Abstract

The rapid response to the COVID-19 pandemic has resulted in increased municipal waste in the form of used face masks (FMs), which pose a global threat to the environment. To mitigate this, the study explores the applicability of shredded FMs as alternative reinforcing material in sands. Laboratory-grade Ottawa sand and naturally collected sea sand are adopted as the base sands for testing. The primary physical properties of the base materials and the FMs are first examined, and the soil particles are imaged via scanning electron microscopy. Thirty consolidated undrained (CU) triaxial compression tests were conducted to evaluate the effects of the weight fraction of FM, FM length, and the initial effective mean stress on the undrained shear strength parameters of the sands. The experimental results proved that FM inclusion can lead to a substantial improvement in the undrained shear strength of the sands; however, such improvement was sensitive to the initial effective mean stress, with higher undrained shear strength gains associated with lower initial effective mean stress. For a given FM content, the critical state ratio and angle of friction at the critical state increased with the FM length. Finally, the results revealed that FM-reinforced sands exhibit dilative and strain-hardening behaviors.

Similar content being viewed by others

Introduction

In recent decades, tension-resisting materials have been widely used by various researchers to reinforce the soils, improving the shear strength, density, and compressibility (Rowe and Li 2002; Li and Rowe 2008; Jones 2013; Shukla 2017; Lian et al. 2020; Develioglu and Pulat 2021; Wang et al. 2021). Among these, using randomly distributed fibers to reinforce the soils has recently attracted great interest from researchers and engineers because their performance exceeds that of conventional reinforcements, such as geotextiles, strips, and geogrids (Ye et al. 2017; Wang et al. 2020; Bao et al. 2020). Numerous studies have demonstrated that mixing sand with fibers can effectively improve the mechanical performance of the latter. The tensile strength of the fibers intersecting the shear failure surface in the sand increases the shear strength of the sand (Consoli et al. 2002; Velloso et al. 2012; Sotomayor and Casagrande 2018; Louzada et al. 2019; Ghadr and Bahadori 2019; Correia et al. 2021). Previous studies also showed that the reinforcement type, length, aspect ratio, content, and particle size affect reinforcement effectiveness (Ibraim et al. 2010; Michalowski and Cermak 2002; Ghadr and Bahadori 2019; Ghadr 2020). Zornberg et al. (2004) reported that soil mixed with waste tire shreds can be used as an alternative backfill material to solve low soil shear strength problems, and Li et al. (2016) showed that using tire wastes can improve soil performance. Their results showed that waste materials with frictional resistance can potentially improve the soil’s mechanical properties.

The COVID-19 pandemic has led to a sudden increase in the use of personal protective equipment (PPE) such as plastic gloves and face masks (FMs) (Fadare and Okoffo 2020; Ludwig-Begall et al. 2020; Sangkham 2020; Zambrano-Monserrate et al. 2020; Ammendolia et al. 2021; Boroujeni et al. 2021). Further, several countries have mandated the wearing of face masks. Although useful in preventing the spread of COVID-19, FMs end up as environmental waste. Reportedly, more than 700 million FMs are used daily in Africa and more than 2.2 billion in Asia (Nzediegwu and Chang 2020; Peng et al. 2020; Sangkham 2020; Saberian et al. 2021; Kilmartin-Lynch et al. 2021). A conservative estimation in June 2020 states that an average of 129 billion FMs were disposed of into the environment. Saberian et al. (2021) estimated that 6.88 billion FMs are globally produced daily, which end up in landfills or being burned in place. Therefore, inappropriate solid waste management of used PPE can cause long-term environmental pollution (Fadare and Okoffo 2020; Prata et al. 2020; Ammendolia et al. 2021). Notice that disposable FMs (PPE) are not biodegradable; thus, it would take hundreds of years to break them down (Dhawan et al. 2019). Consequently, effective methods of reusing, rather than disposing of, face masks are essential to decreasing their potential environmental risks.

