Abstract

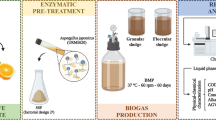

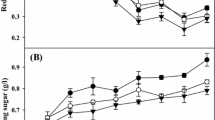

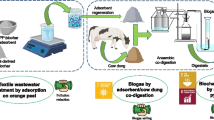

The present study evaluated the hybrid enzymatic hydrolysis and fermentation of Prosopis juliflora pods (Pj pods) for the enhanced biohydrogen production from the activated anaerobic sludge through the waste to energy approach (WtE). The pretreatment effect of sulfuric acid, citric acid, sodium hydroxide, and ammonia has been studied on the Pj pods to make cellulose more accessible for enzyme hydrolysis. The sulfuric acid pretreatment obtained the maximum glucose, 193.19 mg/g BM. The cellulolytic enzyme cocktail comprising cellulase, 80 IU/g, and xylanase, 234.58 IU/g from the newly isolated Trichoderma harzianum BPGF1, is used to hydrolyze the sulfuric acid-treated Pj pods. After the separate enzymatic hydrolysis, the acid-treated Pj pods produced 342.51 mg/g BM glucose. The hybrid enzymatic hydrolysis and fermentation of Pj pods with activated anaerobic sludge was optimized using the central composite design (CCD). The microbial consortium in the anaerobic sludge was identified by next-generation sequencing (NGS) through metagenomic analysis, and the hydrogen was analyzed by gas chromatography. The maximum biohydrogen yield of 1552.25 ± 53.61 mM/L was achieved in the medium containing Pj pods, 13.6% w/v, vitamin solutions, 1.44% v/v, cellulase, 62.74 IU/g BM, and inoculum, 8.67% v/v at an initial pH of 6.49 under anaerobic conditions.

Similar content being viewed by others

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- % v/v:

-

% Of volume per volume

- % w/v:

-

% Of weight per volume

- (NH4)2SO4 :

-

Ammonium sulfate

- 1H NMR:

-

Hydrogen nuclear magnetic resonance

- ASTM:

-

American society for testing materials

- BLAST:

-

Basic local alignment search tool

- BM:

-

Biomass

- CaCO3 :

-

Calcium carbonate

- CCD:

-

Central composite design

- CHNS:

-

Carbon, hydrogen, nitrogen and sulfur

- CP/MAS NMR:

-

Cross–polarization magic angle spinning NMR

- FTIR:

-

Fourier Transform infrared spectroscopy

- HHF:

-

Hybrid hydrolysis and fermentation

- H2SO4 :

-

Sulfuric acid

- HPLC:

-

High-performance liquid chromatography

- IU:

-

International units

- KH2PO4:

-

Potassium di-hydrogen phosphate

- KOH:

-

Potassium hydroxide

- LCB:

-

Lignocellulosic biomass

- MgSO4:

-

Magnesium sulfate

- Na2HPO4 :

-

Sodium hydrogen phosphate

- Na2S:

-

Sodium sulfide

- NaCl:

-

Sodium chloride

- NaOH:

-

Sodium hydroxide

- AFEX:

-

Ammonia fiber expansion

- NGS:

-

Next generation sequencing

- OD:

-

Optical density

- Pj pods:

-

Prosopis>juliflora Pods

- RSM:

-

Response surface methodology

- SEM:

-

Scanning electron microscope

- STP:

-

Sewage treatment plant

- CBP:

-

Consolidated bioprocessing

- SSF:

-

Simultaneous saccharification and fermentation

- TCD:

-

Thermal conductivity detector

- TG-DSC:

-

Thermal gravimetric differential scanning calorimetry

- VFA:

-

Volatile fatty acids

- XRD:

-

X-ray crystallography

- XRF:

-

X-ray fluorescence spectroscopy

References

Bu J, Wang Y-T, Deng M-C, Zhu M-J (2021) Enhanced enzymatic hydrolysis and hydrogen production of sugarcane bagasse pretreated by peroxyformic acid. J Bioresour Technol 326:124751

