Abstract

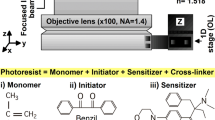

High-speed high-resolution 3D printing of polymers is highly desirable for many applications, yet still technologically challenging. Today, optics-based printing is in the lead. Projection-based linear optical approaches have achieved high printing rates of around 106 voxels s–1, although at voxel volumes of >100 μm3. Scanning-based nonlinear optical approaches have achieved voxel volumes of <1 μm3, but suffer from low printing speed or high cost because of the required femtosecond lasers. Here we present an approach that we refer to as light-sheet 3D laser microprinting. It combines image projection with an AND-type optical nonlinearity based on two-colour two-step absorption. The underlying photoresin is composed of 2,3-butanedione as the photoinitiator, (2,2,6,6-tetramethylpiperidin-1-yl)oxyl as the scavenger and dipentaerythritol hexaacrylate as the multifunctional monomer. Using continuous-wave laser diodes at 440 nm wavelength for projection and a continuous-wave laser at 660 nm for the light-sheet, we achieve a peak printing rate of 7 × 106 voxels s–1 at a voxel volume of 0.55 μm3.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data underlying the plots in this paper and its Supplementary Information and the related 3D printing files are available via the open-access data repository of the Karlsruhe Institute of Technology (https://doi.org/10.5445/IR/1000150926).

References

Fassi, I. & Shipley, D. Micro-Manufacturing Technologies and Their Applications: A Theoretical and Practical Guide (Springer International Publishing, 2017).

Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T. Q. & Hui, D. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. B Eng. 143, 172–196 (2018).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Zheng, X. et al. Multiscale metallic metamaterials. Nat. Mater. 15, 1100–1106 (2016).

Shusteff, M. et al. One-step volumetric additive manufacturing of complex polymer structures. Sci. Adv. 3, eaao5496 (2017).

Kelly, B. E. et al. Volumetric additive manufacturing via tomographic reconstruction. Science 363, 1075–1079 (2019).

Loterie, D., Delrot, P. & Moser, C. High-resolution tomographic volumetric additive manufacturing. Nat. Commun. 11, 852 (2020).

Tumbleston, J. R. et al. Continuous liquid interface production of 3D objects. Science 347, 1349–1352 (2015).

Walker, D. A., Hedrick, J. L. & Mirkin, C. A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science 366, 360–364 (2019).

Beer, M. P. de et al. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Sci. Adv. 5, eaau8723 (2019).

Kato, J., Takeyasu, N., Adachi, Y., Sun, H.-B. & Kawata, S. Multiple-spot parallel processing for laser micronanofabrication. Appl. Phys. Lett. 86, 044102 (2005).

Matsuo, S., Juodkazis, S. & Misawa, H. Femtosecond laser microfabrication of periodic structures using a microlens array. Appl. Phys. A 80, 683–685 (2005).

Hahn, V. et al. Rapid assembly of small materials building blocks (voxels) into large functional 3D metamaterials. Adv. Funct. Mater. 30, 1907795 (2020).

Saha, S. K. et al. Scalable submicrometer additive manufacturing. Science 366, 105–109 (2019).

Somers, P. et al. Rapid, continuous projection multi-photon 3D printing enabled by spatiotemporal focusing of femtosecond pulses. Light Sci. Appl. 10, 199 (2021).

Hahn, V., Mayer, F., Thiel, M. & Wegener, M. 3-D laser nanoprinting. Opt. Photonics News 30, 28–35 (2019).

Regehly, M. et al. Xolography for linear volumetric 3D printing. Nature 588, 620–624 (2020).

Oron, D., Tal, E. & Silberberg, Y. Scanningless depth-resolved microscopy. Opt. Express 13, 1468–1476 (2005).

Tal, E., Oron, D. & Silberberg, Y. Improved depth resolution in video-rate line-scanning multiphoton microscopy using temporal focusing. Opt. Lett. 30, 1686–1688 (2005).

Hahn, V. et al. Two-step absorption instead of two-photon absorption in 3D nanoprinting. Nat. Photon. 15, 932–938 (2021).