Saberian et al. (2021) conducted a series of experimental tests, including unconfined compression tests, modified compaction tests, and resilient modulus tests, on the recycled concrete aggregate (RCA) mixed with different percentages of the shredded face mask. Their results showed that incorporating shredded face masks can increase the strength, stiffness, flexibility, and ductility of RCA. Rehman and Khalid (2021) used a face mask and silica fume in the form of a composite binary admixture to improve the mechanical characteristics of fat clay. The composite binary admixture not only enhanced the strength parameters as compared to silica fume but also improved the deformability and ductility of stabilized soil due to the high tensile strength of face mask fibers. Tang et al. (2020) suggested that sterilized waste materials may be used in geotechnical applications. Zhang et al. (2021) performed a series of consolidated-drained (CD) triaxial tests on granular soil–FM chip mixtures and indicated that the mechanical properties of granular soil can be improved by the addition of FM chips.

To alleviate the environmental problems inherent to the COVID-19 pandemic, a series of consolidated undrained (CU) triaxial compression tests were conducted to explore the applicability of shredded FM as an alternative material for soil reinforcement. The influence of the sand grain size, FM contents and lengths, effective mean stress (p′) on the stress–strain relationship, undrained shear strength parameters, and the stress path of sand–FM mixture were systematically examined. This study aims to broadly determine the potential of using shredded FM in soil stabilization.

Materials and method

Grain size distribution

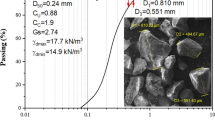

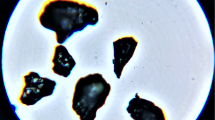

Laboratory-grade Ottawa sand (OS) and naturally collected sea sand (SS) are herein used as the base materials in the test samples. The laboratory-grade OS is commercially available, whereas the SS was obtained from a shallow open trench in the Anping district of Tainan City, Taiwan (N 22° 59′ 25.04″, E 120° 8′ 49.69″) (Fig. 1). The X-ray fluorescence analysis indicated that the OS and SS are predominantly siliceous (SiO2 > 80% in both). Figure 2 illustrates the particle size distributions for the OS and the naturally collected SS. The geometrical and physical parameters of the testing samples and FM are presented in Table 1. Both OS and SS are poorly graded, and their grade curve characteristics (Cu and Cc) are similar. The scanning electron microscopy (SEM) images of the OS and SS are shown in Fig. 3, indicating that the particle size distribution of OS particles is larger than those of SS. Seemingly, the surface of OS is smoother than that of the SS.

Grain shape

According to Wadell (1932), the sphericity ratio (rs) and the roundness (rr) can be used, respectively, to measure the convergence of particle dimensions and the surface features of particles relative to their equivalent mean radius. Herein, the same approach was adopted; the shape and the roundness ratio of SS (rs = 0.67 and rr = 0.38) are similar to those of OS (rs = 0.69 and rr = 0.4). Notably, rounded particles typically exhibit higher rr values.

Shredded face mask

Medical face masks (FMs) are commonly used in many countries to prevent the spread of COVID-19. Herein, their applicability in reinforcing geotechnical materials (i.e., sands) is explored as an alternative to disposal in a landfill. However, due to restrictions during the COVID-19 pandemic as well as safety concerns, reusing FM wastes in the test procedure was prohibited. Therefore, only new medical face masks were used in the experiment.

The top, middle, and bottom layers of the FM are made of nonwoven fabric, melt-blown nonwoven fabric, and polypropylene composite fiber, respectively. The metal strips and FM earloops were first detached from the masks. FMs were then shredded into controlled sizes to achieve a 5-mm equivalent diameter (Dfm) and 1 and 2-cm length (lfm) (Fig. 4). For convenience, FM with longitudinal dimensions of 1 and 2 cm will be denoted as FM1cm and FM2cm, respectively. The shredded FM size satisfied both the commonly used fiber aspect ratio (ARfm = lfm / D50) as well as the specimen aspect ratio (ARS = D / lfm) for fiber-reinforced systems (the diameter of the test sample, D, is 50 mm), as shown in Table 1. The upper-bound and lower-bound standards of the fiber aspect ratios are selected as 100 (Shukla 2017) and 10 (Diambra and Ibraim 2015) to ensure appropriate interactions between the soil and the reinforcement elements. Herein, the ARfm (26.88 and 53.76 for FM1cm-reinforced OS and FM2cm- reinforced OS, respectively, and 44.84 and 89.69 for FM1cm-reinforced SS and FM2cm-reinforced SS, respectively) is within the upper and lower bounds. Conventionally, the specimen aspect ratio, ARS, ranges between 0.17 and 10.2 (Ghadr et al. 2020). In this study, the ARS (2.5 and 5 for lfm = 1 and 2 cm, respectively) is between 0.17 and 10.2. Ang and Loehr (2003) recommended an optimum specimen aspect ratio of 1.25 based on the stress–strain behavior and strength following a series of unconfined compression tests for compacted silty clay loams.