Eker S, Sarp M (2017) Hydrogen gas production from waste paper by dark fermentation: effects of initial substrate and biomass concentrations. Int J Hydrog Energy 42:2562–2568

Sharmila VG, Tamilarasan K, Kumar MD, Kumar G, Varjani S, Kumar SA, Banu JR (2022) Trends in dark biohydrogen production strategy and linkages with transition towards low carbon economy: an outlook, cost-effectiveness, bottlenecks and future scope. J Int J Hydrog Energy 47:15309–15332

Harish B, Ramaiah MJ, Uppuluri KB (2015) Bioengineering strategies on catalysis for the effective production of renewable and sustainable energy. Renew Sustain Energy Rev 51:533–547

Boboescu IZ, Ilie M, Gherman VD, Mirel I, Pap B, Negrea A, Kondorosi É, Bíró T, Maróti G (2014) Revealing the factors influencing a fermentative biohydrogen production process using industrial wastewater as fermentation substrate. J Biotechnol Biofuels 7:1–15

García AB, Cammarota MC (2019) Biohydrogen production from pretreated sludge and synthetic and real biodiesel wastewater by dark fermentation. J Int J Energy Res 43:1586–1596

Hu B-B, Li M-Y, Wang Y-T, Zhu M-J (2018) Enhanced biohydrogen production from dilute acid pretreated sugarcane bagasse by detoxification and fermentation strategy. J Int J Hydrog Energy 43:19366–19374

Liu Z, Zhang C, Wang L, He J, Li B, Zhang Y, Xing X-H (2015) Effects of furan derivatives on biohydrogen fermentation from wet steam-exploded cornstalk and its microbial community. J Bioresource technol 175:152–159

de Sá LRV, de Oliveira Faber M, da Silva ASA, Cammarota MC, Ferreira-Leitão VS (2020) Biohydrogen production using xylose or xylooligosaccharides derived from sugarcane bagasse obtained by hydrothermal and acid pretreatments. J Renew Energy 146:2408–2415

Cheng J-R, Zhu M-J (2016) Biohydrogen production from pretreated lignocellulose by Clostridium thermocellum. J Biotechnol Bioprocess Eng 21:87–94

Sangyoka S, Reungsang A, Lin C-Y (2016) Optimization of biohydrogen production from sugarcane bagasse by mixed cultures using a statistical method. J Sustain Environ Res 26:235–242

Soares LA, Rabelo CABS, Sakamoto IK, Delforno TP, Silva EL, Varesche MBAJB (2018) Metagenomic analysis and optimization of hydrogen production from sugarcane bagasse. J Biomass Bioenergy 117:78–85

Cao G-L, Xia X-F, Zhao L, Wang Z-Y, Li X, Yang Q (2013) Development of AFEX-based consolidated bioprocessing on wheat straw for biohydrogen production using anaerobic microflora. J Int J Hydrog energy 38:15653–15659

Zhi Z, Wang H (2014) White-rot fungal pretreatment of wheat straw with Phanerochaete chrysosporium for biohydrogen production: simultaneous saccharification and fermentation. J Bioprocess Biosys Eng 37:1447–1458

Zhang S-C, Lai Q-H, Lu Y, Liu Z-D, Wang T-M, Zhang C, Xing X-H (2016) Enhanced biohydrogen production from corn stover by the combination of Clostridium cellulolyticum and hydrogen fermentation bacteria. J Biosci Bioeng 122:482–487

Zhang K, Ren N-Q, Wang A-J (2015) Fermentative hydrogen production from corn stover hydrolyzate by two typical seed sludges: effect of temperature. J Int J Hydrog Energy 40:3838–3848

Zhang T, Jiang D, Zhang H, Jing Y, Tahir N, Zhang Y, Zhang Q (2020) Comparative study on bio-hydrogen production from corn stover: photo-fermentation, dark-fermentation and dark-photo co-fermentation. J Int J Hydrog Energy 45:3807–3814

