Abstract

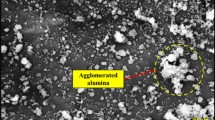

The growths in e-mobility are the factor that impetus the research in lightweight material with improved mechanical properties, especially strength. The research concentrates on developing a novel metal matrix nano-composite of high-quality AA8011 aluminium alloy reinforced with varying weight percentages of nano-particles of B4C (0, 0.3, 0.6, 0.9, 1.2 and 1.5 wt%). The high-energy electromagnetic frequency stir casting technique was used to fabricate nano-composite, which enhanced the wetting of matrix and reinforcement. The rupture strength of nano-composite primarily hinges on the structure and formation of nano-composite. The morphology and distribution of nano-particles in metal matrix nano-composites (MMNC) were characterized by using Field Emission Scanning Electron Microscope. The yield strength, yield point, tensile strength, elongation, and reduction of area of MMNC under uniaxial tensile stresses were determined by Universal Testing Machine. The machine learning algorithms automatically characterized the fractured material texture in conjunction with the described techniques. The unique textural information extracted from each fractured sample distinguished the surfaces as agglomeration, brittle and ductile texture. The fractography analysis of MMNCs revealed the transition of composite from cup and cone to cleavage fracture, which ensured the property change of matrix by the addition of nano-reinforced particles.

Similar content being viewed by others

References

Tanwir Alam M D, and Ansari A H, Int. J Adv Technol Eng Sci 5 (2017).

Yahaya S N M, and Majid A A A, Acad J Sci Res 5 (2017) 708.

Bauri R, Pancholi V, Samajdar I, and Surappa M K, Sci Technol Adv Mat 6 (2005) 933.

Ramanan G, Suresh S, Rajesh Prabha N, and Edwin Raja Dhas J, Mater Res Express 6 (2019) 066544.

Manivannana I, Ranganathan S, Gopalakannan S, Suresh S, Nagakarthigan K, and Jubendradass R, J Surf 8 (2017) 127.

Kailainathan S, Kalyana Sundaram S, and Nijanthan K, Int J Innov Res Sci Eng Technol 3 (2014).

Fayomi J, Popoola A P I, Oladijo O P, Popoola O M, and Fayomi O S I, J Alloys Compd (2019)

Aghaie-Khafri M, J Mater Sci 39 (2004) 6467.

Yakubu O H, Usman I, Aliyu A, and Emmanuel O O, Niger J Technol 35 (2016) 122.

Fayomi J, Popoola A P I, Oladijo O P, Popoola O M, and Fayomi O S I, Results Phys 14 (2019).

Karthikkumar C, Baranirajan R, Premnauth I, and Manimaran P, Int J Eng Res Gen Sci 4 (2016).

Pujar V, Srinivas H K, and Nagaral M, Int J Adv Mech Eng 8 (2018) 117.

Vijaya Ramnath B, Elanchezhian C, Jaivignesh M, Rajesh S, Parswajinan C, and Siddique Ahmed Ghias A, Mater Des 58 (2014) 332.

Suresh S M, Mishra D, Srinivasan A, Arunachalam R M, and Sasikumar R, J Eng Appl Sci 6 (2011).

Vinyas M, Athul S J, Harursampath D, Loja Mar and Nguyen Thoi T, Mater Res Express 6 (2019).

Kant S, and Verma A S, Int J Mech Solids 12 (2017) 61.

Amit P, Abhishek V, Bhaskar Chandra K, and Sansar S S, Int J Ap Mat Com-Pol 4 (2015).

Selvan B M M, Anandakrishnan V, Duraiselvam M, and Sundarameenakshi S, Mater Test 61 (2019) 779.

Harichandran R, and Selvakumar N, Arch Civ Mech Eng (2015)

Shen Q, Wu C, Luo G, Fang P, Li C, Wang Y, and Zhang L J. Alloy Compd 588 (2014) 265.

Ashok N, and Shanmughasundaram P, Mater Tech 51 (2017) 667.

Alizadeh A, and Taheri-Nassaj E, Mater Charact 67 (2012) 119.

Satorres Martínez S, Ortega Vázquez C, Gamez Garcia J, and Gomez Ortega J, Measurement 111 (2017) 374.

Jardine M A, Miller J A, Becker M, Computers and Geosciences 111 (2018) 105–117. https://doi.org/10.1016/j.cageo.2017.11.005

Gonzalez-Ariasa C, Viafaraa C C, Coronadob J J, and Martinezc F, Wear 426–427 (2019) 1702.

DeCost B L, and Holm E A, Comput Mater Sci 126 (2017) 438.

Dutta S, Das A, Barat K, and Roy H, Measure 45 (2012) 1140.

Jun B, and Kim D, Pattern Recognit 45 (2012) 3304.

Saad S, and Sagheer A, ICIAP (2015) 472

Varol T, Canakci A, and Ozsahin S, Compos Part B Eng, 54 (2013) 224.

Lloyd D J, Int Mater Rev 39 (1994) 1.

Ibrahim I A, Mohamed F A, and Lavernia E J, J Mater Sci 26 (1991) 1137.

Kelley P M, Int Met Rev 18 (1973) 31.

Cortes C, and Vapnik V, Mach Learn 20 (1995) 273.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arun, J., Raj, T.G.A., Roy, K.E.R. et al. A Novel Automatic Image Intensity Analysis Using Machine Learning Algorithms and Characterization of Tensile Fracture Surface of AA8011-B4C Nano-composite. Trans Indian Inst Met 75, 2891–2903 (2022). https://doi.org/10.1007/s12666-022-02654-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02654-x