Bäckström, H. L. J., Sandros, K., Lindgren, J.-E., Varde, E. & Westin, G. Transfer of triplet state energy in fluid solutions. I. Sensitized phosphorescence and its application to the determination of triplet state lifetimes. Acta Chem. Scand. 14, 48–62 (1960).

Lewis, G. N. & Kasha, M. Phosphorescence and the triplet state. J. Am. Chem. Soc. 66, 2100–2116 (1944).

Sidman, J. W. & McClure, D. S. Electronic and vibrational states of biacetyl and biacetyl-d6 I. Electronic states. J. Am. Chem. Soc. 77, 6461–6470 (1955).

Bäckström, H. L. J. & Sandros, K. The quenching of the long-lived fluorescence of biacetyl in solutions. Acta Chem. Scand. 12, 823–832 (1958).

Green, W. A. Industrial Photoinitiators: A Technical Guide (CRC Press, 2010).

Singh, A., Scott, A. R. & Sopchyshyn, F. Flash photolysis of camphorquinone and biacetyl. J. Phys. Chem. 73, 2633–2643 (1969).

Almgren, M. The natural phosphorescence lifetime of biacetyl and benzil in fluid solution. Photochem. Photobiol. 6, 829–840 (1967).

Taylor, R. P. & Blacet, F. E. Photochemical oxidation of biacetyl by molecular oxygen. Ind. Eng. Chem. 48, 1505–1508 (1956).

Padnos, N. & Noyes, W. A. Photolysis of biacetyl-oxygen mixtures at 4358 Å. J. Phys. Chem. 68, 464–468 (1964).

Schwerzel, R. E. & Caldwell, R. A. Quenching of excited states by stable free radicals. II. Mechanism of triplet quenching by di-tert-butyl nitroxide. J. Am. Chem. Soc. 95, 1382–1389 (1973).

Lissi, E. A. & Encina, M. V. Polymerization photosensitized by carbonyl compounds. J. Polym. Sci. Polym. Chem. Ed. 17, 2791–2803 (1979).

Concheanainn, C. O. & Sidebottom, H. W. Temperature dependence of the triplet lifetime of biacetyl in the gas phase. J. Photochem. 13, 55–66 (1980).

Sawaki, Y. Mechanistic study on the photo-oxidation of α-diketones: interaction of triplet α-diketones with oxygen. Tetrahedron 41, 2199–2205 (1985).

Likhtenshtein, G. I. Nitroxides Brief History, Fundamentals, and Recent Developments (Springer Nature, 2020).

Gijsman, P. A review on the mechanism of action and applicability of hindered amine stabilizers. Polym. Degrad. Stab. 145, 2–10 (2017).

Irshadeen, I. M. et al. Action plots in action: in-depth insights into photochemical reactivity. J. Am. Chem. Soc. 143, 21113–21126 (2021).

Decker, C. & Jenkins, A. D. Kinetic approach of oxygen inhibition in ultraviolet- and laser-induced polymerizations. Macromolecules 18, 1241–1244 (1985).

Mueller, J. B., Fischer, J., Mayer, F., Kadic, M. & Wegener, M. Polymerization kinetics in three-dimensional direct laser writing. Adv. Mater. 26, 6566–6571 (2014).

Chen, Y., Kadic, M. & Wegener, M. Roton-like acoustical dispersion relations in 3D metamaterials. Nat. Commun. 12, 3278 (2021).

Frenzel, T., Kadic, M. & Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 358, 1072–1074 (2017).

Braun, P. V. & Brongersma, M. L. Photochemistry democratizes 3D nanoprinting. Nat. Photon. 15, 871–873 (2021).

Mayer, F. et al. Multimaterial 3D laser microprinting using an integrated microfluidic system. Sci. Adv. 5, eaau9160 (2019).

Maruyama, T., Hirata, H., Furukawa, T. & Maruo, S. Multi-material microstereolithography using a palette with multicolor photocurable resins. Opt. Mater. Express 10, 2522–2532 (2020).

Wang, B. et al. Stiffness control in dual color tomographic volumetric 3D printing. Nat. Commun. 13, 367 (2022).

Hanemann, T. & Honnef, K. Optical and thermomechanical properties of doped polyfunctional acrylate copolymers. Polymers 10, 337 (2018).

