Abstract

The incorporation of lead into most consumer items such as gasoline, paints, and welding materials is generally prohibited. However, lead–acid batteries (LABs) have become popular and have emerged as a major area where lead is utilized. Appropriate recycling technologies and the safe disposal of LABs (which contain approximately 65% lead) and lead-containing waste are, therefore, vital for the sustainable development of the lead industry. This paper gives an overview of the status of the secondary lead industry from the perspective of China and summarizes the recovery technologies for waste lead paste in pyrometallurgy and hydrometallurgy. Although the pyrometallurgical methods of lead recovery have issues of high energy consumption and a large risk of lead dust and SO2 flue gas emissions, they are still the dominant industrial technology. The full hydrometallurgical recovery process is a reasonable choice for small- and medium-sized lead-recycling enterprises, with the preparation of battery material from waste lead paste through a short process being a major goal. However, efficient methods for the development of clean and economical conversion reagents, the economic treatment of wastewater, and the disposal of the resulting byproducts are urgently needed. Pre-desulfurization-free combined electrolysis provides a new approach for the clean hydrometallurgical extraction of waste lead paste.

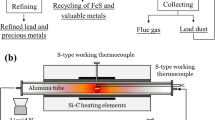

Graphical Abstract

Similar content being viewed by others

References

Yang JK, Zhu XF, Liu WC, Yang HY, Xiao B (2009) Review of recovery technology for lead paste from spent lead acid battery. Mod Chem Ind 29(3):32–37. https://doi.org/10.16606/j.cnki.issn0253-4320.2009.03.018 (in Chinese)

eastmoney.com (2021) The supply and demand situation of the global and Chinese lead industry in 2020, the production of secondary lead is expanding year by year. https://caifuhao.eastmoney.com/news/20210121130833058614530

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657. https://doi.org/10.1038/451652a

Zhang QY (2013) The current status on the recycling of lead-acid batteries in China. Int J Electrochem Sci 8(5):6457–6466

Li L, Zhu XF, Yang DN, Gao LX, Liu JW, Kumar RV, Yang JK (2012) Preparation and characterization of nano-structured lead oxide from spent lead acid battery paste. J Hazard Mater 203:274–282. https://doi.org/10.1016/j.jhazmat.2011.12.021

Xu JM, Li Y (2021) Analysis of global lead supply and demand pattern from 2020 to 2035. China Min Mag 30(2):14–20. https://doi.org/10.12075/j.issn.1004-4051.2021.02.033 (in Chinese)

Rada S, Cuibus D, Vermesan H, Rada M, Culea E (2018) Structural and electrochemical properties of recycled active electrodes from spent lead acid battery and modified with different manganese dioxide contents. Electrochim Acta 268:332–339. https://doi.org/10.1016/j.electacta.2018.02.135

Sun Z, Cao HB, Zhang XH, Lin X, Zheng WW, Cao GQ, Sun Y, Zhang Y (2017) Spent lead-acid battery recycling in China—a review and sustainable analyses on mass flow of lead. Waste Manage 64:190–201. https://doi.org/10.1016/j.wasman.2017.03.007

Khan SA (2016) E-products E-waste and the Basel convention: regulatory challenges and impossibilities of international environmental law. Rev Eur Comp Int Env 25(2):248–260. https://doi.org/10.1111/reel.12163

Gu Y, Wang JP, Wang X, Che D, Wu QX (2018) Situation and sustainable development proposals for lead resource development in China. Resour Ind 20(1):39–46. https://doi.org/10.13776/j.cnki.resourcesindustries.20180212.001 (in Chinese)

Pan JQ, Bian YR (2014) Development and current situation of the recovery technology for lead acid batteries. J B Univ Technol (Natural Science) 14(3):1–14. https://doi.org/10.13543/j.cnki.bhxbzr.2014.03.018 (in Chinese)

Tong PY, Zhao RR, Zhang RB, Yi FY, Shi G, Li AJ, Chen HY (2015) Characterization of lead (II)-containing activated carbon and its excellent performance of extending lead-acid battery cycle life for high-rate partial-state-of-charge operation. J Power Sources 286(15):91–102. https://doi.org/10.1016/j.jpowsour.2015.03.150

