Abstract

The mechanical behavior and constitutive relation of rock joints have caught more and more attention in the field of geotechnical engineering. The disturbed state concept (DSC) theory offers a powerful tool for building a constitutive model to interpret the mechanical response of geomaterials. In this paper, a new constitutive model for joint shear deformation was developed based on the DSC theory. The characteristics of quasi-elastic phase, pre-peak hardening phase, peak shear strength, post-peak softening phase and residual strength during the whole process of joint shear deformation are considered in this model. In the framework of this shear constitutive model, the rock material was assumed to consist of two kinds of micro-units with different mechanical responses, namely the relatively intact unit and the fully adjusted unit. Subsequently, the DSC theory was used to connect the mechanical behavior of micro-units with the macroscopic joint shear deformation characteristics, and a disturbance factor was introduced to reveal the disturbed state evolution process inside the rock. In addition, the proposed DSC model was simple in form, less in parameters and reasonable in physical meaning. The model was cross-validated by experimental data of different kinds of natural joints and artificial joint replicas. Finally, the model is compared with existing models, and the model effectiveness is quantitatively evaluated through statistical indicators. The values of R2 are greater than 0.9, and the AAREP and RMSE of the proposed DSC model are closer to 0 than those of other models. The research results can provide a valuable reference for further understanding of shear deformation mechanism.

Similar content being viewed by others

Data availability

Some or all data, models or codes that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- A :

-

Nominal shear area

- A 0 :

-

Area of a single unit

- A RI :

-

Total area of rock units in RI state

- A FA :

-

Total area of rock units in FA state

- B :

-

Model parameter

- C 1 :

-

Integration constants

- C 2 :

-

Integration constants

- D :

-

Disturbance factor

- D ′ :

-

Disturbance rate

- FA :

-

Fully adjusted state

- k s :

-

Joint shear stiffness

- M :

-

Represents the total number of data points

- m :

-

Sum of the number of rock units in RI state

- n :

-

Sum of the number of rock units in FA state

- N :

-

Total number of rock units

- RI :

-

Relatively intact state

- α :

-

Fitting coefficients

- β :

-

Fitting coefficients

- λ :

-

Fitting coefficients

- σ n :

-

Normal stress

- τ :

-

Nominal shear stress

- τ mea :

-

Measured shear stress value

- τ pre :

-

Predicted shear stress value

- τ r :

-

Residual shear stress

- τ p :

-

Peak shear stress

- τ RI :

-

Shear stress borne by rock units in RI state

- τ FA :

-

Shear stress sustained by rock units in FA state

- δ :

-

Shear displacement

- δ p :

-

Peak shear displacement

- δ m :

-

Shear displacement necessary to mate the joints

- r :

-

DSC model parameter

- ŋ :

-

DSC model parameter

References

Fan X, Yu H, Deng Z, He Z, Zhao Y. Cracking and deformation of cuboidal sandstone with a single nonpenetrating flaw under uniaxial compression. Theor Appl Fract Mec. 2022;119: 103284. https://doi.org/10.1016/j.tafmec.2022.103284.

Chen Y, Lin H, Wang Y, Xie S, Zhao Y, Yong W. Statistical damage constitutive model based on the Hoek-Brown criterion. Arch Civ Mech Eng. 2021;21(3):117. https://doi.org/10.1007/s43452-021-00270-y.

Keneti A, Sainsbury BA. Review of published rockburst events and their contributing factors. Eng Geol. 2018;246:361–73. https://doi.org/10.1016/j.enggeo.2018.10.005.

Saadat M, Taheri A. A cohesive discrete element based approach to characterizing the shear behavior of cohesive soil and clay-infilled rock joints. Comput Geotech. 2019;114: 103109. https://doi.org/10.1016/j.compgeo.2019.103109.

Sow D, Carvajal C, Breul P, Peyras L, Rivard P, Bacconnet C, et al. Modeling the spatial variability of the shear strength of discontinuities of rock masses: application to a dam rock mass. Eng Geol. 2017;220:133–43. https://doi.org/10.1016/j.enggeo.2017.01.023.

Xing Y, Kulatilake P, Sandbak LA. Effect of rock mass and discontinuity mechanical properties and delayed rock supporting on tunnel stability in an underground mine. Eng Geol. 2018;238:62–75. https://doi.org/10.1016/j.enggeo.2018.03.010.

Day JJ, Diederichs MS, Hutchinson DJ. New direct shear testing protocols and analyses for fractures and healed intrablock rockmass discontinuities. Eng Geol. 2017;229:53–72. https://doi.org/10.1016/j.enggeo.2017.08.027.

