbial growth would be less serious in the cathode. In addition, aeration can also act as fouling control in an aerobic cathode. The unique feature of BESs, electricity generation, was found to be able to reduce the deposition of sludge on membrane surface by enhancing the electrostatic repulsive force between them, resulting in less membrane fouling.45 This is further demonstrated in a BES with a conductive filtration cathode, in which the accumulated negative charges on the cathode created electrostatic repulsion to reduce foulants.46 When forward osmosis (FO) membrane is integrated into BESs forming osmotic BESs,47 a cathode hosts draw solution that generates an osmotic pressure and extracts water from the anode. FO-based BESs potentially have low fouling and low energy demand; however, regeneration of draw solute in an energy efficient way will be a key to the successful operation.

Outlook

Despite the potential advantages of using cathodes to improve wastewater treatment, we must also understand the challenges associated with this approach. First, there is always a tradeoff between contaminant removal and energy recovery in BESs. Because electrons are involved in the removal of many contaminants, the more electrons flow, the better will be the contaminant removal. As a result, BESs will need to be operated under a mode for high current generation, which does not produce much power or energy. The benefit from enhanced contaminant removal may compensate for low energy production. The second challenge is how to overcome the cathode limitation to accommodate both high current generation and contaminant removal. Although those two tasks are correlated, the detailed interactions between the two should be further investigated. For example, some intermediates or end-products of contaminant removal may limit further current generation by covering the cathode surface (e.g., metal deposition) or poisoning the catalysts. Third, intrusion of undesired electron acceptors/donors can deteriorate the BES performance. Supplying an anolyte to the cathode can introduce electron donors (e.g., organics and ammonia) and thus create competition for terminal electron acceptors (e.g., oxygen). To minimize such an effect, it is important to reduce the concentration of organic matter to as low as possible before entering the cathode, or to increase the oxygen supply at the expense of energy consumption. Fourth, some cathode-supported treatments may be better conducted outside the cathode. Although an electrical field may reduce foulants, installation of membrane will complicate the cathode structure and operation/maintenance. In addition, fouling can hardly be avoided and it will be difficult to apply anti-fouling/membrane cleaning strategies inside the cathode. Likewise, algal growth may be better conducted in a separate photobioreactor that receives the cathode effluent, because of the special requirement for illumination and difficulty in harvesting algal biomass within the cathode.

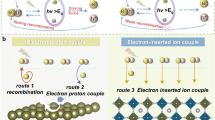

Future design of BESs for utilizing cathode treatment should not neglect the anode, and a synergistic linkage between the anode and the cathode would lead to a functional BES with maximized treatment performance. We present two examples of such systems in Fig. 2. When domestic wastewater is treated in BES, organic compounds are mostly removed in the anode via anaerobic oxidation and electron production; then, the anode effluent is supplied to the cathode, where ammonium nitrogen can be removed via multiple biological pathways (Fig. 2a). Because cathodic reduction of recalcitrant compounds like dye does not always completely degrade the contaminant, the cathode effluent can be transported to the anode, where further oxidation may occur and also provide some electrons to cathodic reduction reaction (Fig. 2b). Additional organic matter may need to be added to the anode to ensure sufficient electron supply. Clearly, more efforts should be invested to explore efficient ways to use cathodes for enhancing wastewater treatment in BES.

References

Pant, D. et al. Bioelectrochemical systems (BES) for sustainable energy production and product recovery from organic wastes and industrial wastewaters. RSC Adv. 2, 1248–1263 (2012).

Gude, V. G. Wastewater treatment in microbial fuel cells – an overview. J. Clean. Prod. 122, 287–307 (2016).

Zhang, Y. & Angelidaki, I. Microbial electrolysis cells turning to be versatile technology: Recent advances and future challenges. Water Res. 56, 11–25 (2014).

Sevda, S., Yuan, H., He, Z. & Abu-Reesh, I. M. Microbial desalination cells as a versatile technology: Functions, optimization and prospective. Desalination 371, 9–17 (2015).

Rabaey, K. & Rozendal, R. A. Microbial electrosynthesis — revisiting the electrical route for microbial production. Nat. Rev. Microbiol. 8, 706 (2010).

Sadhukhan, J. et al. A critical review of integration analysis of microbial electrosynthesis (MES) systems with waste biorefineries for the production of biofuel and chemical from reuse of CO2. Ren. Sust. Energ. Rev. 56, 116–132 (2016).

Escapa, A., Mateos, R., Martínez, E. J. & Blanes, J. Microbial electrolysis cells: An emerging technology for wastewater treatment and energy recovery. From laboratory to pilot plant and beyond. Ren. Sust. Energ. Rev. 55, 942–956 (2016).

