Abstract

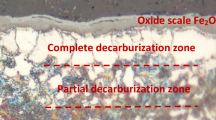

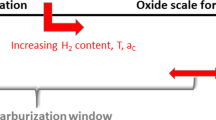

The initial stages of oxidation of 9Cr steel in CO2, O2, CO2–O2 and CO2–O2–H2O is studied by gas phase analysis (GPA) at 550 °C using 13C16,16O2, 18,18O2 and 2H216O isotopic molecules in order to discriminate the reactions of all gas molecules. Protective and non-protective oxide scales are formed on 9Cr steel depending on the exact composition of the gas mixture. In pure CO2, 9Cr steel forms a slow growing chromium-rich oxide scale without any carburization. Adding O2 impurities in CO2 favors the formation of fast growing iron-rich duplex oxide scale coupled to strong carburization. Adding several % of O2 in CO2 favors again the formation of slow growing oxide scale but with different structure and composition than in pure CO2. GPA analyses combined with oxide scale analyses demonstrate that the composition and structure of the transient oxide scale formed on 9Cr surface is determined by the rate at which surface adsorbed oxygen atoms are supplied by the gas phase in the first minutes of exposure. The presence of the very oxidizing O2 molecules in CO2 increases drastically the surface oxidation rate, favoring formation of a non-protective oxide scale which transmits carbon permitting carburization of the steel. Adding water vapor to a CO2 gas environment slows carburization. Preferential adsorption of water vapor molecules over CO2/CO molecules in the inner oxide scale is proposed to explain this result. A unified mechanism for the formation of the transient oxide scale on 9Cr steel in CO2/O2/H2O gas mixtures is described.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings can be shared if necessary.

References

R. Oleksak and F. Rouillard, in Materials Performance in CO2 and Supercritical CO2. Comprehensive Nuclear Materials, 2nd edition, Vol. 4 (Elsevier, 2020), p. 422.

S. Bouhieda, F. Rouillard, V. Barnier, and K. Wolski, Oxidation of Metals 80, 2013 (493).

S. Bouhieda, F. Rouillard, and K. Wolski, Materials at High Temperature 29, 2011 (151).

G. H. Meier, K. Y. Jung, N. Mu, et al., Oxidation of Metals 74, 2010 (319).

J. P. Abellan, T. Olszewski, G. H. Meier, et al., International Journal of Materials Science 101, 2010 (287).

W. J. Quadakkers, T. Olszewski, J. P. Abellan, et al., VDI-Berichte 2012, 2010 (81).

D. Huenert and A. Kranzmann, Corrosion Science 53, 2011 (2306).

J. P. Abellan, T. Olszewski, G. H. Meier, L. Singheiser, and W. J. Quadakkers, International Journal of Materials Research 101, 2010 (287).

T. Gheno, D. Monceau, and D. J. Young, Corrosion Science 77, 2013 (246).

F. Rouillard and D. J. Young, Corrosion Science 178, 2021 109092.

E. F. Rauch and M. Véron, Materials Characterization 98, 2014 (1).

F. Rouillard, G. Moine, L. Martinelli, and J. C. Ruiz, Oxidation of Metals 77, 2012 (27).

I. Wolf, H. J. Grabke, and P. Schmidt, Oxidation of Metals 29, 1988 (289).

F. Rouillard and T. Furukawa, Corrosion Science 105, 2016 (120).

F. Rouillard, G. Moine, M. Tabarant, and J. C. Ruiz, Oxidation of Metals 77, 2012 (57–70).

G. B. Gibbs, Oxidation of Metals 7, 1973 (173).

R. P. Oleksak, M. Kapoor, D. E. Perea, G. H. Holcomb, and O. N. Dogan, npj Materials Degradation 2, 2018 (25).

J. Robertson and M. I. Manning, Materials Science and Technologiy 4, 1988 (1064).

A. Atkinson and D. W. Smart, Journal of the Electrochemical Society 135, 1988 (2886).

L. Martinelli, F. Balbaud-Célérier, A. Terlain, et al., Corrosion Science 50, 2008 (2537).

T. Gheno, D. Monceau, J. Zhang, and D. J. Young, Corrosion Science 53, 2011 (2767).

D. J. Young, P. Huczkowski, T. Olszewski, et al., Corrosion Science 88, 2014 (161).

K. E. Nygren, Z. Yu, F. Rouillard, and A. Couet, Corrosion Science 163, 2020 108292.

L. Martinelli, C. Desgrange, F. Rouillard, et al., Corrosion Science 100, 2015 (253).

HSC Thermochemistry® software version 10.3.4, Metso Outotec Finland Oy.

C. Anghel, E. Hornlünd, G. Hultquist, and M. Limbäck, Applied Surface Science 233, 2004 (392).

J. Chapovaloff, F. Rouillard, K. Wolski, and M. Pijolat, Corrosion Science 69, 2013 (31).

G. Hultquist, M. J. Graham, J. L. Smialek, and B. Jönsson, Corrosion Science 93, 2015 (324).

Acknowledgements

The authors are grateful to Ms R. Benyhia for carrying out part of the oxidation tests during their Master internship, Mr M. Tabarant for the GDOES analyses and Mr Schlegel for the Raman analyses.

Funding

This study was funded by the French Alternative Energies and Atomic Energy Commission.

Author information

Authors and Affiliations

Contributions

Conceptualization: F.R; Methodology: F.R; Formal analysis and investigation: F.R, F.J, L.L-R, F.M, L.M, DJ.Y; Writing—original draft preparation: F.R, L.L-R, L.M, DJ.Y; Funding acquisition: F.R; Resources: F.R; Supervision: F.R.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rouillard, F., Jomard, F., Latu-Romain, L. et al. The Role of O2 and H2O Impurities in Dictating the Oxidation Mechanism and Protective Capacity of 9Cr Steels in Hot CO2. High Temperature Corrosion of mater. 100, 557–595 (2023). https://doi.org/10.1007/s11085-023-10186-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10186-y