Abstract

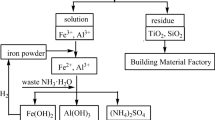

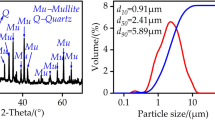

The clean recovery of red mud (RM) and coal fly ash (CFA) has drawn widespread attentions owing to the increasing awareness of environmental protection. In this study, a new strategy for recycling RM and CFA simultaneously by extracting valuable metallic elements from them was proposed. The process is mainly composed of two stages, e.g., vacuum carbothermal reduction and magnetic separation. The effects of RM/CFA ratio, duration, and temperature on the mineralogical evolution of RM and CFA during the vacuum reduction were investigated thoroughly. The results show that the Fe–Si alloys can be prepared effectively by the vacuum reduction of RM and CFA because the hematite (Fe2O3) in RM can react with the mullite (Al6Si2O13) in CFA to form Fe–Si alloys at a low temperature. Additionally, the produced Fe–Si alloys and the other valuable components can be separated through the magnetic separation, because of the strong magnetic property of the Fe–Si alloys. After separation, the magnetic portion was mainly composed of Fe5Si3 and FeSi phases, while the non-magnetic portion consisted of 64.04 wt% Al2O3, 7.49 wt% SiO2, and 10.35 wt% TiO2. The alumina/silica mass ratio (A/S) in the non-magnetic product achieved 8.55, which is similar to that of the high-quality bauxite ores and can be a raw material to produce alumina and enrich titanium by the Bayer process. This strategy takes full advantages of the valuable metals in the RM and CFA, which shows a good prospect for industrial application.

Graphical Abstract

Similar content being viewed by others

References

Sahu MK, Patel RK (2016) Chapter 19-Methods for utilization of red mud and its management. Environmental materials and waste. Academic Press, Boca Raton, pp 485–524. https://doi.org/10.1016/B978-0-12-803837-6.00019-6

Evans K (2016) The history, challenges, and new developments in the management and use of Bauxite residue. J Sust Metall 2:316–331. https://doi.org/10.1007/s40831-016-0060-x

Rivera RM, Ulenaers B, Ounoughene G, Binnemans K, Gerven TV (2018) Extraction of rare earths from bauxite residue (red mud) by dry digestion followed by water leaching. Miner Eng 119:82–92. https://doi.org/10.1016/j.mineng.2018.01.023

Lyu F, Hu YH, Wang L, Sun W (2021) Dealkalization processes of bauxite residue: a comprehensive review. J Hazard Mater 403:123671. https://doi.org/10.1016/j.jhazmat.2020.123671

Liu ZB, Li HX (2015) Metallurgical process for valuable elements recovery from red mud-a review. Hydrometallurgy 155:29–43. https://doi.org/10.1016/j.hydromet.2015.03.018

Xue Y, Liu XM (2021) Detoxification, solidification and recycling of municipal solid waste incineration fly ash: a review. Chem Eng J 420:130349. https://doi.org/10.1016/j.cej.2021.130349

Wang SH, Jin HX, Deng Y, Xiao YD (2021) Comprehensive utilization status of red mud in China: a critical review. J Clean Prod 289:125136. https://doi.org/10.1016/j.jclepro.2020.125136

Khairul MA, Zanganeh J, Moghtaderi B (2019) The composition, recycling and utilisation of Bayer red mud. Resour Conserv Recycl 141:483–498. https://doi.org/10.1016/j.resconrec.2018.11.006

Jayasankar K, Ray PK, Chaubey AK, Padhi A, Satapathy BK, Mukherjee PS (2012) Production of pig iron from red mud waste fines using thermal plasma technology. Int J Miner Metall Mater 19:679–684. https://doi.org/10.1007/s12613-012-0613-3

Jamieson E, Jones A, Cooling D, Stockton N (2006) Magnetic separation of red sand to produce value. Miner Eng 19:1603–1605. https://doi.org/10.1016/j.mineng.2006.08.002

Li YR, Wang J, Wang XJ, Luan ZK (2011) Feasibility study of iron mineral separation from red mud by high gradient superconducting magnetic separation. Physica C 471:91–96. https://doi.org/10.1016/j.physc.2010.12.003

Samouhos M, Taxiarchou M, Pilatos G, Tsakiridis PE, Devlin E, Pissas M (2017) Controlled reduction of red mud by H2 followed by magnetic separation. Miner Eng 105:36–43. https://doi.org/10.1016/j.mineng.2017.01.004

Yu ZL, Shi ZX, Chen YM, Niu YJ, Wang YX, Wan PY (2012) Red mud treatment using oxalic acid by UV irradiation assistance. Trans Nonferrous Met Soc China 22:456–460. https://doi.org/10.1016/S1003-6326(11)61198-9

Yang Y, Wang XW, Wang MY, Wang HG, Xian PF (2015) Recovery of iron from red mud by selective leach with oxalic acid. Hydrometallurgy 157:239–245. https://doi.org/10.1016/j.hydromet.2015.08.021