Jain, A. & He, Z. “NEW” resource recovery from wastewater using bioelectrochemical systems: Moving forwards with functions. Front. Environ. Sci. Eng. 12, 1 (2018).

Pandey, P. et al. Recent advances in the use of different substrates in microbial fuel cells toward wastewater treatment and simultaneous energy recovery. Appl. Energy 168, 706–723 (2016).

Pant, D., Van Bogaert, G., Diels, L. & Vanbroekhoven, K. A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresour. Technol. 101, 1533–1543 (2010).

Zhang, F., Ge, Z., Grimaud, J., Hurst, J. & He, Z. Long-term performance of liter-scale microbial fuel cells treating primary effluent installed in a municipal wastewater treatment facility. Environ. Sci. Technol. 47, 4941–4948 (2013).

Ge, Z. & He, Z. Long-term performance of a 200 liter modularized microbial fuel cell system treating municipal wastewater: Treatment, energy, and cost. Environ. Sci. 2, 274–281 (2016).

Bajracharya, S. et al. Biotransformation of carbon dioxide in bioelectrochemical systems: State of the art and future prospects. J. Power Sources 356, 256–273 (2017).

Mu, Y., Rozendal, R. A., Rabaey, K. & Keller, J. Nitrobenzene removal in bioelectrochemical systems. Environ. Sci. Technol. 43, 8690–8695 (2009).

Solanki, K., Subramanian, S. & Basu, S. Microbial fuel cells for azo dye treatment with electricity generation: A review. Bioresour. Technol. 131, 564–571 (2013).

Butler, C. S., Clauwaert, P., Green, S. J., Verstraete, W. & Nerenberg, R. Bioelectrochemical perchlorate reduction in a microbial fuel cell. Environ. Sci. Technol. 44, 4685–4691 (2010).

Cao, Y., Hu, Y., Sun, J. & Hou, B. Explore various co-substrates for simultaneous electricity generation and Congo red degradation in air-cathode single-chamber microbial fuel cell. Bioelectrochemistry 79, 71–76 (2010).

Pan, Y. et al. Removal of azo dye in an up-flow membrane-less bioelectrochemical system integrated with bio-contact oxidation reactor. Chem. Eng. J. 326, 454–461 (2017).

Fu, F. & Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 92, 407–418 (2011).

Nancharaiah, Y. V., Venkata Mohan, S. & Lens, P. N. L. Metals removal and recovery in bioelectrochemical systems: A review. Bioresour. Technol. 195, 102–114 (2015).

Tandukar, M., Huber, S. J., Onodera, T. & Pavlostathis, S. G. Biological chromium(VI) reduction in the cathode of a microbial fuel cell. Environ. Sci. Technol. 43, 8159–8165 (2009).

Nancharaiah, Y. V., Mohan, S. V. & Lens, P. N. L. Biological and bioelectrochemical recovery of critical and scarce metals. Trends Biotechnol. 34, 137–155 (2016).

Xue, H., Zhou, P., Huang, L., Quan, X. & Yuan, J. Cathodic Cr(VI) reduction by electrochemically active bacteria sensed by fluorescent probe. Sens. Actuators B Chem. 243, 303–310 (2017).

Gregory, K. B., Bond, D. R. & Lovley, D. R. Graphite electrodes as electron donors for anaerobic respiration. Environ. Microbiol. 6, 596–604 (2004).

Clauwaert, P. et al. Biological denitrification in microbial fuel cells. Environ. Sci. Technol. 41, 3354–3360 (2007).

Kelly, P. T. & He, Z. Nutrients removal and recovery in bioelectrochemical systems: a review. Bioresour. Technol. 153, 351–360 (2014).

Rodríguez Arredondo, M. et al. Bioelectrochemical systems for nitrogen removal and recovery from wastewater. Environ. Sci. 1, 22–33 (2015).

Sevda, S., Sreekishnan, T. R., Pous, N., Puig, S. & Pant, D. Bioelectroremediation of perchlorate and nitrate contaminated water: a review. Bioresour. Technol. 255, 331–339 (2018).

Virdis, B., Rabaey, K., Rozendal, R. A., Yuan, Z. & Keller, J. Simultaneous nitrification, denitrification and carbon removal in microbial fuel cells. Water Res. 44, 2970–2980 (2010).

Cecconet, D., Zou, S., Capodaglio, A. G. & He, Z. Evaluation of energy consumption of treating nitrate-contaminated groundwater by bioelectrochemical systems. Sci. Total Environ. 636, 881–890 (2018).

