Abstract

In this paper, a novel nanocomposite (carbonic salicylate @ aluminum oxide nanocomposite, AC-COO-Sal@Al2O3) and modifier carbon biosorbents were synthesized from low-cost raw materials (commercial activated carbon). Infrared spectra demonstrated the presence of several active groups in the material matrixes of nanocomposite and biosorbents. X-ray diffraction analysis showed that the surfaces were in the form of crystals embedded into the amorphous structure. There is good thermal stability up to 800 °C and also in acidic and alkaline mediums. The modifier of the activated carbon (AC), carbonic acid (AC-COOH), carbonic salicylate (MAC-COO-Sal), and the nanocomposite were applied to remove the hazard species from wastewater. The different parameters (pH, time, concentration, and temperature) were applied to explain the removal process. The removal percentages and capacities were 97–100% and 166–266 mg/g with a relative standard deviation of 0.2–0.8% (n = 5). The lower detection limit of the tested dye was 0.6–1.9 μg/L which indicates the higher sensitivity detection of methylene blue in wastewater. Also, the method was successfully applied for the removal of free chlorine and metal ions from the contaminated water samples.

Similar content being viewed by others

1 Introduction

Water is the key to life, and it is very necessary for agriculture and in the activity of every day for living organisms (Schmidt et al. 2020; Kenawy et al. 2022). The biggest problem is that it is not always found in sufficient quantity and the required quality (Moawed et al. 2019; Torres-Badajoz et al. 2022). Nevertheless, the increased use of water in modern industries makes it vulnerable to pollution. Moreover, some factories dispose of their pollutants in waterways, causing diseases and other environmental risks to aquatic life (Jiang et al. 2020; Mokhtari et al. 2020). Therefore, treating bearing waste using a low-cost method has multiple benefits, including water treatment and waste management (Molavi et al. 2020; Bazan-Wozniak et al. 2020).

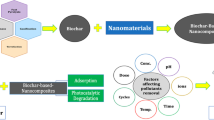

Adsorption over activated carbon derived from biomass waste has been shown to be the most feasible and economic method (Gundogdu et al. 2013; Liang et al. 2020; Alshabib 2022). The low functionality groups on the AC surface are an inconvenience, which causes to decrease in the uses in the sorption of cationic or anionic species (Soylak 1998; Soylak et al. 2000; Arena et al. 2016). On the other side, the structure of aluminum oxide nanoparticles (Al2O3NPs) has great concern in the last few years due to their excellent physical and chemical properties besides their thermal stability (Islam et al. 2019; Zhang et al. 2019). Moreover, it is available at a low cost and is not harmful to the environment (Li et al. 2019; Yilmaz et al. 2020). Generally, the addition of Al2O3NP to the modified activated carbon increases its properties whether adsorption or catalytic degradation of organic pollutants (Pathania et al. 2016; Edalati et al. 2019).

The aim of this work is to synthesize new sorbent easy to synthesis, low cost, environmentally friendly and can be reused. To achieve this goal, the carbonic AC-COO-Sal@Al2O3 nanocomposite was synthesized. In the first step, the matrix of activated carbon (AC) must be formulated with effective functional groups to stabilize the Al2O3NPs on its surface of it. Therefore, the matrix of AC was modified with salicylic ester groups through oxidation of AC and then esterification with salicylic acid. Secondary, the carbonic salicylic ester (AC-COO-Sal) was refluxed with Al2O3NPs in ethanol. The final sorbent AC-COO-Sal@Al2O3 and also the AC, AC-COOH and AC-COO-Sal was characterized using XRD patterns, SEM, IR, and UV–Vis spectra, and TGA. The batch technique was used under different conditions, e.g., time, concentration, pH, and temperature, to optimize for removing cationic dyes, free chlorine, and metal ions from wastewater.

