Abstract

The chemical regeneration process has been extensively applied to reactivate biochar, supporting its reusability and leading to significant operating cost reduction. However, no recent review discusses the effectiveness of biochar chemical regeneration. Thus, this article comprehensively reviews the chemical regeneration of biochar contaminated with organic and inorganic pollutants. Performance of the chemical regeneration depends on adsorption mechanism, functional groups, adsorbent pore structure, and changes in active adsorbent sites. Secondary contamination is one of the challenges facing the sustainable adaptation of the chemical regeneration process in the industry. The paper discusses these challenges and draws a roadmap for future research to support sustainable wastewater treatment by biochar.

Similar content being viewed by others

Introduction

Persistent water pollution is a severe global problem that threatens human beings, other creatures, and the environment in the 21st century1,2. The problem aggravates with the limited access to safe potable water, the rapid growth of the global population, industrial development, and climate change. Clean water and sanitation are among the United Nations Sustainable Development Goals (SDG) to be realized by 20303. Therefore, significant research efforts have been exerted to propose innovative and proactive treatment methods to turn wastewater into clean water for drinking and irrigation purposes. Table 1 summarizes the limitations of different methods used for wastewater treatment. Traditional methods such as chlorination, electrochemical treatment, and membrane filtration have been broadly applied in wastewater treatment4. Nevertheless, these methods were proved to be inefficient and expensive5,6. Advanced techniques like adsorption, ultrafiltration, chemical precipitation, and coagulation were developed to address the limitations of the traditional methods7. However, most of these methods (like coagulation and flocculation) generate sludge that should be disposed of appropriately, which, in turn, negatively affects the environment and increases the cost of the treatment process. Also, these ways are energy-intensive processes, making the cost of wastewater treatment expensive8.

The adsorption process has received particular attention owing to its high efficiency, simplicity, and easy operation9. Its operational and capital costs depend mainly on the adsorbent cost, which is a porous material with a high surface area and large porosity (i.e., pore volume)10. Consequently, using low-cost and eco-friendly adsorbents is the main challenge facing the broad implementation of the adsorption method in wastewater treatment processes11. Recent research works focus on converting low-value waste biomass to high-value adsorbents for water purification12. Biochar, sometimes called pyrochar, is carbon-rich material extracted from waste and biomass materials such as wood, leaves, manure, and tree roots. It is widely utilized in adsorbing organic and inorganic contaminants from effluent waters, such as biopharmaceuticals13, heavy metals14, pesticides15, and pentachlorophenol16. Various organic wastes (biomasses), such as agricultural and municipal wastes, are used as feedstock to synthesize biochar. Such wastes are collected from the environment and turned into high-value biochar adsorbents through different preparation methods, followed by other modification techniques. The main goal of the preparation and modification techniques is to produce thermal and chemical stable biochar with high surface area and pore volume17. Figure 1 illustrates different feedstocks, preparation, and modification methods used for producing biochar18. The chemical composition, cation exchange capacity, and moisture content of the biomass affect the yield and the elemental analysis of the resultant biochar19. Table 2 lists the characterization of each method.

One of the primary benefits of biochar is its high-cost efficiency owing to the low cost of the feedstock and simplicity of preparation methods20. Reactivation (regeneration) of biochar after the adsorption process to be used for several cycles reduces the operational and running cost of the wastewater treatment process significantly. In other words, adsorbent’s high recycling and reuse are critical for wastewater management’s economic efficiency21,22. Therefore, various regeneration techniques have been proposed, developed, and evaluated to reuse adsorbents. The techniques are influenced by the adsorbent type (either composite or pristine), its properties, and the type of adsorbate. Figure 2 shows that these techniques could be categorized into two main groups: desorption and decomposition process23. The decomposition regeneration depends on completely mineralizing the adsorbed pollutants or transforming them into less toxic byproducts24. This allows restoring the adsorption capacity of biochar. Oxidation and ultrasound decomposition methods usually use high thermal energy, so they could be considered a thermal decomposition approach. In contrast, desorption regeneration methods are based on breaking the bonds between biochar surface and contaminants by thermal or non-thermal methods. Thermal regeneration is a destructive method used only if the adsorbate is a waste, so there is no need for its recovery25,26. High energy consumption in the thermal regeneration (temperature up to 800 °C) increases the process cost, which could reach up to 50% of the total cost of production of new biochar27. The non-thermal methods preserve the adsorbents and can be reused for several cycles. Among these methods, the chemical one is widely applied according to published papers analyzed in the following discussion28.

Methods

The number of publications that discuss biochar applications in wastewater purification continuously increases, as proven in Fig. 3. As can be seen, the cumulative number of research and review papers published till 2021 is around 2200. The number of research papers published in 2013 and 2021 was 26 and 675, respectively (about 26 times during the last 8 years). Because biochar received much attention, many review papers were published to discuss the performance of biochar in removing contaminants from effluent waters. The total number of review papers about using biochar in wastewater treatment reached about 226 articles by 2021, compared to one review paper in 2013.

The number of papers presented research about biochar is extracted by searching “biochar” and “wastewater” in title, keywords, and abstract. Word :regeneration” is added to extract the number of papers discussing regeneration. This word is replaced by ‘chemical regeneration’ to have the number of biochar papers having a chemical regeneration method. Overview of the published papers about biochar with emphasis on the chemical regeneration process.

Biochar should be reactivated (regenerated) to be reused instead of burning or disposing it in the environment and introducing another problem. Therefore, the regeneration process is critical because it determines the practicability and economic feasibility of using biochar in wastewater treatment and even controls the cost of the whole treatment process. Figure 3 also presents the number of research papers presented in the Scopus database29 that discussed the regeneration process of biochar. It is found that the total number of these papers is 117 articles (over the last 10 years); 63 of them are focused on the chemical regeneration process. Analyzing the published papers (about 2200 papers), it is found that open literature has one review paper about the regeneration of bioadsorbents like biochar30. Another review paper presented a concise section, without details, about the regeneration process of biochar used for arsenic removal31. To the authors’ knowledge, no review paper focuses explicitly on the chemical regeneration process of biochar, which is critical for the sustainability of wastewater treatment. It is worth mentioning that the same trend and observation are found using the Web of Science database. Therefore, this work comprehensively reviews the chemical regeneration process that generates biochar after adsorbing organic pollutants and heavy metal ions. The paper discusses the factors that affect process efficiency. It also demonstrates the challenges and future prospects of biochar regeneration.

The paper is constructed into three sections, besides this section and the introduction. The main section (Section #3) of the present review is devoted to the chemical regeneration process as an effective method for biochar reactivation. Factors affecting the regeneration process are discussed in Section #4. Different approaches for managing secondary pollutants are mentioned in Section #5. The challenges and outlook of biochar as a sustainable adsorbent for wastewater treatment are highlighted in Section #6. Finally, the conclusion is drawn in Section #7.

Chemical regeneration

Chemical regeneration is one of the most popular ways to regenerate adsorbent materials32. It relies mainly on adsorbate concentration and interaction forces on the adsorbent20. The chemical regeneration process uses solvents and chemical reagents to desorb the adsorbate from the biochar. Organic adsorbents with limited thermal stability and low boiling point are more suitable for chemical regeneration33. Several solvents (organic/inorganic) were used to desorb both organic/inorganic adsorbates34,35,36,37. Thus, in this work, the chemical regeneration is classified based on pollutant type, not on the solvent type. The regeneration of inorganic pollutants (heavy metals) and organic pollutants (dyes and antibiotics) are discussed and critically analyzed. Regeneration data for each pollutant is collected from two approaches. The first type is regeneration studies, discussing regeneration efficiency for each cycle. The second type is desorption studies that discuss the desorption efficiency of each pollutant from the biochar at each cycle. Both types of studies are presented and critically analyzed in this work. Regeneration (removal) efficiencies are more expressive than desorption efficiencies. This is because the desorption experiments do not include the performance of the next adsorption cycle (affected by the degradation in biochar). However, regeneration (removal) efficiencies include this effect, and they measure the adsorption efficiency after each desorption process. Both regeneration and removal data are discussed and reported in tables.

