Abstract

Of late, given the difficulties in gold extraction and severe environmental pollution emanating from cyanide extraction of Carlin-type gold concentrate (CTGC), a novel pressure oxidation pretreatment followed by sodium jarosite decomposition and fine grinding was first proposed to extract gold from the CTGC in a non-cyanide system. Thermodynamic computations of the Gibbs free energy and the Eh–pH diagram of different reaction systems were calculated to reveal the reaction mechanism during the treatment process. The optimal pressure oxidation pretreatment conditions were determined as follows: stirring speed 600 r/min, liquid-to-solid ratio of 4, pH 1.2–1.3, partial pressure of oxygen 1200 kPa, temperature 225 °C, and time 1.5 h. The extraction of gold increased from 9.7 to 82.1%. The sulfur conversion mechanism and the distribution of the gold phase as a function of leaching temperature during the pressure oxidation leaching process were investigated. The precise regulation and control mechanism of sodium jarosite decomposition and fine grinding were clarified. Furthermore, the polysulfide leaching results show that pressure oxidation leaching of the CTGC followed by sodium jarosite decomposition and fine grinding can efficiently liberate gold from the mineral envelope and provide favorable conditions for gold extraction in a non-cyanide leaching system. The leaching efficiency of gold in the polysulfide system reached 96.8%. This process has proved to be a promising alternative for efficient and environmentally friendly extraction of gold from the refractory gold ore.

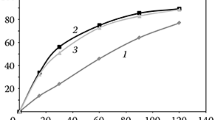

Graphical Abstract

Similar content being viewed by others

References

Ahmed MR, Mohammed HS, El-Feky MG, Abdel-Monem YK (2020) Gold leaching using thiourea from uranium tailing material, Gabal El-Missikat, Central Eastern Desert, Egypt. J Sustain Metall 6(4):1354–1367

Xue-yi G, Lei Z, Tian Qing-hua QIN, Hong, (2020) Stepwise extraction of gold and silver from refractory gold concentrate calcine by thiourea. Hydrometallurgy 194:105330

Zhao H-F, Yang H-Y, Tong L-L, Zhang Q, Kong Ye (2020) Biooxidation-thiosulfate leaching of refractory gold concentrate. Int J Miner Metall Mater 27(8):1075–1082

James M, Omid M, Rina K, Ahmad G (2021) Gold extraction from refractory sulfide gold concentrates: a comparison of bio-oxidation and neutral atmospheric pre-treatment and economic implications. J Sustain Metall 7(3):1354–1367

Alexander B, Raslan MS, Bernd F (2018) Screening of non-cyanide leaching reagents for gold recovery from waste electric and electronic equipment. J Sustain Metall 4(2):265–275

Sugyeong L, Farzaneh S, Ahmad G (2022) Enhanced gold recovery from alkaline pressure oxidized refractory gold ore after its mechanical activation followed by thiosulfate leaching. J Sustain Metall 8(1):186–196

Snyders CA, Akdogan G, Bradshaw SM, van Vreden JH, Smith R (2018) The development of a caustic pre-leaching step for the recovery of Au from a refractory ore tailings heap. Miner Eng 121:23–30

Barbu CA, Tomus N, Radu AD, Zlagnean M, Popescu I-C (2021) Gravity separation: highly effective tool for gold-bearing residue’s recycling. J Sustain Metall 7(4):1852–1861

Wang H-j, Feng Y-l, Li H-r, Kang J-x (2020) Simultaneous extraction of gold and zinc from refractory carbonaceous gold ore by chlorination roasting process. Trans Nonferrous Metals Soc China 30:1111–1123

Yang H-y, Liu Q, Song X-l, Dong J-k (2013) Research status of carbonaceous matter in carbonaceous gold ores and bio-oxidation pretreatment. Trans Nonferrous Metals Soc China 23:3405–3411

Lei Z, Xue-yi G, Qing-hua T, Dong Li, Shui-ping Z, Hong Q (2022) Improved thiourea leaching of gold with additives from calcine by mechanical activation and its mechanism. Miner Eng 178:107403

Yang HM, Hu YH, Ao WQ, Qiu GZ, Wang DZ (2002) Ultrafine milling for the processing of gold-bearing sulphides. Rare Met 21:133–136

Lei C, Yan B, Chen T, Wang X-l, Xiao X-m (2018) Silver leaching and recovery of valuable metals from magnetic tailings using chloride leaching. J Clean Prod 181:408–415

Xiao-E D, Wen-Shuai Ke, Chen T, Lv J, Zhou X, Liu C-P (2016) Increasing leaching rate of gold cyanide of two-stage calcination generated from refractory ore containing arsenopyrite and pyrrhotite. Rare Met 35:804–810