2 Experimental

2.1 Apparatus

The structure of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 sorbents was investigated by XRD patterns using an X-ray diffractometer (D8-Brucker Model) equipped with Cu Kα radiation (λ = 1.54 Å). The surface morphology of sorbents was examined using scanning electron microscopy analysis (SEM, JEOL model JSM-6510LV, USA). Thermogravimetric analysis (TGA), differential thermal analysis (DTA), and differential scanning calorimetry (DSC) were estimated by the DSC-TGA device model (SDTQ 600, USA) under an N2 atmosphere with a heating rate of 10 °C/min (29–1000 °C).

2.2 Reagents and Materials

A 10 g of commercial activated carbon powder (< 128 μm) was soaked in 0.1 mol/ HCl and NaOH for 24 h. The AC material was repeatedly washed with hot distilled water until the pH of the washed solution was near 7 and dried at 110 °C to a constant weight and was then stored in well-closed bottles.

Activated carbonic acid (AC-COOH): An oxidation process was performed, adding 100 mL of nitric acid to 10 g of AC and boiling it until all reddish-brown fumes come out, then washed with distilled water and dried at 110 °C.

Activated carbonic salicylic ester (AC-COO-Sal): The AC-COOH was refluxed with 5 g salicylic acid for 6 h in ethanol then washed with distilled water and dried at 110 °C.

The carbonic salicylic ester @ aluminum oxide nanocomposite (MAC-COO-Sal@Al2O3) was synthesized by refluxing of MAC-COO-Sal with 5 g of Al2O3NPs for 6 h. Then, the product was washed with distilled water and dried at 110 °C.

2.3 Recommended Procedures

The capacities of sorbents and the removal percentage of methylene blue were determined using the batch technique. A 25 mL of methylene blue solutions were shacked for 60 min with 0.1 g of sorbent. The removal percentages of dye and capacities of sorbents were calculated using the following equations:

where C° is the initial concentration of dye (mg/L), Ce is the concentration of remaining dye in solution (mg/L), V is the volume of the tested sample and m is the amount of sorbent (g).

3 Results and Discussion

3.1 Characterization of Sorbents

The surface morphology of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 sorbents was investigated using scanning electron microscopy (SEM) with different magnifications. The SEM images at 20,000 × magnification (Fig. 1) illustrate that the surface of AC was rough and amorphous and the particles of AC were nearly spherical in shape. At higher magnification of the AC image (30,000x), it shows that some gaps have appeared. The surface of AC was completely changed after oxidation to AC-COOH and coupling with salicylic acid and Al2O3, the gaps between the particles were increased and also the spherical particles convert to a nearly hexagonal shape in the AC-COO-Sal@Al2O3 image.

The XRD patterns of AC, AC-COOH, and AC-COO-Sal showed strong and narrow diffraction peaks around 2θ, 26°, and 44° (Fig. 2), we're referring to the presence of a degree of crystallinity of the carbon matrix. The broad diffraction bands observed at 2θ, 24°, and 41° which clear that these sorbents kept their amorphous character, usually observed for the activated carbon material. The AC-COO-Sal@Al2O3 nanocomposite was lower band intensity than that of the AC-COO-Sal, indicating the formation of the nanocomposite with a significant change in the amorphous phase. The diffraction peaks of AC-COO-Sal@Al2O3 at 8.4, 12.5°, 18.2°, 26.3°, 33.0°, 35.8°, 44.2°, and 66.8° are observed in Figs. 2. The diffraction bands at 2θ around 24° and 41° were consumed and also the new diffraction peaks appeared attributed to the coupling between AC and Al2O3NPs.

The surface area of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 was estimated using iodine number (amount of iodine adsorbed onto the sorbent). The small size of the iodine molecule (0.15–0.42 nm2) can enter into micropores of sorbent (pore sizes ≥ 10 Å). The iodine number of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 was 1.03, 0.83 0.80, and 0.66 mmol/g, respectively (Table 1). The surface area of sorbent was calculated using the following equation: S = IN × N × A/M, where S is the area covered by adsorbed iodine molecules at the maximum mono-layer surface (m2/g), N is the Avogadro number (6.02 × 1023), A is the iodine surface area (0.2096 × 10−18 m2) and M is the iodine molar mass (126.9 g/mol). Thus, calculated specific surface areas were 488.6, 393.8, 379.5, and 313.1 m2/g. The results indicate that the tested sorbents have a high surface area. The particle sizes of the sorbents were in the following series AC < AC-COOH < AC-COO-Sal < AC-COO-Sal@Al2O3.

