Abstract

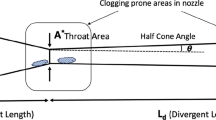

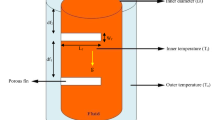

The O2–CO2 mixing injection method was proposed to mitigate CO2 emissions and enhance the CO content in flue gas during the BOF steelmaking process. Despite the reported advantages of the O2–CO2 mixing injection method, limited research existed regarding the impact of Laval nozzle structures designed by various CO2 mixing rates on the flow characteristics of supersonic mixing jets. In this research, we investigated four types of Laval nozzle structures designed for varying CO2 mixing rates through a series of experimental tests and numerical simulations. The results indicated that when the CO2 additional flow rate increased from 0 to 15 mass pct, the impaction ability of the mixing jet enhanced. However, this increasing rate was gradually suppressed due to the thermo-physical property variations between O2 and CO2. Under room and high ambient temperature conditions, the average axial velocity variation within the velocity potential core was 1.58 and 1.68 m/(s·mass pct), respectively. To further validate the metallurgical effects, a pilot test was conducted using a 1.0 ton converter with O2 and CO2 blowing rates of 210 and 31.5 Nm3/h, respectively, demonstrating that the Laval nozzle structure designed based on the O2–CO2 mixing gas thermo-physical property could achieve superior metallurgical outcomes.

Similar content being viewed by others

References

H. Matsuura and F. Tsukihashix: ISIJ Int., 2015, vol. 55, pp. 413–18.

L. Holappa: Miner. Process. Extr. Metall. Trans. Inst. Min. Metall., 2019, vol. 128, pp. 3–16.

K. Thomas, B. Philip, S. Volker, S. Johannes, and K. Marcus: in AISTech 2015—Proceedings of the Iron and Steel Technology Conference and ICSTI 2015, 2015, pp. 2031–40.

C. Yi, R. Zhu, B. Chen, C. Wang, and J. Ke: ISIJ Int., 2009, vol. 49, pp. 1694–99.

G. Wei, R. Zhu, T. Cheng, K. Dong, L. Yang, T. Tang, and X. Wu: ISIJ Int., 2018, vol. 58, pp. 842–51.

H. Liu, J. Liu, S. Johannes, F.M. Penz, L. Sun, R. Zhang, and Z. An: Metall. Trans. B, 2020, vol. 51B, pp. 756–62.

W. Wu, R. Zhu, G. Wei, C. Wang, and H. Wang: Metall. Trans. B, 2022, vol. 53B, pp. 1396–1410.

Y. Fan, X. Hu, H. Matsuura, and K. Chou: ISIJ Int., 2023, vol. 63, pp. 10–19.

Y. Sun, S. Tian, P. Ciais, Z. Zeng, J. Meng, and Z. Zhang: Nat. Commun., 2022, vol. 13, p. 297.

W. Dong, A. Xu, C. Zhao, C. Ji, H. Li, N. Hao, H. Zhou, T. Xia, and R. Zhu: ISIJ Int., 2023, vol. 63, pp. 846–53.

W. Dong, A. Xu, H. Li, S. Guan, C. Ji, N. Hao, and X. Deng: Metall. Trans. B, 2022, vol. 53B, pp. 3575–84.

M. Zhou, L. Ai, L. Hong, Y. Hou, and C. Sun: Metall. Trans. A, 2023, vol. 54A, pp. 2208–18.

J. Sun, J. Zhang, W. Lin, L. Cao, X. Feng, and Q. Liu: Steel Res. Int., 2021, vol. 92, p. 2100179.

A.G. Chernyatevich, L.S. Molchanov, E.N. Sigarev, K.I. Chubin, and A.A. Pokhvalityi: Steel Transl., 2021, vol. 51, pp. 538–47.

M. Li, L. Li, B. Zhang, Q. Li, W. Wu, and Z. Zou: Metall. Trans. B, 2020, vol. 51B, pp. 1718–30.

N. Oda, S. Koseki, Y. Uchida, Y. Hino, and N. Kikuchi: ISIJ Int., 2021, vol. 61, pp. 1794–1800.

F. Zhao, F. Liu, D. Sun, R. Zhu, and K. Dong: Metall. Trans. B, 2021, vol. 52B, pp. 2626–41.

H.J. Odenthal, A. Kemminger, F. Krause, L. Sankowski, N. Uebber, and N. Vogl: Steel Res. Int., 2018, vol. 89, p. 1700098.

S. Hu, R. Zhu, R. Liu, K. Dong, F. Liu, G. Ma, and R. Su: J. Iron. Steel Res. Int., 2018, vol. 25, pp. 28–36.

O. Kubashewski and C.B. Alcock: Metallurgical Thermochemistry, 5th ed. Pergamon Press, New York, 1979, pp. 15–19.

B. Han, G. Wei, R. Zhu, W. Wu, J.J. Jiang, C. Feng, J.F. Dong, S.Y. Hu, and R.Z. Liu: J. CO2 Util., 2019, vol. 34, pp. 53–62.

C. Feng, S. Chen, J. Dong, R. Zhu, G. Wei, and K. Dong: JOM, 2021, vol. 73, pp. 2985–94.

H. Xu, Y. He, J. Liu, M. Xie, and G. Huang: ISIJ Int., 2022, vol. 62, pp. 669–76.

Y. Zhou, G. Wei, R. Zhu, and K. Dong: Sep. Purif. Technol., 2023, vol. 315, p. 123693.

Y. Zhou, G. Wei, and R. Zhu: J. CO2 Util., 2022, vol. 60, p. 102016.

Z. Yuan and Y. Pan: Oxygen Lance Technology for Steelmaking, 1st ed. Metallurgical Industry Press, Beijing, 2007, pp. 33–35.

F. Liu, R. Zhu, K. Dong, and S. Hu: Metall. Trans. B, 2016, vol. 47B, pp. 228–43.

F. Liu, R. Zhu, K. Dong, and S. Fan: ISIJ Int., 2018, vol. 58, pp. 496–504.

F. Liu, D. Sun, R. Zhu, R. Su, and X. Wang: Metall. Trans. B, 2018, vol. 49B, pp. 2050–62.

M. Li, Q. Li, S. Kuang, and Z. Zou: Metall. Trans. B, 2016, vol. 47B, pp. 116–26.

F. Qian, R. Mutharasan, and B. Farouk: Metall. Trans. B, 1996, vol. 27B, pp. 911–20.

Z. Li, R. Zhu, R. Liu, X. Wang, and Q. Li: Steel Res. Int., 2012, vol. 83, pp. 11–15.

Acknowledgments

The authors would like to express their thanks for the support by the National Nature Science Foundation of China (NSFC 52322407, NSFC 52074024 and NSFC 52293392) and National Key R&D Program of China (2020YFC1910002).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, J., Liu, F., Wei, G. et al. Flow Characteristic of Supersonic Jet Related to O2–CO2 Mixing Injection Method. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-02993-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-02993-8