Mahinroosta M, Karimi Z, Allahverdi A (2020) Recycling of red mud for value-added applications: a comprehensive review. Encycl Renew Sustain Mater 2:561–582. https://doi.org/10.1016/B978-0-12-803581-8.11474-2

Laxmidhar P, Subhakanta D (2020) Characterization and utilization of coal fly ash: a review. Emerg Mater Res 9:921–934. https://doi.org/10.1680/jemmr.18.00097

Ji HY, Mi X, Tian QK, Liu CL, Yao JX, Ma SH, Zeng GS (2021) Recycling of mullite from high-alumina coal fly ash by a mechanochemical activation method: effect of particle size and mechanism research. Sci Total Environ 784:147100. https://doi.org/10.1016/j.scitotenv.2021.147100

Wang C, Xu GG, Gu XJ, Gao YH, Zhao P (2021) High value-added applications of coal fly ash in the form of porous materials: a review. Ceram Int 47:22302–22315. https://doi.org/10.1016/j.ceramint.2021.05.070

Sun Q, Tian S, Sun QW, Li B, Cai C, Yj X, Wei X, Mu QW (2019) Preparation and microstructure of fly ash geopolymer paste backfill material. J Clean Prod 225:376–390. https://doi.org/10.1016/j.jclepro.2019.03.310

Pandey VC, Singh N (2010) Impact of fly ash incorporation in soil systems. Agric Ecosyst Environ 136:16–27. https://doi.org/10.1016/j.agee.2009.11.013

Yang CN, Zhang JB, Hou XJ, Li SP, Li HQ, Zhu GY, Qi F (2021) Study on the correlation between Fe/Ti forms and reaction activity in high-alumina coal fly ash. Sci Total Environ 792:148419. https://doi.org/10.1016/j.scitotenv.2021.148419

Ding J, Ma Sh, Shen S, Xie ZL, Zheng SL, Zhang Y (2017) Research and industrialization progress of recovering alumina from fly ash: a concise review. Waste Manage 60:375387. https://doi.org/10.1016/j.wasman.2016.06.009

Yao ZT, Xia MS, Sarker PK, Chen T (2014) A review of the alumina recovery from coal fly ash, with a focus in China. Fuel 120:74–85. https://doi.org/10.1016/j.fuel.2013.12.003

Liu CL, Zheng SL, Ma Sh, Luo Y, Ding J, Wang XH, Zhang Y (2018) A novel process to enrich alumina and prepare silica nanoparticles from high-alumina fly ash. Fuel Process Technol 173:40–47. https://doi.org/10.1016/j.fuproc.2018.01.007

Xue Y, Yu WZ, Jiang WY, Wen L, You ZX, Lv XW (2019) A novel process to extract alumina and prepare Fe–Si alloys from coal fly ash. Fuel Process Technol 185:151–157. https://doi.org/10.1016/j.fuproc.2018.12.013

Lv XD, Huang R, Wu QZ, Wu QH, Zhang JZ (2019) Volatilisation behaviour of iron, silicon and magnesium during vacuum carbothermal reduction of ilmenite concentrate. Can Metall Q 58:419–426. https://doi.org/10.1080/00084433.2019.1619062

Xue Y, Yu WZ, Mei J, Jiang WY, Lv XW (2019) A clean process for alumina extraction and FeSi alloy preparation from coal fly ash via vacuum thermal reduction. J Clean Prod 240:118262. https://doi.org/10.1016/j.jclepro.2019.118262

Lv W, Bai CG, Lv XW, Hu K, Lv XM, Xiang JY, Song B (2018) Carbothermic reduction of ilmenite concentrate in semi-molten state by adding sodium sulfate. Powder Technol 340:354–361. https://doi.org/10.1016/j.powtec.2018.09.043

Mondillo N, Herrington R, Boni M (2021) Bauxites. In: Alderton D, Elias SA (eds) Encyclopedia of geology, 2nd edn. Elsevier Ltd., pp 694–707. https://doi.org/10.1016/B978-0-08-102908-4.00046-1

Fan GQ, Dang J, Zhang R, Lv ZP, He WC, Lv XW (2021) A novel recycling approach for efficient extraction of titanium from high-titanium-bearing blast furnace slag. Waste Manage 120:626–634. https://doi.org/10.1016/j.wasman.2020.10.024

Farzana R, Rajarao R, Sahajwalla V (2014) Synthesis of Fe–Si alloy using waste glass and plastic. Mater Lett 116:101–103. https://doi.org/10.1016/j.matlet.2013.10.105

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant Nos. 52074058 and U2003215).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was João António Labrincha Batista.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, P., Yu, W., Chen, H. et al. A New Strategy for Collaborative Utilization of Red Mud and Coal Fly Ash via Vacuum Reduction Technology. J. Sustain. Metall. 8, 1370–1380 (2022). https://doi.org/10.1007/s40831-022-00578-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00578-w