FTIR spectroscopy was used to identify specific functional groups of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 (Fig. 3). AC spectrum has absorbance peaks at 3399, 2915, 2842, 1938, and 1556 cm−1 that were assigned to stretching vibration of OH, C-H aromatic and aliphatic, C = O anhydride and C = C aromatic. The peaks of OH, CH, and C = C groups were slightly shifted in AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 spectra, while the peak 1938 cm−1 for the C = O group was highly shifted to 1862, 1803 and 1801 cm−1. Also, other new peaks for the C = O bond appeared at 1699, 1997, and 1660 cm−1 after oxidation and esterification processes. Finally, the new peaks have appeared at 773, 748, and 528 cm−1 for aluminum Al-O in the AC-COO-Sal@Al2O3 nanocomposite spectrum.

The amount of acidic and basic functional groups of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 were determined using Boehm titration. The total acidic sites (–COOH, –CO, and –OH) of tested sorbents were 0.28, 0.60, 0.98, and 0.61 mmol/g while the number of basic sites was 0.49, 0.08, 0.05, and 0.18 mmol/g. The obtained results show that the number of acidic sites increased while the basic sites decreased after oxidation and esterification processes.

The zero-point charge test for the AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 is a very important index to detect the charge of surface-active centers of these sorbents. The zero-point charge is the point that the number of negative charges on the sorbent surface is equal to the positive charges. Figure 4 shows where the values of pHzpc were 7.5, 2.2, 1.8, and 3.4; if the pH of the aqueous solution is below these values, the surface of the sorbents will become positively charged. By comparing the pHzpc, + ΔpH and -ΔpH values with the number of surface-active sites, it was found that the pHzpc values correspond to the number of acidic and sites on the surfaces of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3.

Thermal properties of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 were evaluated using TGA, DTA and DSC analysis. TGA curves of tested sorbents show a smooth stepwise with two steps of thermal decomposition. The first step of the decomposition due to loss of moisture at ranges of 30–95, 30–102, 30 -126, and 30–99 °C with weight loss percentages were 17.4, 23.2, 7.2, and 8.6%, respectively. The weight loss in this step was usually due to the evaporation of adsorbed water molecules. But the weight loss for the AC-COOH (23%) was higher than other sorbents (7–17%) attributed to decompose of carboxylic groups. The DTA curves of sorbents showed that one endothermic peak appeared in this step at 76, 75, 66 and 51 °C (Fig. 5). The DTA is a powerful tool to detect the different phase transformations of the matter. Therefore, the difference values of endothermic points of tested sorbents indicate that these sorbents have different surfaces (active sites). The endothermic points of DSC curves at the first step were 87, 84, 78 and 57 °C. The weight loss was 20, 23, 32, and 9% of the second step at ranges 95–800, 102–800, 126–800 and 99–800 °C. The weight loss of AC-COO-Sal is higher than other sorbents due to the decomposition of salicylic acid. The other endothermic points were at 620, 213 and 240 °C for AC, AC-COO-Sal, and AC-COO-Sal@Al2O3. Finally, the AC-COO-Sal@Al2O3 nanocomposite is more stable than other tested sorbents due to the coupling of Al2O3NPs to AC.

The chemical stabilities of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 were studied at different pHs (1–14) and organic solvents using the batch technique at 24 h. The AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 are good stability in pH ranges from pH 1–14, and methanol, ethanol, acetone, benzene, toluene, dimethylformamide, and dimethyl sulfoxide.

3.2 Application of Carbon Sorbents

The validity of the AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 successfully was assessed using batch and column techniques. The removal of free chlorine, detection and removal of methylene blue dye and cation exchange from tap and wastewater of Damietta industrial city were examined. The samples were collected from six locations for two months.