Pan C, Fan Y, Xing Y, Hou H, Zhang M (2008) Statistical optimization of process parameters on biohydrogen production from glucose by Clostridium sp. Fanp2. J Bioresource technology 99:3146–3154

Xu JF, Ren Nq, Su DX, Qiu J (2010) Bio-hydrogen production from acetic acid steam-exploded corn straws by simultaneous saccharification and fermentation with Ethanoligenens harbinense B49. J Int J Energy Res 34:381–386

Zhang T, Jiang D, Zhang H, Lee D-J, Zhang Z, Zhang Q, Jing Y, Zhang Y, Xia C (2020) Effects of different pretreatment methods on the structural characteristics, enzymatic saccharification and photo-fermentative bio-hydrogen production performance of corn straw. J Bioresource technol 304:122999

Medina-Morales MA, Luis E, Paredes-Peña LA, Morales-Martínez TK, Rodríguez-De la Garza JA, Moreno-Dávila IM, Tamayo-Ordóñez MC, Rios-González LJ (2021) Biohydrogen production from thermochemically pretreated corncob using a mixed culture bioaugmented with Clostridium acetobutylicum. J Int J Hydrog Energy 46:25974–25984

Kim D-H, Jo I-S, Kang B-J, Lee B-D, Kumar S, Kim S-H, Yoon J (2022) Evaluation of bio-hydrogen production using rice straw hydrolysate extracted by acid and alkali hydrolysis. J Int J Hydrog Energy. https://doi.org/10.1016/j.ijhydene.2021.12.139

Kim M, Liu C, Noh J-W, Yang Y, Oh S, Shimizu K, Lee D-Y, Zhang Z (2013) Hydrogen and methane production from untreated rice straw and raw sewage sludge under thermophilic anaerobic conditions. J Int J Hydrogen energy 38:8648–8656

Alemahdi N, Man HC, Nasirian N, Yang Y (2015) Enhanced mesophilic bio-hydrogen production of raw rice straw and activated sewage sludge by co-digestion. J Int J Hydrog Energy 40:16033–16044

Asadi N, Zilouei H (2017) Optimization of organosolv pretreatment of rice straw for enhanced biohydrogen production using Enterobacter aerogenes. J Bioresour technol 227:335–344

Argun H, Dao S (2017) Bio-hydrogen production from waste peach pulp by dark fermentation: effect of inoculum addition. J Int J Hydrog Energy 42:2569–2574

Saraphirom P, Reungsang A (2013) Enhancement of biohydrogen production from sweet sorghum syrup by anaerobic seed sludge in an anaerobic sequencing batch reactor by nutrient and vitamin supplementations. J Environ Technol 34:2503–2511

Das SR, Basak N (2022) Optimization of process parameters for enhanced biohydrogen production using potato waste as substrate by combined dark and photo fermentation. J Biomass Convers Biorefin :1–21

Diah K, Joni P, Endang S, Sumi H (2018) Biohydrogen production through separate hydrolysis and fermentation and simultaneous saccharification and fermentation of empty fruit bunch of palm oil. J Res J Chem Environ Technol 22:193–197

Abdul PM, Jahim JM, Harun S, Markom M, Lutpi NA, Hassan O, Balan V, Dale BE, Nor MTM (2016) Effects of changes in chemical and structural characteristic of ammonia fibre expansion (AFEX) pretreated oil palm empty fruit bunch fibre on enzymatic saccharification and fermentability for biohydrogen. J Bioresour technol 211:200–208

Farghaly A, Roux SL, Peu P, Dabert P, Tawfik A (2019) Effect of starvation period on microbial community producing hydrogen from paperboard mill wastewater using anaerobic baffled reactor. J Environ technol 40:2389–2399