Heavy metals

Pb(II)

Chemical regeneration process was employed to recover Pb(II) after being adsorbed by biochar. Tables 3 and 4 show the adsorption (removal) and desorption efficiency of biochar used to treat wastewater contaminated with Pb(II). Magnetic biochar/MgFe-LDH (LMBC) was regenerated after adsorbing Pb(II) from aqueous solution38. The regeneration was done by washing it with 2 M NaOH for 1.5 h for 5 adsorption/desorption cycles. The removal efficiency after the first cycle was around 83%. Progression in cycles made a slight decrease in removal efficiency in each cycle. After the fifth cycle, the efficiency was around 76.5%. The interaction between surface co-precipitation and NaOH may be responsible for Pb(II) desorption without changing the LMBC’s chemical structure. Regeneration cycles of cotton stalk-derived biochar polluted with Pb(II) ions using 0.01 M HNO3 for 3 adsorption/desorption cycles were conducted39. After the first regeneration cycle, the removal and desorption efficiencies were 95% and 89.4%, respectively, and decreased to 85% and 62% in the third cycle, respectively. During the desorption phase, the active sorption sites held by Pb(II) were liberated from the biochar surface. Mn-Zn ferrite/biochar composite (BC) (MZF-BC50) was regenerated after being loaded with Pb(II) using 0.2 M HCl as a regeneration agent in 6 consecutive adsorption/desorption cycles40. A slight drop in efficiencies was observed after the sixth cycle (removal efficiency: 91.2%). It was concluded that, after six cycles, as the MZF-BC50 maintained its adsorption activity. Biochar obtained from watermelon seeds (BC) and hydrogen peroxide treated biochar (HP-BC) were regenerated after Pb(II) adsorption using 1.0 M HCl for 5 successive adsorption/desorption cycles41. There was a slight reduction in the removal efficiency, which might be attributed to partial desorption of Pb(II) onto the surface of the adsorbents and solid loss in the solution. During the Pb(II) adsorption onto wheat straw biochar (WBC)42, the removal mechanisms were surface complexation, precipitation, and cation exchange. The surface complexation removal mechanism was due to the polar groups existing on the biochar. Moreover, Pb(II) adsorption by precipitation was promoted by the mineral components on the biochar. Furthermore, the ions of these mineral components (i.e., Ca(II), Mg(II), and K(I)) enabled the cation-exchange mechanism contribution to the adsorption. These functional groups initiated these mechanisms, therefore, initiated chemisorption. The complexation and precipitation mechanisms will highly negatively impact the regeneration process. The highest desorption efficiency among many tested desorbing agents was around 50% only. Therefore, biochar with high mineral ash content may exhibit surface precipitation and cation exchange as the dominant removal mechanisms. At the same time, surface complexation may be dominant in biochar rich with organic functional groups (OFGs). The content of biochar (ash or oxygen groups) can be controlled by the pyrolysis temperature43, thereby, controlling the removal mechanism and regeneration performance. Electron-rich functional groups like aromatic compounds, and C-O groups can rise π-interactions as a dominant removal mechanism44.

Cu(II) and Zn(II)

Tables 5 and 6 list the chemical regeneration and desorption efficiency of biochar used to treat wastewater contaminated with Cu(II) and Zn(II). In a fixed-bed column adsorption/desorption experiment, 0.2 M HCl was used to regenerate Hickory wood alkaline modified biochar (HMB) that had been contaminated with heavy metals, including Cu(II)45. The desorption process started with a significant release (desorption rate) peak for Cu(II), followed by a gradual decrease in the desorption rate throughout the regeneration phase. According to mass balance calculation, the acid was 85.1% efficient in regenerating the HMB. Si–Mn binary modified biochar (SMBC) polluted by Cu(II) was regenerated for 5 adsorption /desorption cycles46. The removal rate in the first cycle was 98.7% and degraded to around 80% in the fifth cycle. This trend was mainly because, during the desorption process, EDTA-2Na interacted with other metal ions in SMBC, disrupting the original structure of biochar to some extent. mBR-C loaded with Cu(II) was recovered using NaOH solution (0.1 M, 250 mL)47. The adsorption capacity of 85% was kept after two cycles of adsorption-desorption in a fixed-bed column. The high regeneration capacity could be attributed to the intensive activation of NaOH on the carbon materials, which improved interconnected pore structures and decreased pore deformation, hence promoting adsorption capacity. Adsorption of heavy metals (Cu(II) and Zn(II)) on ABC1 biochar was physisorption and chemisorption44. Physisorption of ABC1was mainly due to pore filling effects which resulted from pHpzc of 8.2 (slightly basic) due to the FG delocalized π electrons. The pH of the adsorption solution was 6. Therefore, as pH < pHpzc, the biochar was positively charged, and physisorption was not favored by electrostatic attraction as it repelled the positive metal cations. However, chemisorption at this pH is dominant using metal cations exchange. Heavy metal ions also reacted with OFGs via complexation and precipitation. These strong mechanisms explain the deterioration in the removal efficiency from 90% at the first cycle to 62% after 6 cycles.

Zn(II) was desorbed after being adsorbed by treated raw jujube seeds biochar (UAJS) using 0.1 M of HNO3, HCl, and H2SO448. The desorption efficiencies were around 90%, 93%, and 91% for HNO3, HCl, and H2SO4, respectively. As HCl achieved relatively higher desorption efficiency, it was used for 5 adsorption/desorption cycles. The desorption efficiency at the fifth cycle was around 87% which was not much of a reduction in the efficiency, meaning it was stable. HAP-BC was regenerated after Zn(II) adsorption using 0.2 M HCl for 5 cycles49. The removal efficiency was 95% for the first cycle and remained constant for the second cycle. Declination in removal efficiency started from the third cycle and continued till reaching 75% in the fifth cycle. The adsorption capacity decrease over the cycles was attributed to adsorbent waste and degradation. However, this degradation was not that much. Therefore, after five regeneration cycles, the Hydroxyapatite-biochar (HAP-BC) surface was rough, and most of its particles remained on the surface. As a result, HAP-BC remained stable. A composite of biochar/pectin/alginate hydrogel beads (BPA) was used to absorb Cu(II) from an aqueous solution50. The adsorption process was mainly controlled by chemisorption. Adsorption pH was not possible to favor the physisorption using higher pH, as the free cationic form of Cu(II) occurs at pH <6, otherwise, Cu(OH) may be formed and precipitate on the biochar surface. In turn, heavy metals (especially Cu) solutions are limited to acidic pH to avoid precipitating, thus, avoiding lower regeneration performance. This agrees with the conclusions of Cd(II) and Pb(II) desorption studies from MgBC400 using NaOH (high pH)51. Even in acidic conditions, precipitants may form21. Therefore, it can be concluded that surface precipitation is a general—unavoidable—mechanism for metal cations adsorption/desorption.

Cd(II) and Ni(II)

Chemical regeneration has been applied to regenerate biochar saturated with Cd(II) and Ni(II). MBCG and a BCG were regenerated to release Cd(II) adsorbed on their surfaces32. Both biochar materials were eluted with 0.3 M HNO3 solution and then regenerated with 0.03 M NaOH for five adsorption/desorption cycles. The poor removal efficiency was present (under 10%). However, the MCBG’s regeneration capacity remains consistent since it kept 92.1% of its original (zeroth cycle) efficiency. On the other hand, comparing BCG’s last cycle regeneration efficiency to the initial efficiency, it declined dramatically (78.4%) by the fifth cycle. The mesoporous structure of MBCG helped to prevent the loss of inner active sites over time, resulting in better regeneration.