Guo Y-j, Guo X, Wu H-y, Li S-p, Wang G-h, Liu X-x, Qiu G-z, Wang D-z (2017) A novel bio-oxidation and two-step thiourea leaching method applied to a refractory gold concentrate. Hydrometallurgy 171:213–221

Li Z-Y, Wang W-W, Kue K, Cheng M-X (2016) High-temperature chlorination of gold with transformation of iron phase. Rare Met 35:881–886

Zhang S-H, Zheng Y-J, Cao P, Li C-H, Lai S-Z, Wang X-J (2018) Process mineralogy characteristics of acid leaching residue produced in low-temperature roasting-acid leaching pretreatment process of refractory gold concentrates. Int J Miner Metall Mater 25:1132–1139

Zhu P, Gu GB (2006) Kinetics of stripping of gold loaded in DBC organic phase by sodium sulfite. Rare Met 25:1–6

Yin SH, Chen W, Fan XL, Liu JM, Wu LB (2021) Review and prospects of bioleaching in the Chinese mining industry. Int J Miner Metall Mater 28:1397–1412

Chen X-y, Lan X-z, Zhang Q-l, Zhou J, Song Y-h (2010) Behavior of S2O32− and SO32− in sulfur-bearing aqueous solution system for gold leaching. Trans Nonferrous Metals Soc China 20:46–49

Ma CJ, Li JY, Liu RJ (2015) A review of Thiocyanate hydrometallurgy for the recovery of gold. Appl Mech Mater 76:53–61

Yang Y-b, Zhang X, Xu B, Li Q, Jiang T, Wang Y-x (2015) Effect of arsenopyrite on thiosulfate leaching of gold. Trans Nonferrous Metals Soci China 25:3454–3460

Yang Y-b, Li Q, Jiang T, Guo Y-f, Li G-h, Xu B (2010) Co-intensification of gold leaching with heavy metals and hydrogen peroxide. Trans Nonferrous Metals Soci China 20:903–909

Nie Y, Chen J, Wang Q, Zhang C, Shi C, Zhao J (2021) Use of dry grinding process to increase the leaching of gold from a roasted concentrate containing hematite in the thiosulfate system. Hydrometallurgy 201:105582

Dong Z, Jiang T, Bin Xu, Yang Y, Li Q (2019) An eco-friendly and efficient process of low potential thiosulfate leaching-resin adsorption recovery for extracting gold from a roasted gold concentrate. J Clean Prod 229:387–398

Jin J, Han Y, Li H, Huai Y, Peng Y, Gu X, Yang W (2019) Mineral phase and structure changes during roasting of fine-grained carbonaceous gold ores and their effects on gold leaching efficiency. Chin J Chem Eng 27:1184–1190

Jiajia Wu, Ahn J, Jaeheon L (2021) Gold deportment and leaching study from a pressure oxidation residue of chalcopyrite concentrate. Hydrometallurgy 201:105583

Ahtiainen R, Liipo J, Lundström M (2021) Simultaneous sulfide oxidation and gold dissolution by cyanide-free leaching from refractory and double refractory gold concentrates. Miner Eng 170:107042

Azizitorghbeh A, Wang J, Ramsay JA, Ghahreman A (2021) A review of thiocyanate gold leaching—chemistry, thermodynamics, kinetics and processing. Miner Eng 160:106689

Gui Q, Khan MI, Wang S, Zhang L (2020) The ultrasound leaching kinetics of gold in the thiosulfate leaching process catalysed by cobalt ammonia. Hydrometallurgy 196:105426

Pak K-S, Zhang T-A, Kim C-S, Kim G-H (2020) Research on chlorination leaching of pressure-oxidized refractory gold concentrate. Hydrometallurgy 194:105325

Xiaoyang Xu, Ming X, Chuangkai C, Jinyi G, Wentao D (2017) Research on the pressure peroxidation-cyanidation process treating a carbonaceous gold ore. Gold 11(50–53):67

Guo X-y, Zhang L, Tian Q-h, Yu D-w, Cui F-h (2020) Gold leaching of high pressure acid leaching residue using a non-cyanide system and its mechanism. Chin J Nonferrous Metals 30:1131–1141

Elgersma F, Witkam GJ, Rosmalen GMV (1993) Simultaneous dissolution of zinc ferrite and precipitation of ammonium jarosite. Hydrometallurgy 34:23–47

Achimovicova M, Balaz P (2015) Influence of mechanical activation on selectivity of acid leaching of arsenopyrite. Hydrometallurgy 77:3–7

Baláž P, Dutková E (2009) Fine milling in applied mechanochemistry. Miner Eng 22:681–694

Zhao S-x, Wang G-r, Yang H-y, Chen G-b, Qiu X-m (2021) Agglomeration-aggregation and leaching properties of mechanically activated chalcopyrite. Trans Nonferrous Metals Soc China 31:1465–1474