Wang JJ, Dong L, Liu MM, Wang JY, Shao QS, Li AJ, Yan W, Jung JCY, Zhang JJ (2020) Significantly improved high-rate partial-state-of-charge performance of lead-acid batteries induced by trace amount of graphene oxide nanosheets. J Energy Storage. https://doi.org/10.1016/j.est.2020.101325

Agrawal A, Sahu KK, Pandey BD (2004) Recent trends and current practices for secondary processing of zinc and lead. Part I: lead recovery from secondary sources. Waste Manag Res 22(4):240–247. https://doi.org/10.1177/0734242X04044916

May GJ, Davidson A, Monahov B (2018) Lead batteries for utility energy storage: a review. J Energy Storage 15:145–157. https://doi.org/10.1016/j.est.2017.11.008

He Y, Zheng Y, He Y, Guo XL, Dong Y, Zhou YT, Lin H, Cao GQ (2020) Situation of production, utilization and disposal of used lead-acid batteries in China. Chin Batt Ind 24(4):216–224 (in Chinese)

Shao QS, Yan W, Li AJ, Zhang JJ (2017) Development, present status and applications of lead-acid battery. Chin J Nat 39(4):258–264. https://doi.org/10.3969/j.issn.0253-9608.2017.04.004 (in Chinese)

Li GH (2016) Cause and maintenance of premature failure of valve regulated lead acid battery. Mod Salt Chem Ind 43(5):28–29. https://doi.org/10.19465/j.cnki.2095-9710.2016.05.013 (in Chinese)

He Y, Jin XQ, Jin J, Zheng Y, Cui JY, Li Y (2017) Analysis of the main problems in pollution control of reclaim and utilization of used lead accumulators and countermeasures. Environ Protect Sci 43(3):75–79

Bernardes AM, Espinosa DCR, Tenório JAS (2004) Recycling of batteries: a review of current processes and technologies. J Power Sources 130(1):291–298. https://doi.org/10.1016/j.jpowsour.2003.12.026

Gao Y (2019) Research on current situation and development trend of recycled lead in China. World Nonferrous Metals 10:168–169 (in Chinese)

Zhang X (2017) Study on new recovery technology and electrochemical performance of high purity lead and α-PbO from the spent lead acid batteries. PhD Thesis, BUCT, Beijing (in Chinese)

Bai BY, Hu XW, Li YP, Qiao Q (2016) Present situation, problems and countermeasures of the secondary lead industry in China. Environ Eng 34(5):126–130. https://doi.org/10.13205/j.hjgc.201605028 (in Chinese)

He Y, Chen Y, Jin XQ, Cui JY, Huang YL (2019) Situation analysis of the recovery and utilization of used lead-acid batteries in China. Earth Environ Sci 227:05260. https://doi.org/10.1088/1755-1315/227/5/052062

He Y, Wang W, Ding H, Jia J, Zheng Y, Hu HL (2021) Achievements and prospects of implementation of the extended producer responsibility (EPR) system for waste lead-acid batteries. Chin J Environ Eng 15(7):2218–2222. https://doi.org/10.12030/j.cjee.202008156 (in Chinese)

Gao Q, Zhu LG, Shu YH, Chen HY, Xia XW (2013) Research and discussion on the waste lead-acid battery fragmentized separation system. Chin LABAT Man 1:3–7. https://doi.org/10.16679/j.cnki.21-1121.2013.01.001 (in Chinese)

Kreusch MA, Ponte MJJS, Ponte HA, Kaminari NMS, Marino CEB, Mymrin V (2007) Technological improvements in automotive battery recycling. Resour Conserv Recycl 52(2):368–380. https://doi.org/10.1016/j.resconrec.2007.05.004

Paff SW, Bosilovich BE (1995) Use of lead reclamation in secondary lead smelters for the remediation of lead contaminated sites. J Hazard Mater 40(2):139–164. https://doi.org/10.1016/0304-3894(94)00070-W

Hu HQ, Fan W, Huang HX, He BK (2014) Automatic control system for crushing and separation equipment for lead-acid battery based on S7–300PLC. Chin LABAT Man 153(4):190–195. https://doi.org/10.16679/j.cnki.21-1121.2016.04.010 (in Chinese)