Sample preparation and testing program

To prepare the test sample (FM-reinforced sands), both OS (0% fine fragment, with maximum particle size ranging from 0.106 to 0.850 mm) and SS (1% fine fragment, with maximum particle size ranging from 0.075 to 0.600 mm) in dry condition were mixed with the shredded FM at 0%, 0.3%, and 0.5% content (by dry sand weight). With reference to the ASTM D4767-11 standard (ASTM, 2020), a series of consolidated undrained (CU) triaxial compression tests were then conducted. Figure 5 shows the monotonic triaxial apparatus used in this study (Humboldt Mfg. Co.), with a load cell accuracy of \(\pm\) 0.001 kN (HM-2300.020, Humboldt Mfg. Co.), a linear strain conversion transducer accuracy of \(\pm\) 0.001 mm (HM-2310.20, Humboldt Mfg. Co.), and a pore pressure transducer accuracy of \(\pm\) 0.1 kPa (HM-4170, Humboldt Mfg. Co.). The height of the sample was 100 mm, and the diameter was 50 mm.

Several methods exist for remolding granular soil samples at the laboratory scale. The soil can be placed in the split molds through water sedimentation, dry deposition, spooning, or pouring, and tamping, tapping, or vibration can be utilized for compaction (Consoli et al. 2005; Soriano et al. 2017; Mirzababaei et al. 2016) in dry, moist, or saturated conditions. Herein, the testing samples were molded via the spooning technique. The spooned testing samples were then packed and later saturated. In the mixing phase, the shredded FM was slowly and randomly added to the sand until the predetermined weight of the testing sample was reached. Notably, the shredded FM should be evenly distributed throughout the sand. Afterward, the CO2 gas and de-aired water were slowly allowed to pass through the testing sample for approximately 30 min. The cell and the pore water pressures were then evenly incremented (in this study, each step was 20 kPa) to achieve a B-Skempton value of at least 0.98. Next, isotopic consolidation was performed on the samples with different initial effective mean stresses, \({p}_{c}^{^{\prime}}\)= 100, 200, and 300 kPa. In total, 30 CU triaxial compression tests were carefully performed. Table 2 lists the testing samples and summarizes the testing conditions. The CU triaxial compression tests were performed using a strain rate of 1 mm/min. The experimental results are first represented by the effective stress path and stress–strain relationships in the following sections.

Experiment repeatability

Prior to exploration of the applicability of shredded FMs as alternative reinforcing material in sands, experiment repeatability of the test results was first assessed by repeating tests under the same conditions. The initial effective mean stresses were the same as those used in the experiment. Figure 6a shows the stress–strain behaviors, and Fig. 6b shows the variation in excess pore water pressure (Δu) and axial strain behaviors of SS. The similar results were deemed adequate for demonstrating the experiment repeatability under different initial effective mean stresses (Araujo et al. 2021). Satisfactory results of the repeat tests are realized in terms of the magnitudes and trends. Figure 6c depicts the Mohr–Coulomb envelopes, which are well comparative. Last, almost identical friction angles of 37.24° and 37.81° can be characterized by the initial set and repeated set of tests, respectively.

