Abstract

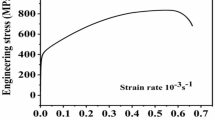

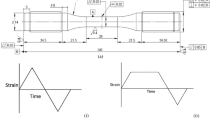

IN-617 is a superalloy of nickel, primarily used as tubes of superheater, re-heater and steam generator in nuclear core because of its excellent performance in that environment. However, during service the length of tubular components progressively increases due to tensile mean stress resulting from the asymmetric cyclic stressing and the components fail in much smaller number of cycles than that tested under symmetric loading (without tensile mean stress). The present investigation deals with cumulative plastic strain arising under different levels of mean stress (σm), amplitude of stress(σa), and rate of stress (\(\dot{\sigma }\)); and their effect on fatigue life. While the accumulation of permanent deformation enhances with rise in σm and σa and the number of cycles to failure (Nf) decreases, there is opposite effect of \(\dot{\sigma }\) the permanent strain is decreased from rise in \(\dot{\sigma }\) and cyclic life is enhanced. TEM analysis of tested samples showed variation in dislocation substructures developed under the different variables.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Paul SK,J Mater Res Technol8(5) (2019) 4894.

Paul SK,Sivaprasad S, Dhar S andTarafder S,JMater Sci47(11) (2012) 4660.

Dutta K and Ray KK, Mater Sci Eng A575 (2013) 127.

Shi H, Chen G, Wang Y and Chen X, Int J Press Vessels Pip 102 (2013) 14.

Wang Y, Yu D, Chen Gand Chen X,Int J Fatigue 52 (2013) 106.

Kang G,Gao Q, Cai Land Sun Y,Nucl Eng Des 216(1–3) (2002) 13.

Ray KK, Dutta K, Sivaprasad SandTarafder S,Procedia Eng2(1) (2010)1805.

Vishnuvardhan S, Raghava G,Gandhi P, Saravanan M, Goyal S, Arora P,Gupta SKandBhasin V,Int J Press Vessels Pip 105 (2013) 79.

Mishra P, Santhi Srinivas NC,Sastry GVSandSingh V,Trans Indian Inst Met 74(4) (2021) 937.

De PS,Kundu A, Chakraborti PC, Mater Des 57 (2014) 87.

Lim CB, Kim KS and Seong JB,IntJ Fatigue 31(3) (2009) 501.

Dutta K and Ray KK,Mater Sci Eng A 540 (2012) 30.

Kreethi R, Verma P and Dutta K,Trans Indian Inst Metals68(2) (2015) 229.

`14. Lin YC, Liu ZH, Chen XM, Chen J, Mater Sci Eng A57 (2013) 234.

Lin YC, Chen XM and Chen G,J Alloys Compd 509(24) (2011) 6838.

Zhu J, Chen X, Xue FandYu W,Int J Fatigue 35(1) (2012) 16.

Tao G and Xia Z,Polym Test 26(4) (2007) 451.

Rajpurohit RS, Santhi Srinivas NC, Singh SR and Singh V,IntJ Press Vessels Pip 159 (2018) 84.

Cheng H, Chen G, Zhang Z, Chen X, J Nucl Mater 458 (2015) 129.

Sarkar A, Nagesha A,Parameswaran P, Sandhya R, Mathew MD,MaterSci Eng A 564 (2013) 359.

Kang G, Gao Q and Yang X,Mech Mater 34(3) (2002) 145.

Kang G, Gao Q, and Yang X, IntJ Non-Linear Mech 39(5) (2004) 843

Ohno N, J Soc Mater Sci Jpn 46 (3Appendix) (1997) 1.

Chaboche JL,Int J plast 7(7) (1991) 661.

Zhang B, Wang R, Hu D, Jiang K, Hao X, Mao J, Jing F, Int J Fatigue 139 (2020) 105786.

Kang G, Dong Y,Wang H, Liu Y andCheng X,Mater Sci Eng.527(21-22),5952-61(2010)

Kang G, Dong Y, Liu Y and Jiang H, MaterCharact 92 (2014) 26.

Kreethi R, Mondal AK and Dutta K, Mater Sci Eng A679 (2017)66.

Mishra P,Rajpurohit RS, Santhi Srinivas NC, SastryGVS and Singh V, Met Mater Int27(12) (2021) 4922.

Rao CV, Santhi Srinivas NC, Sastry GVS and Singh V,Mater Sci Eng A 765 (2019) 138286.

Rao CV, Santhi Srinivas NC, Sastry GVS andSingh V,Mater Sci Eng A 742 (2019) 44.

Hrutkay K,Kaoumi D,Mater Sci Eng A 599 (2014) 196.

Carroll L, Wright R, J Press Vessel Technol 135(6)(2013).

Totemeier TC and Tian H, Mater Sci Eng A 468 (2007) 81.

El-Awadi GA, Abdel-Samad S andElshazly ES,Appl Surf Sci 378 (2016) 224.

Lei Q, Zhang X, Gao M, Wen W, Jia Y, Liu H, Li Y, Liu J andZhou X,Corros Sci 182 (2021)109289

Guo Y, Wang B and HouS,Acta Metall Sin-Engl 26(3) (2013) 307.

Mishra P, SanthiSrinivas NC and SinghV,Mater Lett 314 (2022) 131916.

Paul SK, Sivaprasad S, Dhar S, Tarafder S, Int J Press Vessels Pip 87 (2010) 440.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, P., Srinivas, N.C.S., Sastry, G.V.S. et al. Ratcheting Fatigue of Superalloy IN-617 Under Tensile Mean Stress at RT. Trans Indian Inst Met 75, 3127–3138 (2022). https://doi.org/10.1007/s12666-022-02667-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02667-6