Ma C, Xue X, Zhu LG, Gao Q (2017) The recycling technology of used lead-acid battery and integrated equipment in the industry. Chin LABAT Man 54(06):15–19. https://doi.org/10.16679/j.cnki.21-1121.2017.06.005 (in Chinese)

Bai L, Qiao Q, Li YP, Wan S, Xie MH, Chai FH (2015) Statistical entropy analysis of substance flows in a lead smelting process. Resour Conserv Recy 94:118–128. https://doi.org/10.1016/j.resconrec.2014.11.011

Liu B, Zhang K, Tang HJ, Yu QZ, Wang J, Li SZ (2015) Pollution control technology of lead for lead-acid battery manufacturing industry. Environ Sci Surv 34(3):68–72. https://doi.org/10.13623/j.cnki.hkdk.2015.03.019 (in Chinese)

Zhu XF (2012) Study on leaching process of spent lead battery paste with organic acid preparation of ultrafine lead oxide by calcination at low temperature. PhD Thesis, Environmental Engineering, HUST, Wuhan, 1–12 (in Chinese)

Zhang W, Yang JK, Wu X, Hu YC, Yu WH, Wang JX, Dong JX, Li MY, Liang S, Hu JP, Kumar RV (2016) A critical review on secondary lead recycling technology and its prospect. Renew Sustain Energy Rev 61:108–122. https://doi.org/10.1016/j.rser.2016.03.046

Lei LX, Ju CS, Gao PR, Zhou SB. Device for separating electrode plates of laminated battery. CN Patent 203166044U, August 28, 2013 (in Chinese)

Zhu XF, Yang DN, Hu HY, He X, Liu LJ, Li L, Liu JW, Yang JK (2012) Properties of lead paste from spent lead-acid battery. Chin J Environ Eng 6(9):3259–3262. https://doi.org/10.16679/j.cnki.21-1121.2018.02.001 (in Chinese)

Li MY, Yang JK, Yu WH, Hu YC, Liang S, Wang JX, Zhang W, Zhang PY, Liu JW, Wu X, Hou HJ, Liu BC, Hu JP, Kumar RV (2017) A facile approach for synthesizing tetrabasic lead sulfate derived from recycled lead-acid battery paste and its electrochemical performance. J Electrochem Soc 164(12):A2321–A2327. https://doi.org/10.1149/2.0611712jes

Kim MB, Lee WS, Yong HL (2000) The QSL lead slag fuming process using an ausmelt furnace. In: Lead-Zinc 2000, The Minerals, Metals and Materials Society, 331–343. https://doi.org/10.1002/9781118805558.ch20

Queneau PE, Siegmund A (1996) Industrial-scale Leadmaking with the QSL continuous oxygen convener. JOM 48(4):38–44. https://doi.org/10.1007/bf03222918

Jiang JM (2013) Situation and development trend of lead smelting technology at home and abroad. Energy Saving of Nonferrous Metallurgy 29(03):4–8. (in Chinese)

Wan Z, Liu CQ, Tan J, Li J, Chen QY, Wang H, Liao Z, Zhang PM (2013) Simultaneous equilibrium about smelting process in functional area of Kivcet flash furnace. Chin J Nonferrous Metals 23(10):2942–2948. https://doi.org/10.19476/j.ysxb.1004.0609.2013.10.028 (in Chinese)

Wang JK, Zhou TX, Feng GL (2004) ISA-YMG smelting process for lead bullion. Eng Sci 6(4):61–66. (in Chinese)

Wang XM, Zhang XZ (2015) Research of zinc fuming extraction from lead smelting slag by SKS bottom blowing stove. China Nonferrous Metall 3:12–14. (in Chinese)

Wang CY, Gao W, Yin F, Song YZ, Zheng XB, Liang DH (2012) New technology of lead oxygen-enriched flash smelting. Nonferrous Metals (Extractive Metallurgy) 4:6–10. https://doi.org/10.3969/j.issn.1007-7545.2012.04.002 (in Chinese)

Li XB, Li YX, Lin GM, Bin WD, Zhang L (2011) Practice of direct lead smelting process with “tri-continuous furnace” in Wanyang Smelting Co. Ltd. China Nonferrous Metall 12(6):13–16 (in Chinese)

