Abstract

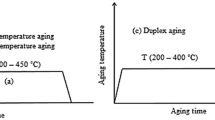

Metastable beta titanium alloys have emerged as a subject of intense research in the last three to four decades. They are epitomized by heat treatability to high strength, high hardenability, and excellent workability. Heat treatment comprises solution treating and aging. In the recent years, there has been much interest in carrying out aging in two steps, rather than in a single step. Duplex aging on different grades of beta alloys resulted in improved microstructure and better combination of mechanical properties. Duplex aging suppresses formation of grain boundary alpha and eliminates precipitate-free zones, leading to improved ductility and fatigue life. There is thus a strong case to adopt duplex aging. A low heating rate to aging temperature may be tantamount to duplex aging. There are a few grades, where duplex aging impairs ductility, becoming counterproductive. The paper reviews the subject of duplex aging of metastable titanium alloys.

Similar content being viewed by others

References

J Mater Eng Perform 14 (2005) 681.

Banerjee D and Williams J C, Acta Mater 61 (2013) 844.

Cotton J D, Briggs R D, Boyer R R, Tamirisakandala S, Russo P, Shchetnikov N, and Fanning J C, J Min Met Mat S 67 (2015) 1281.

Nyakana S, Fanning J, and Boyer R, J Mater Eng Perform 14 (2005) 799.

Boyer R R and Rosenberg H W, Beta titanium alloys in the 80’s, in Proceedings of the Symposium, Metallurgical Society of AIME, (1983).

Eylon D, Boyer R R, and Koss D A, Beta titanium alloys in the 1990's. United States in annual meeting of the Minerals, Metals and Materials Society (TMS), Denver, CO (United States), (1993).

Kolli R P and Devaraj A, Metals (Basel) 8 (2018) 1.

Rajaraman S, Manivasagam G, and Muktinutalapati N, Trans Indian Inst Met 70 (2016).

Yumak N and Aslantaş K, J Mater Res Technol 9 (2020) 15360.

S Sudhagara Rajan, Vishnu, Jithin, Manivasagam, Geetha & Muktinutalapati, Nageswara. Heat Treatment of Metastable Beta Titanium Alloys. In book: Metal Heat Treatments, Publisher: IntechOpen

Jiang H, Du Z & Wang D. Metals (Basel) 11 (2021).

Du ZX, Ma Y, Liu F, Zhao X, Chen Y, Li G, et al., Mater Sci Eng A 754 (2019).

Imiwa N, Arai A, Takatori H & Ito K. ISIJ Int 31 (1991) 856.

Boyer RR, Rack HJ & Venkatesh V. Mater Sci Eng A 243 (1998) 97.

Kazanjian SM & Starke EA. Int J Fatigue 21 (1999) 127.

Furuhara T, Maki T, and Makino T, J Mater Process Technol 117 (2001) 318.

Ivasishin O M, Markovsky P E, Yu Matviychuk V, Semiatin S L, Ward C H, and Fox S, J Alloy Compd 457 (2008) 296.

Schmidt P, El-Chaikh A, and Christ H J, Metall Mater Trans A-physical Metall Mater Sci - Met MATER TRANS A 42 (2011) 2652.

Chaikh A, Schmidt P, and Christ H J, Procedia Eng 2 (2010) 1973.

Santhosh R, Geetha M, Saxena V K, Rao N, and M, Int J Fatigue 73 (2015) 88.

Santhosh R, Geetha M, Saxena V K, and Nageswararao M, J Alloys Compd 605 (2014) 222.

Campanelli L, Silva P, and Bolfarini C, Mater Sci Eng A 658 (2016).

Yumak N, Aslantaş K & Çetkin A. J Test Eval 49 (2020).

Ji X, Ge P, Xiang S, and Tan Y, Materials (Basel), Switzerland, 14 (2021) 209.

Ren L, Han X W, Ma W, Zhou C, and L, Mater Charact 144 (2018) 1.

