Abstract

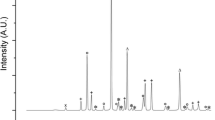

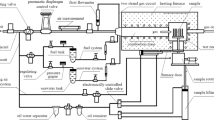

The hot corrosion behaviors of Inconel alloys with different Cr contents (Inconel 600, 601, and 690), which are used widely in nuclear plants, were investigated in molten LiCl–Li2O salts. The hot corrosion behaviors were studied by measuring the mass and attack depth changes, surface and cross-sectional morphologies and elemental distributions, and compositional changes at the subscale and substrate scale as well as the spalled oxide scale. At 288 h, the weight losses of Inconel 601 and Inconel 690 were approximately four and twelve times higher, respectively, than that of Inconel 600. The corrosion products of all tested alloys were Cr2O3, NiO, and FeCr2O4. Inconel 600, which exhibited a dense and continuous external corrosion layer and an internal corrosion layer with localized corrosion behavior, exhibited superior corrosion resistance compared with those of Inconel 601 and 690, which showed a spalled external corrosion layer and an internal corrosion layer with uniform corrosion behavior. Thus, the corrosion resistance of the Inconel alloys tested in the hot lithium molten salts in an oxidizing atmosphere is closely related to the contents of the primary alloying elements in the alloys. Of the various alloys analyzed in this study, Inconel 600 exhibited the highest corrosion resistance. Thus, a Cr content of 16.30 wt% or less, Ni content of at least 73.66 wt%, and Fe content considerably lower than 8.15 wt% can result in excellent corrosion resistance.

Similar content being viewed by others

References

A. Rehman, M. H. Bidabadi, Y. Liang, et al., Corrosion Science 165, 108369 (2020). https://doi.org/10.1016/j.corsci.2019.108369.

A. G. Fernández and L. F. Cabeza, Journal of Energy Storage 229, 101381 (2020). https://doi.org/10.1016/j.est.2020.101381.

Y. Grosu, A. Anagnostopoulos, M. E. Navarro, Y. Ding, and A. Faik, Solar Energy Materials and Solar Cells 215, 110650 (2020). https://doi.org/10.1016/j.solmat.2020.110650.

A. Ruh and M. Spiegel, Corrosion Science 48, 679 (2006). https://doi.org/10.1016/j.corsci.2005.02.015.

G. Z. Chen and D. J. Fray, TW Nature 407, 361 (2000). https://doi.org/10.1038/35030069.

J. E. Indacochea, J. L. Smith, K. R. Litko, E. J. Karell, and A. G. Rarez, Oxidation of Metals 55, 1 (2001). https://doi.org/10.1023/A:1010333407304.

M. Lee, C. W. Lee, H. C. Ham, J. Han, S. P. Yoon, and K. B. Lee, International Journal of Hydrogen Energy 42, 16235 (2017). https://doi.org/10.1016/j.ijhydene.2017.03.096.

S. A. Song, H. T. Kim, K. Kim, S. N. Lim, S. P. Yoon, and S. C. Jang, International Journal of Hydrogen Energy 44, 12085 (2019). https://doi.org/10.1016/j.ijhydene.2019.03.080.

F. Sher, N. K. Al-Shara, S. Z. Iqbal, Z. Jahan, and G. Z. Chen, International Journal of Hydrogen Energy 45, 28260 (2020). https://doi.org/10.1016/j.ijhydene.2020.07.183.

S. W. McAlpine, N. C. Skowronski, W. Zhou, G. T. Zheng, and M. P. Short, Journal of Nuclear Materials 532, 151994 (2020). https://doi.org/10.1016/j.jnucmat.2020.151994.

Q. Liu, Z. Wang, W. Liu, H. Yin, Z. Tang, and Y. Qian, Corrosion Science 180, 109183 (2021). https://doi.org/10.1016/j.corsci.2020.109183.

M. A. Uusitalo, P. M. Vuoristo, and T. A. Mäntylä, Corrosion Science 46, 1311 (2004). https://doi.org/10.1016/j.corsci.2003.09.026.

W. B. Kim, S. C. Kwon, S. H. Cho, and J. H. Lee, Corrosion Science. 170, 108664 (2020). https://doi.org/10.1016/j.corsci.2020.108664.