Results and discussion

Definition of soil states

A steady state is defined as a soil deformation state with no increasing or decreasing effective stress (Yoshimine et al. 1999; Yoshimine and Ishihara 1998; Vaid and Sivathayalan 2000). Figure 7 shows the generally undrained shear behavior of sand under large deformation. A steady state follows medium to large sand deformation during undrained shearing. When the sand density ranges from medium to high, a point of minimum effective mean stress appears (named phase transformation (PT)), where the dilatancy behavior changes from initial compressive to dilative. The quasi steady state (QSS) occurs when both the shear stress and the effective mean stress reached a minimum (Alarcon-Guzman et al. 1988). The ultimate steady state is typically defined as the sand reaching the final stage of the steady state. If the PT or QSS coincides with the USS, this state is termed the critical steady state (CSS). Ishihara (1996) defined three types of stress–strain behavior, which are shown in Fig. 7. The behaviors are nonflow (medium to dense), flow with limited deformation (medium to loose), and flow (loose). Accordingly, the test samples in this study are in the category of medium to dense sands.

Transition states throughout the isotopically consolidated triaxial specimens during the undrained shearing: steady-state points (Yoshimine and Ishihara 1998 with modifications)

Stress path and stress–strain behaviors

The stress paths and stress–strain behaviors of sands and FM-reinforced sands, based on the 30 CU triaxial compression tests, are presented in Figs. 8, 9, 10, and 11. Evidently, the inclusion of FM improved the overall sand strength. Additionally, the inclusion of FM results in a change from brittle to ductile behavior. Furthermore, the strain hardening (SH) and nonflow (NF) deformation are illustrated in Figs. 8, 9, 10, and 11. Notably, FM-reinforced OS samples were stronger than the FM-reinforced SS samples, likely due to the higher median grain size (D50) and robust interlocking between particles of OS. This finding is supported by the similar trends observed under the other effective mean stresses. It is shown that the undrained shear behavior of the sands is affected by the longitudinal dimension of the shredded FM (FM2cm and FM1cm). To further present and discuss the details of Figs. 8, 9, 10, and 11, the undrained shear strength at 20% strain (q20) is introduced in the following section.

Undrained shear strength at 20% strain (q20)

Figure 12a, b show the undrained shear strength of unreinforced and FM-reinforced OS and SS at 20% strain (q20) under initial various effective mean stresses (p′). The q20 of both types of sand increased with the inclusion of the FM. With an increment in the effective mean stress, q20 of both unreinforced and FM-reinforced samples increased. Specifically, increasing the FM length increases q20. Similar behavior was reported by Falorca and Pinto (2011), Shukla (2017), and Zhao et al. (2020) for fiber-reinforced sands. According to Maher and Gray (1990) and Falorca and Pinto (2011), however, shear strength increased with the increasing length of the fiber reinforcement; the improvement in shear strength saturates when the length of the fiber reinforcement exceeded the upper bound. Generally, the FM-reinforced OS exhibited a higher q20 than the FM-reinforced SS. Interestingly, a more significant gain in q20 is observed in the FM-reinforced OS (sharper increment) than the FM-reinforced SS (milder increment). Smiliar observation was made by Maher and Gray (1990), Michalowski and Cermak (2002), Ghadr and Bahadori (2019), and Ghadr (2020), who stated that the strengthening effect of the fiber (for a given FM content in this study) can decrease in sands with larger D50. Lastly, it is evident that 0.3% FM content, regardless of the FM lengths and effective mean stresses, is generally associated with the higher q20, specifically for OS.

The percentage increase in undrained shear strength at 20% strain (Δq20%) in FM-reinforced sands is utilized in this investigation. Hence, Δq20% is defined as

where \(q_{\tt 20rf}\) and \(q{_\mathtt 20unrf}\) are the undrained shear strengths at 20% strain in the reinforced and unreinforced samples, respectively.

Figure 13a, b show the results of Δq20% of FM-reinforced sands under different effective mean stresses (p′). The observed strengthening effect of the FM on Δq20% suggested that the mean effective principal stress, as well as the FM length and content, are important. Generally, the Δq20% of all samples decreased with an increase in the effective mean principal stress. The same was observed by Freilich et al. (2010), Mirzababaei et al. (2018), and Correia et al. (2021). Likely, at higher p′, the extension and pulling out of the fiber reinforcement would become more difficult (Li 2005; Attom and Al-Tamimi 2010; Hamidi and Hooresfand 2013; Najjar et al. 2013; Correia et al. 2021). Second, it was revealed that the strengthening effect of FM2cm is more significant than that of FM1cm. Consequently, the optimum FM length is 2 cm for both sands.

