Abstract

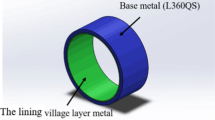

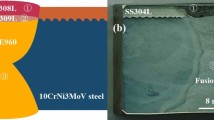

The L415/N08825 bimetallic composite pipe welded joint was produced by gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) using nickel superalloy Inconel 6625 filler. The dendritic austenite grows in the direction perpendicular to the fusion line in the weld metal. The main elements, such as Cr, Ni, Mo and Fe show a large concentration gradient in the interface of the HAZ and weld metal. The unmixed zone in the three-phase zone is because of the differences in thermo-physics properties. The yield strength and tensile strength are 432 and 582 MPa, respectively. The interface between the cladding layer and the base layer fracture first, then the cladding layer, and the base layer finally. Compared with the impact toughness of the weld metal, the HAZ has a better impact toughness. Moreover, the average hardness of the weld is higher than that of the base metal and the HAZ. After welding, the HAZ is softened, and the hardness of the fusion line is higher than that of the base metal. The mechanical properties of the welded joint meet the standard requirements and it is advisable to use the GTAW + SMAW process for the welding of L415/N08825 bimetallic composite pipe.

Similar content being viewed by others

Data availability

All data generated or used during the study are included in the submitted article.

Code availability

Not applicable.

References

Zhang LJ, Pei Q, Zhang JX, Bi ZY, Li PC. Study on the microstructure and mechanical properties of explosive welded 2205/X65 bimetallic sheet. Mater Des. 2014;64:462–76.

Kacar R, Acarer M. An investigation on the explosive cladding of 316L stainless steel-din-P355GH steel. J Mater Process Technol. 2004;152(1):91–6.

Gou NN, Zhang JX, Zhang LJ, Li ZG, Bi ZY. Single pass fiber laser butt welding of explosively welded 2205/X65 bimetallic sheets and study on the properties of the welded joint. Int J Adv Manuf Technol. 2016;86(9):2539–49.

Wang B, Ouyang L, Xu J, Huang P, Liu E, Yang B. Study on stress corrosion cracking behavior of incoloy825/X65 bimetallic composite pipe welded joint in wet hydrogen sulfide environment. Metals. 2022;12(4):632.

Liying L, Jun X, Bin H, Xiaolei W. Microstructure and mechanical properties of welded joints of L415/316L bimetal composite pipe using post internal-welding process. Int J Press Vessels Pip. 2020;179:104026.

Kim JW, Lee K, Kim JS, Byun TS. Local mechanical properties of Alloy 82/182 dissimilar weld joint between SA508 Gr. 1a and F316 SS at RT and 320 C. J Nucl Mater. 2009;384(3):212–21.

Joseph A, Rai SK, Jayakumar T, Murugan N. Evaluation of residual stresses in dissimilar weld joints. Int J Press Vessel Pip. 2005;82(9):700–5.

Hou J, Peng QJ, Takeda Y, Kuniya J, Shoji T, Wang JQ, Ke W. Microstructure and mechanical property of the fusion boundary region in an Alloy 182-low alloy steel dissimilar weld joint. J Mater Sci. 2010;45(19):5332–8.

Ma C, Peng Q, Mei J, Han EH, Ke W. Microstructure and corrosion behavior of the heat affected zone of a stainless steel 308L–316L weld joint. J Mater Sci Technol. 2018;34(10):1823–34.

Hou J, Peng Q, Takeda Y, Kuniya J, Shoji T. Microstructure and stress corrosion cracking of the fusion boundary region in an Alloy 182–A533B low alloy steel dissimilar weld joint. Corros Sci. 2010;52(12):3949–54.

Yajiang L, Haijun M, Juan W. A study of crack and fracture on the welding joint of Fe3Al and Cr18–Ni8 stainless steel. Mater Sci Eng. 2011;528(13–14):4343–7.

Wang B, Lei BB, Wang W, Xu M, Wang L. Investigations on the crack formation and propagation in the dissimilar pipe welds involving L360QS and N08825. Eng Fail Anal. 2015;58:56–63.

Zhang G, Lv D, Wang Q, Zhao K, Wang Y. Microstructure and hardness of the cladding interface of the 304/Q245R explosion cladding panel. Chin J Weld. 2017;38(7):9–12.

Zhou S, Chai D, Yu J, Ma G, Wu D. Microstructure characteristic and mechanical property of pulsed laser lap-welded nickel-based superalloy and stainless steel. J Manuf Process. 2017;25:220–6.

Wang Y, Cui H, Fan M, Chen Y, Lu F. Characterization on the gradient microstructure near the fusion interface of dissimilar metal between high Cr heat-resistant steel and Ni-based Alloy 617. Mater Charact. 2019;151:227–36.