D. A. Shores and B. P. Mohanty, Corrosion Science 46, 2909 (2004). https://doi.org/10.1016/j.corsci.2004.04.013.

G. Lei, C. Li, Z. Jiang, and H. Huang, Corrosion Science 165, 108408 (2020). https://doi.org/10.1016/j.corsci.2019.108408.

Y. Wu, B. Leng, X. Li, L. Jiang, X. Ye, Y. Chen, X. Yang, Z. Li, and X. Zhou, Journal of Nuclear Materials 542, 152529 (2020). https://doi.org/10.1016/j.jnucmat.2020.152529.

W. H. Doniger, C. Falconer, M. Elbakhshwan, K. Britsch, A. Couet, and K. Sridharan, Corrosion Science 174, 108823 (2020). https://doi.org/10.1016/j.corsci.2020.108823.

B. U. Yoo, S. C. Kwon, S. H. Cho, H. H. Nersisyan, and J. H. Lee, Journal of Alloys and Compounds 771, 924 (2019). https://doi.org/10.1016/j.jallcom.2018.09.001.

X. Zhuang, W. Liu, and X. Xu, Solar Energy 189, 254 (2019). https://doi.org/10.1016/j.solener.2019.07.065.

B. Zhu and G. Lindbergh, Electrochimica Acta 46, 2593 (2001). https://doi.org/10.1016/S0013-4686(01)00471-6.

M. Spiegel, P. Biedenkopf, and H. J. Grabke, Corrosion Science 39, 1193 (1997). https://doi.org/10.1016/S0010-938X(97)00020-6.

T. Tz, Materials Chemistry and Physics 87, 201 (2004). https://doi.org/10.1016/j.matchemphys.2004.05.039.

S. Mitsushima, N. Kamiya, and K. I. Ota, Journal of the Electrochemical Society 137, 2713 (1990). https://doi.org/10.1149/1.2087031.

X. Yang, L. Yang, J. Wang, Z. Chen, M. Chen, J. Zhang, and F. Wang, Corrosion Science 221, 111377 (2023). https://doi.org/10.1016/j.corsci.2023.111377.

S. K. Gill, J. Sure, Y. Wang, B. Layne, L. He, S. Mahurin, J. F. Wishart, and K. Sasaki, Corrosion Science 179, 109105 (2021). https://doi.org/10.1016/j.corsci.2020.109105.

B. Wei, C. Chen, J. Xu, L. Yang, Y. Jia, Y. Du, M. Guo, C. Sun, Z. Wang, and F. Wang, Corrosion Science 195, 109996 (2022). https://doi.org/10.1016/j.corsci.2021.109996.

J. Feng, L. Mao, G. Yuan, Y. Zhao, J. Vidal, and L. E. Liu, Corrosion Science 197, 110097 (2022). https://doi.org/10.1016/j.corsci.2022.110097.

Z. Xu, B. Guan, X. Wei, J. Lu, J. Ding, and W. Wang, Solar Energy 238, 216 (2022). https://doi.org/10.1016/j.solener.2022.03.074.

X. Li, B. Leng, X. Ye, C. Liu, L. Chang, and X. Zhou, Corrosion Science. 194, 109940 (2022). https://doi.org/10.1016/j.corsci.2021.109940.

Q. Liu, X. Liu, G. Hao, and H. Xu, Corrosion Science 213, 111001 (2023). https://doi.org/10.1016/j.corsci.2023.111001.

H. Sun, P. Zhang, and J. Wang, Corrosion Science 143, 187 (2018). https://doi.org/10.1016/j.corsci.2018.08.021.

X. Wang, Z. Liu, K. Cheng, Y. Shen, and J. Li, Corrosion Science 221, 111308 (2023). https://doi.org/10.1016/j.corsci.2023.111308.

B. Meng, J. Wang, L. Yang, M. Chen, S. Zhu, and F. Wang, Journal of Materials Science & Technology 132, 69 (2023). https://doi.org/10.1016/j.jmst.2022.04.054.

X. L. Li, S. M. He, X. T. Zhou, P. Huai, Z. J. Li, A. G. Li, and X. H. Yu, Journal of Nuclear Materials 464, 342 (2015). https://doi.org/10.1016/j.jnucmat.2015.05.007.

T. S. Sidhu, S. Prakash, and R. D. Agrawal, Materials Science and Engineering: A 430, 64 (2006). https://doi.org/10.1016/j.msea.2006.05.099.

