Abstract

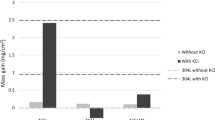

Biomass corrosion is a serious problem that affects the reliability and efficiency of biomass boilers. Ni-based coatings are a potential choice to combat biomass corrosion. In this study, the Ni-clad Al coatings were prepared by air plasma spraying, and the coatings were pre-oxidized in an air atmosphere at 700 °C for 6 h. The corrosion resistance of the as-sprayed and pre-oxidized Ni-clad Al coating exposed to KCl was studied at 600 °C for 168 h. The as-sprayed Ni-clad Al coating showed a much higher corrosion rate due to the porous nature of the coating and faster penetration of corrosion products. The pre-oxidation treatment significantly reduced the corrosion rate of the Ni-clad Al coating. The maximum weight gain of the pre-oxidized Ni-clad Al coating was reduced by 23.5% compared to the as-sprayed Ni-clad coating. After pre-oxidation, multiple NiO layers were formed, and voids were significantly reduced. The corrosion products on the surface of the coating changed from nickel-rich oxides to aluminum-rich oxides after the pre-oxidation treatment.

Similar content being viewed by others

References

N.L. Panwar, S.C. Kaushik and S. Kothari, Role of Renewable Energy Sources in Environmental Protection: A Review, Renew. Sustain. Energy Rev., 2011, 15, p 1513-1524.

M. Li, N. Luo and Y. Lu, Biomass Energy Technological Paradigm (BETP): Trends in This Sector, Sustainability., 2017, 9, p 567.

F. Trifirò, Fuels from Biomass, Tec. Ital. J. Eng. Sci., 2019, 63, p 86-93.

H.L. Chum and R.P. Overend, Biomass and Renewable Fuels, Fuel Process. Technol., 2001, 71, p 187-195.

C. De Blasio, Biodiesel, Green Energy Technol. C. De Blasio Ed., Springer, Cham, 2019, p 253-265

A. Demirbas, Potential Applications of Renewable Energy Sources, Biomass Combustion Problems in Boiler Power Systems and Combustion Related Environmental Issues, Prog. Energy Combust. Sci., 2005, 31, p 171-192.

I. Obernberger, T. Brunner and G. Bärnthaler, Chemical Properties of Solid Biofuels-Significance and Impact, Biomass Bioenerg., 2006, 30, p 973-982.

H.P. Nielsen, F.J. Frandsen, K. Dam-Johansen and L.L. Baxter, The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers, Prog. Energy Combust. Sci., 2000, 26, p 283-298.

L.J.R. Nunes, J.C.O. Matias and J.P.S. Catalão, Biomass Combustion Systems: A Review on the Physical and Chemical Properties of the Ashes, Renew. Sustain. Energy Rev., 2016, 53, p 235-242.

D.L. Wu, K.V. Dahl, T.L. Christiansen, M. Montgomery and J. Hald, Corrosion Behaviour of Ni and Nickel Aluminide Coatings Exposed in a Biomass Fired Power Plant for Two Years, Surf. Coat. Technol., 2019, 362, p 355-365.

A.A. Khan, W. de Jong, P.J. Jansens and H. Spliethoff, Biomass Combustion in Fluidized Bed Boilers: Potential Problems and Remedies, Fuel Process. Technol., 2009, 90, p 21-50.

Y.Y. Lee and M.J. McNallan, Ignition of Nickel in Environments Containing Oxygen and Chlorine, Metall. Trans. A., 1991, 18, p 1099-1107.

A. Zahs, M. Spiegel and H.J. Grabke, Chloridation and Oxidation of Iron, Chromium, Nickel and their Alloys in Chloridizing and Oxidizing Atmospheres at 400-700 °C, Corros. Sci., 2000, 42, p 1093-1122.

C. Pettersson, J. Pettersson, H. Asteman, J.E. Svensson and L.G. Johansson, KCl-Induced High Temperature Corrosion of the Austenitic Fe-Cr-Ni Alloys 304L and SANICRO 28 at 600 °C, Corros. Sci., 2006, 48, p 1368-1378.