Han W, Jiang YJ, Luan HJ, Liu JK, Wu XL, Du YT. Fracture evolution and failure mechanism of rock-like materials containing cross-flaws under the shearing effect. Theor Appl Fract Mec. 2020. https://doi.org/10.1016/j.tafmec.2020.102815.

Fathipour-Azar H. New interpretable shear strength criterion for rock joints. Acta Geotech. 2022;17(4):1327–41. https://doi.org/10.1007/s11440-021-01442-z.

Xie S, Han Z, Hu H, Lin H. Application of a novel constitutive model to evaluate the shear deformation of discontinuity. Eng Geol. 2022. https://doi.org/10.1016/j.enggeo.2022.106693.

Patton FD, editor. Multiple modes of shear failure in rock. Proceeding of the1st Congress of International Society of Rock Mechanics; 1966.

Develi K. Computation of direction dependent joint surface parameters through the algorithm of triangular prism surface area method: a theoretical and experimental study. Int J Solids Struct. 2020;202:895–911. https://doi.org/10.1016/j.ijsolstr.2020.06.038.

Selvadurai APS, Yu Q. Mechanics of a discontinuity in a geomaterial. Comput Geotech. 2005;32(2):92–106. https://doi.org/10.1016/j.compgeo.2004.11.007.

Asadollahi P, Tonon F. Constitutive model for rock fractures: Revisiting Barton’s empirical model. Eng Geol. 2010;113(1):11–32. https://doi.org/10.1016/j.enggeo.2010.01.007.

Lin QB, Cao P, Wen GP, Meng JJ, Cao RH, Zhao ZY. Crack coalescence in rock-like specimens with two dissimilar layers and pre-existing double parallel joints under uniaxial compression. Int J Rock Mech Min Sci. 2021. https://doi.org/10.1016/j.ijrmms.2021.104621.

Tang ZC, Zhang YB. Temperature-dependent peak shear-strength criterion for granite fractures. Eng Geol. 2020. https://doi.org/10.1016/j.enggeo.2020.105552.

Tang ZC, Peng MH, Xiao SG. Basic friction angle of granite fracture after heating and rapid cooling treatments. Eng Geol. 2022. https://doi.org/10.1016/j.enggeo.2022.106626.

Mpalaskas AC, Matilzas TE, Van Hemelrijck D, Papakitsos GS, Aggelis DG. Acoustic emission monitoring of granite under bending and shear loading. Arch Civ Mech Eng. 2016;16(3):313–24. https://doi.org/10.1016/j.acme.2016.01.006.

Goodman R. Methods of geological engineering in discontinuous rocks: Goodman, RE Univ. California, Berkeley, USA Textbook. Figs, tabls, refs. St. Paul: West Publishing Co., 1976, XII, 472P. 1976; 13(10):115.

Saeb S, Amadei B. Modelling rock joints under shear and normal loading. Int J Rock Mech Min Sci. 1992;29(3):267–78. https://doi.org/10.1016/0148-9062(92)93660-C.

Duriez J, Darve F, Donzé F-V. Incrementally non-linear plasticity applied to rock joint modelling. Int J Numer Anal Met. 2013;37(5):453–77. https://doi.org/10.1002/nag.1105.

Grujovic N, Divac D, Zivkovic M, Slavkovic R, Milivojevic N, Milivojevic V, et al. An inelastic stress integration algorithm for a rock mass containing sets of discontinuities. Acta Geotech. 2013;8(3):265–78. https://doi.org/10.1007/s11440-012-0194-3.

Gens A, Carol I, Alonso E. A constitutive model for rock joints formulation and numerical implementation. Comput Geotech. 1990;9(1–2):3–20. https://doi.org/10.1016/0266-352X(90)90026-R.

Wang J, Ichikawa Y, Leung C. A constitutive model for rock interfaces and joints. Int J Rock Mech Min Sci. 2003;40(1):41–53. https://doi.org/10.1016/s1365-1609(02)00113-2.

Simon R. Analysis of fault-slip mechanisms in hard rock mining. Canada: McGill University; 1999.

Khosravi A, Simon R. Verification of the csds model in estimating the postpeak behavior of hard rocks. Int J Geomech. 2018. https://doi.org/10.1061/(asce)gm.1943-5622.0001090.

Li Y, Oh J, Mitra R, Hebblewhite B. Experimental studies on the mechanical behaviour of rock joints with various openings. Rock Mech Rock Eng. 2016;49(3):837–53. https://doi.org/10.1007/s00603-015-0781-3.

