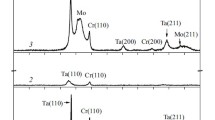

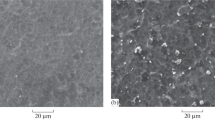

The effect of addition of 0 – 10 at.% Si on the microstructure and high-temperature oxidation resistance of alloys based on TaCr2 Laves phase and obtained by mechanical alloying with subsequent vacuum hot pressing is studied. Phase and x-ray diffraction analyses of ready alloys are performed before and after oxidation. The surface morphology of the specimens is studied by electron microscopy. It is shown that silicon promotes the appearance of a TaCr2 phase of hexagonal modification. An oxide film with a duplex structure represented by an outer layer of Cr2O3 and an inner layer of TaCrO4 forms on the surface of the alloy due to oxidation. Alloying with 5 – 8 at.% Si raises the resistance of the TaCr2 alloy to oxidation at 1437 K, and the kinetics of the isothermal oxidation is describable by a parabolic law.

Similar content being viewed by others

References

A. Bhowmik, H. T. Pang, S. Neumeier, et al., “Microstructure and oxidation resistance of Cr – Ta – Si alloys,” Mater. Res. Soc., 1295, 323 – 328 (2011).

M. Takeyama and C. T. Liu, “Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb,” Mater. Sci. Eng. A, 132, 61 – 66 (1991).

D. J. Thoma, K. A. Nibur, K. C. Chen, et al., “The effect of alloying on the properties of (Nb, Ti)Cr2 C15 Laves phases,” Mater. Sci. Eng. A, 329 – 331, 408 – 415 (2002).

C. T. Liu, J. H. Zhu, M. P. Brandy, et al., “Physical metallurgy and mechanical properties of transition-metal Laves phase alloy,” Intermetallics, 8(9 – 11), 1119 – 1129 (2000).

X. H. Qu, D. Y. He, and B. Y. Huang, “Research on Laves phase chrominidecompounds,” High Technol. Lett., 6(12), 27 – 30 (1996).

H. Baker, ASM Handbook, Vol. 3, Alloy Phase Diagrams, ASM International, USA (1992), 522 p.

M. P. Brady, J. H. Zhu, C. T. Liu, et al., “Oxidation resistance and mechanical properties of Laves phase reinforced Cr in-situ composites,” Intermetallics, 8(9 – 11), 1111 – 1118 (2000).

N. Vellios and P. Tsakiropoulos, “Study of the role of the Fe and Sn additions in the microstructure of Nb – 24Ti – 18Si – 5Cr silicide based alloys,” Intermetallics, 18, 1729 – 1736 (2010).

I. Grammenos and P. Tsakiropoulos, “Study of the role of Mo and Ta additions in the microstructure of Nb – 18Si – 5Hf silicide based alloy,” Intermetallics, 18, 1524 – 1530 (2010).

K. Li, S. Li, and H. Fu, “Microstructure evolution of Laves phase Cr2Nb alloys prepared by arc melting,” Acta Metall. Sinica, 47(6), 663 – 670 (2011).

P. Duwez and H. Martens, “Crystal structure of TaCr2 and NbCr2,” J. Min. Met. Mater. Soc., 4(1), 72 – 74 (1952).

R. C. Mittal, S. K. Si and K. P. Gupta, “Si-stabilised C14 Laves phases in transition metal system,” J. Less-Common Met., 60(1), 75 – 82 (1978).

A. Bhowmik, C. N. Jones, I. M. Edmonds, et al., “Effect of Mo, Al and Si on the microstructure and mechanical properties of Cr – Cr2 Ta based alloys,” J. Alloys Compd., 530(2), 169 – 177 (20120.

A. Bhowmik, H. T. Pang, I. M. Edmonds, et al., “Effect of silicon additions on the high temperature oxidation behavior of Cr – Cr2 Ta alloys,” Intermetallics, 32, 373 – 383 (2013).

A. Bhowmik, R. J. Bennett, B. Monserrat, et al., “Alloys based on Cr – Cr2 Ta containing Si,” Intermetallics, 48, 62 – 70 (2014).

R. Z. Tang and R. Z. Tian, Binary Alloy Phase Diagrams and Crystal Structure of Intermediate Phase, Central South University Press, Changsha (2009), 126 p.

P. Massard, J. C. Bernier, and A. Michel, “Effet Jahn–Teller dans le systeme Ta2CrO6 and TaCrO4,” J. Solid State Chem., 4(2), 269 – 274 (1972).

L. Royer, S. Mathieu, C. Liebaut, et al., “Study of the microstructure and oxidation behavior of chromium base alloys strengthened by NiAl precipitates,” Mater. Sci. Forum, 595 – 598, 117 – 125 (2008).

S. Y. Kondrat’ev, G. P. Anastasiadi, A. V. Ptashnik, and S. N. Petrov, “Kinetics of the high-temperature oxidation of heat-resistant statically and centrifugally cast HP40NbTi alloys,” Oxid. Met., 91(1 – 2), 33 – 53 (2019).

M. P. Brady and P. F. Tortorelli, “Alloy design of intermetallics for protective scale formation and for use as precursors for complex ceramic phase surfaces,” Intermetallics, 12, 779 – 789 (2004).

S. Yu. Kondrat’ev, G. P. Anastasiadi, A. V. Ptashnik, and S. N. Petrov, “Evolution of the microstructure and phase composition of a subsurface of cast HP-type alloy during a long-term high-temperature aging,” Mater. Charact., 150, 166 – 173 (2019).

D. Caplan and G. I. Sproule, “Effect of oxide grain structure on the high-temperature oxidation of Cr,” Oxid. Met., 9, 459 – 472 (1975).

N. Birks, G. H. Meyer, and F. S. Pettit, Introduction to the High-Temperature Oxidation of Metals, Cambridge University Press & Higher Education Press (2010), 338 p.

S. Yu. Kondrat’ev, G. P. Anastasiadi, and A. I. Rudskoy, “Nanostructure mechanism of formation of oxide film in heat-resistant Fe – 25Cr – 35Ni superalloys,” Metal Sci. Heat Treat., 56(9 – 10), 531 – 536 (2015).

S. Yu. Kondrat’ev, G. P. Anastasiadi, A. V. Ptashnik, and S. N. Petrov, “The mechanisms of scale and subsurface diffusion zone formation of heat-resistant HP40NbTi alloy at long-term high-temperature exposure,” Materialia, 7, Art. 100427 (2019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yao, J., Lu, S., Xiao, X. et al. Effect of Silicon on the Oxidation Kinetics and Microstructure of the Surface Layer of TaCr2 Alloys Obtained by Vacuum Hot Pressing. Met Sci Heat Treat 64, 121–126 (2022). https://doi.org/10.1007/s11041-022-00771-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00771-4