Abstract

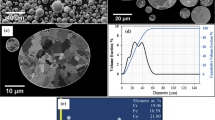

The effects of several cold spray process parameters on deposition efficiency and bonding quality of Al-6061 powder on the same material were investigated. Single particles were deposited at different particle impact velocities, nozzle-orientations, and nozzle travel speeds. Thick multilayer deposits were prepared to evaluate the effects of substrate surface finish and nozzle-orientation on deposition efficiency and bonding strength. Microstructural evaluation was performed on both deposited single particles and multilayer thick deposits by using optical microscopy, SEM, and TEM. It was confirmed that bonding occurs in peripheral regions of the splats, while only partial bonding develops at the polar region even at high impact velocities. Further, there is a critical spray angle below which no deposition takes place. This critical spray angle depends on nozzle travel speed and the duration of spray. A new method for substrate surface preparation was proposed by spraying at angles below the critical spray angle with the same powder prior to coating. Using low angle spraying as a surface preparation strategy provides a bonding strength of 54 MPa as compared to 22 MPa obtained for grit blasted substrates. Spray angle also affects deposition efficiency, porosity, and microstructure. Reducing the spray angle from 90° to 30° results in decreasing the deposition efficiency from 48 to 16%, increasing the porosity from 0.84 to 1.36%, and changing the microstructure from tightly bonded microstructure into columnar microstructure with porosity developed at inter-columnar regions.

Similar content being viewed by others

References

C. Chen, Y. Xie, S. Yin, M.P. Planche, S. Deng, R. Lupoi and H. Liao, Evaluation of the Interfacial Bonding Between Particles and Substrate in Angular Cold Spray, Mater. Lett., 2016, 173, p 76-79.

S. Bagherifard and M. Guagliano, Fatigue Performance of Cold Spray Deposits: Coating, Repair and Additive Manufacturing Cases, Int. J. Fatigue, 2020, 139, p 105744.

R. Partovi-Nia, S. Ramamurthy, D. Zagidulin, J. Chen, R. Jacklin, P. Keech and D.W. Shoesmith, Corrosion of Cold Spray Deposited Copper Coating on Steel Substrates, Corrosion, 2015, 71(10), p 1237-1247.

M.R. Rokni, S.R. Nutt, C.A. Widener, V.K. Champagne and R.H. Hrabe, Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26(6), p 1308-1355.

A. Nourian-Avval and S. Müftü, Effect of Substrate Surface Finish and Particle Velocity on Fatigue Performance of Cold Spray Coated A6061 Aluminum Alloy, Surf. Coat. Technol., 2022, 444, p 128676.

S. Julien, A. Nourian-Avval, W. Liang, T. Schwartz, O.C. Ozdemir and S. Müftü, Bulk Fracture Anisotropy in Cold-Sprayed Al 6061 Deposits, Eng. Fract. Mech., 2022, 263, p 108301.

B. Yildirim, H. Fukanuma, T. Ando, A. Gouldstone and S. Müftü, A Numerical Investigation into Cold Spray Bonding Processes, J. Tribol., 2015, 137(1), p 011102.

W. Xie, A. Alizadeh-Dehkharghani, Q. Chen, V.K. Champagne, X. Wang, A. Nardi and J.H. Lee, Dynamics and Extreme Plasticity of Metallic Microparticles in Supersonic Collisions, Sci. Rep., 2017, 7(1), p 1-9.

Z. Khalkhali, W. Xie, V.K. Champagne, J.H. Lee and J.P. Rothstein, A Comparison of Cold Spray Technique to Single Particle Micro-Ballistic Impacts for the Deposition of Polymer Particles on Polymer Substrates, Surf. Coat. Technol., 2018, 351, p 99-107.

M. Gardon, A. Latorre, M. Torrell, S. Dosta, J. Fernández and J.M. Guilemany, Cold Gas Spray Titanium Coatings onto a Biocompatible Polymer, Mater. Lett., 2013, 106, p 97-99.

R. Lupoi and W. O’Neill, Deposition of Metallic Coatings on Polymer Surfaces Using Cold Spray, Surf. Coat. Technol., 2010, 205(7), p 2167-2173.