3.2.1 Detection of Methylene Blue Dye in Wastewater

The lowest concentration of dyes in wastewater is high risk because it is not detected by the naked eye. Therefore, the sensitive detection of dye is very necessary. The detection of methylene blue (MB) in different samples of wastewater is examined using preconcentration/separation/recovery of batch and column techniques. The limits of detection (LOD) and the limits of quantitation (LOQ) are estimated for the MB dye in wastewater samples using AC, AC-COOH, AC-COO-Sal and AC-COO-Sal@Al2O3 nanocomposite (Table 2). The average values of LOD and LOQ were 2.5 and 8.9 μg/L (n = 6) which indicates the higher sensitivity detection of dyes. The average relative standard deviation (RSD %) was 1.05 for six replicating procedures. The lower values of RSD% indicate the good accuracy and precision of the proposed method. The small values of LOD and RSD% indicate that this method is suitable for the detection of cationic dyes at a trace concentration before their determination with high accuracy.

The plot of the amount of dye per unit mass of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 (capacity, Q) with concentrations of MB shows that the perfect linear curve with average correlation factors (R2) was 0.999 with good average values of intercept was 2 × 10–4 (Table 3). Besides, the average capacity (Q) of tested sorbents for methylene blue was 0.38 mmol/g (121 mg/g). The result indicates that AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 are good sorption capacities.

3.2.2 Removal of Methylene Blue Dye from Wastewater

The effects of pH, time, the weight of sorbents and temperature on the removal percentages of MB from aqueous solution were tested using the batch technique at pH 1–14, 1–30 min and 25–80 °C. The removal percentages of MB dye were 90–100% at pH ranges 1–14 (Fig. 6). This result shows that it is unnecessary to adjust the pH of the industrial wastewater before the removal of MB dye. The effect of time for removing MB was tested; the maximum removal percentages of MB dye from aqueous solution were reached at 1–3 min. The removal percentages of MB dye were slightly affected by increased temperature; these results attributed to unnecessary adjusting of the temperature of the industrial wastewater before removal of MB dye.

A 25 mL of industrial wastewater samples were spiked with different amounts of MB dye (100–1000 μg); then, the solutions were shacked for 15 min with 0.1 g of the tested sorbent. The average removal percentage of MB dye from the industrial wastewater samples is found to be 97%. The relative standard deviation (RSD%) for five replicating procedures is 0.78%.

The AC-COO-Sal@Al2O3 nanocomposite is applied for the removal of MB dye from different locations of water samples. Over thirty industrial wastewater samples from three Factories in Damietta city were collected. The average removal percentages of dye from the industrial wastewater samples were 98.5% (Table 4). Also, the average values of LOD and LOQ were 1.3 and 4.3 µg/L. The average value of RSD% was found to be 0.5%, which is considered a relevant value (less than 10%) for water samples.

3.2.3 Removal of Free Chlorine Wastewater

A 100 mL aliquot of tap water samples was passed through the AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 columns at a flow rate of 5 mL/min. The percentages of the removed chlorine from the water samples were 98–100% (Table 5). These results indicated that the AC, AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 are suitable sorbents for the removal of free chlorine from water.

3.2.4 Cation Exchange

Ion exchange resins were used to demineralize water and to separate mixtures of ions. One important characteristic of ion exchange resin is its capacity, expressed in terms of milliequivalents of exchangeable ion per gram of resin. Exchange capacity can be measured by exchanging sodium ions (Na+) for hydrogen form (H + initially attached to the resin). The hydrogen ion is then titrated with a standard sodium hydroxide solution. A 50 mL of 0.5 mol/L Na2SO4 solutions were passed through AC, AC-COOH, AC-COO-Sal or AC-COO-Sal@Al2O3 columns and the effluent solutions were titrated with 0.1 NaOH (Exchange capacity = mLNaOH × NNaOH/mass Resin). The cation exchange capacities of sorbents were 0.0, 184.0, 9.2 and 23.0 mg/g (Table 6). Although the carboxylic sites of AC, AC-COO-Sal, and AC-COO-Sal@Al2O3 are a large amount (Table 2), their capacities of them are small compared to AC-COOH.

