Abstract

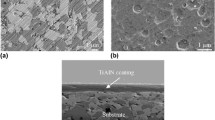

Through the use of tool coatings, a significant increase in tool life is possible. Particularly in the case of coatings obtained by physical vapor deposition, compressive residual stresses show a clearly positive influence on the wear behavior of coated carbide tools. In addition to being influenced by the coating process itself, the residual stress state of the coating can also be influenced by post-treatment processes like heat treatment or wet blasting. Compressive residual stresses can be measured using known X-ray diffraction techniques. However, these methods are very limited on strongly curved surfaces such as cutting edges. Raman spectroscopy has great potential for measurements in such areas. In order to use the Raman method to measure residual stresses on cutting tools, the TiAlN coatings were subjected to wet blasting and heat treatment. The residual stress state was determined by X-ray diffraction using the sin2ψ method and the depth-resolved scattering vector method. Then, measurements of Raman scattering of light were carried out and the peak shift of the transversal/longitudinal optical mode in the Raman spectrum was measured. Finally, the peak shift in the cutting edge area was determined. The investigations show that residual stresses mechanically induced by wet blasting can be reliably detected by Raman spectroscopy. Heat treatment effects are also clearly detectable, but here the correlation between peak shift and residual stresses determined by X-ray diffraction methods differs from the previous results due to the change in the crystal lattice dimensions. The residual stresses in the cutting edge area, converted from Raman peak shifts, show values of a plausible order of magnitude.

Similar content being viewed by others

REFERENCES

S. V. Konovalov, V. E. Kormyshev, V. E. Gromov, Y. F. Ivanov, E. V. Kapralov, and A. P. Semin, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 10, 1119 (2016). https://doi.org/10.1134/S1027451016050098

A. T. Tabrizi and H. Aghajani, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 15, 1217 (2021). https://doi.org/10.1134/S1027451021060197

K. Bobzin, Oberflächentechnik für den Maschinenbau (Wiley, Weinheim, 2013).

B. Breidenstein, Oberflächen und Randzonen hoch belasteter Bauteile, Postdoctoral Thesis (Gottfried Wilhelm Leibniz Universität, Hannover, 2011).

F. Klocke, C. Gorgels, A. Stuckenberg, and E. Bouzakis, Key Eng. Mater. 428, 23 (2010). doi 10.4028/www.scientific.net/KEM.438.23

B. Breidenstein and B. Denkena, CIRP Ann. 62, 67 (2013). https://doi.org/10.1016/j.cirp.2013.03.101

C. Genzel and W. Reimers, Z. Metallkd. 94, 655 (2003). https://doi.org/10.3139/146.030655

J. M. Plöger, Randzonenbeeinflussung durch Hochgeschwindigkeitsdrehen, Doctoral Thesis (Universität Hannover, Hannover, 2002).

G.-P. Xu, G. Xu, Z.-M. Yin, and R.-C. Chiang, Adv. Mater. Res. 76–78, 690 (2009). doi 10.4028/www.scientific.net/AMR.76-78.690

C. P. Constable, D. B. Lewis, J. Yarwood, and W. D. Münz, Surf. Coat. Technol. 184, 291 (2004). https://doi.org/10.1016/j.surfcoat.2003.10.014

M. Ahlgren and H. Blomqvist, Surf. Coat. Technol. 200, 157 (2005). https://doi.org/10.1016/j.surfcoat.2005.02.078

A. C. Vlasveld, S. G. Harris, E. D. Doyle, D. B. Lewis, and W. D. Munz, Surf. Coat. Technol. 149, 217 (2002). https://doi.org/10.1016/S0257-8972(01)01448-7

H. Oettel, R. Wiedemann, and S. Preißler, Surf. Coat. Technol. 74–75, 273 (1995). https://doi.org/10.1016/0257-8972(95)08235-2

C. Bergmann, Surf. Coat. Technol. 36, 243 (1988). https://doi.org/10.1016/0257-8972(88)90154-5

E. Bouzakis, Steigerung der Leistungsfähigkeit PVD-beschichteter Hartmetallwerkzeuge durch Strahlbehandlung, Doctoral Thesis (RWTH Aachen Univ., Aachen, 2008).

G. Skordaris, K. D. Bouzakis, T. Kotsanis, P. Charalampous, E. Bouzakis, B. Breidenstein, B. Bergmann, and B. Denkena, CIRP J. Manuf. Sci. Technol. 18, 145 (2016). https://doi.org/10.1016/j.cirpj.2016.11.003

A. Kimura, Surf. Coat. Technol. 120–121, 438 (1999). https://doi.org/10.1016/S0257-8972(99)00491-0

C. P. Constable, Raman Microscopic Studies of PVD Deposited Hard Ceramic Coatings, Doctoral Thesis (Sheffield Hallam Univ., Sheffield, 2000).

S. Ono, K. Mibe, N. Hirao, and Y. Ohishi, J. Phys. Chem. Solids 76, 120 (2015). https://doi.org/10.1016/j.jpcs.2014.09.001

C. P. Constable, J. Yarwood, and W. D. Münz, Surf. Coat. Technol. 116–119, 155 (1999). https://doi.org/10.1016/S0257-8972(99)00072-9

H. C. Barshilia, M. S. Surya Parakash, A. Jain, and K. S. Rajam, Vacuum 77, 196 (2005). https://doi.org/10.1016/j.vacuum.2004.08.020

J. M. Andersson, J. Vetter, J. Müller, and J. Sjölen, Surf. Coat. Technol. 240, 211 (2014). https://doi.org/10.1016/j.surfcoat.2013.12.018

A. Debelle, G. Abadias, A. Michel, and C. Jaouen, Appl. Phys. Lett. 84, 5034 (2004) https://doi.org/10.1063/1.1763637

D. Tuschel, Spectroscopy 34 (9), 10 (2019).

L. Spieß, G. Teichert, R. Schwarzer, H. Behnken, and C. Genzel, Moderne Röntgenbeugung (Vieweg Teubner, Berlin, 2009).

Funding

The authors would like to thank the German Research Foundation (DFG) for funding research project BR 2967/11-1 BE1720/41-1 “Effects of cutting edge residual stresses on the wear behavior of PVD-coated cutting tools.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Breidenstein, B., Vogel, N., Behrens, H. et al. Determination of Local Residual Stress on Post-Treated TiAlN-Coated Tungsten Carbide Tools. J. Surf. Investig. 16, 663–671 (2022). https://doi.org/10.1134/S1027451022040231

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022040231