Hilts SR (2003) Effect of smelter emission reductions on children’s blood lead levels. Sci Total Environ 303(1–2):51–58. https://doi.org/10.1016/S0048-9697(02)00357-1

Lyakov NK, Atanasova DA, Vassilev VS, Haralampiev GA (2007) Desulphurization of damped battery paste by sodium carbonate and sodium hydroxide. J Power Sources 171(2):960–965. https://doi.org/10.1016/j.jpowsour.2007.06.014

Ramus K, Hawkins P (1993) Lead/acid battery recycling and the new Isasmelt process. J Power Sources 42(1–2):299–313. https://doi.org/10.1016/0378-7753(93)80159-M

Ellis TW, Mirza AH (2010) The refining of secondary lead for use in advanced lead-acid batteries. J Power Sources 195(14):4525–4529. https://doi.org/10.1016/j.jpowsour.2009.12.118

Qiu DF, Xu CH (2006) Recycling of non-ferrous metals resource. Metallurgical Industry Press, Beijing, pp 137–143

Prengaman RD (1995) Recovering lead from batteries. JOM 47(1):31–33. https://doi.org/10.1007/bf03221127

Zhou ZH (2002) Pollution free pyrometallurgical regeneration of lead and its alloys from used and scrapped batteries. Shanghai Nonferrous Metals 23(4):15–21. https://doi.org/10.13258/j.cnki.snm.2002.04.004 (in Chinese)

Buengeler J, Cattaneo E, Riegel B, Sauer DU (2018) Advantages in energy efficiency of flooded lead-acid batteries when using partial state of charge operation. J Power Sources 375(31):53–58. https://doi.org/10.1016/j.jpowsour.2017.11.050

Yanakieva VP, Haralampiev GA, Lyakov NK (2000) Desulphurization of the damped lead battery paste with potassium carbonate. J Power Sources 85(1):178–180. https://doi.org/10.1016/S0378-7753(99)00398-5

Ma Y, Zhang JF, Huang Y, Cao J (2018) A novel process combined with flue-gas desulfurization technology to reduce lead dioxide from spent lead-acid batteries. Hydrometallurgy 178:146–150. https://doi.org/10.1016/j.hydromet.2018.04.006

Yu WH, Zhang PY, Yang JK, Li MY, Hu YC, Liang S, Wang JX, Li SY, Xiao KK, Hou HJ, Hu JP, Kumar RV (2018) A low-emission strategy to recover lead compound products directly from spent lead-acid battery paste: key issue of impurities removal. J Clean Prod 210(10):1534–1544. https://doi.org/10.1016/j.jclepro.2018.11.133

Liu TT, Qiu KQ (2018) Removing antimony from waste lead storage batteries alloy by vacuum displacement reaction technology. J Hazard Mater 347(5):334–340. https://doi.org/10.1016/j.jhazmat.2018.01.017

Chen YZ, Tang W, Wu YX, Li G, Zhao ZB (2017) Present situation and development trend of secondary lead process at home and abroad. China Nonferrous Metall 3:17–22. https://doi.org/10.19612/j.cnki.cn11-5066/tf.2017.03.006 (in Chinese)

Zhao ZB, Chen XY (2016) The pilot-scale test of desulfurization and reduction of scrap lead paste in the bottom blowing furnace. Chin LABAT Man 53:207–209. https://doi.org/10.16679/j.cnki.21-1121.2016.05.002 (in Chinese)

Zhao ZB, Lu GJ, Chen XY (2019) Study on pyro-desulfurization smelting technology of waste lead acid battery paste. World Nonferrous Metals 18:5–7 (in Chinese)

Wu YX, Huang XF, Wang YJ, Tang W, Liu SH (2016) Practice of bottom-blowing reduction smelting process for paste mud of waste lead storage batteries. World Nonferrous Metals 14:97–98 (in Chinese)

Chen LG, Xu ZC, Liu M, Huang YM, Fan RF, Su YH, Hu GC, Peng XW, Peng XC (2012) Lead exposure assessment from study near a lead-acid battery factory in China. Sci Total Environ 429:191–198. https://doi.org/10.1016/j.scitotenv.2012.04.015