Cd(II) desorption using HNO3 from OSR550 was studied52. OSR550 showed the maximum Cd(II) desorption abilities under mild HNO3 concentration, where Cd(II) and different heavy metals were desorbed from biochar obtained from Coaltec Energy, Inc using different concentrations of HNO3, H2SO4, and HCl53. Higher acid concentrations may degrade the biochar structure, lowering sorption and desorption efficiency owing to biosorbent loss. 0.1 M acid concentration was low enough not to damage the biochar surface and achieved high desorption efficiency for most metals. Therefore, 0.1 M concentration was used to compare different acids. HNO3 was the best fit for heavy metal removal in this study. Therefore, 0.1 HNO3 was used for 3 adsorption/desorption cycles, and the first and third cycle Cd(II) desorption efficiencies were 72% and 68%, respectively.

For six consecutive cycles, the regeneration efficiency of ABC1 polluted with Ni(II) was investigated using 0.1 M NaOH44. After the first cycle, the removal efficiency was reduced to around 87% from 92% in the initial cycle. After the first three cycles, it was further reduced to 80%. By the end of the sixth cycle, the reduction in removal efficiency was around 16%. The reduction in the removal efficiency was due to the loss of active sites and pores blockage in the ABC1. PLB was used to adsorb heavy metals (Cu(II), Zn(II), and Ni(II)) from wastewater28. In the first two cycles, removal efficiencies of Ni(II) were 67% and 55%, respectively28. After the third cycle, the removal efficiency dropped drastically to 19% and ended at 3% by the sixth cycle. The difference in the first cycle’s removal efficiencies of different heavy metals may be attained in the different metal radii and pKa. Biochar had a large average pore size of 30.15 nm, its pHpzc was around 2, and the pH of the adsorption solution was 5. Thus, physical adsorption was favored using electrostatic attraction. However, chemisorption was dominant rather than physisorption. Therefore, the type of pollutant matters in the prediction of removal mechanisms. Even when physisorption is favored, chemisorption dominates. Moreover, at alkaline pH in the adsorption process, heavy metal ions can form precipitates and surface complexes54. Thus, the first adsorption process in alkaline conditions may be successful. However, due to the precipitants and complexes formed, the desorbing agents could not completely regenerate the biochar. Therefore, the subsequent adsorption cycle performance deteriorates due to active site loss and pore blockage. This trend was observed in many studies. Tables 7 and 8 present the chemical adsorption and desorption efficiency of biochar used to treat wastewater contaminated with Cd(II) and Ni(II).

Organic pollutants

Dyes

Tables 9 and 10 summarize the chemical regeneration of biochar contaminated with different types of dyes. Sulfur-treated Tapioca peel (S@TP) biochar was regenerated after Malachite Green (MG) and Rhodamine B (RhB) adsorption using 0.1 M NaOH for five cycles55. For MG dye, the removal efficiencies of the first and fifth cycles were around 82% and 57%, respectively. However, for RhB dye, the removal efficiencies were around 88% and 68% for the first and last cycles, respectively. With each cycle, the regeneration efficiency of the S@TP biochar reduced, which might be attributable to the increasing clustering of the adsorbent surface. Activated empty fruit fibers biochar (PEF) loaded with cibacron blue (CB) from an aqueous solution was regenerated using 0.3 M HCl for 7 cycles56. The removal efficiencies for the first and seventh cycles were 99.5% and 91%, respectively. Protonation of carbonyl/hydroxyl group(s) at the surface of PEF in acidic solution might explain the high desorption efficiency reported even after 7 cycles of the adsorption-desorption process. CB was repelled by protonated PEF and liberated from the PEF surface into a desorption solution. Methylene blue (MB) was desorbed from loaded biochar particles/polysulfone fiber membrane (MMM)57. The desorption used acid, base, salt, organic solvent, and 1 M NaCl in an organic solvent solution. A desorption rate of 20–25% was reached in a very acidic solution, but negligible desorption happened in an alkali solution. Very acidic or basic environments were not stable for desorption. The influence of ionic strength implied that MB adsorption was not sufficiently sensitive to salt concentration. Using 1 M NaCl or KCl solutions, the desorption rate was <20%. Ethanol outperformed the competition, and the rate of desorption improved as the volume of ethanol in the aqueous solution increased.

MG dye was adsorbed on ABC1 biochar by both physisorption and chemisorption44. Physisorption was mainly due to pore filling effects. The pHpzc of ABC1 was 8.2 (slightly basic) due to the delocalized π electrons of the functionalities. The pH of the adsorption solution was 6, and the pKa of MG dye was around 4.2. This results in the positively charged biochar surface and the negatively charged MG dye. Therefore, physisorption was favored by electrostatic attraction. Chemisorption was involved as well. However, it involved low-impact mechanisms (hydrogen bonding and π-π interactions). Thus, the regeneration was much better than that for heavy metals. The regeneration efficiency was almost 100% (constant) for 3 cycles and decreased to 78% in the 6th cycle. This emphasized the role of pH, pHpzc, and pKa on physisorption, enhancing organic pollutants’ regeneration performance. As mentioned in the heavy metal discussion, the same ABC1 and same solution were used for the same positively charged metal ions and MG dye. However, different removal mechanisms arise with a whole different regeneration performance. This indicates the role of the adsorbate itself in determining the removal mechanism, thus regeneration performance.

Four Remazol dyes (RBB, RBV5R, RBO3R, and RBBR) were desorbed from green marine algae biochar using 0.01 M NaOH, 0.01 M Na2CO3, 0.01 M NH4OH, HCl, CH3OH, and 0.01 M EDTA35. Desorption studies revealed that acidic eluants had low desorption effectiveness, whereas basic eluants had high desorption efficiency. Municipal sludge biochar was regenerated after MB adsorption from an aqueous solution using ethanol/acetic acid (9/1:v/v) for three cycles58. The removal efficiencies were around 99% and 60% in the first and third cycles, respectively. The removal rate of the desorbed biochar was reduced due to the preceding desorption processes, which solubilized some sections of the biochar, altering its surface structure and resulting in the loss/blockage of adsorption sites. This agreed with using 5% methanol (MeOH)59. RhB was adsorbed into cassava slag biochar (HCS)36. The pHpzc of the HCS biochar was 5, and the pKa of the RhB was 3.5. Therefore, maximum adsorption occurred around solution pH = 4. As the solution pH is less than pHpzc of biochar, the biochar was positively charged. And RhB was negatively charged because the solution pH was more than the pKa. As a result, physisorption was the dominant mechanism via electrostatic interaction. Therefore, regeneration exhibited high performance. The regeneration efficiencies were 97.5% and 93% in the first and fifth cycle, respectively. NaOH has a pH higher than pHpzc and pKa. Therefore, HCS and RhB were negatively charged, resulting in RhB repulsion. It can be concluded that the solution pH in the adsorption process should be adjusted to control the charge of biochar and facilitate the adsorption and desorption process.