H. Che, X. Chu, P. Vo and S. Yue, Metallization of Various Polymers by Cold Spray, J. Therm. Spray Technol., 2018, 27(1-2), p 169-178.

H. Parmar, F. Tucci, P. Carlone and T.S. Sudarshan, Metallisation of Polymers and Polymer Matrix Composites by Cold Spray: State of the Art and Research Perspectives, Int. Mater. Rev., 2022, 67(4), p 385-409.

X. Xie, Y. Ma, C. Chen, G. Ji, C. Verdy, H. Wu and H. Liao, Cold Spray Additive Manufacturing of Metal Matrix Composites (MMCs) Using a Novel Nano-TiB2-Reinforced 7075 Al Powder, J. Alloy. Compd., 2020, 819, p 152962.

X. Xie, S. Yin, R. Raoelison, C. Chen, C. Verdy, W. Li and H. Liao, Al Matrix Composites Fabricated by Solid-State Cold Spray Deposition: A Critical Review, J. Mater. Sci. Technol., 2021, 86, p 20-55.

Y. Xie, S. Yin, C. Chen, M.P. Planche, H. Liao and R. Lupoi, New Insights into the Coating/Substrate Interfacial Bonding Mechanism in Cold Spray, Scr. Mater., 2016, 125, p 1-4.

T. Hussain, D.G. McCartney, P.H. Shipway and D. Zhang, Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components, J. Therm. Spray Technol., 2009, 18(3), p 364-379.

A. Viscusi, A. Astarita, R. Gatta and F. Rubino, A Perspective Review on the Bonding Mechanisms in Cold Gas Dynamic Spray, Taylor Francis, 2018, 35(9), p 743-771.

H. Assadi, F. Gärtner, T. Stoltenhoff and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394.

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H. Kim and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666.

T. Schmidt, F. Gärtner, H. Assadi and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742.

M. Grujicic, C.L. Zhao, W.S. DeRosset and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688.

A. Tiamiyu, Y. Sun, K.A. Nelson and C.A. Schuh, Site-Specific Study of Jetting, Bonding, and Local Deformation During High-Velocity Metallic Microparticle Impact, Acta Mater., 2021, 202, p 159-169.

M. Hassani-Gangaraj, D. Veysset, K.A. Nelson, and C.A. Schuh, Supersonic impact of metallic micro-particles, arXiv preprint arXiv:1612.08081, (2016)

M. Hassani-Gangaraj, D. Veysset, V.K. Champagne, K.A. Nelson and C.A. Schuh, Adiabatic Shear Instability is Not Necessary for Adhesion in Cold Spray, Acta Mater., 2018, 158, p 430-439.

C. Chen, Y. Xie, R. Huang, S. Deng, Z. Ren and H. Liao, On the Role of Oxide Film’s Cleaning Effect into the Metallurgical Bonding During Cold Spray, Mater. Lett., 2018, 210, p 199-202.

Y. Xie, C. Chen, M.P. Planche, S. Deng, R. Huang, Z. Ren and H. Liao, Strengthened Peening Effect on Metallurgical Bonding Formation in Cold Spray Additive Manufacturing, J. Therm. Spray Technol., 2019, 28(4), p 769-779.

S. Yin, X. Suo, Y. Xie, W. Li, R. Lupoi and H. Liao, Effect of Substrate Temperature on Interfacial Bonding for Cold Spray of Ni onto Cu, J. Mater. Sci., 2015, 50(22), p 7448-7457.

S. Yin, X. Suo, H. Liao, Z. Guo and X. Wang, Significant Influence of Carrier Gas Temperature During the Cold Spray Process, Taylor Francis, 2014, 30(6), p 443-450.

Y. Li, Y. Wei, X. Luo, C. Li and N. Ma, Correlating Particle Impact Condition with Microstructure and Properties of the Cold-Sprayed Metallic Deposits, J. Mater. Sci. Technol., 2020, 40, p 185-195.

A. Moridi, S. Hassani-Gangaraj, M. Guagliano and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Taylor Francis, 2014, 30(6), p 369-395.

R. Huang and H. Fukanuma, Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits, J. Therm. Spray Technol., 2012, 21(3-4), p 541-549.