Kuijp TJVD, Lei H, Cherry CR (2013) Health hazards of China’s lead-acid battery industry: a review of its market drivers, production processes, and health impacts. Environ Health 12(1):61. https://doi.org/10.1186/1476-069X-12-61

Wang HM, Xia YF, Xi CQ, Liu JJ, Wang BL (2018) Analysis of “Bottleneck” of extended producer responsibility system on lead-acid batteries. Environ Protect 46:58–61. https://doi.org/10.14026/j.cnki.0253-9705.2018.z1.010 (in Chinese)

Li MY, Yang JK, Liang S, Hu HJ, Hu JP, Liu BC, Kumar RV (2019) Review on clean recovery of discarded/spent lead-acid battery and trends of recycled products. J Power Sources. https://doi.org/10.1016/j.jpowsour.2019.226853

Prengaman RD, Mcdonald HB (1980) Method of recovering lead values from battery sludge. US Patent 4229271, October 21, 1980

Olper M, Fracchia P (1988) Hydrometallurgical process for an overall recovery of the components of exhausted lead-acid batteries. US Patent 4769116, September 6, 1988

Zhang JF, Yi L, Yang LC, Huang Y, Zhou WF, Bian WJ (2016) A new pre-desulphurization process of damped lead battery paste with sodium carbonate based on a “surface update” concept. Hydrometallurgy 160:123–128. https://doi.org/10.1016/j.hydromet.2015.12.016

Ning P, Pan JQ, Li X, Zhou Y, Chen JF, Wang JX (2016) Accelerated desulphurization of waste lead battery paste in a high-gravity rotating packed bed. Chem Eng Process 104:148–153. https://doi.org/10.1016/j.cep.2016.03.007

Liu WF, Deng XB, Zhang DC, Yang TZ, Chen L (2018) A clean process of lead recovery from spent lead paste based on hydrothermal reduction. Trans Nonferrous Met Soc China 28(11):2360–2367. https://doi.org/10.1016/S1003-6326(18)64881-2

Xing P, Wang CY, Wang L, Ma BZ, Chen YQ (2019) Hydrometallurgical recovery of lead from spent lead-acid battery paste via leaching and electrowinning in chloride solution. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2019.105134

Chen WP (1996) New technology of hydrometallurgical recovering lead from waste battery slurry. J Hunan Univ 23(6):111–116 (in Chinese)

Andrews D, Raychaudhuri A, Frias C (2000) Environmentally sound technologies for recycling secondary lead. J Power Sources 88(1):124–129. https://doi.org/10.1016/S0378-7753(99)00520-0

Pan JQ, Yue XH, Sun YZ, Tang L, Wan PY, Yi XB, Wang ZG (2010) Clean wet-method solid-liquid two-phase electroreduction lead recovery method. CN Patent 101831668A, September 15, 2010. (in Chinese)

Lu KY (1985) Electrolyzer for solid state substance containing Pb. CN Patent 85200287U, November 10, 1985. (in Chinese)

Lu KY (1983) Recovery of metallic lead by soid-phase electro-reduction process. Chem Metall 3:67–71 (in Chinese)

Lu KY (2007) Regenerated lead’s new tech and development. Resource Recycling 11:22–25. (in Chinese)

Wang W, Zheng GY (2013) Technical study on lead extraction from lead paste of waste lead-acid batteries by direct electrolysis process. Nonferrous Metals (Extractive Metallurgy) 3(7):13–16

Dai FS, Huang H, Chen BM, Zhang PP, He YP (2019) Recovery of high purity lead from spent lead paste via direct electrolysis and process evaluation. Sep Purif Technol 224:237–246. https://doi.org/10.1016/j.seppur.2019.05.023

Qiu DF (1999) Slurry electrolysis. Metallurgical Industry Press, Beijing

Maruthamuthu S, Dhanibabu T, Veluchamy A, Palanichamy S, Subramanian P, Palaniswamy N (2011) Electrokinetic separation of sulphate and lead from sludge of spent lead acid battery. J Hazard Mater 193(10):188–193. https://doi.org/10.1016/j.jhazmat.2011.07.050