Antibiotics

CoFe2O4-impregnated banana pseudostem (Co-BP350) biochar was regenerated after absorbing amoxicillin (AMX) using ethanol for 5 adsorption/desorption cycles60. The removal efficiencies were 100% and 92% for the first and fifth cycle, respectively. The concentration of AMX on the biochar surface may have choked active areas, resulting in this decrease in the removal efficiency with consecutive cycles. However, after five cycles, the percentage drop did not surpass 5.7%, indicating that the Co-BP350 might be a potent adsorbent. Cefoxitin (CFX) was desorbed from sour cherry stalk waste modified biochar (MPCWSB500) using HCl, NaOH, H3PO4, KH2PO4, acetonitrile, CH3COOH, and CaCl2 at different concentrations61. Desorption efficiencies were around 1% for 0.01 M HCl, 8% for 0.001 M NaOH, 36% for 0.01 M NaOH, 28% for 0.05 M NaOH, 18% for 0.1 NaOH, 0% for acetonitrile, 3% for 0.01 H3PO4, 4% for 0.01 M KH2PO4, 1% for 0.01 M CaCl2 and 10% CH3COOH. The maximum CFX desorption efficiencies were achieved with NaOH solutions of 0.01 M and 0.05 M. Authors selected 0.01 NaOH to perform a regeneration experiment. The removal efficiency was almost constant for 5 adsorption/desorption cycles (around 98%). Interestingly, the desorption efficiency increased to around 72%. g-MoS2 decorated biochar (g-MoS2-BC) was regenerated after adsorbing tetracycline (TC) from different water samples using 0.2 M NaOH for 5 consecutive cycles37. Table 11 lists the reusability of biochar contaminated with different antibiotics.

Factors affecting the chemical regeneration process

The regeneration process includes adsorption/desorption process. So, factors affecting either adsorption or desorption process influence the regeneration process. These factors could be summarized as:

Functional groups (FGs)

Regeneration is affected by the mutual interaction between FGs and the pollutants. Same biochar with the same FGs may interact differently with different contaminants. For heavy metal ions, the dominant adsorption mechanism was, in general, chemisorption. The removal mechanisms based on these groups were complexation with OFGs, precipitations with hydroxyl and C-O groups, and π-interactions44. These mechanisms influence the dominance of chemisorption over physisorption. Therefore, regenerated biochar losses some of its active sites every cycle due to the strong chemical bonds in chemisorption, which negatively impacts the regeneration process. In turn, the same FGs behaved differently during dye adsorption. For instance, ABC1 had FGs rich in electrons. MG dye had nitrogen-containing-FGs deficient in electrons. So, π-interactions were promoted, and the hydrogen bonds developed as well. Therefore, complexation and precipitation mechanisms were not dominating the adsorption, which may be linked to the high regeneration efficiency after the first cycle (100%)44. Comparing the regeneration performance of the MG dye and the metal ions on the same biochar, the effect of nitrogen-containing-FGs on the MG dye adsorption and regeneration is significant.

FGs affect the regeneration of biochar in two ways: (1) They determine the biochar surface’s acidity and basic behavior (biochar charge)62. Thus, they determine the amount of physisorption by electrostatic attraction and hydrogen bonds, hence affecting the difficulty of desorption63. The surface acidity of biochar originates from the OFGs like carboxyl and phenyl44. While basic behavior may result from either: firstly, basic FGs like nitrogen-containing-FGs (Amino) or OFGs (carbonyl). Secondly, from π-electrons in aromatic rings behaving as a Lewis base. (2) Determine the type of removal mechanism (chemisorption or physisorption)54. OFGs may govern some chemisorption removal mechanisms, namely: (I) complexation, (II) precipitation, and (III) cation exchange. Especially in metals, OFGs negatively influence the desorption and regeneration of the pollutant in terms of efficiency and consistency46,51,64. However, how FGs behave depends on solution pH, biochar pHpzc, and pollutant pKa, as presented in Table 12.

Removal mechanisms

The strength of removal mechanisms is generally classified as chemisorption (strong) and physisorption (weak)43,65,66. Chemisorption precipitation and complexation have high impact mechanisms, while π- interactions and ion exchange have low impact mechanisms42,67. According to the literature, biochar adsorbs pollutants by chemisorption has lower regeneration performance than by physisorption56,63. This is mainly because pollutants chemically react with the active adsorbent sites forming complexes or precipitate on the adsorbent surface which may not be reversible in the desorption process65. Thus, the adsorbent loses its active sites gradually each cycle because its pores are getting blocked21,45. This may lead the biochar to lose its functionalities and mass and degrade with the adsorption/desorption cycles68.

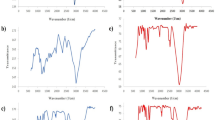

The rich OFGs may drive surface complexation as the primary mechanism. Therefore, precipitations were tougher to desorb than the surface complexation mechanism43. Regeneration of biochar polluted with organic adsorbates seems more straightforward than heavy metals because surface complexation mechanisms are involved, as shown in Fig. 4a. The ranges of first and last cycle removal efficiencies are shown in Fig. 4b. It is found that the efficiencies of the last cycle have a wide range, indicating the instability of the regeneration of heavy metals.

For the organic pollutants, analysis of the reviewed studies showed that the physisorption by electrostatic attraction and interactions (i.e., hydrogen bonds and π interactions) were dominant among organic adsorbates, giving them better and more stable regeneration performance than inorganic adsorbates55,62. Chemisorption (either π interaction or cation exchange) was also involved in dyes adsorption, as shown in Fig. 5a. However, it was relatively reversible44. The regeneration performance was relatively stable compared to inorganics experiencing precipitations and complexations, as shown in Fig. 5b. The first and last cycles have higher median removal efficiency compared to corresponding values of heavy metals. Moreover, their scatter range is less, indicating relatively high efficiency in the last regeneration cycle.

Adsorbent and solution pH

Biochar PZC

The acidic/basic activity of biochar is expressed using its point of zero charge (pHpzc)28. If the solution pH > pHpzc), the biochar deprotonates (negatively charged) and vice versa69. This affects the interaction between biochar and pollutant35,37.

Adsorbate type

it determines if its adsorption involves chemical bonding (chemisorption) or attraction (physisorption). In literature, it is found that most of the inorganic pollutants (heavy metals) chemically react with biochar surface50,70. However, most organic pollutants are physisorbed by attractions and interactions to biochar’s surface, affecting the regeneration performance62.

Adsorbate pKa

Adsorbates have positive or negative charges based on their pKa and the solution pH. When the solution pH<adsorbate pKa, the adsorbate is positively charged. On the other hand, the adsorbate is negatively charged if solution pH>adsorbate pKa37,59. Thus, we can conclude that what determines whether adsorbate is attracted to the biochar (adsorbed) or repelled (desorbed) is the solution’s pH and pHpzc of biochar and pKa of the adsorbate. Adsorbate’s pKa may have one, two, or three pKa values. One pKa value is common among dyes59, and two and three were found in antibiotics61,63,71. In double pKa adsorbates, we get them positively charged, negatively charged, and zwitterionic. The complexity of pKa values is mainly because organic pollutants have multiple functional groups, and their net behavior is different in each solution pH. Thus, solution pH for inorganic adsorbate is crucial for both adsorption and desorption efficiencies.

Solution pH

When the adsorbate is organic, physisorption dominates. Thus, the solution pH should promote opposite charges on both biochar and adsorbate60. However, when chemisorption dominates in heavy metals, the pH of the solution may be acidic, promoting electrostatic repulsion. The adsorption becomes pH-independent as the chemisorption is the dominant49,50. For desorption in alkaline conditions, heavy metal ions form precipitants on the biochar surface54, reducing regeneration performance. Therefore, the highest desorption for heavy metal ions may occur at acidic pH41,70,72. Figure 6 summarizes—based on literature—the effect of solution pH, adsorbate pKa, and biochar pHpzc on adsorption/desorption performance. Figure 7 summarizes the dominant removal mechanisms found in literature, their corresponding driving FGs, and their impact on regeneration. It is seen that the chemisorption process is the dominant process in inorganic pollutants removal57,73.