Kirli B, Karapinar I (2018) The effect of HRT on biohydrogen production from acid hydrolyzed waste wheat in a continuously operated packed bed reactor. J Int J Hydrog energy 43:10678–10685

Valdez-Guzmán BE, Rios-Del Toro EE, Cardenas-López RL, Méndez-Acosta HO, González-Álvarez V, Arreola-Vargas J (2019) Enhancing biohydrogen production from Agave tequilana bagasse: detoxified vs. undetoxified acid hydrolysates. J Bioresource Technol 276:74–80

Bundhoo ZM (2017) Effects of microwave and ultrasound irradiations on dark fermentative bio-hydrogen production from food and yard wastes. J Int J Hydrog Energy 42:4040–4050

Mahmood H, Moniruzzaman M, Iqbal T, Khan M (2019) J Current opinion in Green Sustainable Chemistry. Recent adv Pretreatment Lignocellulosic Biomass Biofuels Value-added Products 20:18–24

Ruiz E, Romero I, Moya M, Cara C, Vidal JD, Castro EJ (2013) Dilute sulfuric acid pretreatment of sunflower stalks for sugar production. J Bioresource technol 140:292–298

Palled V, Anantachar M, Veerangouda M, Prakash K, Ramachandra C, Naik NM, Beladadhi R, Manjunatha K, Ramesh B (2016) Effect of alkaline pre treatment on solids recovery and delignification of Prosopis juliflora. J Energy Environ 22:51–56

Maitan-Alfenas GP, Visser EM, Guimarães VM (2015) Enzymatic hydrolysis of lignocellulosic biomass: converting food waste in valuable products. J Curr Opin Food Sci 1:44–49

Pimentel PSS-R, de Oliveira JB, Astolfi-Filho S, Pereira N (2021) Enzymatic hydrolysis of lignocellulosic biomass using an optimized enzymatic cocktail prepared from secretomes of filamentous fungi isolated from Amazonian biodiversity. J App biochem Biotechnol 193:3915–3935

Lee H, Lee YM, Heo YM, Lee H, Hong J-H, Jang S, Min M, Lee J, Kim JS, Kim G-H (2015) Optimization of endoglucanase production by Trichoderma harzianum KUC1716 and enzymatic hydrolysis of lignocellulosic biomass. J Bioresources 10:7466–7476

Teter S, Sutton KB, Emme B (2014) Enzymatic processes and enzyme development in biorefining. Adv biorefin. Elsevier, 199–233

Zhao L, Cao G-L, Wang A-J, Guo W-Q, Ren H-Y, Ren N-Q (2013) Simultaneous saccharification and fermentation of fungal pretreated cornstalk for hydrogen production using Thermoanaerobacterium thermosaccharolyticum W16. Biores Technol 145:103–107

Sawal R, Ratan R, Yadav S (2004) Mesquite (Prosopis juliflora) pods as a feed resource for livestock-a review. Asian Australas J Anim Sci 17:719–725

Singh S, Swapnil S, Verma S (2011) Antibacterial properties of alkaloid rich fractions obtained from various parts of Prosopis juliflora. J Int J Pharma Sci Res 2:114–120

Silva CGMd, Andrade SAC, Schuler ARP, Souza ELd, Stamford TLM (2011) Production of ethanol from mesquite [Prosopis juliflora (SW) DC] pods mash by Zymomonas mobilis in submerged fermentation. J Scientia Agricola 68:124–127

Patnaik P, Abbasi T, Abbasi S (2017) Prosopis (Prosopis juliflora): blessing and bane. J Tropical Ecol 58:455–483

Dave PN, Bhandari J (2013) Prosopis julifera: a review. J Int Chem Environ technol 1:181–196

Mythili R, Subramanian P, Uma D (2017) Biofuel production from Prosopis juliflora in fluidized bed reactor. Part A: Recovery Util Environ Effects 39:741–746