Porter, G. B. Photooxidation of biacetyl. J. Chem. Phys. 32, 1587–1588 (1960).

Bensasson, R. & Land, E. J. Triplet-triplet extinction coefficients via energy transfer. Trans. Faraday Soc. 67, 1904–1915 (1971).

Acknowledgements

We acknowledge fruitful discussions with P. Jöckle and A. Neil-Unterreiner (both from the Institute of Physical Chemistry, KIT). We thank R. Batchelor and M. Nardi (both formerly at the ITCP, KIT) for synthesizing, purifying and analysing the chemicals related to the project. We thank M. A. Seiberlich (Light Technology Institute, KIT) for a measurement using a white-light interferometer. V.H. was partially funded by the Max Planck School of Photonics. This research has additionally been funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy via the Excellence Cluster ‘3D Matter Made to Order’ (EXC-2082/1-390761711), which has also been supported by the Carl Zeiss Foundation through the ‘Carl-Zeiss-Foundation-Focus@HEiKA’, by the State of Baden-Württemberg and by KIT. We further acknowledge support by the Helmholtz program ‘Materials Systems Engineering’ (MSE), the Karlsruhe School of Optics & Photonics (KSOP), and the Ministry of Science, Research and Arts of Baden-Württemberg as part of the sustainability financing of the projects of the Excellence Initiative II. C.B.-K. acknowledges funding via an Australian Research Council (ARC) Laureate Fellowship enabling his photochemical research program (FL170100014).

Author information

Authors and Affiliations

Contributions

V.H. proposed the idea for light-sheet 3D printing using two-colour two-step absorption to M.W. V.H. and E.B. searched the literature for suitable photoinitiator candidates, including suggestions from C.B.-K. V.H. and P.M. experimentally screened the photoinitiator candidates. V.H. searched the literature for quenchers and scavengers and characterized the photoresins. P.R. characterized the photoresins in argon and oxygen atmospheres. T.S. and W.W. calculated the molecular electronic transitions of biacetyl. V.H. designed the light-sheet 3D printing setup. F.H. set up and programmed the control unit for the LCD and the stages. M.W. supervised the project. All the authors participated in the discussions on the project. V.H. and M.W. drafted an initial version of the manuscript. All the authors contributed to the interpretation of the results and to the writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

V.H., P.M., E.B. and M.W. are inventors on a patent application filed in Germany on light-sheet 3D printing (DE102018009916A1). The other authors declare no competing interests.

Peer review

Peer review information

Nature Photonics thanks Paul Braun and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–20, Tables 1–5, Notes 1–3, Videos 1–5, Methods and references.

Supplementary Video 1

SEM flyby of the quarter-cut roton structure (Fig. 5c).

Supplementary Video 2

Video recording of the printing process of the roton metamaterial structure (Fig. 5c). This view is coaxially aligned to the light-sheet propagation direction. Light from the light-sheet beam and projection beam is removed by chromatic filters. During printing, luminescence can be observed. The video is in real time.

Supplementary Video 3

Video recording of the printing process of the #3DBenchy fleet. The perspective is the same as that in Supplementary Video 2. The video is in real time. In this video, several boats are stitched using a precision stage.

Supplementary Video 4

Low-magnification video recording of the printing process of the #3DBenchy fleet. The light-sheet beam is impinging from the right into the photoresin-filled cuvette. A glass rod serves as the printing substrate and is actuated by a set of high-precision stages. Laser light is filtered out. However, luminescence within the glass-rod can be observed. The video is in real time.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hahn, V., Rietz, P., Hermann, F. et al. Light-sheet 3D microprinting via two-colour two-step absorption. Nat. Photon. 16, 784–791 (2022). https://doi.org/10.1038/s41566-022-01081-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41566-022-01081-0

This article is cited by

-

Seven technologies to watch in 2024

Nature (2024)

-

Light-based vat-polymerization bioprinting

Nature Reviews Methods Primers (2023)

-

Deconvolution volumetric additive manufacturing

Nature Communications (2023)

-

The physics of 3D printing with light

Nature Reviews Physics (2023)