Abstract

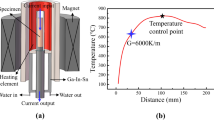

Stably controlling the monocrystalline nature in the repaired zone is a longstanding challenge for the laser additively repair of single-crystal components. In this study, the coupling effect of laser defocusing amount and scanning speed on the molten pool morphology and associated crystal growth behaviors in laser powder deposition of single-crystal superalloy was studied through single-track experiments and an improved mathematical model. Multi-layer experiments were conducted to verify the practicability of optimized processing parameters. The results indicated that the defocusing amount can effectively adjust the laser energy intensity distribution through changing the laser-powder interaction distance and resultantly tailor the molten pool morphology and associated crystal growth behaviors. With the defocusing amount changing from − 3 to + 3 mm, the toe angle of molten pool increases dramatically and induces the formation of nonideal columnar crystals at the toe edge. The increase in laser scanning speed shrinks the molten pool size, restrains the formation of stray grains and nonideal columnar crystals, and enhances the total-remelting ability of stray grains. Coupling tailoring negative defocusing amount and proper scanning speed (− 3 mm and 9 mm/s are optimal under the given conditions) benefits the epitaxial-growth continuity of columnar dendrites and reproduces complete monocrystalline structure in laser SX-repair process.

Similar content being viewed by others

References

P. Nörtershäuser, J. Frenzel, A. Ludwig, K. Neuking, and G. Eggeler, The Effect of Cast Microstructure and Crystallography on Rafting, Dislocation Plasticity and Creep Anisotropy of Single Crystal Ni-Base Superalloys, Mater. Sci. Eng., A, 2015, 626, p 305-312.

T. Ford, Single Crystal Blades, Aircr. Eng. Aerosp. Technol., 1997, 69(6), p 564-566.

J. Yu, X. Sun, N. Zhao, T. Jin, H. Guan, and Z. Hu, Effect of Heat Treatment on Microstructure and Stress Rupture Life of DD32 Single Crystal Ni-Base Superalloy, Mater. Sci. Eng., A, 2007, 460, p 420-427.

X. Yu, C. Wang, X. Zhang, P. Yan, and Z. Zhang, Synergistic Effect of Rhenium and Ruthenium in Nickel-Based Single-Crystal Superalloys, J. Alloy. Compd., 2014, 582, p 299-304.

Y. Jian, L. Jiarong, L. Shizhong, H. Mei, S. Zhenxue, Tensile behavior and deformation mechanism of secondary generation single crystal superalloy DD6 at 1070 C, Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering, 2015/08, 2015, Atlantis Press, pp 2261-2266

R. Reed, A. Yeh, S. Tin, S. Babu, and M. Miller, Identification of the Partitioning Characteristics of Ruthenium in Single Crystal Superalloys using atom Probe Tomography, Scripta Mater., 2004, 51(4), p 327-331.

R.C. Reed, The superalloys: fundamentals and applications, Cambridge University Press, 2006

S. Babu, S. David, J. Park, and J. Vitek, Joining of Nickel Base Superalloy Single Crystals, Sci. Technol. Weld. Joining, 2004, 9(1), p 1-12.

L.J. Roedl, R. Hensley, Gas turbine blade having a monocrystalline airfoil with a repair squealer tip, and repair method, ed., Google Patents, 2007

M.B. Henderson, D. Arrell, R. Larsson, M. Heobel, and G. Marchant, Nickel Based superalloy Welding Practices for Industrial Gas Turbine Applications, Sci. Technol. Weld. Joining, 2004, 9(1), p 13-21.

Y.J. Liang, X. Cheng, J. Li, and H.M. Wang, Microstructural Control During Laser Additive Manufacturing of Single-Crystal Nickel-Base superalloys: New Processing–Microstructure Maps Involving Powder Feeding, Mater. Des., 2017, 130, p 197-207.

Y.J. Liang, J. Li, A. Li, X. Cheng, S. Wang, and H.M. Wang, Experimental Optimization of Laser Additive Manufacturing Process of Single-Crystal Nickel-Base superalloys by a Statistical Experiment Design Method, J. Alloy. Compd., 2017, 697, p 174-181.

