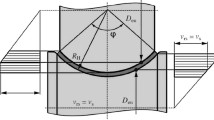

Abstract—A comprehensive study is conducted to determine the causes of defects and geometric-parameter deviations in the near-edge zone of flat rolled products during the production of large-diameter pipes in the TESA 1420 line. The methodology and results of measuring the geometric parameters and the mechanical properties at the edge crimping area are presented. The contact and noncontact sections of a pipe billet in contact with a deforming tool are determined during crimping the edges, and a calculation scheme for determining the geometric parameters in the deformation zone is developed. Mathematical modeling of the edge crimping process using the Deform software package has been carried out with allowance for the deviation of the geometric and mechanical parameters of the initial billet from these parameters of a theoretical circle. According to the modeling results, zones with the maximum residual stresses are determined. The results obtained are used to propose a method for step-by-step crimping of the edges of flat rolled products and a device for its implementation.

Similar content being viewed by others

REFERENCES

A. S. Ushakov and L. A. Kondratov, “On the production of steel pipes,” Stal’, No. 7, 36–40 (2017).

O. V. Yuzov and T. M. Petrakova, “Trends in the indicators of steel pipe production at Russian enterprises,” Stal’, No. 9, 71–77 (2015).

N. I. Novikov and L. V. Zagorodnova, “Innovative activity in ferrous metallurgy in Russia and abroad: similarities and differences,” Ekonom. Prom., No. 4, 18–23 (2015).

E. S. Lobusov and M. T. Hoang, “Measurement of the ovality of large-diameter pipes by inertial means,” Avtom. Sovr. Tekhnol., No. 11, 38–42 (2016).

GOST 26877–91. Metal Products. Methods of Measuring Shape Deviations (Izd. Standartov, Moscow, 1991).

Li-Feng Fan, Jia-Xin Yan, Ying Gao, and Jian-Bin Yun, “Research on deformation characteristics of JCOE forming in large diameter welding pipe,” Adv. Manufact. Technol., No. 10, 268–277 (2016).

Fan Lifeng, Gao Ying, Li Qiang, and Xu Hongshen, “Quality control on crimping of large diameter welding pipe,” Chin. J. Mech. Eng. 25 (6), 1264–1273 (2012).

M. A. Tovmasyan and S. V. Samusev, “Effect of the nonuniform distribution of the mechanical properties of rolled sheets on the shape of a round billet after forming in making large-diameter pipes,” Russ. Metall. (Metally), No. 5, 589–596 (2020). https://doi.org/10.1134/S0036029520050158A.G

S. V. Samusev and M. A. Tovmasyan, “Development of determining methods for the parameters of billets at edge bending on the TESA 1420 line,” Izv. Ferr. Metall. 60 (3), 187–151 (2017).https://doi.org/10.17073/0368-0797-2017-3-187-151

M. A. Tovmasyan and S. V. Samusev, “Experimental study of the change in ovality of large-diameter pipes taking into account the welding deformations effect,” Chern. Metally, No. 9, 43–48 (2019).

M. Yu. Matveev, V. Ya. Ivanov, and N. A. Grum-Grzhimailo, Production of Large-Diameter Electric-Welded Pipes (Metallurgiya, Moscow, 1968).

M. Yu. Matveev, M. B. Ruzhinskii, A. A. Romashov, et al., Technology of Production of Electric-Welded Pipes (Metallurgiya, Moscow, 1967).

V. M. Nerovnyi, Theory of Welding Processes: Textbook for Universities (Izd. MGTU, Moscow, 2016).

M. A. Tovmasyan, “Method of step-by-step crimping of the edges of flat rolled products, method and device for automatic correction of crimping conditions on the edge crimping press section,” RF Patent 2740368, Byull. Izobret., No. 2 (2021).

ACKNOWLEDGMENTS

We thank the employees of Vyksa Steel Works for their assistance in conducting investigations at the production sites of the TESA 1420 line.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Tovmasyan, M.A., Samusev, S.V. & Fortunatov, A.N. Comprehensive Study of the Shaping of the Near-Edge Zone in Flat Rolled Products during the Production of Pipes for Main Pipelines Using Modern Calculation and Measurement Methods. Russ. Metall. 2022, 784–790 (2022). https://doi.org/10.1134/S0036029522070138

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522070138