N. Folkeson, T. Jonsson, M. Halvarsson, L.-G. Johansson and J.-E. Svensson, The influence of small amounts of KCl(s) on the high temperature corrosion of a Fe-2.25Cr-1Mo steel at 400 and 500 °C, Mater. Corros., 2011, 62, p 606-615.

Y. Shinata, Accelerated Oxidation Rate of Chromium Induced by Sodium Chloride, Oxid. Met., 1987, 27, p 315-332.

J. Lehmusto, B.J. Skrifvars, P. Yrjas and M. Hupa, High Temperature Oxidation of Metallic Chromium Exposed to Eight Different Metal Chlorides, Corros. Sci., 2011, 53, p 3315-3323.

R. Jafari and E. Sadeghi, High-Temperature Corrosion Performance of HVAF-Sprayed NiCr, NiAl, and NiCrAlY Coatings with Alkali Sulfate/Chloride Exposed to Ambient Air, Corros. Sci., 2019, 160, p 108066.

E. Sadeghimeresht, N. Markocsan and P. Nylén, A Comparative Study on Ni-Based Coatings Prepared by HVAF, HVOF, and APS Methods for Corrosion Protection Applications, J. Therm. Spray Technol., 2016, 25, p 1604-1616.

T.J. Pan, Y.S. Li, Q. Yang, R.F. Feng and A. Hirose, Internal Oxidation and Phase Transformations of Multi-Phase Fe-Ni-Al and Fe-Ni-Al-Cr Alloys Induced by KCl Corrosion, Corros. Sci., 2011, 53, p 2115-2121.

D. Wu, Z. Yuan, S. Liu, J. Zheng, X. Wei and C. Zhang, Recent Development of Corrosion Factors and Coating Applications in Biomass Firing Plants, Coatings, 2020, 10, p 1001.

S. Kiamehr, K.V. Dahl, M. Montgomery and M.A.J. Somers, KCl-Induced High Temperature Corrosion of Selected Commercial Alloys: Part II: Alumina and Silica-Formers, Mater. Corros., 2016, 67, p 26-38.

J. Lehmusto, P. Yrjas, B.J. Skrifvars and M. Hupa, High Temperature Corrosion of Superheater Steels by KCl and K2CO3 Under Dry and Wet Conditions, Fuel Process. Technol., 2012, 104, p 253-264.

J. Pettersson, H. Asteman, J.E. Svensson and L.G. Johansson, KCl Induced Corrosion of a 304-type Austenitic Stainless Steel at 600°C; The Role of Potassium, Oxid. Met., 2005, 64, p 23-41.

T. Jonsson, J. Froitzheim, J. Pettersson, J.E. Svensson, L.G. Johansson and M. Halvarsson, The Influence of KCl on the Corrosion of an Austenitic Stainless Steel (304L) in Oxidizing Humid Conditions at 600°C: A Microstructural Study, Oxid. Met., 2009, 72, p 213-239.

S. Enestam, D. Bankiewicz, J. Tuiremo, K. Mäkelä and M. Hupa, Are NaCl and KCl Equally Corrosive on Superheater Materials of Steam Boilers?, Fuel, 2013, 104, p 294-306.

J. Pettersson, J.E. Svensson and L.G. Johansson, Alkali Induced Corrosion of 304-Type Austenitic Stainless Steel at 600°C; Comparison between KCl, K2CO3 and K2SO4, Mater. Sci. Forum., 2008, 595-598, p 367-375.

T. Hussain, T. Dudziak, N.J. Simms and J.R. Nicholls, Fireside Corrosion Behavior of HVOF and Plasma-Sprayed Coatings in Advanced Coal/Biomass Co-Fired Power Plants, J. Therm. Spray Technol., 2013, 22, p 797-807.