Excess pore water pressure

Figure 14a–f present the variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands for different FM contents and lengths. Notably, the Δu of all samples initially increased to a peak value and then dropped rapidly. This reduction in excess pore water (Δu) indicates that the samples tended toward dilative behavior, which evolved with varying effective mean stresses, and FM content and length. Therefore, the dilative behavior of the testing samples increased with an increase in FM length. FM-reinforced OS showed a uniformly stronger dilative tendency than the unreinforced samples. Specifically, a higher dilative tendency was observed in OS sample with 0.3% FM. However, a higher dilative tendency for SS was observed with 0.5% FM. This turnover is likely due to the larger D50 of the OS samples, given that similar results have been reported by Michalowski and Cermak (2002), Ghadr and Assadi-langroudi (2019), and Ghadr and Bahadori (2019).

a Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: OS-p′ = 100 kPa. b Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: OS-p′ = 200 kPa. c Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: OS-p′ = 300 kPa. d Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: SS-p′ = 100 kPa. e Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: SS-p′ = 200 kPa. f Variation in excess pore water pressure (Δu) and axial strain behavior of unreinforced and FM-reinforced sands with different FM contents and lengths: SS-p′ = 300 kPa

Critical stress ratio and critical state angle of friction

The mechanical behavior of soil can be interpreted within the framework of critical state. In this study, a critical stress ratio (MCS) was adopted at the critical state, as described by Dafalias (2016) and Yang and Luo (2018). First, the critical state data points, following Yang and Luo (2018), derived from Figs. 8, 9, 10, and 11, were plotted in q-p′ plane, as shown in Fig. 15. It is shown that all data points can be nicely fitted by straight lines through the origin. MCS can then be obtained by calculating the slope of the lines. The values of the obtained MCS are provided in Table 3. Once the MCS was determined, the critical state angle of friction, ϕCS, can be obtained by the following equation:

Accordingly, the ϕCS of unreinforced and FM-reinforced sands are shown in Fig. 16. As shown in Fig. 15, FM-reinforced SS produced the highest MCS. It is also shown that the MCS tends to increase with increasing FM length. Similar results have been reported by Safdar et al. (2021). In addition to the critical stress ratio, Fig. 16 presents the relationship between critical state friction angles and the FM aspect ratio of both OS and SS. It is observed that ϕCS has a direct relationship with the FM aspect ratio. For both types of sand, ϕCS increased with increasing FM length. However, it is found that SS samples produced larger ϕCS, implying that ϕCS increased with decreasing median grain size (D50) of the test sample. A similar observation was made by Kokusho et al. (2004) and Ghadr and Javan (2020) in undrained triaxial tests on sea, river, and typical quartz sands; the measured ϕCS values for river and sea sands were markedly higher. In addition to the critical state angle of frictions, the frictional angles based on the Mohr–Coulomb envelop, ϕMC, were also estimated and provided for further engineering applications, as shown in Table 4.

Conclusion

The use of shredded FM as reinforcing material to sands was evaluated through a series of CU triaxial tests. The major experimental factors were the weight fraction of FM, FM length, and the initial effective mean stress. From the extensive experimental results, the following conclusions could be made:

-

1.

The undrained shear strength of OS and SS can be significantly improved using shredded FM as reinforcing material. Considering the difference in D50 of the base sands, the optimum contents of FM are found to be 0.3% and 0.5% for OS and SS, respectively. In addition to the improved shear strength, FM inclusion corresponds to an increase in the ductility of the samples.

-

2.

The strengthening effect of the shredded FM increased with increasing the FM length and decreasing D50 of the samples. This finding is consistent with observations in cases where fibers were used as reinforcing material (e.g., Li and Zornberg 2019; Ghadr 2020; Zhao et al. 2020; Correia et al. 2021). Furthermore, the strengthening effect of the FM was found to be sensitive to the initial effective mean stress, with a higher gain in the undrained shear strength under a lower initial effective mean stress.