Salvador C, Opini V, Mello M, and Caram R, Materials Science and Engineering: A 743 (2018) 716.

Mantri SA, Choudhuri D & Alam T. Scr Mater 154 (2018) 139–144.

Krugmann H E, Gregory J K, in Titanium Aluminides and Alloys, (eds) Kim Y W, and Boyer R R, TMS, Warrendale (1991) p 549.

Wagner L, Gregory J K, in Beta Titanium Alloys in the 1990’s, (eds) Eylon D, Boyer R R, Koss D A, TMS, Warrendale (1993) p 199..

Wain N, Hao XJ, Ravi GA & Wu X. Mater Sci Eng A 527 (2010) 7673.

Williams J C., Hickman B S., and Leslie D H, Metall Trans 2 (1971) 477.

FH Froes D Eylon HB Bomberger 1985 Titanium Technology: Present Status and Future Trends University of Virginia Titanium Development Association 0935297006

Lutjering G, and Williams J C, Titanium: Engineering Materials and Processes, second (ed.), Springer-Verlag Berlin, Heidelberg (2007) p 40.

Ivasishin O M, Markovsky P E, Semiatin S L, and Ward C H, Mater Sci Eng A 405 (2005) 296.

Nag S, Banerjee R, Srinivasan R, Hwang JY, Harper M, Fraser HL, Acta Mater 57 (2009) 2136.

Dehghan-Manshadi A and Dippenaar R J, Mater Sci Eng A 528 (2011) 1833.

Wu X, del Prado J, Li Q, Huang A, Hu D, Loretto MH, Acta Mater 54 (2006) 5433.

Pande A, Sainis S, Rajaraman S, Manivasagam G, and Nageswara Rao M, Adv Mater Stru Mech Engg 1025–1026 (2014) 445.

Du Z, Xiao S, Xu L, Tian J, Kong F, Chen Y, Mater Des 55 (2014) 183.

Chesnutt J C and Froes F H, Met Trans, A. United States 8 (1977) 1013.

Duerig T W, and Williams J C, in Overview: Microstructure and Properties of Beta Titanium Alloys, in: Beta Titanium Alloys of the 1980’s, (eds) Boyer R R, and Rosenberg H W, TMS, Warrendale, PA, USA (1984) p 19.

Terlinde G T, Duerig T W, and Williams J C, Metall Trans A 14 (1983) 2101.

Terlinde G & Fischer G. Beta Titanium Alloys. Titanium and Titanium Alloys (John Wiley & Sons) (2003), 37

Kawabe Y, and Muneki S, Strengthening Capability of Beta Titanium Alloys, in: Beta Titanium Alloys of the 1990’s, (eds) Eylon D, Boyer R R, and Koss D A, TMS, Warrendale, PA, USA (1993) p 187.

Sauer S, and Lütjering G, Mater Sci Eng A, 319–321 (2001) 393.

Terlinde, G., Witulski, T. and Fischer, G. Forging of Titanium. In Titanium and Titanium Alloys (eds C. Leyens and M. Peters) (2003).

Zhou Y, Multimed Inf Netw Secur Int Conf 2 (2009) 57.

Bhattacharjee A, Joshi V, and Gogia A, Sci Technol 1 (1999) 529.

Styczynski A, Kiese J and Wagner L, in Fatigue ’96, (eds) Lütjering G, and Nowack H, Pergamon Press (1996) p 911.

Rohit B and Muktinutalapati N, J Phys Conf Ser 843 (2017) 12048.

Acknowledgements

The authors are grateful to the management of Vellore Institute of Technology for permitting publication of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kirthika, A.M.A., Rao, M.N. & Manivasagam, G. Duplex aging of metastable beta titanium alloys: A Review. Trans Indian Inst Met 75, 2985–2996 (2022). https://doi.org/10.1007/s12666-022-02696-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02696-1