Abstract

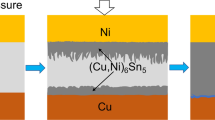

This study employed an improved thermal compression bonding process with two temperature settings (180 °C/250 °C, 250 °C/250 °C) to rapidly fabricate the complete intermetallic compound joints. While observing and evaluating the microstructure and shear strength of the joints, the influence of holding time and temperature gradients on the growth and evolution of the interfacial IMCs were investigated. The results demonstrated that reducing the temperature gradient can mitigate the adverse effects caused by significant differences in IMC thickness, while an overall increase in system temperature accelerated IMC growth. Utilizing vacuum thermal compression bonding allowed the rapidly forming complete IMC joints within 15 to 30 min and suppressed the voids effectively. In comparison to traditional transient liquid phase bonding, the rate of full IMC joints formation was accelerated by a factor of 2 to 4, accompanied by an average shear strength enhancement ranging from 8.9 to 18.7%. Thus, vacuum thermal compression bonding demonstrates the potential for rapidly fabricating high-strength full IMC joints with the judicious selection of appropriate temperature conditions, representing a promising technological advancement.

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the article.

References

K.N. Tu, Y. Liu, Recent advances on kinetic analysis of solder joint reactions in 3D IC packaging technology. Mater. Sci. Eng. R-Rep. 136, 1–12 (2019)

C. Chen, Z. Liang, Lu. Wang Xi, G.-H. Xiao, Intermetallic compound evolution and mechanical properties of Cu/Sn58Bi/Cu 3D structures blended with B4C nanoparticles during isothermal aging. J. Market. Res. 24, 3643–3656 (2023)

S. Lei, C. Ming-he, Z. Liang, He. Peng, X. Lan-sheng, Recent progress in SLID bonding in novel 3D-IC technologies. J. Alloy. Compd. 818, 152825 (2020)

Wu. Shao Hua-kai, B.-D. Ai-ping, Z. Yue, Z. Gui-sheng, Microstructure characterization and mechanical behavior for Ag3Sn joint produced by foil-based TLP bonding in air atmosphere. Mater. Sci. Eng., A 680, 221–231 (2017)

L. Zhang, Z.Q. Liu, S.W. Chen, Y.D. Wang, W.M. Long, Y.H. Guo, S.Q. Wang, G. Ye, W.Y. Liu, Materials, processing and reliability of low temperature bonding in 3D chip stacking. J. Alloys Compd. 750, 980–995 (2018)

S. Lei, C. Ming-he, Z. Liang, Microstructure evolution and grain orientation of IMC in Cu-Sn TLP bonding solder joints. J. Alloy. Compd. 786, 677–687 (2019)

S. Lei, Z. Liang, Z. Yi, C. Ming-he, C. Cong-ping, Interfacial reaction, shear behavior and microhardness of Cu-Sn TLP bonding joints bearing CuZnAl powder for 3D packaging. J. Manuf. Process. 68, 1672–1682 (2021)

L. Sun, Y. Zhang, L. Zhang, C.P. Chen, Reliability and strength of Cu–Sn0.5CuZnAl–Cu TLP bonded joints during thermal cycling. J. Mater. Sci. Mater. Electron. 32, 19264–19274 (2021)

S. Lei, Z. Liang, W. Chun-chun, C. Ming-he, Z. Yi, Transient liquid phase bonding (TLPB) of Cu to Cu using Sn interconnect solder reinforced by submicron Al particles. J. Manuf. Proc. Technol. 307, 117686 (2022)

M.L. Li, L. Zhang, L.L. Gao, X. Wang, C. Chen, X. Lu, Interfacial structures and mechanical properties of Cu/Sn/Cu containing SiC nanowires under transient liquid phase bonding. Intermetallics 148, 107641 (2022)

S. Sunghyun, M. Byungrok, L. Junghoon, K. Namhyun, M. Younghoon, Interlayer material design reducing transient liquid phase bonding time. Electron. Mater. Lett. 16, 106–114 (2020)