Pouya A, Yazdi PB. A damage-plasticity model for cohesive fractures. Int J Rock Mech Min Sci. 2015;73:194–202. https://doi.org/10.1016/j.ijrmms.2014.09.024.

Xie SJ, Lin H, Chen YF, Yong R, Xiong W, Du SG. A damage constitutive model for shear behavior of joints based on determination of the yield point. Int J Rock Mech Min Sci. 2020. https://doi.org/10.1016/j.ijrmms.2020.104269.

Desai CS, Fishman KL. Plasticity-based constitutive model with associated testing for joints. Int J Rock Mech Min Sci. 1991;28(1):15–26. https://doi.org/10.1016/0148-9062(91)93229-y.

Roosta RM, Sadaghiani MH, Pak A, Saleh Y. Rock joint modeling using a visco-plastic multilaminate model at constant normal load condition. Geotech Geol Eng. 2006;24(5):1449. https://doi.org/10.1007/s10706-005-1217-8.

Fernández LE, Ayala G. Constitutive modeling of discontinuities by means of discrete and continuum approximations and damage models. Int J Solids Struct. 2004;41(5):1453–71. https://doi.org/10.1016/j.ijsolstr.2003.10.010.

Fan X, Yang ZJ, Hong M, Yu H, Xie YL. Mechanism of stress distribution and failure around two different shapes of openings within fractured rock-like materials. J Cent South Univ. 2022;29(6):1916–32. https://doi.org/10.1007/s11771-022-5048-z.

Zhao YL, Zhang LY, Wang WJ, Liu Q, Tang LM, Cheng GM. Experimental study on shear behavior and a revised shear strength model for infilled rock joints. Int J Geomech. 2020. https://doi.org/10.1061/(asce)gm.1943-5622.0001781.

Lei Q, Barton N. On the selection of joint constitutive models for geomechanics simulation of fractured rocks. Comput Geotech. 2022;145: 104707. https://doi.org/10.1016/j.compgeo.2022.104707.

Xie SJ, Lin H, Wang YX, Chen YF, Xiong W, Zhao YL, et al. A statistical damage constitutive model considering whole joint shear deformation. Int J Damage Mech. 2020;29(6):988–1008. https://doi.org/10.1177/1056789519900778.

Lin QB, Cao P, Meng JJ, Cao RH, Zhao ZY. Strength and failure characteristics of jointed rock mass with double circular holes under uniaxial compression: Insights from discrete element method modelling. Theor Appl Fract Mec. 2020. https://doi.org/10.1016/j.tafmec.2020.102692.

Cao RH, Cao P, Lin H, Ma GW, Zhang CY, Jiang C. Failure characteristics of jointed rock-like material containing multi-joints under a compressive-shear test: experimental and numerical analyses. Arch Civ Mech Eng. 2018;18(3):784–98. https://doi.org/10.1016/j.acme.2017.12.003.

Xie SJ, Lin H, Wang YX, Cao RH, Yong R, Du SG, et al. Nonlinear shear constitutive model for peak shear-type joints based on improved Harris damage function. Arch Civ Mech Eng. 2020. https://doi.org/10.1007/s43452-020-00097-z.

Xie SJ, Han ZY, Chen YF, Wang YX, Zhao YL, Lin H. Constitutive modeling of rock materials considering the void compaction characteristics. Arch Civ Mech Eng. 2022. https://doi.org/10.1007/s43452-022-00378-9.

Xie S, Lin H, Cheng C, Chen Y, Wang Y, Zhao Y, et al. Shear strength model of joints based on Gaussian smoothing method and macro-micro roughness. Comput Geotech. 2022;143: 104605. https://doi.org/10.1016/j.compgeo.2021.104605.

Park JW, Lee YK, Song JJ, Choi BH. A constitutive model for shear behavior of rock joints based on three-dimensional quantification of joint roughness. Rock Mech Rock Eng. 2013;46(6):1513–37. https://doi.org/10.1007/s00603-012-0365-4.

Desai C, editor. A consistent finite element technique for work-softening behavior. Proc., Int. Conf. on Computational Methods in Nonlinear Mechanics; 1974: University of Texas, Austin.

Sane SM, Desai CS, Jenson JW, Contractor DN, Carlson AE, Clark PU. Disturbed state constitutive modeling of two Pleistocene tills. Quaternary Sci Rev. 2008;27(3):267–83. https://doi.org/10.1016/j.quascirev.2007.10.003.

Desai CS, Toth J. Disturbed state constitutive modeling based on stress-strain and nondestructive behavior. Int J Solids Struct. 1996;33(11):1619–50. https://doi.org/10.1016/0020-7683(95)00115-8.