J. Wang, J. Sun, B. Zou, X. Zhou, S. Dong, L. Li, J. Jiang, L. Deng, and X. Cao, Ceramics International 43, 10415 (2017). https://doi.org/10.1016/j.ceramint.2017.05.077.

E. M. Zahrani and A. M. Alfantazi, Corrosion Science 85, 60 (2014). https://doi.org/10.1016/j.corsci.2014.03.034.

H. Ai, X. X. Ye, L. Jiang, B. Leng, M. Shen, Z. Li, Y. Jia, J. Q. Wang, X. Zhou, Y. Xie, and L. Xie, Corrosion Science 149, 218 (2019). https://doi.org/10.1016/j.corsci.2019.01.012.

X. Wang, L. Xin, F. Wang, S. Zhu, H. Wei, and X. Wang, Journal of Materials Science & Technology 30, 867 (2014). https://doi.org/10.1016/j.jmst.2014.01.001.

S. Mahini, S. K. Asl, T. Rabizadeh, and H. Aghajani, Surface and Coatings Technology 397, 125949 (2020). https://doi.org/10.1016/j.surfcoat.2020.125949.

S. H. Cho, S. S. Hong, D. S. Kang, J. M. Hur, and H. S. Lee, Metals and Materials International 15, 51 (2009). https://doi.org/10.1007/s12540-009-0051-6.

S. H. Cho, J. M. Hur, C. S. Seo, J. S. Yoon, and S. W. Park, Journal of Alloys and Compounds 468, 263 (2009). https://doi.org/10.1016/j.jallcom.2007.12.094.

S. H. Cho, S. C. Kwon, D. Y. Kim, W. S. Choi, Y. S. Kim, and J. H. Lee, Corrosion Science 151, 20 (2019). https://doi.org/10.1016/j.corsci.2019.01.041.

W. B. Kim, W. S. Choi, K. S. Lim, S. H. Cho, and J. H. Lee, Coatings 11, 328 (2021). https://doi.org/10.3390/coatings11030328.

H. Y. Woo, G. S. Lim, W. B. Kim, W. S. Choi, S. H. Cho, K. T. Park, and J. H. Lee, Corrosion Engineering Science and Technology. 56, 513 (2021). https://doi.org/10.1080/1478422X.2021.1916689.

A. Roine, HSC Chemistry 7.1. (Finland: Outotec. Pori, 2018)

F. H. Stott, G. C. Wood, and J. Stringer, Oxidation of Metals 44, 113 (1995). https://doi.org/10.1007/BF01046725.

H. Izuta and Y. Komura, Journal of the Japan Institute of Metals 58, 1196 (1994). https://doi.org/10.2320/jinstmet1952.58.10_1196.

G. C. Wood, Corrosion Science 2, 173 (1962). https://doi.org/10.1016/0010-938X(62)90019-7.

H. F. Liu, X. Xiong, X. B. Li, and Y. L. Wang, Corrosion Science 85, 87 (2014). https://doi.org/10.1016/j.corsci.2014.04.001.

U. R. Evans, An Introduction to Metallic Corrosion, (Edward, London, 1948).

S. Ling, Oxidation of Metalls 40, 179 (1993). https://doi.org/10.1007/BF00665264.

H. M. Tawancy, Oxidation of Metals 45, 323 (1996). https://doi.org/10.1007/BF01046988.

D. Caplan and M. Cohen, Corrosion 15, 57 (1959). https://doi.org/10.5006/0010-9312-15.3.57.

Acknowledgements

The authors acknowledge the financial support of the Ministry of Trade, Industry & Energy (MOTIE), Korea.

Funding

This work was funded by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0023676, HRD Program for Industrial Innovation) and the Industrial Strategic Technology Development Program of MOTIE (High Purity Metal Refining Technology for Titanium Metal with Zero Toxic Gas Emission (Grant Number 20010585)).

Author information

Authors and Affiliations

Contributions

KSL: Conceptualization, Formal analysis, Investigation, Methodology, Validation, Visualization, Draft preparation. WSC: Software, Methodology. WBK: Investigation, Validation. SHC: Conceptualization, Data curation, JHL: Conceptualization, Supervision, Data Curation, Project administration. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to disclose that are relevant to this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lim, KS., Choi, WS., Kim, WB. et al. Effect of Cr Content on Hot Corrosion Behavior of Inconel Alloys in Molten LiCl–Li2O. High Temperature Corrosion of mater. 100, 345–358 (2023). https://doi.org/10.1007/s11085-023-10180-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10180-4