Jampala P, Murugan P, Ramanujam S, Uppuluri KB (2015) Investigation on the effect of carbon and nitrogen sources for the production of cellulosome by Trichoderma reesei NCIM 1186 using saturated placket burman design. J Biocatal Agric Biotechnol 12:1577–1586

Kasirajan S, Umapathy D, Chandrasekar C, Aafrin V, Jenitapeter M, Udhyasooriyan L, Packirisamy ASB, Muthusamy S (2019) Preparation of poly (lactic acid) from Prosopis juliflora and incorporation of chitosan for packaging applications. J biosci 128:323–331

Ramasamy S, Balakrishna HS, Selvaraj U, Uppuluri KB (2014) Production and statistical optimization of oxytetracycline from Streptomyces rimosus NCIM 2213 using a new cellulosic substrate, Prosopis juliflora. J Bioresources 9:7209–7221

Vaidyanath S, Harish B, Gayathri G, Trilokesh C, Uppuluri KB, Anbazhagan V (2020) Maximizing the direct recovery and stabilization of cellulolytic enzymes from Trichoderma harzanium BPGF1 fermented broth using carboxymethyl inulin nanoparticles. Int J Biol Macromol 160:964–970

Meenakshi S, Trilokesh C, Gayathri G, Uppuluri KB, Kaleekkal N (2022) Direct entrapment and statistical optimization of cellulolytic enzymes on PVDF membranes for the hydrolysis of corncob lignocelluloses. J Mol Liq 346:117087

Kang KE, Jeong G-T, Sunwoo C, Park D-H (2012) Pretreatment of rapeseed straw by soaking in aqueous ammonia. J Bioprocess Biosyst Eng 35:77–84

Singh J, Sharma A, Sharma P, Singh S, Das D, Chawla G, Singha A, Nain L, 2020. Valorization of jute (Corchorus sp.) biomass for bioethanol production. J Biomass Convers Biorefin 1–12.

Vaz FL, Rocha Lins J, Alencar BRA, de Abreu ÍBS, Vidal EE, Ribeiro E, Sampaio EVdSB, Menezes RSC, Dutra ED (2021) Chemical pretreatment of sugarcane bagasse with liquid fraction recycling. J Renew Energy 174:666–673

Madsen T, Rasmussen HB, Nilsson L (1995) Anaerobic biodegradation potentials in digested sludge, a freshwater swamp and a marine sediment. J Chemosphere 31:4243–4258

Srikanth R, Siddartha G, Reddy CHS, Harish B, Ramaiah MJ, Uppuluri KB (2015) Antioxidant and anti-inflammatory levan produced from Acetobacter xylinum NCIM2526 and its statistical optimization. J Carbohydrate Polymers 123:8–16

Aguilar-Aguilar F, Adaya L, Godoy-Lozano EE, Pantoja L, dos Santos AS, Eapen D, Sebastian PJ (2021) Anaerobic co-digestion of raw glycerol and swine manure: microbial communities. J Biomass Convers Biorefin :1–12

Trilokesh C, Uppuluri KB (2019) Isolation and characterization of cellulose nanocrystals from jackfruit peel. J Sci Reports 9:1–8

Mahata C, Ray S, Das D (2020) Optimization of dark fermentative hydrogen production from organic wastes using acidogenic mixed consortia. Energy Convers Manag 219:11304

Harish B, Uppuluri KBJMB (2018) Potential anticoagulant activity of trypsin inhibitor purified from an isolated marine bacterium Oceanimonas sp. BPMS22 and its Kinetics. J Marine biotechnol 20:780–791

Ospina-Giraldo M, Royse D, Thon M, Chen X, Romaine C (1998) Phylogenetic relationships of Trichoderma harzianum causing mushroom green mold in Europe and North America to other species of Trichoderma from world-wide sources. J Mycologia 90:76–81

Xiang Q, Kim JS, Lee Y (2003) A comprehensive kinetic model for dilute-acid hydrolysis of cellulose. Biotechnol Fuels Chem :337–352