Soundarrajan C, Sivasankar A, Maruthamuthu S, Veluchamy A (2012) Improved lead recovery and sulphate removal from used lead acid battery through electrokinetic technique. J Hazard Mater 217–218(30):452–456. https://doi.org/10.1016/j.jhazmat.2012.03.040

Xu M, Xu Q, Xiong GH, Liu HY, Li M (2017) Research status of industrial sulfate wastewater treatment technology. Ind Water Wastew 48(4):7–10 (in Chinese)

Li KF, Wu P, Shen YL, Xu R, Zhang HQ (2013) Development and prospects of the sulfate wastewater treatment. Technol Water Treat 39(11):17–22. https://doi.org/10.16796/j.cnki.1000-3770.2013.11.004 (in Chinese)

Wang CY, Qiu DF, Jiang PH (2003) Thermodynamic analysis of slurry electrolysis process of refractory Sb-Pb concentrate. Nonferrous Metals 03:55–58 (in Chinese)

Zhang YL, Wang CY, Ma BZ, Jie XW, Xin P (2019) Extracting antimony from high arsenic and gold-containing stibnite ore using slurry electrolysis. Hydrometallurgy 186:284–291. https://doi.org/10.1016/j.hydromet.2019.04.026

Jie XW, Wang HB, Zhang YL, Gao W, Zheng CZ, Ruan SF, Wang ZW, Zhang KK, Yang YQ, Cui CW (2021) Method for preparing crude lead from waste lead plaster through pre-desulfurization-free combined electrolysis. CN Patent 112064062A, February 12, 2021 (in Chinese)

Hu B, Yang F, Chen L (2019) Research progress of technology for recycling lead paste from spent lead-acid batteries. Appl Chem Ind 48(11):2742–2748. https://doi.org/10.16581/j.cnki.issn1671-3206.20190923.006 (in Chinese)

Liu W, Ma BB, Fu Y, Zhang K, Mezaal MA, Li FJ, Zhao XY, Lei LX (2016) Electrochemical property of α-PbO prepared from the spent negative powders of lead acid batteries. J Solid State Electrochem 21(1):1–12. https://doi.org/10.1007/s10008-016-3333-1

Lei LX, Liu W, Ma BB (2016) The sustainable production of lead acid batteries: concept and applications. Chin Batt Ind 20(1):46–53

Zhu XF, Yang JK, Gao LX, Liu JW, Yang DN, Sun XJ, Zhang W, Wang Q, Li L, He DS, Kumar RV (2013) Preparation of lead carbonate from spent lead paste via chemical conversion. Hydrometallurgy 134(135):47–53. https://doi.org/10.1016/j.hydromet.2013.01.018

Sonmez MS, Kumar RV (2009) Leaching of waste battery paste components. Part 1: lead citrate synthesis from PbO and PbO2. Hydrometallurgy 95(1–2):53–56. https://doi.org/10.1016/j.hydromet.2008.04.012

Sonmez MS, Kumar RV (2009) Leaching of waste battery paste components. Part 2: Leaching and desulfurization of PbSO4 by citric acid and sodium citrate solution. Hydrometallurgy 95(1–2):82–86. https://doi.org/10.1016/j.hydromet.2008.04.019

Yang JK, Zhu XF, Kumar RV (2011) Ethylene glycol-mediated synthesis of PbO nanocrystal from PbSO4: a major component of lead paste in spent lead acid battery. Mater Chem Phys 131(1–2):336–342. https://doi.org/10.1016/j.matchemphys.2011.09.052

Yang JK, Kumar RV, Singh DP (2012) Combustion synthesis of PbO from lead carboxylate precursors relevant to developing a new method for recovering components from spent lead-acid batteries. J Chem Technol Biot 87(10):1480–1488. https://doi.org/10.1002/jctb.3772

Hu YC, Yang JK, Zhang W, Xie YL, Wang JX, Yuan YQ, Kumar RV, Liang S, Hu JP, Wu X (2016) A novel leady oxide combined with porous carbon skeleton synthesized from lead citrate precursor recovered from spent lead-acid battery paste. J Power Sources 304:128–135. https://doi.org/10.1016/j.jpowsour.2015.11.030