R. Jafari, E. Sadeghimeresht, T.S. Farahani, M. Huhtakangas, N. Markocsan and S. Joshi, KCl-Induced High-Temperature Corrosion Behavior of HVAF-Sprayed Ni-Based Coatings in Ambient Air, J. Therm. Spray Technol., 2018, 27, p 500-511.

M. Bai, L. Reddy and T. Hussain, Experimental and Thermodynamic Investigations on the Chlorine-Induced Corrosion of HVOF Thermal Sprayed NiAl Coatings and 304 Stainless Steels at 700 °C, Corros. Sci., 2018, 135, p 147-157.

S. Paul and M.D.F. Harvey, Corrosion Testing of Ni alloy HVOF Coatings in High Temperature Environments for Biomass Applications, J. Therm. Spray Technol., 2013, 22, p 316-327.

E. Sadeghi and N. Markocsan, Shrikant Joshi, Advances in Corrosion-Resistant Thermal Spray Coatings for Renewable Energy Power Plants: Part II—Effect of Environment and Outlook, J. Therm. Spray Technol., 2019, 28, p 1789-1850.

E. Sadeghimeresht, L. Reddy, T. Hussain, N. Markocsan and S. Joshi, Chlorine-Induced High Temperature Corrosion of HVAF-Sprayed Ni-Based Alumina and Chromia Forming Coatings, Corros. Sci., 2018, 132, p 170-184.

J. Eklund, J. Phother, E. Sadeghi, S. Joshi and J. Liske, High-Temperature Corrosion of HVAF-Sprayed Ni-Based Coatings for Boiler Applications, Oxid. Met., 2019, 91, p 729-747.

H. Asteman and M. Spiegel, Investigation of the HCl (g) Attack on Pre-Oxidized Pure Fe, Cr, Ni and Commercial 304 Steel at 400 °C, Corros. Sci., 2007, 49, p 3626-3637.

P. Viklund and R. Pettersson, HCl-Induced High Temperature Corrosion of Stainless Steels in Thermal Cycling Conditions and the Effect of Preoxidation, Oxid. Met., 2011, 76, p 111-126.

S.C. Okoro, M. Kvisgaard, M. Montgomery, F.J. Frandsen and K. Pantleon, Pre-Oxidation and its Effect on Reducing High-Temperature Corrosion of Superheater Tubes During Biomass Firing, Surf. Eng., 2017, 33, p 428-432.

O. Hunziker and W. Kurz, Directional Solidification and Phase Equilibria in the Ni-Al System, Metall. Mater. Trans. A., 1999, 30, p 3167-3175.

B. Gleeson, N. Mu and S. Hayashi, Compositional Factors Affecting the Establishment and Maintenance of Al2O3 Scales on Ni-Al-Pt Systems, J. Mater. Sci., 2009, 44, p 1704-1710.

R. Peraldi, D. Monceau and B. Pieraggi, Correlations Between Growth Kinetics and Microstructure for Scales Formed by High-Temperature Oxidation of Pure Nickel. II. Growth Kinetics, Oxid. Met., 2002, 58, p 275-295.

B. Grégoire, X. Montero, M.C. Galetz, G. Bonnet and F. Pedraza, Correlations Between the Kinetics and the Mechanisms of Hot Corrosion of Pure Nickel at 700 °C, Corros. Sci., 2019, 155, p 134-145.

D.L. Wu, K.V. Dahl, F.B. Grumsen, T.L. Christiansen, M. Montgomery and J. Hald, Breakdown Mechanism of γ-Al2O3 on Ni2Al3 Coatings Exposed in a Biomass Fired Power Plant, Corros. Sci., 2020, 170, p 108583.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52101100), the Natural Science Foundation of Jiangsu Province (Grant No. BK20190915) and the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 21KJB430008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, D., Wu, H., Yuan, Z. et al. Improvement of Corrosion Resistance and Structural Integrity of Plasma Sprayed Ni-clad Al Coatings via Pre-oxidation. J Therm Spray Tech 31, 2422–2434 (2022). https://doi.org/10.1007/s11666-022-01451-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01451-8