Desorbing agents

Based on the previous discussion, we may conclude that the metal desorption is as complex as its adsorption. There is no straightforward way to tell which regeneration agent is the best for each pollutant. This is mainly because the desorption process depends on the biochar composition, FGs, its physiochemical properties, and adsorbate43,56. However, some guidelines may be suggested:

For heavy metals

(1) Both acidic and alkaline desorbing agents were dominant in the previous studies57,74. (2) Acidic outperformed alkaline desorbing agents due to the minimal surface precipitants (pore blockage), resulting from dissolving the adsorbate complexes on the biochar. (3) HNO3 was concluded to be better than HCl in many studies because HCl may form more precipitants and complexations, leading to metals re-adsorption on the biochar after desorption. (4) Acidic desorbing agents react with the mineral structure of biochar, thus destroying it every cycle. This is not noticed in the desorption efficiency. However, there is a noticeable deterioration in the adsorption efficiency of the upcoming cycles. (5) Salts may not have the highest desorption capabilities, but they will not degrade the biochar structure. (6) Alkaline agents may have better regeneration performance with biochar having fewer OFGs and more carbon/nitrogen FGs38.

For organic pollutants

(1) Alkaline dominates acidic desorbing agents in terms of performance because the adsorption is mostly physisorption (electrostatic attraction), and the desorption is electrostatic repulsion35,60,75. In most cases, electrostatic repulsions occur at alkaline pH61,73. The data extracted from the literature highlights that acidic agents, besides their relative rarity, have much more scatter and instability than alkaline agents. (2) No surface degradation occurred in most of the studies. (3) Regeneration of organic pollutants is more stable than the chemisorbed metals (inorganic) pollutants. (4) Acids may be used based on the pH that satisfies the electric repulsion when adsorbates76.

Surface area and morphology of biochar

Adsorption process via physisorption enhances using biochar with higher surface area. However, no correlation was found between the desorption performance and adsorbent surface area39,40,56. High regeneration performance occurred when relatively high bonding strength and low surface area existed. For the strongly chemisorbed heavy metals on biochar, the morphology of biochar after each regeneration cycle was affected because the biochar’s pores were blocked with precipitants, and its active sites were lost (i.e., destroying its original structure)46. This biochar degradation may occur abruptly and entirely after the first cycle21,77 or gradually after that50,51. The deterioration of the biochar structure may be reduced by modifying the biochar to have stronger C-C bonds77. After the regeneration process, X-ray photoelectron spectroscopy and FTIR analysis could be used to characterize biochar78,79,80.

Acidic desorbing agents were mainly the cause of biochar structure deterioration during dissolving the chemisorbed pollutant complexes53. HNO3 was found to be the most involved acid in many structural deteriorations due to its strong acidity and H+ ions interactions with the mineral composition of the biochar68. On the other hand, HCl was reported to be benign on the biochar surface with less impact on the morphology of the regenerated biochar48,49. Not many morphology deteriorations were reported for organic pollutants due to the weak bond between adsorbent and pollutant58. Interestingly, acid erosion of the biochar after regeneration may be beneficial because the surface area got enlarged. This approach enhances the adsorption (physisorption) process in subsequent cycles13.

Management and disposal of spent adsorbents

The major limitation of chemical regeneration is secondary pollution. Therefore, sustainable management of spent adsorbents should be considered to rescue the environment. Different disposal techniques were proposed, such as reuse, incineration, and landfilling81,82. In case of reuse, the spent adsorbents are used in applications such as soil amendment, energy conversion, storage devices, capacitors, and catalyst/catalyst support. Studies highlighted that nutrient-enriched biochar is an environmentally-friendly fertilizer that could be a substitution for synthetic fertilizer83. Metal-impregnated biochar might replace carbon nanotubes materials, and they might be used for tar removal or as supercapacitors soon82. Incineration is a final management technique and is commonly referred to waste-to-energy process, in which spent adsorbent is utilized as a source of thermal energy, instead of coal, with reduced corrosiveness and toxic gas emission84. Landfilling is another management method for dumping spent adsorbents in landfills. The concentration of adsorbate in spent sorbent should be determined before disposal to decide whether the process is permitted. Heavy metals-contaminated biochar requires a pretreatment process before final disposal in a landfill. Besides these methods, other ways could be used, such as microwave irradiation, phytocapping, and phytoremediation85.

Remarks, challenges, and future perspectives

Chemical regeneration of biochar has been recognized as a fabulous sustainable technique that can reduce the process’s cost and energy consumption. Chemical regeneration, unlike thermal regeneration, is an effective regeneration method that does not require high temperatures. Most chemical regeneration temperatures range between 20 and 35°C, significantly reducing cost and becoming a suitable method for more biochar types. There is no straightforward rule regarding the selection of chemical regeneration agents. Both organic and inorganic agents can be used for organic and inorganic biochars and still have high regeneration performance. Literature showed that the performance of chemical regeneration depends on the reaction between pollutants, biochar material, and chemical regeneration agents. Adsorption mechanism, FGs at biochar surface after adsorption, adsorbent pore structure, and changes in active adsorbent sites affect the chemical regeneration performance. Regeneration of biochar polluted with organic adsorbates seems more straightforward than heavy metals. This is attributed to fewer involved mechanisms with physisorption dominating the adsorption. The discussed studies prove that cation exchange is a biochar common heavy metal removal mechanism. Most results indicated a decline in regeneration performance when the number of cycles increases. However, when the operating parameters are optimized, the decline in performance becomes insignificant. Precipitations were shown to be tougher to desorb than surface complexation mechanism.

Both cyclic desorption efficiencies and adsorption efficiencies are discussed. High desorption efficiency does not always mean high regeneration performance in many cases. High desorption efficiency means the desorbing agent may desorb most pollutants from the biochar surface. However, it does not tell any information about the status of adsorbent material. The agent may degrade the adsorbent (biochar) surface, losing its active sites and blocking its pores. Therefore, high desorption efficiency does not talk much about regeneration performance. In other words, it does not tell how the biochar will perform in pollutant adsorption with cycle progression. Despite the chemical regeneration advantages, it has some drawbacks, such as the secondary toxic materials that could adversely affect the biochar stability in removing the contaminants.

In future research works, numerous challenges need to be considered to fully adopt this technique for practical applications:

-

Most studies used biochar to adsorb and desorb a single pollutant in synthetic wastewaters. This approach is neither realistic nor practical. Therefore, future works should consider real effluent wastewater with a mixture of pollutants to illustrate the adsorbate effects on the performance of the regeneration process.

-

Research efforts should develop low-cost technologies to recover contaminants from spent adsorbents.

-

Investigating biochar characteristics (i.e., surface morphology, porosity, functionalities) after each regeneration cycle should be done for a deep understanding of the process. This could develop an artificial intelligence model to predict the optimal regeneration conditions and support the sustainable use of biochar in wastewater purification applications.

-

Different modifications for biochar’s surface increase its adsorption capacity but might negatively affect the regeneration process. Therefore, researchers have to propose other modification techniques that could support the complete chemical regeneration of biochar.

-

In-situ functionalization and modification of biochar resulting from the choice of biomass feedstocks can reflect the merits of biochar in price and source.

-

Many previous works highlighted the effectiveness of using biochar in extracting and recovering valuable metals from wastewater. However, these studies were conducted at the lab-scale level. Thus, more research should be exerted to increase the value of using biochar in wastewater treatment and raise the technological readiness level of such an adsorption/desorption method.

-

Chemical regeneration depends on the oxidative destruction of organic pollutants. However, the possible generation of unidentified toxic by-products still needs more research.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Din Dar, M. U. et al. Blue green infrastructure as a tool for sustainable urban development. J. Clean. Prod. 318, 128474 (2021).

Elbeltagi, A. et al. Applications of Gaussian process regression for predicting blue water footprint: case study in Ad Daqahliyah, Egypt. Agric. Water Manag. 255, (2021).

Sun, Y. et al. The potential of biochar and lignin-based adsorbents for wastewater treatment: comparison, mechanism, and application—a review. Ind. Crops Prod. 166, (2021).

Palansooriya, K. N. et al. Occurrence of contaminants in drinking water sources and the potential of biochar for water quality improvement: a review. Crit. Rev. Environ. Sci. Technol. 50, 549–611 (2020).