-

3.

The effects of FM content and length on the excess pore water pressure (Δu) were examined. Regardless of the initial effective mean stress, samples reinforced with longer FM developed higher dilative behavior. The results of the excess pore water pressure also suggested that the FM-reinforced samples acted as a denser material—a slight initial increase followed by a gradual decrease in excess pore water pressure.

-

4.

It was found that the critical state line slope MCS and critical state angle of friction ϕCS of the samples increased with the inclusion of shredded FM. A direct relationship between ϕCS and FM aspect ratio can be observed. Specifically, samples reinforced by longer FM resulted in larger ϕCS.

References

Alarcon-Guzman A, Leonards GA, Chameau JL (1988) Undrained monotonic and cyclic strength of sands. J Geotech Engineering Asce 114(10):1089–1109

Ammendolia J, Saturno J, Brooks AL, Jacobs S, Jambeck JR (2021) An emerging source of plastic pollution: environmental presence of plastic personal protective equipment (PPE) debris related to COVID-19 in a metropolitan city. Environ Pollut 269:116160

Ang EC, Loehr JE (2003) Specimen size effects for fiber-reinforced silty clay in unconfined compression. Geotech Test J 26(2):191–200

Araujo GLS, Moreno JAS, Zornberg JG (2021) Shear behavior of mixtures involving tropical soils and tire shreds. Constr Build Mater 276:122061

ASTM D4767–11 (2020) Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International, West Conshohocken, PA

Attom MF, Al-Tamimi AK (2010) Effects of polypropylene fibers on the shear strength of sandy soil. Int J Geosci 1(01):44

Bao X, Jin Z, Cui H, Ye G, Tang W (2020) Static liquefaction behavior of short discrete carbon fiber reinforced silty sand. Geosynth Int 27(6):606–619

Boroujeni M, Saberian M, Li J (2021) Environmental impacts of COVID-19 on Victoria, Australia, witnessed two waves of Coronavirus. Environ Sci Pollut Res 28(11):14182–14191

Consoli NC, Casagrande MD, Coop MR (2005) Effect of fiber reinforcement on the isotropic compression behavior of a sand. J Geotech Geoenviron 131(11):1434–1436

Consoli NC, Montardo JP, Prietto PDM, Pasa GS (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron 128(6):462–472

Correia NS, Rocha SA, Lodi PC, McCartney JS (2021) Shear strength behavior of clayey soil reinforced with polypropylene fibers under drained and undrained conditions. Geotext Geomembranes 49(5):1419–1426

Dafalias YF (2016) Must critical state theory be revisited to include fabric effects? Acta Geotech Slov 11:479–491

Develioglu I, Pulat HF (2021) Shear strength of alluvial soils reinforced with PP fibers. Bull Eng Geol Environ 80(12):9237–9248

Dhawan R, Bisht BMS, Kumar R, Kumari S, Dhawan SK (2019) Recycling of plastic waste into tiles with reduced flammability and improved tensile strength. Process Saf Prog 124:299–307

Diambra A, Ibraim E (2015) Fibre-reinforced sand: interaction at the fibre and grain scale. Geotech Lett 65(4):296–308

Fadare OO, Okoffo ED (2020) Covid-19 face masks: a potential source of microplastic fibers zhaoin the environment. Sci Total Environ 737:140279

Falorca IMCFG, Pinto MIM (2011) Effect of short, randomly distributed polypropylene microfibres on shear strength behaviour of soils. Int J Geotech Eng 18(1):2–11

Freilich BJ, Li C, Zornberg JG (2010) Effective shear strength of fiber-reinforced clays. Brazil, 1997–2000. In 9th Inter Conf On Geosynt

Ghadr S (2020) Effect of grain size on undrained anisotropic behaviour of sand–fibre composite. Transp Geotech 22:100323

Ghadr S, Assadi-Langroudi A (2019) Effect of grain size and shape on undrained behaviour of sands. Int J Geosynth Ground Eng 5(3):1–9