Zhu ML, Wang DQ, Xuan FZ. Effect of long-term aging on microstructure and local behavior in the heat-affected zone of a Ni–Cr–Mo–V steel welded joint. Mater Charact. 2014;87:45–61.

Choi KJ, Kim T, Yoo SC, Kim S, Lee JH, Kim JH. Fusion boundary precipitation in thermally aged dissimilar metal welds studied by atom probe tomography and nanoindentation. J Nucl Mater. 2016;471:8–16.

Ju H, Zhuo S, Liu J, Chen Z, Cui H, Wang Y, Li S. Effects of long-term thermal aging on the microstructure and mechanical behaviors of 16MND5/Alloy 152 dissimilar metal weld. J Market Res. 2022;18:3961–70.

Chen ZR, Lu YH, Ding XF, Shoji T. Microstructural and hardness investigations on a dissimilar metal weld between low alloy steel and Alloy 82 weld metal. Mater Charact. 2016;121:166–74.

Naffakh H, Shamanian M, Ashrafizadeh F. Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J Mater Process Technol. 2009;209(7):3628–39.

Wang W, Lu Y, Ding X, Shoji T. Microstructures and microhardness at fusion boundary of 316 stainless steel/Inconel 182 dissimilar welding. Mater Charact. 2015;107:255–61.

Wang S, Ding J, Ming H, Zhang Z, Wang J. Characterization of low alloy ferritic steel–Ni base alloy dissimilar metal weld interface by SPM techniques, SEM/EDS, TEM/EDS and SVET. Mater Charact. 2015;100:50–60.

Ming H, Wang J, Han EH. Comparative study of microstructure and properties of low-alloy-steel/nickel-based-alloy interfaces in dissimilar metal weld joints prepared by different GTAW methods. Mater Charact. 2018;139:186–96.

Ming H, Zhang Z, Wang J, Han EH, Wang P, Sun Z. Microstructure of a safe-end dissimilar metal weld joint (SA508-52-316L) prepared by narrow-gap GTAW. Mater Charact. 2017;123:233–43.

Okonkwo BO, Ming H, Wang J, Meng F, Xu X, Han EH. Microstructural characterization of low alloy steel A508–309/308L stainless steel dissimilar weld metals. Int J Press Vessels Pip. 2021;190: 104297.

Bi Z, Yang J, Niu J, Zhang J. Fracture toughness of welded joints of X100 high-strength pipeline steel. Acta Metall Sin. 2013;49(5):576–82.

Shu W, Wang X, Li S, He S. Nucleation and growth of intragranular acicular ferrite and its effect on grain refinement of the heat-affected-zone. Acta Metall Sin. 2011;47(4):435–41.

Lv S, Wang T, FENG J. Microstructure and mechanical properties of TIG welded 20G/316L clad pipe joint. Trans China Weld Inst. 2009;30(04):93–6.

Bagherifard S, Slawik S, Fernández-Pariente I, Pauly C, Mücklich F, Guagliano M. Nanoscale surface modification of AISI 316L stainless steel by severe shot peening. Mater Des. 2016;102:68–77.

Ramkumar KD, Patel SD, Praveen SS, Choudhury DJ, Prabaharan P, Arivazhagan N, Xavior MA. Influence of filler metals and welding techniques on the structure–property relationships of Inconel 718 and AISI 316L dissimilar weldments. Mater Des (1980–2015). 2014;62:175–88.

Peng Q, Xue H, Hou J, Sakaguchi K, Takeda Y, Kuniya J, Shoji T. Role of water chemistry and microstructure in stress corrosion cracking in the fusion boundary region of an Alloy 182–A533B low alloy steel dissimilar weld joint in high temperature water. Corros Sci. 2011;53(12):4309–17.

Kumar TS, Nagesha A, Kannan R. Thermal cycling effects on the creep−fatigue interaction in type 316LN austenitic stainless steel weld joint. Int J Press Vessels Pip. 2019;178: 104009.

Deng W, Gao X, Qin X, Zhao D, Du L, Wang G. Impact fracture behavior of X80 pipeline steel. Acta Metall Sin. 2010;46(5):533–40.

Funding

The Technology Project of Nanchong and Southwest Petroleum University (SWPU) Cooperation, SXHZ054, Liang Wang, SWJBGS004, Liang Wang

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Wu, D., Xu, M. et al. Microstructure and mechanical properties of L415/N08825 bimetallic composite pipe welded joint using GTAW + SMAW. Archiv.Civ.Mech.Eng 23, 18 (2023). https://doi.org/10.1007/s43452-022-00554-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00554-x