Hilson G, Monhemius AJ (2006) Alternatives to cyanide in the gold mining industry: what prospects for the future? J Clean Prod 14(12–13):1158–1167

Wang F, Guo MS, Wang K (2006) Preparation of certified reference materials for chemical phase analysis of gold ore samples. Rock Miner Anal 25:263–269

Xinxia N, Wenkang C (2017) Improvement on measurement of chemical phase analysis of gold in carbonaceous gold ores. Chem Anal Meterage 26(4):101–104

Dean JA, Jun-fa WEI (2003) Lange’s handbook of chemistry. Science Press, Beijing

Da-lun YE, Jian-hua HU (2002) Practical inorganic thermodynamics data book. Metallurgical Industry Press, Beijing

Chuan-xian LIN (1985) Handbook of thermodynamic data for minerals and related compounds. Science Press, Beijing

Brion D (1980) Etude par spectroscopie de photoelectrons de la degradation superficielle de FeS2, CuFeS2, ZnS et PbS a l’air et dans l’eau. Appl Surf Sci 5:133–152

Descostes M, Mercier F, Beaucaire C, Zuddas P, Trocellier P (2001) Nature and distribution of chemical species on oxidised pyrite surface: complementarity of XPS and nuclear microprobe analysis. Nuclear Instrum. Methods Phys Res Sect B Beam Interact Mater Atoms 181:603–609

Descostes M, Mercier F, Thromat N, Beaucaire C, Gautier-Soyer M (2000) Use of XPS in the determination of chemical environment and oxidation state of iron and sulfur samples: constitution of a data basis in binding energies for Fe and S reference compounds and applications to the evidence of surface species of an oxidized pyrite in a carbonate medium. Appl Surf Sci 165:288–302

Huang H-g (2007) Intigations on acidic hot-press preoxidation of refractory gold concentrates. Min Metall Eng 27:42–45

Ahamed AM, Pons MN, Ricoux Q, Issa S, Goettmann F, Lapicque F (2021) New pathway for utilization of jarosite, an industrial waste of zinc hydrometallurgy. Miner Eng 170:107030

Chu M, Li C-x, Zhang P, Ji W-b, Wei C, Deng Z-g, Li X-b, Fan G, Li M-t (2020) Hydrothermal decomposition of hazardous jarosite residue produced in zinc hydrometallurgy and transformation behavior of iron containing phase. Chin J Nonferrous Metals 30:1119–1130

Liu S-p, Wang H-b, Jiang K-x, Feng Y-p, Huang S (2009) Utilization of jarosite containing zinc. Min Metall 18(1):23–28

Yang F, Deng Z-g, Wei C, Li C-x, Li X-b (2014) Iron-removal by hematite from leaching liquor of high iron sphalerite. Chin J Nonferrous Metals 24(2):2387–2391

Balaz P, Ssekula F, Jakabsky S, Kammel R (1995) Application of attrition grinding in alkaline leaching of tetrahedrite. Miner Eng 8:1299–1308

King RP (2001) Modeling and simulation of mineral processing systems. Butterworth-Heinemann, Oxford

Zhao QQ, Yamada S, Jimbo G (1989) The mechanism and grinding limit of planetary ball milling. J Soc Powder Technol 302(7):297–302

Opoczky L, Farnady F (1984) Fine grinding and states of equilibrium. Powder Technol 39(1):107–115

Ebadi H, Pourghahramani P (2019) Effects of mechanical activation modes on microstructural changes and reactivity of ilmenite concentrate. Hydrometallurgy 188:38–46

Cullity DB (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley, Reading

Granata G, Takahashi K, Ka To T, Tokoro C (2019) Mechanochemical activation of chalcopyrite: relationship between activation mechanism and leaching enhancement. Miner Eng 131:280–285

Wen Q, Yufeng Wu, Wang X, Zhuang Z, Yan Yu (2017) Researches on preparation and properties of sodium polysulphide as gold leaching agent. Hydrometallurgy 171:77–85

Kim R, Ghahreman A (2020) A mechanism of metastable sulfur speciation and the adsorption on a gold surface in the presence of sulfidic ore and lead in cyanide medium. Hydrometallurgy 193:105294

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 52104355) and National Natural Science Foundation of China (Grant No. 52074363).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

The contributing editor for this article was Grace Ofori-Sarpong.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Guo, Xy., Tian, Qh. et al. Non-cyanide Extraction of Gold from Carlin-Type Gold Concentrate by Pressure Oxidation Pretreatment–Jarosite Decomposition–Fine Grinding: An Eco-Friendly Process and Its Mechanism. J. Sustain. Metall. 8, 1299–1317 (2022). https://doi.org/10.1007/s40831-022-00567-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00567-z