Ghadr S, Bahadori H (2019) Anisotropic behavior of fiber-reinforced sands. J Mater Civ Eng 31(11):04019270

Ghadr S, Javan A (2020) Effect of shredded rubber on undrained shear strength of fine-grained sands. Transp Infrastruct Geotechnol 7(4):562–589

Ghadr S, Samadzadeh A, Bahadori H, Assadi-Langroudi A (2020) Liquefaction resistance of fibre-reinforced silty sands under cyclic loading. Geotext Geomembranes 48(6):812–827

Hamidi A, Hooresfand M (2013) Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotext Geomembranes 36:1–9

Ibraim E, Diambra A, Wood DM, Russell AR (2010) Static liquefaction of fibre reinforced sand under monotonic loading. Geotext Geomembranes 28(4):374–385

Ishihara K (1996) Soil behaviour in earthquake geotechnics. Clarendon Press, Oxford

Jones CJFP (2013) Earth reinforcement and soil structures, Butterworths Book Co London

Kilmartin-Lynch S, Saberian M, Li J, Roychand R, Zhang G (2021) Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J Clean Prod 296:126460

Kokusho T, Hara T, Hiraoka R (2004) Undrained shear strength of granular soils with different particle gradations. J Geotech Geoenviron 130(6):621–629

Li AL, Rowe RK (2008) Effects of viscous behavior of geosynthetic reinforcement and foundation soils on the performance of reinforced embankments. Geotext Geomembranes 26(4):317–334

Li B, Huang M, Zeng X (2016) Dynamic behavior and liquefaction analysis of recycled-rubber sand mixtures. J Mater Civ Eng 28(11):04016122

Li C (2005) Mechanical response of fiber-reinforced soil. PhD thesis. Faculty of the Graduate School of the University of Texas at Austin

Li C, Zornberg JG (2019) Shear strength behavior of soils reinforced with weak fibers. J Geotech Geoenviron 145(9):06019006

Lian B, Peng J, Zhan H, Cui X (2020) Effect of randomly distributed fibre on triaxial shear behavior of loess. Bull Eng Geol Environ 79(3):1555–1563

Louzada NDSL, Malko JAC, Casagrande MDT (2019) Behavior of clayey soil reinforced with polyethylene terephthalate. J Mater Civ 31(10):04019218

Ludwig-Begall LF, Wielick C, Dams L, Nauwynck H, Demeuldre PF, Napp A, Thiry E (2020) The use of germicidal ultraviolet light, vaporized hydrogen peroxide and dry heat to decontaminate face masks and filtering respirators contaminated with a SARS-CoV-2 surrogate virus. J Hosp Infect 106(3):577–584

Maher MH, Gray DH (1990) Static response of sands reinforced with randomly distributed fibers. J Geotech Eng Asce 116(11):1661–1677

Michalowski RL, Cermak J (2002) Strength anisotropy of fiber-reinforced sand. Comput Geosci 29(4):279–299

Mirzababaei M, Arulrajah A, Haque A, Nimbalkar S, Mohajerani A (2018) Effect of fiber reinforcement on shear strength and void ratio of soft clay. Geosynth Int 25(4):471–480

Mirzababaei M, Mohamed M, Arulrajah A, Horpibulsuk S, Anggraini V (2016) Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth Int 25(1):50–66

Najjar SS, Sadek S, Alcovero A (2013) Quantification of model uncertainty in shear strength predictions for fiber-reinforced sand. J Geotech Geoenviron 139(1):116–133

Nzediegwu C, Chang SX (2020) Improper solid waste management increases potential for COVID-19 spread in developing countries. Resour Conserv Recycl 161:104947

Peng J, Wu X, Wang R, Li C, Zhang Q, Wei D (2020) Medical waste management practice during the 2019–2020 novel coronavirus pandemic. Am J Infect Control 48(8):918–921

Prata JC, da Costa JP, Lopes I, Duarte AC, Rocha-Santos T (2020) Environmental exposure to microplastics: an overview on possible human health effects. Sci Total Environ 702:134455