Yang DN, Liu JW, Wang Q, Yuan XQ, Zhu XF, Li L, Zhang W, Hu YC, Sun XJ, Kumar RV, Yang JK (2017) A novel ultrafine leady oxide prepared from spent lead pastes for application as cathode of lead acid battery. J Power Sources 257:27–36. https://doi.org/10.1016/j.jpowsour.2014.01.091

Wang Q, Liu JW, Yang DN, Yuan XQ, Li L, Zhu XF, Zhang W, Hu YC, Sun XJ, Liang S, Hu JP, Kumar RV, Yang JK (2015) Stannous sulfate as an electrolyte additive for lead acid battery made from a novel ultrafine leady oxide. J Power Sources 285:485–492. https://doi.org/10.1016/j.jpowsour.2015.03.125

Zhu XF, He X, Yang JK, Gao LX, Liu JW, Yang DN, Sun XJ, Zhang W, Wang Q, Kumar RV (2013) Leaching of spent lead acid battery paste components by sodium citrate and acetic acid. J Hazard Mater 250–251(4):387–396. https://doi.org/10.1016/j.jhazmat.2013.02.018

Zhu XF, Li L, Sun XJ, Yang DN, Gao LX, Liu JW, Kumar RV, Yang JK (2012) Preparation of basic lead oxide from spent lead acid battery paste via chemical conversion. Hydrometallurgy 117(118):24–31. https://doi.org/10.1016/j.hydromet.2012.01.006

Pan JQ, Song S, Ma YQ, Sun YZ, Niu YJ (2013) An atomic economic method to yield PbO by recovering spent lead acid batteries. CN Patent 103146923A, June 12, 2013 (in Chinese)

Pan JQ, Song S, Sun YZ (2013) A method of recovery spent lead acid batteries to yield PbO directly. CN Patent 103014347A, April 3, 2013 (in Chinese)

Pan JQ, Zhang X, Sun YZ, Li W, Song S, Wan PY (2016) Preparation of high purity lead oxide from spent lead acid batteries via desulfurization and recrystallization in sodium hydroxide. Ind Eng Chem Res 55(7):2059–2068. https://doi.org/10.1021/acs.iecr.5b04221

Lei LX, Zhang K, Liu W, Ma BB (2015) Lead-acid cell positive electrode with lead sulfate as active material and method for preparing lead-acid cell through positive electrode. CN Patent 105206800A, December 30, 2015 (in Chinese)

Liu Y, Gao PG, Bu XF, Kuang GZ, Liu W, Lei LX (2014) Nanocrosses of lead sulphate as the negative active material of lead acid batteries. J Power Sources 263:1–6. https://doi.org/10.1016/j.jpowsour.2014.03.135

Zhang K, Liu W, Ma BB, Ma MZ, Lei LX (2016) Lead sulfate used as the positive active material of lead acid batteries. J Solid State Electrochemistry 20(8):1–7. https://doi.org/10.1007/s10008-016-3243-2

Bode DP, Loosemore DV, Botts GD (2006) SureCure—a new material to reduces curing time and improve curing reproducibility of lead–acid batteries. J Power Sources 158(2):1133–1139. https://doi.org/10.1016/j.jpowsour.2006.02.057

Ferg EE, Billing DG, Venter AM (2017) Thermal characterization of tetrabasic lead sulfate used in the lead acid battery technology. Solid State Sci 64:13–22. https://doi.org/10.1016/j.solidstatesciences.2016.11.017

Zhan L, Shen SH, Xie B, Yang K (2019) A novel method of preparing PbS from waste lead paste through in-situ vulcanization and reduction. J Clean Prod 208(2019):778–784. https://doi.org/10.1016/j.jclepro.2018.10.190

Acknowledgements

This work was financially supported by the National Key R&D Program of China (2019YFC1908301) and the Major Science and Technology Projects of Qinghai Province (Grant Number 2018-GX-A7).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Zhi Sun.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jie, X., Yao, Z., Wang, C. et al. Progress in Waste Lead Paste Recycling Technology from Spent Lead–Acid Battery in China. J. Sustain. Metall. 8, 978–993 (2022). https://doi.org/10.1007/s40831-022-00576-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00576-y