Bhandari N, Macdonald DG, Bakhshi NN (1984) Kinetic studies of corn stover saccharification using sulphuric acid. J Biotechnol Bioeng 26:320–327

Leenakul W, Tippayawong, N.J.J.o.S.E., Environment, (2010) Dilute acid pretreatment of bamboo for fermentable sugar production. J Sustain Energy Environ Technol 1:117–120

Slathia PS, Raina N, Kiran A, Kour R, Bhagat D, Sharma P (2020) Dilute acid pretreatment of pine needles of Pinus roxburghii by response surface methodology for bioethanol production by separate hydrolysis and fermentation. J Biomass Convers Biorefin 10:95–106

Dagnino EP, Chamorro ER, Romano SD, Felissia FE, Area MC (2013) Optimization of the pretreatment of prosopis nigra sawdust for the production of fermentable sugars. J Bioresources 8:499–514 (waste)

Sun Y, Cheng J (2005) Dilute acid pretreatment of rye straw and bermudagrass for ethanol production. J Bioresource technol 96:1599–1606

Antonopoulou G, Dimitrellos G, Beobide AS, Vayenas D, Lyberatos G (2015) Chemical pretreatment of sunflower straw biomass: the effect on chemical composition and structural changes. J Waste Biomass Valori 6:733–746

Gomes MG, Gurgel LVA, Baffi MA, Pasquini D (2020) Pretreatment of sugarcane bagasse using citric acid and its use in enzymatic hydrolysis. J Renew Energy 157:332–341

Zhang H, Wu S (2014) Dilute ammonia pretreatment of sugarcane bagasse followed by enzymatic hydrolysis to sugars. J Cellulose 21:1341–1349

Dessì P, Porca E, Frunzo L, Lakaniemi AM, Collins G, Esposito G, Lens PNJ (2018) Inoculum pretreatment differentially affects the active microbial community performing mesophilic and thermophilic dark fermentation of xylose. J Int Hydrog Energy 43:9233–9245

Yang G, Yin Y, Wang J (2019) Microbial community diversity during fermentative hydrogen production inoculating various pretreated cultures. Int J Hydrog Energy 44:13147–13156

Chiariotti A, Crisà A (2018) Bio-hydrogen production from buffalo with rumen inoculum and metagenomic characterization of bacterial and archaeal community. J Front Sustain food syst 2:13

Khanna N, Kotay SM, Gilbert JJ, Das D (2011) Improvement of biohydrogen production by Enterobacter cloacae IIT-BT 08 under regulated pH. J Biotechnol 152:9–15

Marone A, Varrone C, Fiocchetti F, Giussani B, Izzo G, Mentuccia L, Rosa S, Signorini A (2015) Optimization of substrate composition for biohydrogen production from buffalo slurry co-fermented with cheese whey and crude glycerol, using microbial mixed culture. J Int J Hydrog Energy 40:209–218

Anthony P, Harish B, Jampala P, Ramanujam S, Uppuluri KB (2016) Statistical optimization, purification and applications of xylanase produced from mixed bacteria in a solid liquid fermentation using Prosopis juliflora. J Biocatal agric biotechnol 8:213–220

Azman NF, Abdeshahian P, Al-Shorgani NKN, Hamid AA, Kalil MS (2016) Production of hydrogen energy from dilute acid-hydrolyzed palm oil mill effluent in dark fermentation using an empirical model. J Int J Hydrog energy 41:16373–16384

Funding

KBU was financially supported by DST/SERB, India (EEQ/2019/000245).

Author information

Authors and Affiliations

Contributions

KBU conceived the idea and designed the experiments. GG conducted all the experiments. KBU and GG analyzed the data and wrote and edited the manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval

No human participants and/or animals were involved in this research.

Competing interests

The authors declare no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gayathri, G., Uppuluri, K.B. Hybrid hydrolysis and fermentation optimization of Prosopis juliflora pods for the enhanced biohydrogen production by dark fermentation. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03278-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03278-3