3.2.5 Removal Mechanism

The Gibbs free energy (ΔG° = --RTlnK) was −15.4, −15.4, −10.2 and −9.2 kJ/mol, and the negative values of ΔG° showed that the removal process of MB was spontaneous. The removal rate of MB dye was passing through two steps, the first step was rapid the ≈80% of MB removal within 60 s followed by the second step was slower than one. Therefore, the intraparticle diffusion model (Morris-Weber, Q vs. t1/2) was good explained the two steps of the removal process. The average diffusion rate constant (kM) was 27.2 and 0.2 mg/g min1/2, and the average correlation coefficient (R2) was 0.973 and 0.477 (Table 7). Also, the pseudo-second-order model was well fitted due to the high values of the correlation coefficient (R2: 0.999, 0.999, 0.995 and 0.999) which indicate that the adsorption process may be controlled by chemisorption. The average initial rate constant was 0.19 g/mmol min. Unordered diffusion rate values and also kinetic rates constant attributed to the difference in surface active sites of sorbents.

The equilibrium data for the removal of MB dye using the tested sorbents were analyzed using Freundlich, Langmuir, and Dubinin–Radushkevich models. The R2 of the Freundlich isotherm model was 0.914, 0.841, 0.899 and 0.799. These values show that the Freundlich model is more suitable for interpreting the removal process (multilayer sorption on the heterogeneous surface of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3. Also, the Freundlich constants (1/n) were in the values between 0.5 and 0.9 which may be attributed to the heterogeneous surface structure of the sorbents with a non-uniform distribution of heat sorption over the surface.

4 Conclusion

The present work is concerned with the preparation of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 as a new sorbent that has the ability to detect and remove basic cationic dyes (MB) from wastewater. The carbonic salicylate @ aluminum oxide nanocomposite (AC-COO-Sal@Al2O3) and modifier carbon biosorbents were prepared from commercial activated carbon. Infrared spectra demonstrated the presence of several active groups in the material matrixes of nanocomposite and biosorbents. X-ray diffraction analysis showed that the surfaces were in the form of crystals embedded into the amorphous structure. There is good thermal stability up to 800 °C and also in acidic and alkaline mediums. These are new and efficient sorbents for the removal of free chlorine from water and cation exchange. The times required for complete removal of MB dye from wastewater were 1–3 min at pH 1–14 and 25 °C. The average capacities of AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 were 0.38 mmol/g mmol/g for MB dye. The thermodynamic parameter (ΔG°) for the removal of MB dye from wastewater using tested sorbents was estimated, and the average values of ΔG°–12.8 kJ/mol indicated that the spontaneous nature. The dye removal kinetics is described by pseudo-second-order models and intraparticle diffusion models. The AC, AC-COOH, AC-COO-Sal, and AC-COO-Sal@Al2O3 were successfully applied for removing MB dye from five replicating wastewater samples with a lower relative standard deviation of 0.78% and the lower detection limit was 1.3 μg/L.

References

Alshabib M (2022) Removal of naphthalene from wastewaters by adsorption: a review of recent studies. Int J Environ Sci Technol 19:4555–4586

Arena N, Lee J, Clift R (2016) Life Cycle Assessment of activated carbon production from coconut shells. J Clean Prod 125:68–77

Bazan-Wozniak A, Pietrzak R (2020) Adsorption of organic and inorganic pollutants on activated bio-carbons prepared by chemical activation of residues of supercritical extraction of raw plants. Chem Eng J 393:124785

Edalati K, Fujita I, Takechi S, Nakashima Y, Kumano K, Razavi-Khosroshahi H, Arita M, Watanabe M, Sauvage X, Akbay T, Ishihara T, Fuji M, Horita Z (2019) Photocatalytic activity of aluminum oxide by oxygen vacancy generation using high-pressure torsion straining. Scripta Mater 173:120–124

Gundogdu A, Duran C, Senturk HB, Soylak M, Imamoglu M, Onal Y (2013) Physicochemical characteristics of a novel activated carbon produced from tea industry waste. J Anal Appl Pyrol 104:249–259