Xiao Y, Desai CS. Constitutive modeling for overconsolidated clays based on disturbed state concept. I: theory. Int J Geomech. 2019. https://doi.org/10.1061/(asce)gm.1943-5622.0001474.

Fan R-D, Liu M, Du Y-J, Horpibulsuk S. Estimating the compression behaviour of metal-rich clays via a Disturbed State Concept (DSC) model. Appl Clay Sci. 2016;132–133:50–8. https://doi.org/10.1016/j.clay.2016.05.014.

Huang M, Jiang S, Xu C, Xu D. A new theoretical settlement model for large step-tapered hollow piles based on disturbed state concept theory. Comput Geotech. 2020;124: 103626. https://doi.org/10.1016/j.compgeo.2020.103626.

Desai CS. Disturbed state concept as unified constitutive modeling approach. J Rock Mech Geotech. 2016;8(3):277–93. https://doi.org/10.1016/j.jrmge.2016.01.003.

Oh J, Cording EJ, Moon T. A joint shear model incorporating small-scale and large-scale irregularities. Int J Rock Mech Min Sci. 2015;76:78–87. https://doi.org/10.1016/j.ijrmms.2015.02.011.

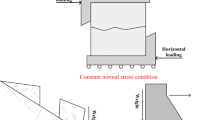

AC10520942. Standard test method for performing laboratory direct shear strength tests of rock specimens under constant normal force. ASTM Internat.; 2008.

Liu D, He M, Cai M. A damage model for modeling the complete stress–strain relations of brittle rocks under uniaxial compression. Int J Damage Mech. 2018;27(7):1000–19. https://doi.org/10.1177/1056789517720804.

Liu DQ, Wang Z, Zhang XY. Characteristics of strain softening of rocks and its damage constitutive model. Rock Soil Mech. 2017;38(10):2901–8. https://doi.org/10.16285/j.rsm.2017.10.017.

Lezon CE, Pintos PM, Bozzini C, Romero AA, Casavalle P, Friedman SM, et al. Mechanical mandible competence in rats with nutritional growth retardation. Arch Oral Biol. 2017;80:10–7. https://doi.org/10.1016/j.archoralbio.2017.03.009.

Zhao YL, Zhang CS, Wang YX, Lin H. Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int J Rock Mech Min Sci. 2021. https://doi.org/10.1016/j.ijrmms.2020.104550.

Singh HK, Basu A. A comparison between the shear behavior of ‘real’ natural rock discontinuities and their replicas. Rock Mech Rock Eng. 2018;51(1):329–40. https://doi.org/10.1007/s00603-017-1334-8.

Usefzadeh A, Yousefzadeh H, Salari-Rad H, Sharifzadeh M. Empirical and mathematical formulation of the shear behavior of rock joints. Eng Geol. 2013;164:243–52.

Zhou H, Cheng GT, Zhu Y, Chen J, Lu JJ, Cui GJ, et al. Experimental study of shear deformation characteristics of marble dentate joints. Rock Soil Mech. 2019;40(3):852–60. https://doi.org/10.16285/j.rsm.2017.0964.

Gui Y, Xia C, Ding W, Qian X, Du S. Modelling shear behaviour of joint based on joint surface degradation during shearing. Rock Mech Rock Eng. 2019;52(1):107–31. https://doi.org/10.1007/s00603-018-1581-3.

Yang Z, Wu Y, Zhou Y, Tang H, Fu S. Assessment of machine learning models for the prediction of rate-dependent compressive strength of rocks. Minerals. 2022;12(6):731.

Chen YF, Lin H, Xie SJ, Ding XR, He DL, Yong WX, et al. Effect of joint microcharacteristics on macroshear behavior of single-bolted rock joints by the numerical modelling with PFC. Environ Earth Sci. 2022. https://doi.org/10.1007/s12665-022-10411-y.

Tang ZC, Zhang QZ, Peng J, Jiao YY. Experimental study on the water-weakening shear behaviors of sandstone joints collected from the middle region of Yunnan province P. R. China. Eng Geol. 2019;258: 105161. https://doi.org/10.1016/j.enggeo.2019.105161.

Mehrishal S, Sharifzadeh M, Song J-J, Shahriar K. An investigation of the possibility of estimating the residual shear strength of rough joints using planar small joint in limestone rocks. J Struct Geol. 2021;142: 104220. https://doi.org/10.1016/j.jsg.2020.104220.

Zhang C, Bai Y, An Y, Wang H, Zeng X. A new method for evaluating rock brittle characteristics based on full stress-strain curve. J Highw Transp Res Develop. 2021;38(3):63–72. https://doi.org/10.3969/j.issn.1002-0268.2021.03.009.