Shah, A. I. et al. Prospectives and challenges of wastewater treatment technologies to combat contaminants of emerging concerns. Ecol. Eng. 152, 105882 (2020).

Liu, F., Zhu, S., Li, D., Chen, G. & Ho, S. H. Detecting ferric iron by microalgal residue-derived fluorescent nanosensor with an advanced kinetic model. iScience 23, (2020).

Bhat, S. A. et al. Sustainable nanotechnology based wastewater treatment strategies: achievements, challenges and future perspectives. Chemosphere 288, 132606 (2021).

Wu, W., Shi, Y., Liu, G., Fan, X. & Yu, Y. Recent development of graphene oxide based forward osmosis membrane for water treatment: a critical review. Desalination 491, 114452 (2020).

de Araujo, C. M. B. et al. Wastewater treatment using recyclable agar-graphene oxide biocomposite hydrogel in batch and fixed-bed adsorption column: bench experiments and modeling for the selective removal of organics. Colloids Surf. A Physicochem. Eng. Asp. 639, 128357 (2022).

Mohammed, R. H. et al. Metal-organic frameworks in cooling and water desalination: synthesis and application. Renew. Sustain. Energy Rev. 149, 111362 (2021).

Yin, X. et al. Phosphate removal from actual wastewater via La(OH)3-C3N4 adsorption: performance, mechanisms and applicability. Sci. Total Environ. 814, 152791 (2022).

Qasem, N. A. A. & Mohammed, R. H. Removal of heavy metal ions from wastewater: a comprehensive and critical review. npj Clean Water https://doi.org/10.1038/s41545-021-00127-0.

Wu, Z. et al. Tough porous nanocomposite hydrogel for water treatment. J. Hazard. Mater. 421, 126745 (2022).

Li, Y., Yu, H., Liu, L. & Yu, H. Application of co-pyrolysis biochar for the adsorption and immobilization of heavy metals in contaminated environmental substrates. J. Hazard. Mater. 420, 126655 (2021).

Ogura, A. P. et al. A review of pesticides sorption in biochar from maize, rice, and wheat residues: current status and challenges for soil application. J. Environ. Manage. 300, 113753 (2021).

Wang, Y., Cui, C., Zhang, G., Xin, Y. & Wang, S. Electrocatalytic hydrodechlorination of pentachlorophenol on Pd-supported magnetic biochar particle electrodes. Sep. Purif. Technol. 258, 118017 (2021).

Song, B. et al. Preparation of nano-biochar from conventional biorefineries for high-value applications. Renew. Sustain. Energy Rev. 157, 112057 (2022).

Li, C. et al. Multi-functional biochar preparation and heavy metal immobilization by co-pyrolysis of livestock feces and biomass waste. Waste Manag. 134, 241–250 (2021).

Li, Y., Xing, B., Ding, Y., Han, X. & Wang, S. A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresour. Technol. 312, 123614 (2020).

Barquilha, C. E. R. & Braga, M. C. B. Adsorption of organic and inorganic pollutants onto biochars: challenges, operating conditions, and mechanisms. Bioresour. Technol. Rep. 15, 100728 (2021).

Herath, A. et al. KOH-activated high surface area Douglas Fir biochar for adsorbing aqueous Cr(VI), Pb(II) and Cd(II). Chemosphere 269, 134893 (2021).

Wan, S. et al. Enhanced lead and cadmium removal using biochar-supported hydrated manganese oxide (HMO) nanoparticles: Behavior and mechanism. Sci. Total Environ. 616–617, 1298–1306 (2018).

Omorogie, M. O., Babalola, J. O. & Unuabonah, E. I. Regeneration strategies for spent solid matrices used in adsorption of organic pollutants from surface water: a critical review. Desalin. Water Treat. 57, 518–544 (2016).

Liao, Y. et al. Efficient removal mechanism and microbial characteristics of tidal flow constructed wetland based on in-situ biochar regeneration (BR-TFCW) for rural gray water. Chem. Eng. J. 431, 134185 (2022).

Sabio, E. et al. Thermal regeneration of activated carbon saturated with p-nitrophenol. Carbon N.Y. 42, 2285–2293 (2004).

San Miguel, G., Lambert, S. D. & Graham, N. J. D. The regeneration of field-spent granular-activated carbons. Water Res. 35, 2740–2748 (2001).

U.S. EPA. Wastewater technology fact sheet - granular activated carbon adsorption and regeneration. U.S. Environ. Prot. Agency EPA 832-F-, 1–7 (2000).

Iamsaard, K. et al. Adsorption of metal on pineapple leaf biochar: Key affecting factors, mechanism identification, and regeneration evaluation. Bioresour. Technol. 344, 126131 (2022).

Scopus. Scopus - Document search | Signed in. Document search https://www.scopus.com/search/form.uri?display=basic#basic (2021).

Hassan, M., Naidu, R., Du, J., Liu, Y. & Qi, F. Critical review of magnetic biosorbents: their preparation, application, and regeneration for wastewater treatment. Sci. Total Environ. 702, 134893 (2020).

Amen, R. et al. A critical review on arsenic removal from water using biochar-based sorbents: the significance of modification and redox reactions. Chem. Eng. J. 396, 125195 (2020).

Wu, Z., Chen, X., Yuan, B. & Fu, M. L. A facile foaming-polymerization strategy to prepare 3D MnO2 modified biochar-based porous hydrogels for efficient removal of Cd(II) and Pb(II). Chemosphere 239, 124745 (2020).

Dai, Y., Zhang, N., Xing, C., Cui, Q. & Sun, Q. The adsorption, regeneration and engineering applications of biochar for removal organic pollutants: a review. Chemosphere 223, 12–27 (2019).

Zubair, M., Ihsanullah, I., Abdul Aziz, H., Azmier Ahmad, M. & Al-Harthi, M. A. Sustainable wastewater treatment by biochar/layered double hydroxide composites: Progress, challenges, and outlook. Bioresour. Technol. 319, 124128 (2021).

Gokulan, R., Avinash, A., Prabhu, G. G. & Jegan, J. Remediation of remazol dyes by biochar derived from Caulerpa scalpelliformis - An eco-friendly approach. J. Environ. Chem. Eng. 7, 103297 (2019).

Wu, J., Yang, J., Huang, G., Xu, C. & Lin, B. Hydrothermal carbonization synthesis of cassava slag biochar with excellent adsorption performance for Rhodamine B. J. Clean. Prod. 251, 119717 (2020).

Zeng, Z. et al. Research on the sustainable efficacy of g-MoS2 decorated biochar nanocomposites for removing tetracycline hydrochloride from antibiotic-polluted aqueous solution. Sci. Total Environ. 648, 206–217 (2019).

Jia, Y. et al. A novel magnetic biochar/MgFe-layered double hydroxides composite removing Pb2+ from aqueous solution: Isotherms, kinetics and thermodynamics. Colloids Surf. A Physicochem. Eng. Asp. 567, 278–287 (2019).

Gao, L. et al. Impacts of pyrolysis temperature on lead adsorption by cotton stalk-derived biochar and related mechanisms. J. Environ. Chem. Eng. 9, 105602 (2021).

Niu, Z. et al. Green synthesis of a novel Mn–Zn ferrite/biochar composite from waste batteries and pine sawdust for Pb2+ removal. Chemosphere 252, 126529 (2020).

Ahmed, W. et al. Enhanced adsorption of aqueous Pb(II) by modified biochar produced through pyrolysis of watermelon seeds. Sci. Total Environ. 784, 147136 (2021).

Miao, Q. & Li, G. Potassium phosphate/magnesium oxide modified biochars: Interfacial chemical behaviours and Pb binding performance. Sci. Total Environ. 759, 143452 (2021).