V.K. Champagne, D.J. Helfritch, S.P.G. Dinavahi and P.F. Leyman, Theoretical and Experimental Particle Velocity in Cold Spray, J. Therm. Spray Technol., 2011, 20(3), p 425-431.

X.J. Ning, J.H. Jang and H.J. Kim, The Effects of Powder Properties on In-Flight Particle Velocity and Deposition Process During Low Pressure Cold Spray Process, Appl. Surf. Sci., 2007, 253(18), p 7449-7455.

Q. Wang, N. Ma, X. Luo and C. Li, Towards Better Understanding Supersonic Impact-Bonding Behavior of Cold Sprayed 6061–T6 Aluminum Alloy Based on a High-Accuracy Material Model, Addit. Manuf., 2021, 48, p 102469.

B. Aldwell, E. Kelly, R. Wall, A. Amaldi, G.E. O’Donnell and R. Lupoi, Machinability of Al 6061 Deposited with Cold Spray Additive Manufacturing, J. Therm. Spray Technol., 2017, 26(7), p 1573-1584.

S. Kumar, G. Bae and C. Lee, Influence of Substrate Roughness on Bonding Mechanism in Cold Spray, Surf. Coat. Technol., 2016, 304, p 592-605.

R. Singh, K.H. Rauwald, E. Wessel, G. Mauer, S. Schruefer, A. Barth and R. Vassen, Effects of Substrate Roughness and Spray-Angle on Deposition Behavior of Cold-Sprayed Inconel 718, Surf. Coat. Technol., 2017, 319, p 249-259.

P. Richer, B. Jodoin and L. Ajdelsztajn, Substrate Roughness and Thickness Effects on Cold Spray Nanocrystalline Al-Mg Coatings, J. Therm. Spray Technol., 2006, 15(2), p 246-254.

T. Hussain, D.G. McCartney, P.H. Shipway and D. Zhang, Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical, J. Therm. Spray Technol., 2009, 18(3), p 364-379.

T. Marrocco, D.G. McCartney, P.H. Shipway and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272.

J. Wu, H. Yang, S. Yoon. Fang and C. Lee, The Bond Strength of Al-Si Coating on Mild Steel by Kinetic Spraying Deposition, Appl. Surf. Sci., 2006, 252(22), p 7809-7814.

S. Yin, X. Suo, J. Su, Z. Guo, H. Liao and X. Wang, Effects of Substrate Hardness and Spray Angle on the Deposition Behavior of Cold-Sprayed Ti Particles, J. Therm. Spray Technol., 2014, 23(1-2), p 76-83.

X.T. Luo, Y.J. Li, C.X. Li, G.J. Yang and C.J. Li, Effect of Spray Conditions on Deposition Behavior and Microstructure of Cold Sprayed Ni Coatings Sprayed with a Porous Electrolytic Ni Powder, Surf. Coat. Technol., 2016, 289, p 85-93.

C.J. Li, W.Y. Li, Y.Y. Wang and H. Fukanuma, Effect of Spray Angle on Deposition Characteristics in Cold Spraying, Therm. Spray, 2003, 2003, p 91-96.

C.J. Li, W.Y. Li and H. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 15(2), p 212-222.

X. Wang, F. Feng, M.A. Klecka, M.D. Mordasky, J.K. Garofano, T. El-Wardany and V.K. Champagne, Characterization and Modeling of the Bonding Process in Cold Spray Additive Manufacturing, Addit. Manuf., 2015, 8, p 149-162.

Y.K. Wei, X.T. Luo, X. Chu, G.S. Huang and C.J. Li, Solid-State Additive Manufacturing High Performance Aluminum Alloy 6061 Enabled by an In-situ Micro-Forging Assisted Cold Spray, Mater. Sci. Eng., A, 2020, 776, p 139024.

R. Sinclair-Adamson, M. Harbidge and R. Murray, Sintering of Cold Spray Additively Manufactured Aluminum 6061, J. Therm. Spray Technol., 2021, 30(6), p 1493-1511.

A.C. Hall, L.N. Brewer and T.J. Roemer, Preparation of Aluminum Coatings Containing Homogenous Nanocrystalline Microstructures Using the Cold Spray Process, J. Therm. Spray Technol., 2008, 17(3), p 352-359.