S.S. Babu, N. Raghavan, J. Raplee, S.J. Foster, C. Frederick, M. Haines, R. Dinwiddie, M.K. Kirka, A. Plotkowski, Y. Lee, and R.R. Dehoff, Additive Manufacturing of Nickel Superalloys: Opportunities for Innovation and Challenges Related to Qualification, Metall. and Mater. Trans. A., 2018, 49(9), p 3764-3780.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang, Additive Manufacturing of Metallic Components - PROCESS, Structure and Properties, Progress Mater. Sci., 2018, 92, p 112-224.

H. Chen, G. Huang, Y. Lu, S. Lin, and D. Liu, Epitaxial Laser Deposition of Single Crystal Ni-Based superalloy: Variation of Stray Grains, Mater. Charact., 2019, 158, 109982.

M. Rappaz, S. David, J. Vitek, and L. Boatner, Analysis of Solidification Microstructures in Fe-Ni-Cr Single-Crystal Welds, Metall. Trans. A, 1990, 21(6), p 1767-1782.

M. Rappaz, S. David, J. Vitek, and L. Boatner, Development of Microstructures in Fe− 15Ni− 15Cr Single Crystal Electron Beam Welds, Metall. Trans. A, 1989, 20(6), p 1125-1138.

W. Liu and J. DuPont, Effects of Melt-Pool Geometry on Crystal Growth and Microstructure Development in Laser Surface-Melted superalloy Single Crystals: Mathematical Modeling of Single-Crystal Growth in a Melt Pool (part I), Acta Mater., 2004, 52(16), p 4833-4847.

W. Liu and J. DuPont, Effects of Substrate Crystallographic Orientations on Crystal Growth and Microstructure Development in Laser Surface-Melted Superalloy Single Crystals, Acta Mater., 2005, 53(5), p 1545-1558.

Z. Liu and H. Qi, Mathematical Modeling of Crystal Growth and Microstructure Formation in Multi-layer and Multi-track Laser Powder Deposition of Single-crystal Superalloy, Phys. Procedia, 2014, 56, p 411-420.

Z. Liu and J. Shu, Control of the Microstructure Formation in the Near-Net-Shape Laser Additive tip-Remanufacturing Process of Single-Crystal Superalloy, Opt. Laser Technol., 2021, 133, 106537.

R. Acharya and S. Das, Additive Manufacturing of IN100 Superalloy Through Scanning Laser Epitaxy for Turbine Engine Hot-Section Component Repair: Process Development, Model. Microstruct. Character., Process Control, Metall. Mater. Trans. A, 2015, 46(9), p 3864-3875.

R. Vilar and A. Almeida, Repair and Manufacturing of Single Crystal Ni-Based Superalloys Components by Laser Powder Deposition—A Review, J. Laser Appl., 2015, 27(S1), p S17004.

Z. Liu and H. Qi, Effects of Substrate Crystallographic Orientations on Crystal Growth and Microstructure Formation in Laser Powder Deposition of Nickel-Based Superalloy, Acta Mater., 2015, 87, p 248-258.

J. Hunt, Steady State Columnar and Equiaxed Growth of Dendrites and Eutectic, Mater. Sci. Eng., 1984, 65(1), p 75-83.

M. Gäumann, C. Bezencon, P. Canalis, and W. Kurz, Single-Crystal Laser Deposition of Superalloys: Processing–Microstructure Maps, Acta Mater., 2001, 49(6), p 1051-1062.

M. Gäumann, S. Henry, F. Cleton, J.D. Wagniere, and W. Kurz, Epitaxial Laser Metal Forming: Analysis of Microstructure Formation, Mater. Sci. Eng., A, 1999, 271(1), p 232-241.

Z. Liu and Z. Wang, Effect of Substrate Preset Temperature on Crystal Growth and Microstructure Formation in Laser Powder deposition of Single-Crystal Superalloy, J. Mater. Sci. Technol., 2018, 34(11), p 2116-2124.