Bogusz, A., Nowak, K., Stefaniuk, M., Dobrowolski, R. & Oleszczuk, P. Synthesis of biochar from residues after biogas production with respect to cadmium and nickel removal from wastewater. J. Environ. Manag. 201, 268–276 (2017).

Choudhary, M., Kumar, R. & Neogi, S. Activated biochar derived from Opuntia ficus-indica for the efficient adsorption of malachite green dye, Cu+2 and Ni+2 from water. J. Hazard. Mater. 392, 122441 (2020).

Ding, Z., Hu, X., Wan, Y., Wang, S. & Gao, B. Removal of lead, copper, cadmium, zinc, and nickel from aqueous solutions by alkali-modified biochar: batch and column tests. J. Ind. Eng. Chem. 33, 239–245 (2016).

Liu, J. et al. Preparation of Si–Mn/biochar composite and discussions about characterizations, advances in application and adsorption mechanisms. Chemosphere 281, 130946 (2021).

Pan, J. et al. Waste-to-resources: green preparation of magnetic biogas residues-based biochar for effective heavy metal removals. Sci. Total Environ. 737, 140283 (2020).

Gayathri, R., Gopinath, K. P. & Kumar, P. S. Adsorptive separation of toxic metals from aquatic environment using agro waste biochar: Application in electroplating industrial wastewater. Chemosphere 262, 128031 (2021).

Wang, Y. Y., Liu, Y. X., Lu, H. H., Yang, R. Q. & Yang, S. M. Competitive adsorption of Pb(II), Cu(II), and Zn(II) ions onto hydroxyapatite-biochar nanocomposite in aqueous solutions. J. Solid State Chem. 261, 53–61 (2018).

Zhang, W. et al. Novel pectin based composite hydrogel derived from grapefruit peel for enhanced Cu(II) removal. J. Hazard. Mater. 384, 121445 (2020).

Wu, J., Wang, T., Wang, J., Zhang, Y. & Pan, W. P. A novel modified method for the efficient removal of Pb and Cd from wastewater by biochar: Enhanced the ion exchange and precipitation capacity. Sci. Total Environ. 754, 142150 (2021).

Lam, Y. Y., Lau, S. S. S. & Wong, J. W. C. Removal of Cd(II) from aqueous solutions using plant-derived biochar: kinetics, isotherm and characterization. Bioresour. Technol. Rep. 8, 100323 (2019).

Kołodyńska, D., Krukowska, J. & Thomas, P. Comparison of sorption and desorption studies of heavy metal ions from biochar and commercial active carbon. Chem. Eng. J. 307, 353–363 (2017).

Li, Y. et al. Development of an acidized biochar-supported hydrated Fe(III) oxides for highly efficient cadmium and copper sequestration from water. Sci. Total Environ. 784, 147017 (2021).

Vigneshwaran, S., Sirajudheen, P., Karthikeyan, P. & Meenakshi, S. Fabrication of sulfur-doped biochar derived from tapioca peel waste with superior adsorption performance for the removal of Malachite green and Rhodamine B dyes. Surf. Interfaces 23, 100920 (2021).

Jabar, J. M. & Odusote, Y. A. Removal of cibacron blue 3G-A (CB) dye from aqueous solution using chemo-physically activated biochar from oil palm empty fruit bunch fiber. Arab. J. Chem. 13, 5417–5429 (2020).

He, J., Cui, A., Deng, S. & Chen, J. P. Treatment of methylene blue containing wastewater by a cost-effective micro-scale biochar/polysulfone mixed matrix hollow fiber membrane: performance and mechanism studies. J. Colloid Interface Sci. 512, 190–197 (2018).

Fan, S. et al. Removal of methylene blue from aqueous solution by sewage sludge-derived biochar: Adsorption kinetics, equilibrium, thermodynamics and mechanism. J. Environ. Chem. Eng. 5, 601–611 (2017).

Fernando, J. C. et al. Nitric acid surface pre-modification of novel Lasia spinosa biochar for enhanced methylene blue remediation. Groundw. Sustain. Dev. 14, 100603 (2021).

Chakhtouna, H., Benzeid, H., Zari, N., Qaiss, A. E. K. & Bouhfid, R. Functional CoFe2O4-modified biochar derived from banana pseudostem as an efficient adsorbent for the removal of amoxicillin from water. Sep. Purif. Technol. 266, 118592 (2021).

Sayin, F., Akar, S. T. & Akar, T. From green biowaste to water treatment applications: Utilization of modified new biochar for the efficient removal of ciprofloxacin. Sustain. Chem. Pharm. 24, 100522 (2021).

Parsa, M., Nourani, M., Baghdadi, M., Hosseinzadeh, M. & Pejman, M. Biochars derived from marine macroalgae as a mesoporous by-product of hydrothermal liquefaction process: characterization and application in wastewater treatment. J. Water Process Eng. 32, 100942 (2019).

Ma, Y. et al. Hydrothermal synthesis of magnetic sludge biochar for tetracycline and ciprofloxacin adsorptive removal. Bioresour. Technol. 319, 124199 (2021).

Zhang, S. et al. Fabrication of L-cysteine stabilized α-FeOOH nanocomposite on porous hydrophilic biochar as an effective adsorbent for Pb2+ removal. Sci. Total Environ. 720, 137415 (2020).

Bogusz, A., Oleszczuk, P. & Dobrowolski, R. Application of laboratory prepared and commercially available biochars to adsorption of cadmium, copper and zinc ions from water. Bioresour. Technol. 196, 540–549 (2015).

do Nascimento, B. F. et al. Adsorption of Reactive Black 5 and Basic Blue 12 using biochar from gasification residues: batch tests and fixed-bed breakthrough predictions for wastewater treatment. Bioresour. Technol. Rep. 15, 100767 (2021).

Khan, Z. & Anjaneyulu, Y. Influence of soil components on adsorption-desorption of hazardous organics-development of low cost technology for reclamation of hazardous waste dumpsites. J. Hazard. Mater. 118, 161–169 (2005).

Mohan, D., Sarswat, A., Ok, Y. S. & Pittman, C. U. Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent - a critical review. Bioresour. Technol. 160, 191–202 (2014).

Wang, S. et al. Calcite modification of agricultural waste biochar highly improves the adsorption of Cu(II) from aqueous solutions. J. Environ. Chem. Eng. 9, 106215 (2021).

Yu, J., Zhu, Z., Zhang, H., Qiu, Y. & Yin, D. Mg–Fe layered double hydroxide assembled on biochar derived from rice husk ash: facile synthesis and application in efficient removal of heavy metals. Environ. Sci. Pollut. Res. 25, 24293–24304 (2018).

Ahmed, M. B. et al. Chloramphenicol interaction with functionalized biochar in water: sorptive mechanism, molecular imprinting effect and repeatable application. Sci. Total Environ. 609, 885–895 (2017).

Yang, Z., Yang, X., Wang, T., Hu, R. & Wu, J. Oxygen-functionalized Typha angustifolia biochars derived from various pyrolysis temperatures: Physicochemical properties, heavy metal capture behaviors and mechanism. Colloids Surf. A Physicochem. Eng. Asp. 628, 127259 (2021).

Ravindiran, G., Saravanan, P., Alagumalai, A. & Subbarayan, S. Soft computing-based models and decolorization of Reactive Yellow 81 using Ulva Prolifera biochar. Chemosphere 287, 132368 (2022).

Cheng, S. et al. High-efficiency removal of lead/cadmium from wastewater by MgO modified biochar derived from crofton weed. Bioresour. Technol. 343, 126081 (2022).

Zhang, P. et al. A green biochar/iron oxide composite for methylene blue removal. J. Hazard. Mater. 384, 121286 (2020).