B.A. Bedard et al., Microstructure and Micromechanical Response in Gas-Atomized Al 6061 Alloy Powder and Cold-Sprayed Splats, J. Therm. Spray Technol., 2018, 27(8), p 1563-1578.

M.R. Rokni, C.A. Widener, O.C. Ozdemir and G.A. Crawford, Microstructure and Mechanical Properties of Cold Sprayed 6061 Al in As-sprayed and Heat Treated Condition, Surf. Coat. Technol., 2017, 309, p 641-650.

A.G. Gavras, D.A. Lados, V.K. Champagne and R.J. Warren, Effects of Processing on Microstructure Evolution and Fatigue Crack Growth Mechanisms in Cold-Spray 6061 Aluminum Alloy, Int. J. Fatigue, 2018, 110, p 49-62.

M.R. Rokni, C.A. Widener and V.R. Champagne, Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition, J. Therm. Spray Technol., 2014, 23(3), p 514-524.

V.K. Champagne, D.J. Helfritch, M.D. Trexler and B.M. Gabriel, The Effect of Cold Spray Impact Velocity on Deposit Hardness, Model. Simul. Mater. Sci. Eng., 2010, 18(6), p 065011.

W.C. Evans, X. Dan, A. Houshmand, S. Müftü and T. Ando, Microstructural Characterization of Aluminum 6061 Splats Cold Spray Deposited on Aluminum 6061–T6 Substrate, Metall. Mater. Trans. A, 2019, 50(8), p 3937-3948.

ASTM C633, “Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings”, (2021)

A. Tiamiyu and C.A. Schuh, Particle Flattening During Cold Spray: Mechanistic Regimes Revealed by Single Particle Impact Tests, Surf. Coat. Technol., 2020, 403, p 126386.

P.C. King, G. Bae, S.H. Zahiri, M. Jahedi and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2010, 19(3), p 620-634.

J. Xie, D. Nélias, W.L. Berre, K. Ogawa and Y. Ichikawa, Simulation of the Cold Spray Particle Deposition Process, J. Tribol., 2015, 137, p 4.

Y. Xiong, X. Xiong, S. Yoon, G. Bae and C. Lee, Dependence of Bonding Mechanisms of Cold Sprayed Coatings on Strain-Rate-Induced Non-Equilibrium Phase Transformation, J. Therm. Spray Technol., 2011, 20(4), p 860-865.

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process, J. Therm. Spray Technol., 1999, 8(4), p 576-582.

E. Lin, Q. Chen, O.C. Ozdemir, V.K. Champagne and S. Müftü, Effects of Interface Bonding on the Residual Stresses in Cold-Sprayed Al-6061: A Numerical Investigation, J. Therm. Spray Technol., 2019, 28(3), p 472-483.

Q. Chen, On the Mechanics and Material-Response of Metal Particles in Cold Spray Impacts, Northeastern University, 2020.

Q. Blochet, F. Delloro, F. N’Guyen, D. Jeulin, F. Borit and M. Jeandin, Effect of the Cold-Sprayed Aluminum Coating-Substrate Interface Morphology on Bond Strength for Aircraft Repair Application, J. Therm. Spray Technol., 2017, 26(4), p 671-686.

A.W.Y. Tan, W. Sun, A. Bhowmik, J.Y. Lek, X. Song, W. Zhai and E. Liu, Effect of Substrate Surface Roughness on Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings on Ti6Al4V Substrates, J. Therm. Spray Technol., 2019, 28(8), p 1959-1973.

Acknowledgments

This work has been partially sponsored by a partnership with NAVSEA 04 and the National Center for Manufacturing Sciences under contract number 2020129-142021 to Northeastern University. The findings and opinions expressed in this paper are solely of the authors and do not necessarily represent those of the sponsors, and no official endorsement should be inferred.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nourian, A., Schwartz, T., Boese, S. et al. Effects of Process Parameters on Cold Spray Deposition of Al-6061 Alloy. J Therm Spray Tech 31, 2517–2536 (2022). https://doi.org/10.1007/s11666-022-01456-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01456-3