Amadei B, Wibowo J, Sture S, Price RH. Applicability of existing models to predict the behavior of replicas of natural fractures of welded tuff under different boundary conditions. Geotech Geol Eng. 1998;16(2):79–128.

Grasselli G, Egger P. Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci. 2003;40(1):25–40. https://doi.org/10.1016/S1365-1609(02)00101-6.

Tang Z, Xia C, Xiao S. Constitutive model for joint shear stress-displacement and analysis of dilation. Chin J Rock Mech Eng. 2011;30(5):917–25.

Xie SJ, Lin H, Chen YF, Wang YX. A new nonlinear empirical strength criterion for rocks under conventional triaxial compression. J Cent South Univ. 2021;28(5):1448–58. https://doi.org/10.1007/s11771-021-4708-8.

Xie S, Han Z, Lin H. A quantitative model considering crack closure effect of rock materials. Int J Solids Struct. 2022;251: 111758. https://doi.org/10.1016/j.ijsolstr.2022.111758.

Naderi M, Khamehchi E, Karimi B. Novel statistical forecasting models for crude oil price, gas price, and interest rate based on meta-heuristic bat algorithm. J Petrol Sci Eng. 2019;172:13–22. https://doi.org/10.1016/j.petrol.2018.09.031.

Ali E, Guang W, Ibrahim A. Empirical relations between compressive strength and microfabric properties of amphibolites using multivariate regression, fuzzy inference and neural networks: a comparative study. Eng Geol. 2014;183:230–40. https://doi.org/10.1016/j.enggeo.2014.08.026.

Sun Z, Niu D, Wang X, Zhang L, Luo D. Bond behavior of coral aggregate concrete and corroded Cr alloy steel bar. J Build Eng. 2022;61: 105294. https://doi.org/10.1016/j.jobe.2022.105294.

Acknowledgements

This paper gets its funding from Projects (42277175, 52104110) supported by National Natural Science Foundation of China; Project (2020JJ5715) supported by Hunan Provincial Natural Science Foundation of China; Hunan provincial key research and development Program (2022SK2082); and Hunan Civil Air Defense Research Project (HNRFKJ-2021-07). The authors wish to acknowledge these supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical statement

All authors have read and approved this version of the article. No part of this paper has been published or submitted elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

In this appendix, we provide a detailed procedure for solving the basic equation of DSC theory for stress.

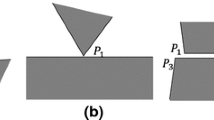

Before modeling the joint plane with the DSC theory, the following basic assumptions were made:

-

(1)

The joint plane is made up of innumerable rock units. Assuming that the total number of units is N (N → + ∞) and the area of a single unit is A0, the nominal shear area A of the joint can be expressed as A = NA0.

-

(2)

The sum of the number of rock units m in RI state and n in FA state at any time is equal to the total number of rock units N, that is, N = m + n.

-

(3)

Before shearing, the rock units are all in RI state. Throughout the shearing of rock joints, the increment of rock units changing from RI state to FA state is gradually augmenting under shearing action. This process is rapid and irreversible. When the shearing process enters the residual phase, the rock units are all in FA state.

The application of external forces, including normal and shear direction, is a quasi-static process in each phase of the joint shear failure process. In view of the mechanical equilibrium along with the loading directions of shear stress, the mechanical equilibrium equation can be obtained as follows:

where τ and A represents nominal shear stress and corresponding nominal shear area, respectively, τRI refers to the shear stress borne by the rock units in RI state, ARI is the total area of these units, τFA denotes the shear stress sustained by the rock units in FA state and AFA is the total area of these units.

Underpinned by the previous assumptions, the three shear areas A, ARI and AFA can all be expressed as the product of the number of rock units and the area of micro-elements A0 in the corresponding state, i.e.,

Then substituting Eq. (A2) into Eq. (A1) yields:

Divide both sides of Eq. (A3) by the NA0 term:

The relative contribution of these rock units in different states (RI or FA) to the joint macroscopic shear behavior could be defined as the disturbance factor D. The number of rock units in the FA state and their growth rate indicate the failure degree of rock materials [52]. As a result, the disturbance factor D can be defined as follows in terms of the proportion of rock units in the FA state to all rock units:

Considering N = m + n, substitute Eq. (A5) into Eq. (A4), and Eq. (A4) can be converted into:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, S., Lin, H. & Chen, Y. New constitutive model based on disturbed state concept for shear deformation of rock joints. Archiv.Civ.Mech.Eng 23, 26 (2023). https://doi.org/10.1007/s43452-022-00560-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00560-z