Islam MA, Ali I, Abdul Karim SM, Firoz MSH, Chowdhury A, Morton DW, Angove MJ (2019) Removal of dye from polluted water using novel nano manganese oxidebased materials. J Water Process Eng 32:100911

Jiang X, Sun P, Xu L, Xue Y, Zhang H, Zhu W (2020) Platanus orientalis leaves based hierarchical porous carbon microspheres as high efficiency adsorbents for organic dyes removal. Chin J Chem Eng 28:254–265

Kenawy E, Tenhu H, Khattab AS, Eldeeb A, Azaam MM (2022) Highly efficient adsorbent material for removal of methylene blue dye based on functionalized polyacrylonitrile. Eur Polym J 169:111138

Liang Q, Liu Y, Chen M, Ma L, Yang B, Li L, Liu Q (2020) Optimized preparation of activated carbon from coconut shell and municipal sludge. Mater Chem Phys 241:122327

Li JF, Rupa EJ, Hurh J, Huo Y, Chen L, Han Y, Chan Ahn J, Park JK, Lee HA, Mathiyalagan R, Yang D-C (2019) Cordyceps militaris fungus mediated Zinc Oxide nanoparticles for the photocatalytic degradation of Methylene blue dye. Optics 183:691–697

Moawed EA, El-Hagrasy MA, Kamal M (2019) Detection and removing of lead from wastewater using chemical treatment of polyurethane foam waste: Batch and column experiments. Desalin Water Treat 159:338–345

Mokhtari N, Afshari M, Dinari M (2020) Synthesis and characterization of a novel fluorene-based covalent triazine framework as a chemical adsorbent for highly efficient dye removal. Polymer 1958:122430

Molavi H, Neshastehgar M, Shojaei A, Ghashghaeinejad H (2020) Ultrafast and simultaneous removal of anionic and cationic dyes by nanodiamond/UiO-66 hybrid nanocomposite. Chemosphere 247:125882

Pathania D, Katwal R, Kaur H (2016) Enhanced photocatalytic activity of electrochemically synthesized aluminum oxide nanoparticles. Int J Miner Metall Mater 23:358–371

Schmidt PJ, Anderson WB, Emelko MB (2020) Describing water treatment process performance: Why average log-reduction can be a misleading statistic. Water Res 1761:115702

Soylak M (1998) Determination of trace amounts of copper in high-purity aluminum samples after preconcentration on an activated carbon column. Fresenius Environ Bull 7:383–387

Soylak M, Elci L, Dogan M (2000) A sorbent extraction procedure for the preconcentration of gold, silver and palladium on an activated carbon column. Anal Lett 33(3):513–525

Torres-Badajoz SG, Rodrıguez-Nunez JR, Lopez-Ramırez E, Pena-Caballero V, Villa-Lerma AG, Madera-Santana TJ, Rodrıguez-Carrillo MG, Castillo OS (2022) Kinetic and equilibrium studies of Cr(VI) adsorption using glutaraldehyde-crosslinked chitosan beads. Iran J Sci Technol Trans Sci 46:147–160

Yilmaz E, Salem S, Sarp G, Aydin S, Sahin K, Korkmaz I, Yuvali D (2020) TiO2 nanoparticles and C-Nanofibers modified magnetic Fe3O4 nanospheres (TiO2@Fe3O4@C–NF): A multifunctional hybrid material for magnetic solid phase extraction of ibuprofen and photocatalytic degradation of drug molecules and azo dye. Talanta 2131:120813

Zhang Y, Yang L, Wang Y-H, Liu A-H (2019) MoxPy nanoparticles supported on mesh structural carbon from biomass for rapid selective dyes adsorption. Talanta 1961:9–17

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moawed, E.A., Mostafa, M.R., El-Ghobashy, H. et al. Application of Carbon Salicylate@Alumina Nanocomposite for Removal of Organic and Inorganic Pollutants from Wastewater. Iran J Sci Technol Trans Sci 46, 1377–1385 (2022). https://doi.org/10.1007/s40995-022-01336-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-022-01336-z