C. Wei-yu, S. Rui-wen, D. Jenq-Gong, Grain structure modification of Cu-Sn IMCs by applying Cu-Zn UBM on transient liquid-phase bonding in novel 3D-IC technologies. Intermetallics 85, 170–175 (2017)

Z. Yi, Z. Ning, D. Wei, Ma. Hai-tao, H. Ming-liang, Coupling effect of thermomigration and cross-interaction on evolution of intermetallic compounds in Cu/Sn/Ni ultrafine interconnects undergoing TLP bonding. J. Mater. Res. 32, 3128–3136 (2017)

H.J. Dong, Z.L. Li, X.G. Song, H.Y. Zhao, J.C. Yang, H. Tian, J.H. Liu, Grain morphology and mechanical strength of high-melting-temperature intermetallic joints formed in asymmetrical Ni/Sn/Cu system using transient liquid phase soldering process. J. Alloy. Compd. 723, 1026–1031 (2017)

H.J. Dong, Z.L. Li, X.G. Song, H.Y. Zhao, H. Tian, J.H. Liu, J.C. Yan, Grain morphology evolution and mechanical strength change of intermetallic joints formed in Ni/Sn/Cu system with variety of transient liquid phase soldering temperatures. Mater. Sci. Eng., A 705, 360–365 (2017)

C. Imediegwu, S. Graham, D.G. Pahinkar, S. Narumanchi, P. Paret, J. Major, Interdiffusion and formation of intermetallic compounds in high-temperature power electronics substrate joints fabricated by transient liquid phase bonding. Microelectron. Reliab. 137, 114788 (2022)

T. Ye, F. Heng, R. Ning, Z. Ya-tao, Wu. Chen Bo-li, P.-W. Feng-shun, Reliable single-phase micro-joints with high melting point for 3D TSV chip stacking. J. Alloy. Compd. 828, 154468 (2020)

W. Xi, Z. Liang, W. Xiao, G. Yong-huan, S. Lei, L. Ying-xia, Lu. Chen Chen, Xiao., Growth behavior and reliability of interfacial IMC for Sn58Bi/Cu and Sn58Bi—AlN/Cu solder joints applied in IGBT modules. J. Market. Res. 21, 4263–4280 (2022)

C. Chen, Z. Liang, Lu. Wang Xi, G.-H. Xiao, Ultrasonic-assisted connection of Cu/Cu structure using Sn58Bi solder enhanced by B4C nanoparticles. J. Mater. Process. Technol. 319, 118062 (2023)

N. Zhao, Y. Zhong, M.L. Huang, H.T. Ma, W. Dong, Growth kinetics of Cu6Sn5 intermetallic compound at liquid-solid interfaces in Cu/Sn/Cu interconnects under temperature gradient. Sci. Rep. 5, 13491 (2015)

X.Y. Bi, X.W. Hu, Q.L. Li, Effect of Co addition into Ni film on shear strength of solder/Ni/Cu system: experimental and theoretical investigations. Mater. Sci. Eng., A 788, 139589 (2020)

Acknowledgements

This work was supported by the High Level Talent Research Initiation Project of Xiamen University of Technology (YKJ22054R), Fujian Provincial “Minjiang Scholar” Distinguished Professor Talent Plan Project, and the Natural Science Foundation of Jiangsu Province (BK20211351).

Funding

High Level Talent Research Initiation Project of Xiamen University of Technology, YKJ22054R. Fujian Provincial “Minjiang Scholar” Distinguished Professor Talent Plan Project, Natural Science Foundation of Jiangsu Province, BK20211351.

Author information

Authors and Affiliations

Contributions

Chen Chen: Conceptualization, Methodology, Data curation, Writing—original draft preparation, and editing; Liang Zhang: Corresponding author, Data curation, Reviewing, and editing; Xing-yu Guo: Reviewing and investigation; Jia-min Zhang: Investigation, Supervision; Xi Huang: Validation, Investigation.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, C., Zhang, L., Guo, XY. et al. Optimizing temperature gradient for rapid fabrication of Cu/Sn/Cu full intermetallic compounds joints via vacuum thermal compression bonding. J Mater Sci: Mater Electron 35, 823 (2024). https://doi.org/10.1007/s10854-024-12604-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12604-6