Lefebvre, O. et al. Full-loop operation and cathodic acidification of a microbial fuel cell operated on domestic wastewater. Bioresour. Technol. 102, 5841–5848 (2011).

Clauwaert, P., Mulenga, S., Aelterman, P. & Verstraete, W. Litre-scale microbial fuel cells operated in a complete loop. Appl. Microbiol. Biotechnol. 83, 241 (2009).

Xiao, L., Young, E. B., Berges, J. A. & He, Z. Integrated photo-bioelectrochemical system for contaminants removal and bioenergy production. Environ. Sci. Technol. 46, 11459–11466 (2012).

Xiao, L. & He, Z. Applications and perspectives of phototrophic microorganisms for electricity generation from organic compounds in microbial fuel cells. Ren. Sust. Energ. Rev. 37, 550–559 (2014).

Lee, D.-J., Chang, J.-S. & Lai, J.-Y. Microalgae–microbial fuel cell: A mini review. Bioresour. Technol. 198, 891–895 (2015).

ElMekawy, A., Hegab, H. M., Vanbroekhoven, K. & Pant, D. Techno-productive potential of photosynthetic microbial fuel cells through different configurations. Ren. Sust. Energ. Rev. 39, 617–627 (2014).

Luo, S., Berges, J. A., He, Z. & Young, E. B. Algal-microbial community collaboration for energy recovery and nutrient remediation from wastewater in integrated photobioelectrochemical systems. Algal Res. 24, 527–539 (2017).

Rozendal, R. A., Leone, E., Keller, J. & Rabaey, K. Efficient hydrogen peroxide generation from organic matter in a bioelectrochemical system. Electrochem. Commun. 11, 1752–1755 (2009).

Feng, C.-H., Li, F.-B., Mai, H.-J. & Li, X.-Z. Bio-electro-fenton process driven by microbial fuel cell for wastewater treatment. Environ. Sci. Technol. 44, 1875–1880 (2010).

Li, N. et al. A novel carbon black graphite hybrid air-cathode for efficient hydrogen peroxide production in bioelectrochemical systems. J. Power Sources 306, 495–502 (2016).

Zhang, Y., Wang, Y. & Angelidaki, I. Alternate switching between microbial fuel cell and microbial electrolysis cell operation as a new method to control H2O2 level in Bioelectro-Fenton system. J. Power Sources 291, 108–116 (2015).

Liu, L., Yuan, Y., Li, F.-b & Feng, C.-h In-situ Cr(VI) reduction with electrogenerated hydrogen peroxide driven by iron-reducing bacteria. Bioresour. Technol. 102, 2468–2473 (2011).

Yuan, H. & He, Z. Integrating membrane filtration into bioelectrochemical systems as next generation energy-efficient wastewater treatment technologies for water reclamation: A review. Bioresour. Technol. 195, 202–209 (2015).

Malaeb, L. et al. A hybrid microbial fuel cell membrane bioreactor with a conductive ultrafiltration membrane biocathode for wastewater treatment. Environ. Sci. Technol. 47, 11821–11828 (2013).

Wang, Y.-K., Li, W.-W., Sheng, G.-P., Shi, B.-J. & Yu, H.-Q. In-situ utilization of generated electricity in an electrochemical membrane bioreactor to mitigate membrane fouling. Water Res. 47, 5794–5800 (2013).

Liu, J., Liu, L., Gao, B. & Yang, F. Integration of bio-electrochemical cell in membrane bioreactor for membrane cathode fouling reduction through electricity generation. J. Membr. Sci. 430, 196–202 (2013).

Qin, M. & He, Z. Resource recovery by osmotic bioelectrochemical systems towards sustainable wastewater treatment. Environ. Sci. 3, 583–592 (2017).

Acknowledgements

This work was supported by Institute for Critical Technology and Applied Science (ICTAS), Virginia Tech.

Author information

Authors and Affiliations

Contributions

Z.H. developed the initial idea and scope of the paper. Z.H. and A.J. discussed and co-wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jain, A., He, Z. Cathode-enhanced wastewater treatment in bioelectrochemical systems. npj Clean Water 1, 23 (2018). https://doi.org/10.1038/s41545-018-0022-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-018-0022-x

This article is cited by

-

Examining current trends and future outlook of bio-electrochemical systems (BES) for nutrient conversion and recovery: an overview

Environmental Science and Pollution Research (2023)

-

A comparative study of bioelectrochemical systems with established anaerobic/aerobic processes

Biomass Conversion and Biorefinery (2022)

-

Accomplishing a N-E-W (nutrient-energy-water) synergy in a bioelectrochemical nitritation-anammox process

Scientific Reports (2019)