Rehman Zu, Khalid U (2021) Reuse of COVID-19 face mask for the amelioration of mechanical properties of fat clay: a novel solution to an emerging waste problem. Sci Total Environ 794:148746

Rowe RK, Li AL (2002) Behaviour of reinforced embankments on soft rate-sensitive soils. Geotech 52(1):29–40

Saberian M, Li J, Kilmartin-Lynch S, Boroujeni M (2021) Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci Total Environ 769:145527

Safdar M, Newson T, Shah F (2021) Consolidated drained (CID) behavior of fibre reinforced cemented Toyoura sand in triaxial loading conditions. Int J Geotech Eng 12(1):1–21

Sangkham S (2020) Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Studies in Chemical and Environmental Engineering 2:100052

Shukla SK (2017) Fundamentals of fibre-reinforced soil engineering. Springer Singapore

Soriano I, Ibraim E, Andò E, Diambra A, Laurencin T, Moro P, Viggiani G (2017) 3D fibre architecture of fibre-reinforced sand. Granul Matter 19:75

Sotomayor JMG, Casagrande MDT (2018) The performance of a sand reinforced with coconut fibers through plate load tests on a true scale physical model. Soils Rocks 41(3):361–368

Tang CS, Paleologos EK, Vitone C, Du YJ, Li JS, Jiang NJ, Singh DN (2020) Environmental geotechnics: challenges and opportunities in the post-COVID-19 world. Environ Geotech 8(3):172–192

Vaid YP, Sivathayalan S (2000) Fundamental factors affecting liquefaction susceptibility of sands. Can Geotech J 37(3):592–606

Velloso RQ, Casagrande MDT, Junior EV, Consoli NC (2012) Simulation of the mechanical behavior of fiber reinforced sand using the discrete element method. Soils Rocks 35(2):201–206

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40(5):443–451

Wang HS, Tang CS, Gu K, Shi B, Inyang HI (2020) Mechanical behavior of fiber-reinforced, chemically stabilized dredged sludge. Bull Eng Geol Environ 79(2):629–643

Wang X, Liu K, Lian B (2021) Experimental study on ring shear properties of fiber-reinforced loess. Bull Eng Geol Environ 80(6):5021–5029

Yang J, Luo XD (2018) The critical state friction angle of granular materials: does it depend on grading? Acta Geotech 13(3):535–547

Ye B, Cheng ZR, Liu C, Zhang YD, Lu P (2017) Liquefaction resistance of sand reinforced with randomly distributed polypropylene fibres. Geosynth Int 24(6):625–636

Yoshimine M, Ishihara K (1998) Flow potential of sand during liquefaction. Soils Found 38(3):189–198

Yoshimine M, Robertson PK, Wride CE (1999) Undrained shear strength of clean sands to trigger flow liquefaction. Can Geotech J 36(5):891–906

Zambrano-Monserrate MA, Ruano MA, Sanchez-Alcalde L (2020) Indirect effects of COVID-19 on the environment. Sci Total Environ 728:138813

Zhang JQ, Wang X, Yin ZY, Yang N (2021) Static and dynamic behaviors of granular soil reinforced by disposable face-mask chips. J Clean Prod 129838

Zhao Y, Xiao Z, Fan C, Shen W, Wang Q, Liu P (2020) Comparative mechanical behaviors of four fiber-reinforced sand cemented by microbially induced carbonate precipitation. Bull Eng Geol Environ 79(6):3075–3086

Zornberg JG, Cabral AR, Viratjandr C (2004) Behaviour of tire shred sand mixtures. Can Geotech J 41(2):227–241

Funding

The study was supported by the Ministry of Science and Technology, Taiwan, and the research was, in part, supported by the Higher Education Sprout Project, Ministry of Education, Taiwan, ROC, Headquarters of University Advancement to the National Cheng Kung University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghadr, S., Chen, CS., Liu, Ch. et al. Mechanical behavior of sands reinforced with shredded face masks. Bull Eng Geol Environ 81, 317 (2022). https://doi.org/10.1007/s10064-022-02810-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-02810-z