Y. Wang, J. Choi and J. Mazumder, Laser-Aided Direct Writing of Nickel-Based Single-Crystal Super Alloy (N5), Metall. Mater. Trans. A., 2016, 47(12), p 5685-5690.

B. Rottwinkel, A. Pereira, I. Alfred, C. Noelke, V. Wesling, and S. Kaierle, Turbine Blade Tip Single Crystalline Clad Deposition with applied Remelting Passes for Well Oriented Volume Extension, J. Laser Appl., 2017, 29(2), 022310.

S. Kaierle, L. Overmeyer, I. Alfred, B. Rottwinkel, J. Hermsdorf, V. Wesling, and N. Weidlich, Single-Crystal Turbine Blade Tip Repair by Laser Cladding and Remelting, CIRP J. Manuf. Sci. Technol., 2017, 19, p 196-199.

Z. Liu and Q. Zhu, Effect of Pulse Frequency on the Columnar-to-Equiaxed Transition and Microstructure Formation in Quasi-Continuous-Wave Laser Powder Deposition of Single-Crystal Superalloy, Metall. and Mater. Trans. A., 2021, 52(2), p 776-788.

H. Helmer, A. Bauereiß, R.F. Singer, and C. Körner, Grain Structure Evolution in Inconel 718 During Selective Electron Beam Melting, Mater. Sci. Eng., A, 2016, 668, p 180-187.

X. Zhao, J. Chen, X. Lin, and W. Huang, Study on Microstructure and Mechanical Properties of Laser Rapid Forming Inconel 718, Mater. Sci. Eng. A, 2008, 478, p 119-124.

T. DebRoy, T. Mukherjee, J.O. Milewski, J.W. Elmer, B. Ribic, J.J. Blecher, and W. Zhang, Scientific, Technological and Economic Issues in Metal Printing and their Solutions, Nat. Mater., 2019, 18(10), p 1026-1032.

Z. Liu, L. Jiang, Z. Wang, and L. Song, Mathematical Modeling of Transport Phenomena in Multi-track and Multi-layer Laser Powder Deposition of Single-Crystal Superalloy, Metall. Mater. Trans. A., 2018, 49(12), p 6533-6543.

H. Qi, M. Azer, and P. Singh, Adaptive Toolpath Deposition Method for Laser Net Shape Manufacturing and Repair of Turbine Compressor Airfoils, Int. J. Adv. Manuf. Technol., 2010, 48(1-4), p 121-131.

Z. Lu, A. Zhang, Z. Tong, X. Yang, D. Li, and B. Lu, Fabricating the Steam Turbine Blade by Direct Laser Forming, Mater. Manuf. Processes, 2011, 26(7), p 879-885.

Z. Liu and H. Qi, Numerical Simulation of Transport Phenomena for a Double-Layer Laser Powder Deposition of Single-Crystal Superalloy, Metall Mater Trans A, 2014, 45A(4), p 1903-1915.

Z. Liu and H. Qi, Effects of Processing Parameters on Crystal Growth and Microstructure Formation in Laser Powder Deposition of Single-Crystal Superalloy, J. Mater. Process. Technol., 2015, 216, p 19-27.

A.J. Pinkerton and L. Li, Modelling powder concentration distribution from a coaxial deposition nozzle for laser-based rapid tooling, J. Manuf. Sci. Eng., 2004, 126(1), p 33-41.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51905253, 51975136, 51575116), the Natural Science Foundation of Guangdong Province of China (Grant No. 2018A030310132), and the Natural Science Foundation of Shenzhen of China (Grant No. JCYJ20190809152401680).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Liang, Z., Zou, T. et al. Control of the Molten Pool Morphology and Crystal Growth Behavior in Laser Powder Deposition of Single-Crystal Superalloy via Adjusting the Defocusing Amount and Scanning Speed. J Therm Spray Tech 31, 2594–2608 (2022). https://doi.org/10.1007/s11666-022-01446-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01446-5