Zazycki, M. A. et al. Chitin derived biochar as an alternative adsorbent to treat colored effluents containing methyl violet dye. Adv. Powder Technol. 30, 1494–1503 (2019).

Liatsou, I., Pashalidis, I. & Dosche, C. Cu(II) adsorption on 2-thiouracil-modified Luffa cylindrica biochar fibres from artificial and real samples, and competition reactions with U(VI). J. Hazard. Mater. 383, 120950 (2020).

Huling, S. G., Jones, P. K., Ela, W. P. & Arnold, R. G. Fenton-driven chemical regeneration of MTBE-spent GAC. Water Res. 39, 2145–2153 (2005).

Chen, Q., Liu, H., Yang, Z. & Tan, D. Regeneration performance of spent granular activated carbon for tertiary treatment of dyeing wastewater by Fenton reagent and hydrogen peroxide. J. Mater. Cycles Waste Manag. 19, 256–264 (2017).

Salvador, F., Martin-Sanchez, N., Sanchez-Hernandez, R., Sanchez-Montero, M. J. & Izquierdo, C. Regeneration of carbonaceous adsorbents. Part II: chemical, microbiological and vacuum regeneration. Microporous Mesoporous Mater. 202, 277–296 (2015).

Lata, S., Singh, P. K. & Samadder, S. R. Regeneration of adsorbents and recovery of heavy metals: a review. Int. J. Environ. Sci. Technol. 12, 1461–1478 (2015).

Baskar, A. V. et al. Recovery, regeneration and sustainable management of spent adsorbents from wastewater treatment streams: a review. Sci. Total Environ. 822, 153555 (2022).

Liu, X., Shen, F., Smith, R. L. & Qi, X. Black liquor-derived calcium-activated biochar for recovery of phosphate from aqueous solutions. Bioresour. Technol. 294, 122198 (2019).

Martín-Lara, M. A., Blázquez, G., Ronda, A. & Calero, M. Kinetic study of the pyrolysis of pine cone shell through non-isothermal thermogravimetry: Effect of heavy metals incorporated by biosorption. Renew. Energy 96, 613–624 (2016).

Fuke, P. et al. Role of microbial diversity to influence the growth and environmental remediation capacity of bamboo: a review. Ind. Crops Prod. 167, 113567 (2021).

Funke, A. & Ziegler, F. Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioref. 4, 160–177 (2010).

Zhang, C. et al. Oxidative torrefaction of biomass nutshells: evaluations of energy efficiency as well as biochar transportation and storage. Appl. Energy 235, 428–441 (2019).

Nunoura, T., Wade, S. R., Bourke, J. P. & Antal, M. J. Studies of the flash carbonization process. 1. propagation of the flaming pyrolysis reaction and performance of a catalytic afterburner. Ind. Eng. Chem. Res. 45, 585–599 (2006).

Cantrell, K. B., Hunt, P. G., Uchimiya, M., Novak, J. M. & Ro, K. S. Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 107, 419–428 (2012).

Klinghoffer, N. B., Castaldi, M. J. & Nzihou, A. Influence of char composition and inorganics on catalytic activity of char from biomass gasification. Fuel 157, 37–47 (2015).

Lin, S., Huang, W., Yang, H., Sun, S. & Yu, J. Recycling application of waste long-root Eichhornia crassipes in the heavy metal removal using oxidized biochar derived as adsorbents. Bioresour. Technol. 314, 123749 (2020).

Qu, J. et al. Microwave-assisted one pot synthesis of β-cyclodextrin modified biochar for concurrent removal of Pb(II) and bisphenol a in water. Carbohydr. Polym. 250, 117003 (2020).

Jiang, S. et al. Recyclable nitrogen-doped biochar via low-temperature pyrolysis for enhanced lead(II) removal. Chemosphere 286, 131666 (2022).

Huang, Z. et al. Surface-functionalized pomelo peel-derived biochar with mercapto-1,2,4-triazloe for selective elimination of toxic Pb (II) in aqueous solutions. Adv. Powder Technol. 32, 1013–1022 (2021).

Hammo, M. M., Akar, T., Sayin, F., Celik, S. & Akar, S. T. Efficacy of green waste-derived biochar for lead removal from aqueous systems: characterization, equilibrium, kinetic and application. J. Environ. Manag. 289, 112490 (2021).

Zhang, J., Hu, X., Zhang, K. & Xue, Y. Desorption of calcium-rich crayfish shell biochar for the removal of lead from aqueous solutions. J. Colloid Interface Sci. 554, 417–423 (2019).

Wiśniewska, M. et al. Simultaneous removal of toxic Pb(II) ions, poly(acrylic acid) and Triton X-100 from their mixed solution using engineered biochars obtained from horsetail herb precursor – Impact of post-activation treatment. Sep. Purif. Technol. 276, 119297 (2021).

Wan, S. et al. Accelerated antimony and copper removal by manganese oxide embedded in biochar with enlarged pore structure. Chem. Eng. J. 402, 126021 (2020).

Yoon, K. et al. Fabrication of engineered biochar from paper mill sludge and its application into removal of arsenic and cadmium in acidic water. Bioresour. Technol. 246, 69–75 (2017).

Vigneshwaran, S., Sirajudheen, P., Nikitha, M., Ramkumar, K. & Meenakshi, S. Facile synthesis of sulfur-doped chitosan/biochar derived from tapioca peel for the removal of organic dyes: Isotherm, kinetics and mechanisms. J. Mol. Liq. 326, 115303 (2021).

Chen, X. L., Li, F., Chen, H. Y., Wang, H. J. & Li, G. G. Fe2O3/TiO2 functionalized biochar as a heterogeneous catalyst for dyes degradation in water under Fenton processes. J. Environ. Chem. Eng. 8, 103905 (2020).

Park, J. H. et al. Adsorption/desorption behavior of cationic and anionic dyes by biochars prepared at normal and high pyrolysis temperatures. Colloids Surf. A Physicochem. Eng. Asp. 572, 274–282 (2019).

Iqbal, M. M. et al. Effective sequestration of Congo red dye with ZnO/cotton stalks biochar nanocomposite: MODELING, reusability and stability. J. Saudi Chem. Soc. 25, 101176 (2021).

Meng, Q. et al. Removal of sulfadiazine from aqueous solution by in-situ activated biochar derived from cotton shell. Environ. Res. 191, 110104 (2020).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

T.A. contributed to the idea and concept, analyzed/interpreted the literature studies, wrote the original and revised manuscript, and provided his insights during revision. E.R. proposed the idea and concept, collected relevant studies, and wrote the original manuscript. M.E. collected relevant studies, wrote the original and revised manuscript. R.H.M. proposed the idea and concept, wrote the original and revised manuscript, provided his advice during revision, and polished the final version. All authors contributed to the interpretation and discussion of reviewed studies.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alsawy, T., Rashad, E., El-Qelish, M. et al. A comprehensive review on the chemical regeneration of biochar adsorbent for sustainable wastewater treatment. npj Clean Water 5, 29 (2022). https://doi.org/10.1038/s41545-022-00172-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-022-00172-3

This article is cited by

-

Graphene oxide synthesis and applications in emerging contaminant removal: a comprehensive review

Environmental Sciences Europe (2024)

-

Removal of lead (II) and toluidine blue from wastewater with new magnetic Bacillus niacini nano-biosorbent

International Journal of Environmental Science and Technology (2024)

-

Facile removal of emerging pollutants using mesoporous TiO2 nanoparticles synthesized via xanthan gum templated greener protocol

International Journal of Environmental Science and Technology (2024)

-

Highly porous biochars from different biomasses as potential adsorbents for chromium removal: optimization by response surface methodology

International Journal of Environmental Science and Technology (2024)

-

Construction and XRD analysis of La@Co3O4@g-C3N4 nanostructures for removal of Co ions from contaminated water

Journal of Materials Science: Materials in Electronics (2024)