Abstract

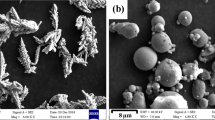

In this study, we investigated the microstructure and wear behaviour of A356/fly ash composites fabricated using the powder metallurgy method. Fly ash was added to A356 Al alloy in four different ratios by weight and mechanically milled for 1 h. The milled composite powders were pre-formed under 800 MPa pressure and sintered for 1 h under vacuum at 590 °C. The microstructures of the produced samples were examined by optical microscope, SEM, EDS and XRD. The hardness measurements and wear tests were performed to determine the effect of fly ash content on the properties of the samples. As a result of the study, it was found that the hardness value increased with the increasing fly ash amount up to 2 wt% and decreased after 2 wt%. The wear test results were consistent with the hardness results. The maximum weight loss occurred in the composite containing 4 wt% fly ash.

Similar content being viewed by others

References

Sekhar R, and Singh T P, J Mater Res Technol, 4 (2015) 197. https://doi.org/https://doi.org/10.1016/j.jmrt.2014.10.013

Kumar G V, Rao C S P, and Selvaraj N, J Miner Mater Charact Eng, 10 (2011) 59.

Vijayakumar S, and Karunamoorthy L, Mater Sci Technol, 29 (2013) 487. https://doi.org/https://doi.org/10.1179/1743284712Y.0000000167

Idusuyi N & Olayinka JI, Dry sliding wear characteristics of aluminium metal matrix composites:a brief overview, J Mater Res Technol, 8 (2019) 3338. https://doi.org/https://doi.org/10.1016/j.jmrt.2019.04.017

Samal P, Vundavilli P R, Meher A, and Mahapatra M M, J Manuf Process, 59 (2020)131. https://doi.org/https://doi.org/10.1016/j.jmapro.2020.09.010

Meignanamoorthy M, Ravichandran M, Alagarsamy S V, Chanakyan C, Kumar S D, and Sakthivelu S, Mater Today Proc, 27 (2020) 1118. https://doi.org/https://doi.org/10.1016/j.matpr.2020.01.479

Vani V V, and Chak S K, Manuf Review, 5 (2018) 7. https://doi.org/https://doi.org/10.1051/mfreview/2018001

Al-Aqeeli N, Abdullahi K, Suryanarayana C, Laoui T, and Nouari S, Mater Manuf Process, 28 (2013) 984. https://doi.org/https://doi.org/10.1080/10426914.2012.746703

Akçamlı N, and Şenyurt B, Ceram Int, 47 (2021) 6813. https://doi.org/https://doi.org/10.1016/j.ceramint.2020.11.024

Dhanashekar M, Loganathan P, Ayyanar S, Mohan S R, and Sathish T, Mater Today Proc, 21 (2020) 1008. https://doi.org/https://doi.org/10.1016/j.matpr.2019.10.052

Zamani N A B N, Iqbal A A, and Nuruzzaman D M, Mater Today Proc, 29 (2020) 190. https://doi.org/https://doi.org/10.1016/j.matpr.2020.05.541

Baghchesara M A, and Abdizadeh H, J Mech Sci Technol, 26 (2012) 367. https://doi.org/https://doi.org/10.1007/s12206-011-1101-9

Ozyurek D, and Ciftci I, Sci Eng Compos Mater, 18 (2011) 5. https://doi.org/https://doi.org/10.1515/secm.2011.003

Fan L J, and Juang S H, Mater Design , 89 (2016) 941. https://doi.org/https://doi.org/10.1016/j.matdes.2015.10.070

Kumar V, Gupta R D, and Batra N K, Procedia Mater Sci, 6 (2014) 1365. https://doi.org/https://doi.org/10.1016/j.mspro.2014.07.116

Rajan T P D, Pillai R M, Pai B C, Satyanarayana K G, and Rohatgi P K, Compos Sci Technol, 67 (2007) 3369. https://doi.org/https://doi.org/10.1016/j.compscitech.2007.03.028

Jailani S H, Rajadurai A, Mohan B, and Sornakumar T, Indian J Eng. Mater Sci, 22 (2015) 414.

Sharma V K, Singh R C, and Chaudhary R, Eng Sci Technol Inter J, 20 (2017) 1318. https://doi.org/https://doi.org/10.1016/j.jestch.2017.08.004

Nagaraj N, Mahendra K V, and Nagaral M, Mater Today Proc, 5 (2018) 3109. https://doi.org/https://doi.org/10.1016/j.matpr.2018.01.116

Prasad K N P, and Ramachandra M, Mater Today Proc, 5 (2018) 2844. https://doi.org/https://doi.org/10.1016/j.matpr.2018.01.075

Itskos G, Rohatgi P K, Moutsatsou A, DeFouw J D, Koukouzas N, Vasilatos, C, and Schultz B F, J Mater Sci, 47 (2012) 4042. https://doi.org/10.1007/s10853-012-6258-9

Ravindran P, Manisekar K, Narayanasamy R, and Narayanasamy P, Ceram Int, 39 (2013) 1169. https://doi.org/https://doi.org/10.1016/j.ceramint.2012.07.041

Kanthavel K, Sumesh K R, and Saravanakumar P, Alex Eng J, 55 (2016) 13. https://doi.org/https://doi.org/10.1016/j.aej.2016.01.024

Siddhi Jailani H, Rajadurai A, Mohan B, Senthil Kumar A, and Sornakumar T, Powder Metall, 54 (2011) 474. https://doi.org/https://doi.org/10.1179/003258909X12502679013936

Ravichandran M, Balasubramanian M, Chairman C A, Marichamy S, Dhinakaran V, and Stalin B, IOP Conf Ser Mater Sci Eng, 988 (2020) 012095. https://doi.org/10.1088/1757-899X/988/1/012095

Rajan S T K, Balaji A N, Narayanasamy P, and Vettivel S C, Bull Pol Ac Tech, 66 (2018) 935. https://doi.org/10.24425/bpas.2018.125941

Kumar M S, Vasumathi M, Begum S R, Luminita S M, Vlase S, and Pruncu C I, J Mater Res Technol, 15 (2021) 1201. https://doi.org/https://doi.org/10.1016/j.jmrt.2021.08.149

Manimaran R, Jayakumar, I, Mohammad Giyahudeen R, and Narayanan L, Energy Sour Part A, 40 (2018) 887. https://doi.org/https://doi.org/10.1080/15567036.2018.1463319

Wang Q, Min F, and Zhu J, J Wuhan Univ Technol Mater Sci Ed. J, 29 (2014) 1019. https://doi.org/10.1007/s11595-014-1036-y

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yıldırım, M., Solakoğlu, S. Microstructure, Hardness, Wear Behaviours of A356/Fly Ash Composites Fabricated by Powder Metallurgy Method. Trans Indian Inst Met 75, 2949–2957 (2022). https://doi.org/10.1007/s12666-022-02677-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02677-4